SQUARE TUBE ROLL HO BOPA MACHINE

Mohala ona oa tlhahiso o etselitsoe ho theha li-tubes tsa lisekoere tse nang le botenya ba 2mm, le litekanyo ho tloha ho 50-100mm ka bophara le 100-200mm ka bolelele.

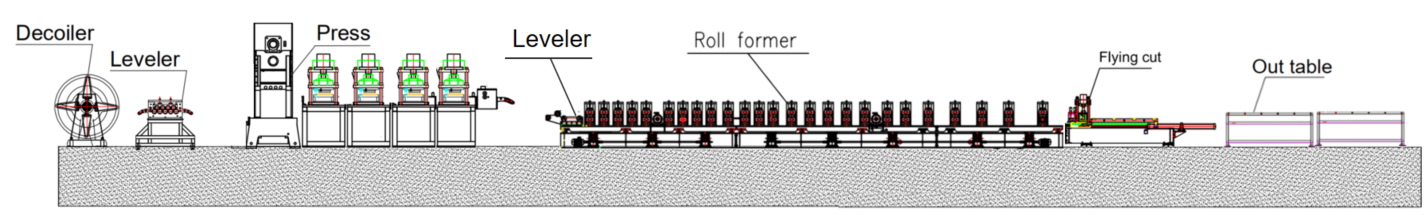

Mohala oa tlhahiso o kenyelletsa lits'ebetso tse 'maloa tsa bohlokoa: ho theola, ho lekanya pele ho punch, ho phunya, ho lekanya ka morao ho punch, ho etsa roll, welding ea laser, ho ntša mosi le ho itšeha.

E na le seta se felletseng le othomathike e tsoetseng pele, mohala ona oa tlhahiso o fana ka mefuta e meng e holimo ho feta mechini e tloaelehileng ea li-welding tube, haholo-holo bakeng sa palo e tlase ea tlhahiso.

SEBELE-TEKELETSO TSE KHOLO EA LITŠOANTŠISO

Flow chart: Hydraulic decoiler with loading car--Leveler--Servo feeder--Punch press--Hydraulic punch--Limiter--Guiding--Leveler--Roll former--Laser weld--Flying saw cut--Tafole ea ka ntle

SEBELE-TEKELETSO TSE KHOLO EA LITŠOANTŠISO

· Lebelo le feto-fetohang la mohala: 5-6m / min ka welding laser

· Lisebelisoa tse lumellanang: Tšepe e chesang e chesang, tšepe e batang, tšepe e ntšo

· Botenya ba thepa: 2mm

· Mochini o etsang roll: Sebopeho sa tšepe sa Cast se nang le motsoako oa bokahohle

· Sistimi ea ho khanna: Sistimi e tsamaisoang ke Gearbox e nang le "cardan shaft" e kopaneng ea bokahohleng

· Sistimi ea ho itšeha: Ho itšeha ka sefofane, ka moqolo o tsoelang pele o sebetsa nakong ea ho itšeha

