vhidhiyo

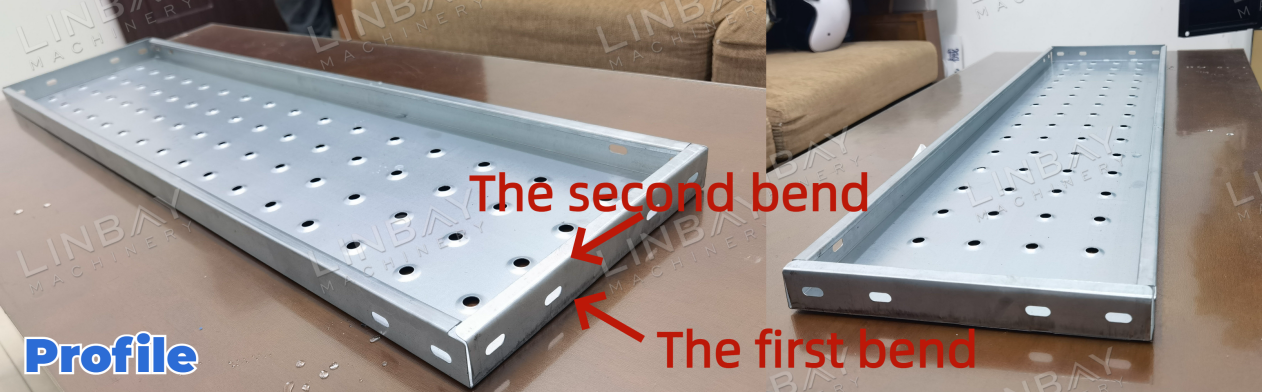

Profile

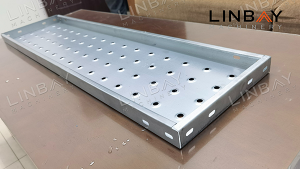

Sherufu pasherufu, iri pamatanda eiyo racking system, inoshanda sechikuva chakasimba chekuchengeta zvinhu zvakachengeteka. Unyanzvi hwedu hwekugadzira hunotarisa pakugadzira masherufu maviri-bend masherufu, ayo anopa kusimba kwepamusoro kana ichienzaniswa neiyo imwe-bend mhando. Uyezve, dhizaini iyi inobvisa mipendero yakapinza, inotungamira kuchengetedza kwemushandisi.

Chaiyo kesi-Main Techinical Parameters

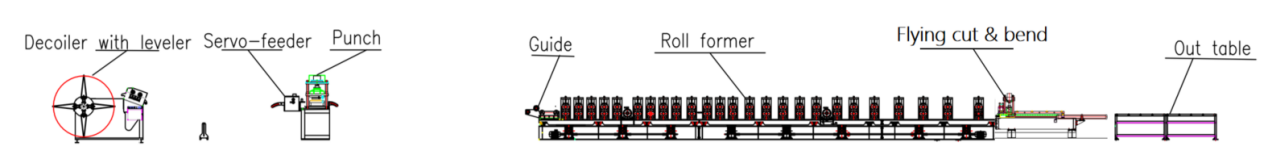

Flow chati

Hydraulic decoiler ine leveler--Servo feeder--Hydraulic punch--Roll forming machine--Hydraulic cut and stamping--Out table

Main Technical Parameters:

