video

Profile

Cross bracing e phetha karolo ea bohlokoa tsamaisong ea rack, e matlafatsang tšehetso le botsitso pakeng tsa liforeimi tse peli tse otlolohileng. E entsoe ka tšepe e tšoarellang e ntšo e nang le botenya bo tlohang ho 1.5 ho isa ho 2.5mm, kopo ea pente ea morao-rao e thusa ho eketsa ho bola le ho hanyetsa mafome, ho netefatsa bophelo bo bolelele le ho tšepahala.

Taba ea 'nete-Mekhahlelo e ka Sehloohong ea Tekheniki

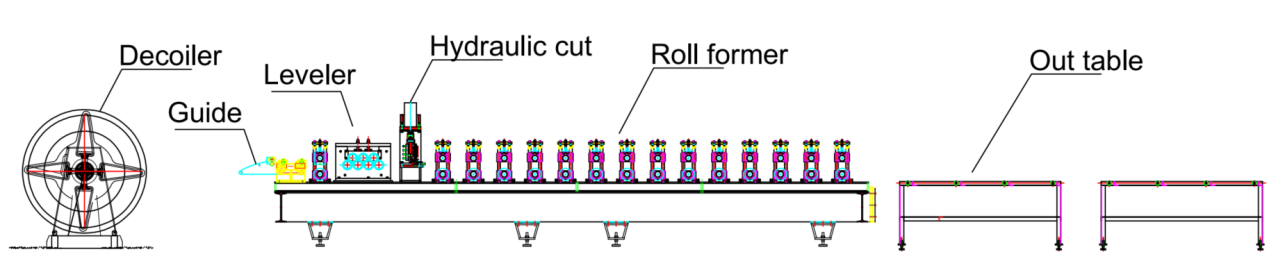

Chate e phallang: Decoiler-- Tataiso--Leveler--Precut-Pre--Foromo ea rollmochini o kenyang--Ka ntle ho tafole

- 1.Lebelo la Line: 0-15m / min, e ka fetoloang

- 2.Dimensions maemong a nnete: bophara bo bongata 80-300mm, bolelele bo tsitsitseng 50mm

- 3.Lisebelisoa tse loketseng: Tšepe ea Galvanized

- 4.Material botenya: 1.5-2mm

- Mochine oa ho etsa 5.Roll: Cast-iron sebopeho le tsamaiso ea ketane ea ho khanna

- 6.Sistimi ea ho khaola: Khaola pele mochini o etsang moqolo, o nang le matla a haeteroliki.

- 7.PLC cabinet: Siemens tsamaiso.

Mechini ea 'nete ea linyeoe

1.Decoiler*1

2.Leveler(E hlomelloa ka mochini o etsang moqolo)*1

3.Mochini oa Hydraulic o sehiloeng esale pele*1

4.Roll forming machine*1

5.Ka ntle ho tafole*2

6.PLC taolo ea khabinete*1

7.Seteishene sa Hydraulic*2

8.Lebokose la likarolo tsa polokelo (Mahala)*1

Taba ea 'nete-Tlhaloso

- Decoiler

Hangata, decoiler e sebetsa e le karolo ea pele ea mohala oa tlhahiso. Letsoho la eona la khatiso le khona ho sireletsa khoele ea tšepe, ho thibela kotsi hore e se ke ea theoha nakong ea phetoho ea li-coil. Lisebelisoa tsa ka ntle tsa coil retainer li thibela li-coil hore li se ke tsa thella mandrel.

Tataiso

Lirolara tse tataisang li tla tataisa coil ea tšepe hantle ka har'a lirolara tse etsang ho boloka tekano lipakeng tsa tšepe ea tšepe le mochini o etsang roll, ho fokotsa ho kheloha ho hong ho ka bang teng kapa ho kheloha.