· Taolo ea PLC: Sisteme ea Siemens

SEBELE-MACHINA

1.Hydraulic decoiler*1

2.Standalone Leveler*1

3.Penya tobetsa*1

4.Mochini oa hydraulic punch*1

5.Sefepi sa servo*1

6.Tekanyo e Kopanetsweng*1

7.Roll forming machine*1

8.Laser tjheseletsa mochini*1

9.Welding Fume Purifier*1

10.Flying saw ho itšeha mochini*1

11.Ho tsoa tafoleng*2

12.PLC taolo ea khabinete*2

13.Seteishene sa Hydraulic*3

14.Lebokose la li-spare parts(Mahala)*1

TLHALOSO SEBELE

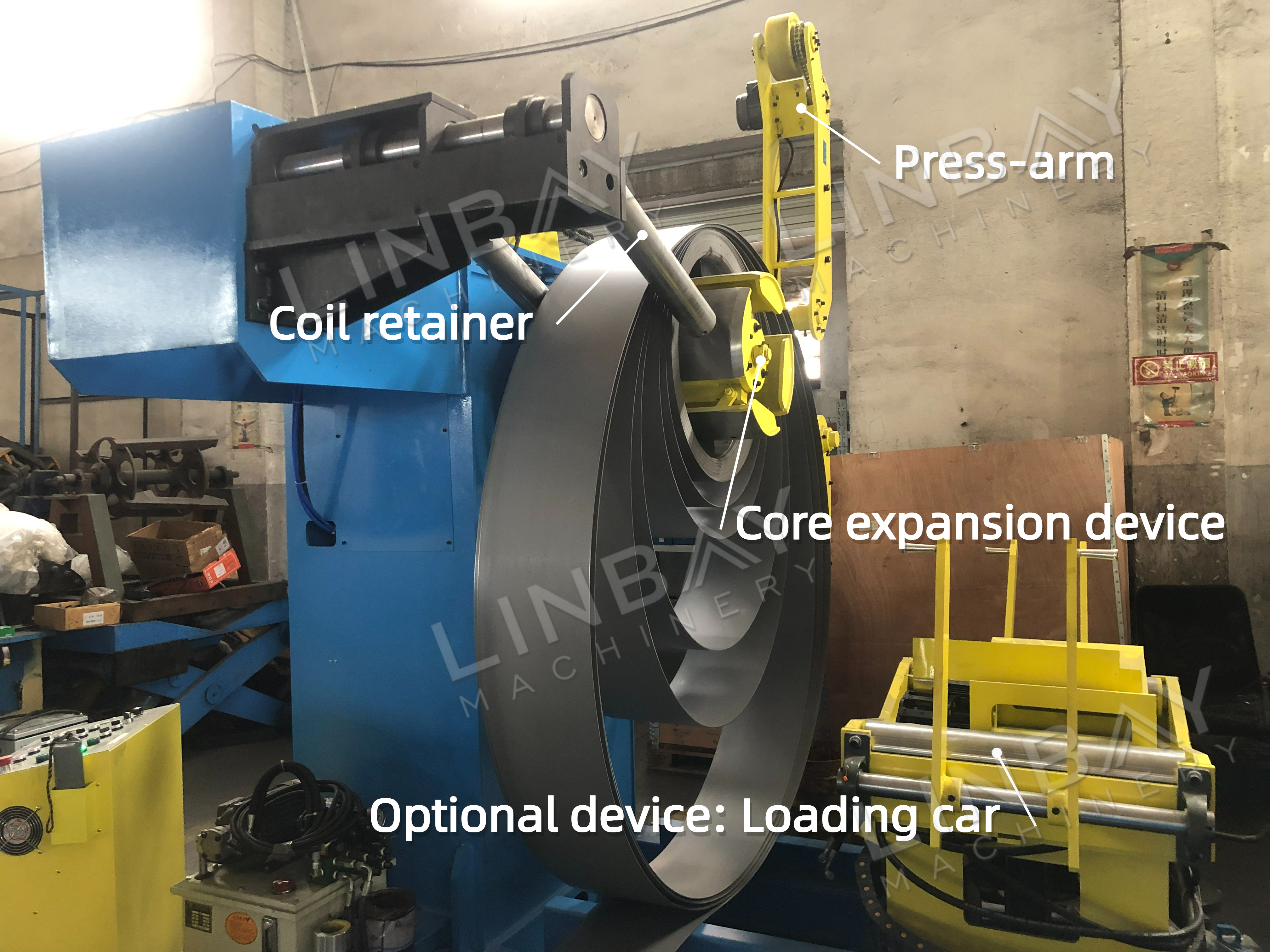

Hydraulic decoiler

•Mosebetsi: Foreimi e tiileng e hahiloe ho ts'ehetsa ho kenya li-coil tsa tšepe. The hydraulic decoiler e ntlafatsa ts'ebetso le polokeho ho fepa li-coil tsa tšepe moleng oa tlhahiso.

