video

Profile

TR 80 ke mokhoa o tloaelehileng har'a ho khabisa fatše. Tabeng ena, 1mm e teteaneng ea 350MPA ea tšepe e phahameng e sebelisoa.

Tlhaloso

Phallo chate

Hydraulic decoiler-Guiding and feeding-Embossing part- Siliting device-Roll forming machine

Hydraulic Decoiler

Re kenya letsoho la khatello holim'a decoiler ho tiisa khoele ea tšepe sebakeng sa eona nakong ea ho khutlisa coil, ho thibela ho lokolloa ka tšohanyetso le kotsi e ka bang teng ho basebetsi. Ho feta moo, li-blades tse sireletsang tšepe li kenngoa ho thibela ho thella ha li-coil nakong ea ts'ebetso ea ho senya. Moralo ona ha o sireletse feela coil ea tšepe le mochini empa hape o netefatsa polokeho ea basebetsi.

Tataiso&Karolo ea Embossing

Mehala e tataisang e boloka tumellano lipakeng tsa coil ea tšepe le mochini, ho netefatsa hore profil e otlolohile. Moleng oohle oa ho theha, lirolara tse ngata tse tataisang li behiloe ka nepo bakeng sa ho nepahala ho ntlafalitsoeng.

Ka tloaelo, embossing e ka ba 2 mm ka botebo, empa tharollong ena re e ekelitse ho4 mm bakeng sa lipaterone tse hlakileng le tse hlakileng haholoanyane.

Sesebelisoa sa Slitting& 'mokelli oa litšila

Pele tšepe ea tšepe e kena ka har'a li-rollers, e kopana le lisebelisoa tsa ho senya ka lehlakoreng le letšehali. E le bophara ba li-coil tse rekiloeng leloaleng la tšepeka kakaretso li haufi empa eseng bophara ba phepelo ea profil ena, sesebelisoa sena se thusa ho seha le ho bokella bophara bo feteletseng,ho boloka litšenyeheloholim'a khoele e petsotsoeng leloaleng la tšepe.

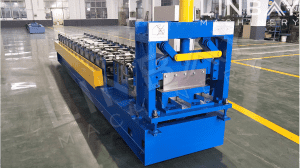

Mochini oa ho etsa Roll

Mochini ona oa ho etsa roll o sebelisa sebopeho sa mabota le sistimi ea ho khanna ketane. Ka lebaka la matla a khoele ea tšepe a fihlang ho 350MPA, lebelo la ho bopa le fokotseha hanyane ho sebetsana le mosebetsi o boima oa ho etsa. Khoeli e feta har'a kakaretso ea li-sete tse 33 tsa liteishene tse etsang roll, e qetellang e hlahisa profil ea mekato ea tšepe litšoantšong tsa bareki.

Mochini oa ho Seha ka Hydraulic&PLC

Mochini ona oa ho itšeha o hlahisa litšila tse ka bang 8mm ka sehiloeng ka seng, empa o na le li-burrs tse nyane mathōkong a sehiloeng. Basebelisi ba ka laola lebelo la tlhahiso, ho beha litekanyo, ho fokotsa bolelele, le tse ling ka skrine ea PLC. Encoder e haufi le mohala oa tlhahiso e fetola bolelele ba li-coil tsa tšepe hore e be matšoao a motlakase, e lumellang mochini oa ho itšeha ho laola.liphoso tsa ho khaola ka hare ho 1mm, ho netefatsa lihlahisoa tsa boleng bo phahameng le ho fokotsa litšila ho tloha ho fokotsa ho fosahetseng.

1. Decoiler

2. Ho fepa

3.Ho phunya

4. Litomo tsa ho etsa roll

5. Mokhoa oa ho khanna

6. Mokhoa oa ho khaola

Ba bang

Tafole e kantle