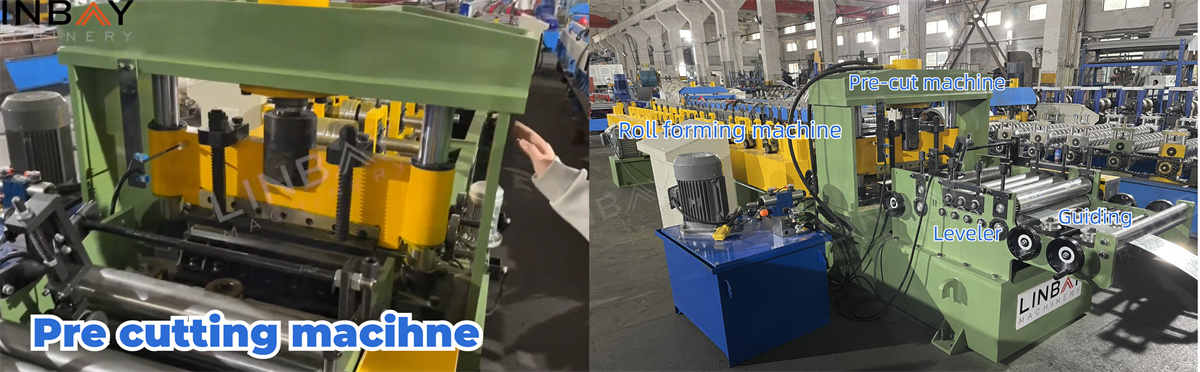

Leveler

Botenya ba sefapano sa sefapano bo fihla ho 2.5mm, 'me feela ha bo otlolohile ka ho feletseng ebile bo sa sothehe bo ka fana ka botsitso bo molemo ka ho fetisisa bakeng sa foreimi ea rack. Mochine o lekanyang o ka batalatsa tšepe ea tšepe, oa lokolla khatello ea ka hare, o etsa hore ho be bonolo ho theha le ho theha ka ho otloloha. Moleng ona oa tlhahiso, mochini o lekanyang o behiloe holim'a mochini oa mochini o etsang roll, o ka bolokang sebaka sa fatše le ho fokotsa litšenyehelo tsa mobu.

Mochine o sehiloeng pele

Ha ho bapisoa le ho seha ka morao, ho seha pele pele ho etsoa ha ho na tšenyo. Tharollo ena e nolofaletsa ho nkeloa sebaka ha lithapo tsa tšepe tsa bophara bo fapaneng bakeng sa ho hlahisa boholo bo bongata moleng o tšoanang oa tlhahiso, ntle le ho baka litšila.

Foromo ea rollmochini o kenyang

Mochine oa ho etsa roll ke karolo ea bohlokoa ka ho fetisisa ea mohala oohle oa tlhahiso. E sebelisa mohaho o matla oa tšepe bakeng sa seteishene sa ho etsa, se entsoeng ka tšepe e tiileng. Ho potoloha ha li-rollers tse etsang li-roller ho tsamaisoa ke tsamaiso ea ketane.

Thepa ea lirolara ke Gcr15, tšepe e nang le carbon chromium e nang le k'habone e phahameng e tsebahalang ka ho thatafala ha eona le ho hanyetsa ho roala. Lirolara li entsoe ka chrome ho lelefatsa bophelo ba tsona ba ts'ebeletso. Li-shafts li entsoe ka thepa ea 40Cr 'me li kena kalafo ea mocheso.

Li-reinforcements li kenyelelitsoe ka tlase ho profil ho matlafatsa matla a eona. Mochini ona oa ho etsa moqolo o ka hlahisa li-cross bracing ka bophara ba 80-300mm le bolelele ba 50mm. Ka ho kenya litekanyo tse lakatsehang ka har'a phanele ea taolo ea PLC, seteishene sa ho theha se tsamaea haufi le liporo ho ea sebakeng se nepahetseng le se nepahetseng. Sebaka sa ho theha se boetse se fetoha ha seteishene sa ho etsa se ntse se tsamaea.

Bakeng sa polokeho ea motsamao oa ho etsa liteishene, 2 li-sensor tsa sebaka li behiloe motheong oa mochini, e tsamaellanang le maemo a ka ntle le a ka hare-hare ao theho bopaseteishenese ka isoa ho.Bakeng sa li-sensor, the sensing point is theMonahomotheo oa liteishene tse thehang. Ka hare-harekutloke ho thibelaho bopaseteishenesho tloha ho atamela haholo le ho baka ho thulana ka rolara.Ka ho fetisisakutloke ho thibelaho bopaseteishene ho tloha disenging from theliporole ho wa.

Seteishene sa Hydraulic

Seteishene sa hydraulic se na le li-fan tse pholileng tse etselitsoeng ho felisa mocheso hantle, ho netefatsa ts'ebetso e sa sitisoeng le ho eketsa tlhahiso. Seteishene sena sa haeteroliki se tumme ka litheko tse tlase tsa ho hloleha ha sona, se hahiloe hore se tšoarelle, se netefatsa hore se tšoarella nako e telele.

Khabinete ea taolo ea PLC le Encoder

Encoder e fetola bolelele bo utloang ba khoele ea tšepe hore e be matšoao a motlakase a fetisetsoang khabineteng ea taolo ea PLC. Ka har'a khabinete ea taolo, lebelo la tlhahiso, tlhahiso ea tlhahiso ea motho ka mong, bolelele ba ho itšeha, le likarolo tse ling li ka laoloa. Ka litekanyo tse nepahetseng le maikutlo a tsoang ho encoder, mochine oa ho itšeha o ka laola liphoso tsa ho itšeha ka hare ho ± 1mm.

1. Decoiler

2. Ho fepa

3.Ho phunya

4. Litomo tsa ho etsa roll

5. Mokhoa oa ho khanna

6. Mokhoa oa ho khaola

Ba bang

Tafole e kantle