1. Kumhanya kwemutsara: Kugadziriswa kubva ku0 kusvika ku4 m / min

2. Profiles: Saizi dzakasiyana-siyana dzine urefu hunoenderana, hwakasiyana muhupamhi nehurefu

3. Material ukobvu: 0.6-0.8mm (nokuda Anwendung ichi)

4. Zvinhu zvakakodzera: Galvanized steel

5. Roll yekugadzira muchina: Inoshandisa cantilevered kaviri-wall panel chimiro uye cheni yekutyaira system.

6. Nhamba yekugadzira zviteshi: 13

7. Kucheka hurongwa: Kucheka panguva imwe chete nekukotama; roll yekutanga inoramba ichishanda panguva yekuita

8. Kugadziriswa kwehukuru: Automatic

9. PLC cabinet: Yakashongedzerwa neSiemens system

Nyaya chaiyo-tsanangudzo

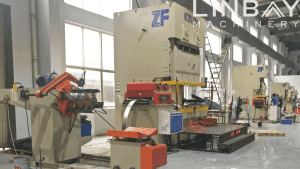

Hydraulic Decoiler ine Leveler

Iyo yakakosha yekuwedzera inogona kugadziriswa kuti ikwane simbi coil yemukati madhayamita kubva pa460mm kusvika 520mm. Panguva yekusunungura, zvibatiso zvekunze zvecoil zvinovimbisa kuti coil yesimbi inogara yakachengeteka pane decoiler, inosimudzira kuchengetedza kwevashandi nekudzivirira iyo coil kubva pakutsvedza.

Iyo leveler inoshongedzerwa nenhevedzano yema rollers ayo zvishoma nezvishoma anodzikamisa coil yesimbi, zvinobudirira kubvisa zvakasara zvinonetsa.

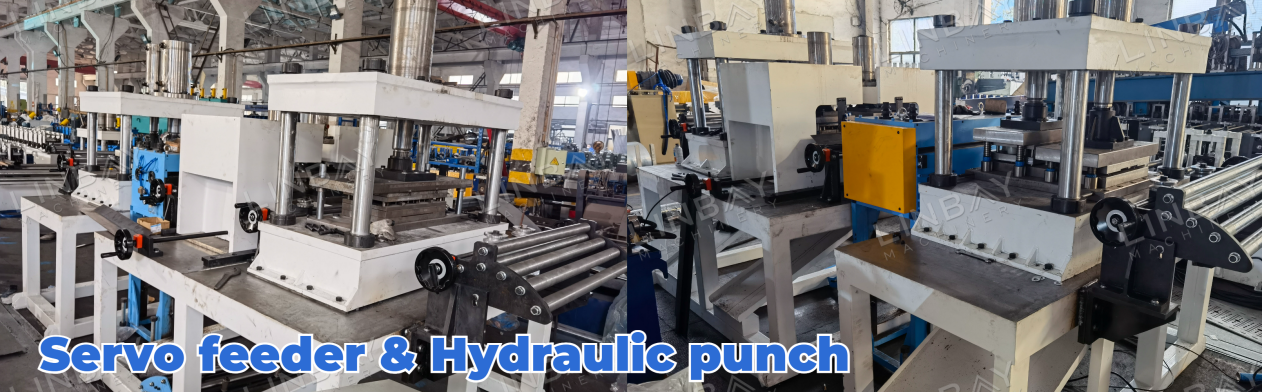

Servo Feeder & Hydraulic Punch

(1)Yakazvimirira Hydraulic Punching

Iyi punching system inoshanda yakazvimiririra, isingagovane chigadziko chemuchina mumwe chete nemuchina wekugadzira roll, kuve nechokwadi chekusagadzikana uye kusakanganiswa kuita kweiyo roll yekugadzira maitiro. Iyo yekudyisa inofambiswa ne servo mota, ine kushoma kwekutanga-kumisa nguva kunonoka. Izvi zvinobvumira kudzora chaiko pamusoro pekufambira mberi kwesimbi mucoil feeder, kuve nechokwadi chekurovera kwakaringana uye kwakanaka.

(2)Optimized mold solution

Maburi akaboorwa pasherufu akaiswa muzvikamu, maburi anoshanda, uye pasi anoramba achiita maburi. Nekuda kwekusiyana-siyana kweaya marudzi egomba pane imwechete sherufu pasherufu, iyo hydraulic punch muchina wakashongedzerwa neina dzakatsaurirwa mold, imwe neimwe yakagadzirirwa imwe chaiyo mhando yegomba. Kuseta uku kunorongedzerwa kupedzisa nemazvo rudzi rwega rwekubaya, nekudaro kuchiwedzera kushanda zvakanaka uye kubereka.