•Sesebelisoa sa Katoloso ea Core: The hydraulic mandrel kapa arbor e lokisa hore e lumellane le likhoele tsa tšepe tse nang le bophara bo ka hare ba 490-510mm, li atoloha le ho etsa konteraka ho tšoara khoele ka thata le ho etsa bonnete ba hore ho senyeha ha bonolo.

•Tobetsa-letsoho: Letsoho la khatiso la hydraulic le tiisa khoele ea tšepe, ho thibela ho phutholoha ka tšohanyetso ka lebaka la khatello ea maikutlo le ho sireletsa basebetsi likotsing tse ka bang teng.

•Coil Retainer: Moqapi o tiisa hore coil e lula e sireletsehile ha e ntse e lumella ho kenya le ho tlosoa habonolo.

•Sistimi ea Taolo: Sistimi e na le PLC le phanele ea taolo, e kenyelletsang konopo ea ho emisa ts'ohanyetso bakeng sa polokeho e eketsehileng.

Sesebelisoa sa Boikhethelo: Ho Laola Koloi

•Phetoho e Ntle ea Coil: E thusa ho fetola likhoele tsa tšepe ka mokhoa o sireletsehileng le ka mokhoa o atlehileng, ho fokotsa litšenyehelo tsa basebetsi.

•Ho tsamaisana ha Hydraulic: Sethala se ka fetoloa ka hydraulically holimo le tlase ho ikamahanya le mandrel. Ho feta moo, koloi e palamisang, e kentsoeng mabili, e khona ho tsamaea ka motlakase haufi le litselana.

•Moqapi oa Tšireletseho: Moralo oa concave o tšoara ka tieo khoele ea tšepe, o thibela ho thella hofe kapa hofe.

Mochini oa boikhethelo: Shearer Butt Welder

· E hokahanya likhoele tsa ho qetela le tse ncha tsa tšepe, e fokotsa nako ea ho fepa le mehato ea ho e lokisa bakeng sa likhoele tse ncha.

· E fokotsa litšenyehelo tsa basebetsi le litšila tsa thepa.

· E etsa bonnete ba ho kuta ka boreleli, ntle le burr bakeng sa ho tsamaisana hantle le ho tjheseletsa.

· E na le welding ea TIG e ikemetseng bakeng sa li-welds tse tsitsitseng le tse matla.

· E kenyelletsa likhalase tsa tšireletso holim'a tafole ea ho cheselletsa ho sireletsa mahlo a basebetsi.

• Litaolo tsa maoto li etsa hore ho kokota ha khoele ho be bonolo.

· Customizable bakeng sa bophara ba li-coil tse fapaneng 'me e ka kopanngoa habonolo meleng e fapaneng ea tlhahiso ka har'a bophara ba eona.

Standalone Leveler

· E fokotsa khatello ea maikutlo le ho se phethahale ha holim'a likhoele tsa tšepe ka deformation ea polasetiki, ho thibela liphoso tsa geometri nakong ea ts'ebetso ea ho theha.

• Ho lekana ho bohlokoa bakeng sa likhoele tse tenya ho feta 1.5mm tse hlokang ho phunngoa.

· Ho fapana le li-level tse kopantsoeng tse kopantsoeng le li-decoilers kapa mochini o etsang roll, li-level tse ikemetseng li sebetsa ka lebelo le holimo.