Encoder & PLC

Iyo encoder inoshandura kureba kwesimbi coil kuita masaini emagetsi, ayo anobva atumirwa kuPLC control cabinet. Mukati meiyo kabati yekudzora, vashandisi vanogona kubata kukurumidza kwekugadzira, kuburitsa kamwe chete, kucheka kureba, uye mamwe ma paramita. Nezviyero zvakarurama uye mhinduro kubva kune encoder, muchina wekucheka unogona kuchengetedza zvikanganiso zvekucheka mukati±1mm.

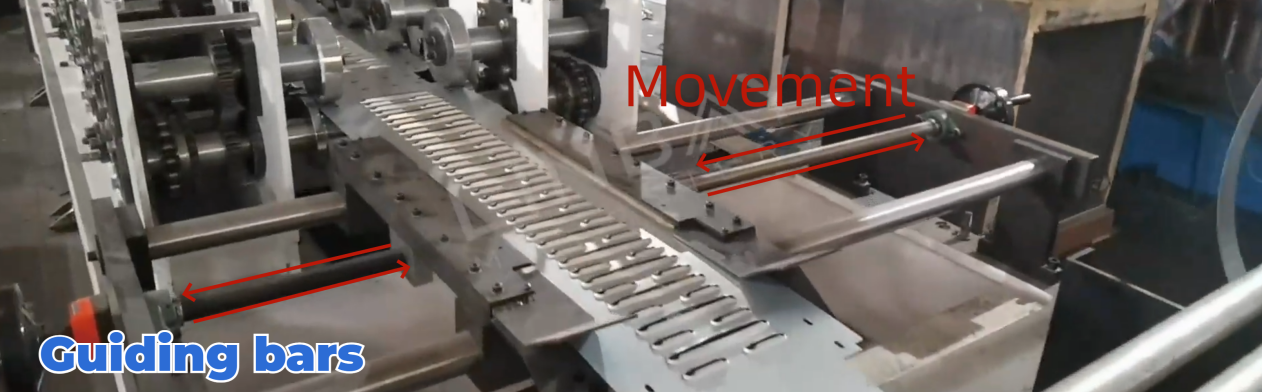

Roll kugadzira muchina

Usati wapinda muchina wekugadzira roll, iyo simbi coil inopfuura nepainogadziriswa inotungamira mabara. Aya mabara anogadziridzwa zvichienderana nehupamhi hwesimbi coil, ichiita kuti ienderane chaizvo nemakina ekugadzira mutsetse wepakati. Uku kurongeka kwakakosha pakuchengetedza kutwasuka uye kutakura mutoro wepasherufu pasherufu.

Muchina wekugadzira uyu unoshandisa kaviri-madziro cantilever chimiro. Sezvo kuumba kuchidiwa chete pamativi maviri epaneti, cantilever roller dhizaini inoshandiswa kuchengetedza roller zvinhu. Iyo ketani yekutyaira system inofambisa ma rollers uye inoshandisa simba kune coil yesimbi, ichigonesa kufambira mberi kwayo uye kuumba.

Muchina uyu unogona kugadzira sherufu mapaneru ehupamhi hwakasiyana. Vashandi vanoisa zviyero zvinodiwa muPLC control cabinet panel. Kana chiratidzo chagamuchirwa, chiteshi chekugadzira chiri kudivi rekurudyi chinozvifambisa chichitevedza njanji. Mapoinzi ekugadzira pane coil yesimbi anogadzirisa nekufamba kwechiteshi chekugadzira uye kugadzira rollers.

Iyo encoder inoiswawo kuti ione chinhambwe chekufamba kwechiteshi, kuve nechokwadi chechokwadi kana uchichinja saizi. Pamusoro pezvo, ma sensor maviri enzvimbo anosanganisirwa: imwe yekuona kure kure uye imwe kune iri padyo chinhambwe icho chiteshi chekugadzira chinogona kufamba panjanji. Iyo yekure kuresa chinzvimbo sensor inodzivirira kufamba kwakanyanya kweiyo chiteshi chekugadzira, kudzivirira kutsvedza, nepo iri padyo chinzvimbo sensor ichidzivirira chiteshi kuti chiende kure zvakanyanya mukati, nekudaro kudzivirira kudhumhana.

Hydraulic kucheka uye kukotama

Masherufu esherufu anogadzirwa pamutsetse wekugadzira uyu anoratidza mabhende maviri padivi rakafara. Isu takagadzira yakasanganiswa yekucheka uye kupeta mold, ichigonesa kucheka uye kupeta kaviri mukati memuchina mumwe. Iyi dhizaini haingochengetedze kureba kwemutsara wekugadzira uye fekitori pasi nzvimbo asiwo inoderedza nguva yekugadzira.

Panguva yekucheka nekukotama, base yekucheka muchina inogona kusimuka ichidzokera kumashure nekumberi mukuwiriranisa nekumhanyisa kwekugadzira kwemuchina wekugadzira. Izvi zvinogonesa kugadzirwa kusingakanganisike uye kunowedzera kushanda zvakanaka.

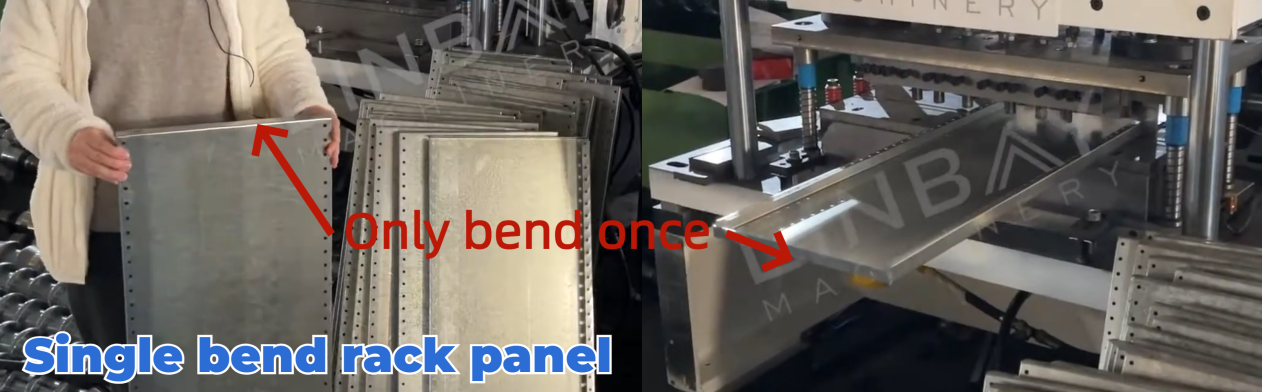

Imwe mhinduro

Kana iwe uchinakidzwa ne-single-bend sherufu mapaneru, ingo dzvanya pamufananidzo kuti utarise zvakadzika mune yakadzama maitiro ekugadzira uye tarisa vhidhiyo inofambidzana.

Misiyano yakakosha:

Iyo yakapetwa kaviri-bend mhando inopa kusimba kwepamusoro, nepo imwe-bend mhando inosanganawo zvakakwana nekuchengetedza zvinodiwa.

Micheto yemhando ye-double-bend haina kupinza, inosimudzira kuchengeteka, asi imwe-bend mhando inogona kuva nemicheto yakapinza.

1. Decoiler

2. Kudyisa

3.Kubaya

4. Roll forming stands

5. Driving system

6. Kucheka hurongwa

Vamwe

Out table