Ho Tebela Karolo

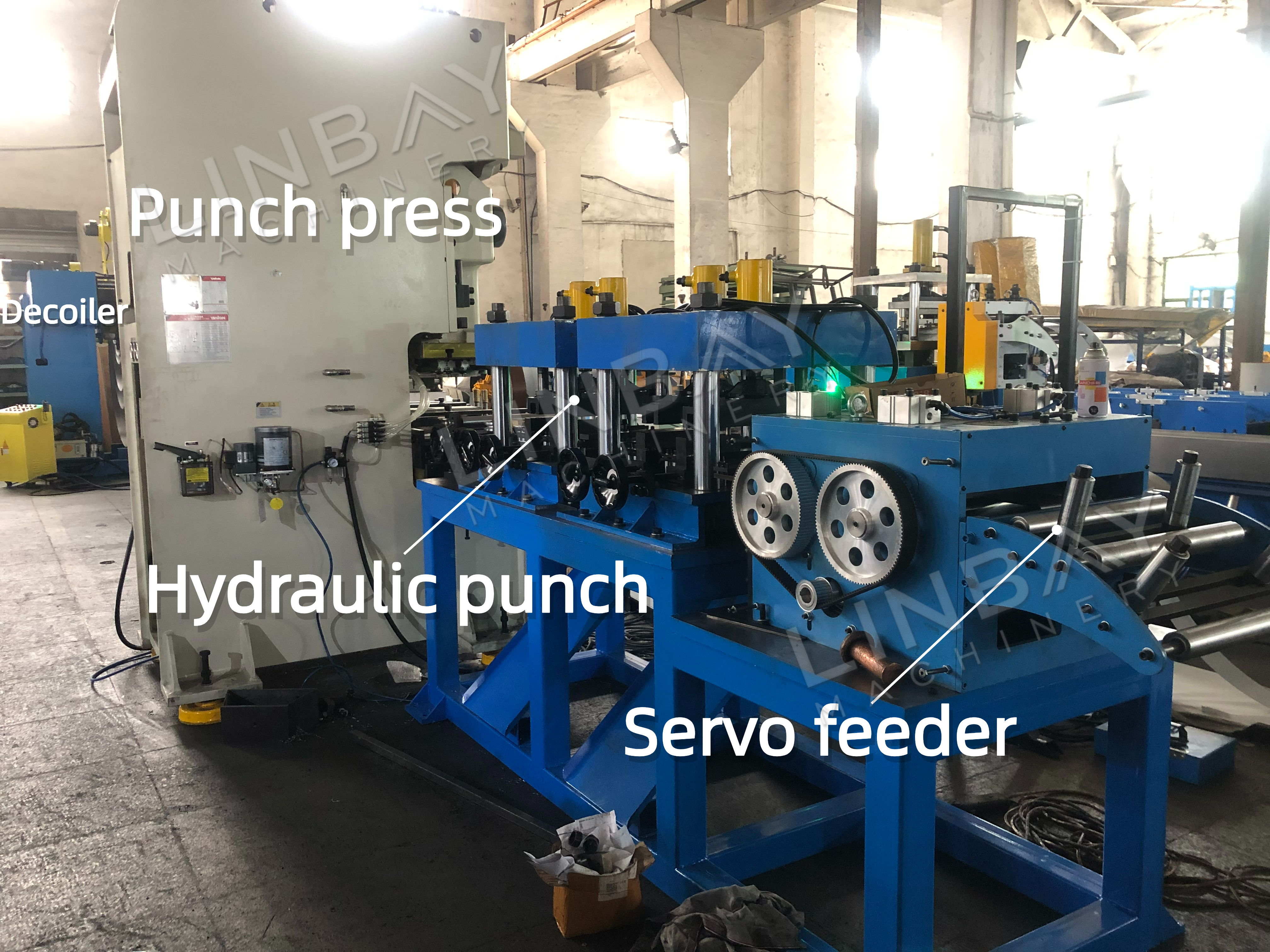

• Moleng ona oa tlhahiso, re sebelisa motsoako oa "punch press" le "hydraulic punch" bakeng sa ho phunya mekoti. Sehlopha sa rona sa boenjiniere se thehile mokhoa o nepahetseng oa ho sebetsana le mekhoa e rarahaneng ea mekoti, ho leka-lekanya katleho le litšenyehelo ka ho kopanya melemo ea mechini ea ho phunya ka bobeli.

Tobetsa ka Punch

· Ho sebetsa ka potlako.

· Ho nepahala ho phahameng ha ho arola mekoti nakong ea ho phunya.

· E loketseng bakeng sa mekhoa e tsitsitseng ea likoti.

Hydraulic Punch

• E fana ka maemo a mangata bakeng sa mekhoa e fapaneng ea mekoti. Punch ea hydraulic e ka ikamahanya le libopeho tse fapaneng tsa lesoba, ea fetola sekhahla sa ho phunya ka mokhoa o nepahetseng le ho khetha ka ho khetha libopeho tse fapaneng ka seterouku se seng le se seng.

Servo Feeder

Fepa, e tsamaisoang ke enjene ea servo, e laola ka nepo phepelo ea likhoele tsa tšepe mochining oa khatiso oa punch kapa mochini o mong oa hydraulic punch. Ka nako ea karabelo e potlakileng le tieho e fokolang ea ho emisa, li-servo motors li netefatsa bolelele bo nepahetseng ba phepelo le sebaka se sa fetoheng sa likoti, se fokotsa haholo litšila ho tsoa litebeleng tse sa nepahalang. Sistimi ena e boetse e baballa matla, e hula matla feela nakong ea ts'ebetso e sebetsang, 'me e boloka matla nakong ea ho se sebetse. Feeder e hlophisehile ka botlalo, e lumella litokiso tse potlakileng boholeng ba mohato le lebelo la ho otla, ho fokotsa nako ea ho seta ha o chencha hlobo ea punch. Ho phaella moo, mochine o ka hare oa pneumatic clamping o sireletsa bokaholimo ba tšepe hore e se ke ea senyeha.

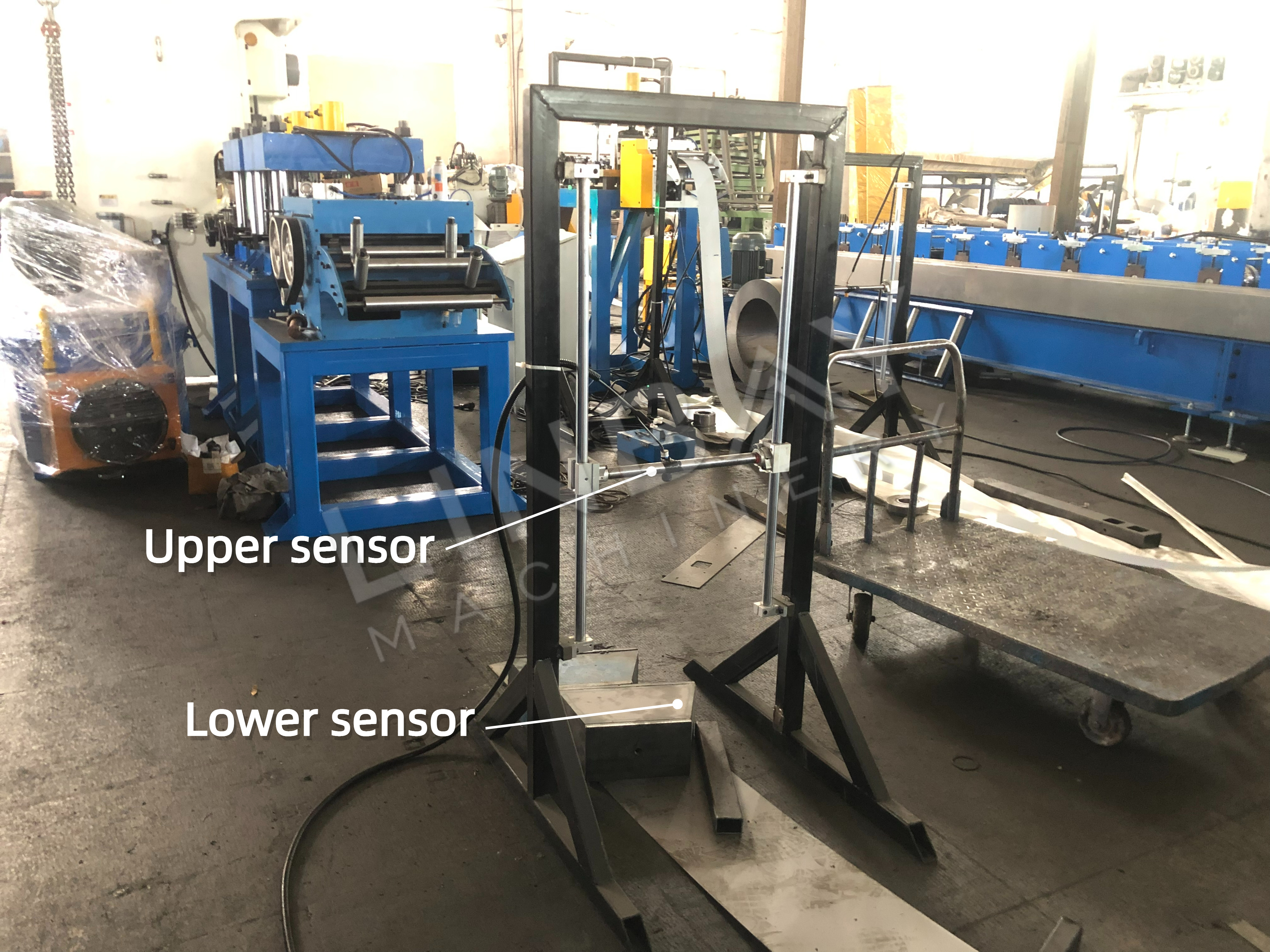

Limiter

E laola lebelo la tlhahiso ho ntlafatsa ts'ebetso le ho boloka ts'ebetso e bolokehileng ea coil ea tšepe le mochini. Haeba coil e kopana le sensor e tlase, ho bolela hore ts'ebetso ea ho theola, ho lekanya le ho otla ka pele ho limiter e sebetsa ka potlako ho feta methati e latelang ea ho theha, welding le ho itšeha. Mekhoa ena ea pejana e lokela ho ema hanyane ho leka-lekanya phallo ea tlhahiso; ho seng joalo, ho ka 'na ha e-ba le li-coil buildup, tsa sitisa ho kena ha eona ka mokhoa o thellang mochineng oa ho etsa le ho baka deformation. Ka lehlakoreng le leng, haeba coil e ama sensor e ka holimo, e bontša hore mehato ea morao-rao e tsamaea ka potlako ho feta ea pele, e hlokang khefu ea mekhoa ka mor'a moeli. Ho hloleha ho etsa joalo ho ka etsa hore khoele e huleloe mochining o etsang roll ka potlako, ho beha kotsi ea ho senyeha mochining o phunyeletsang le ho etsa lirolara. Khefutso efe kapa efe e tla hlahisa tsebiso ponts'ong e tsamaellanang ea khabinete ea PLC, e lumellang basebetsi ho qala ts'ebetso ka ho amohela molaetsa.

Tataiso

Morero oa mantlha: E netefatsa hore coil ea tšepe e hokahane hantle le bohareng ba mochini, ho qoba litaba tse kang ho sotha, ho kobeha, li-burrs le ho se nepahale ha sehlahisoa se felileng. Lirolara tse tataisang li behiloe ka mokhoa o hlophisehileng sebakeng sa ho kena le ka har'a mochini o etsang. Ho bohlokoa ho lekanya lisebelisoa tsena khafetsa, haholo kamora ho tsamaisoa kapa tšebeliso ea nako e telele ea mochini o etsang roll. Pele ho romelloa, sehlopha sa Linbay se lekanya bophara ba tataiso mme se kenyelletsa lintlha tsena bukeng ea mosebelisi, se lumellang bareki ho lekanya mochini ha o fihla.

Secondary Leveler (Beha motheong o tšoanang le mochini o etsang roll)

Coil e boreleli e tiisa hore ho lumellana ha seam ho feta ho etsoa ka morao, e leng se thusang haholo ts'ebetsong ea welding. Boemo ba bobeli bo thusa ho ntlafatsa boleng ba boemo le ho fokotsa khatello ea maikutlo libakeng tse hlajoang. E le mokhoa oa tlatsetso, ho beha sekala sena setsing sa mochini o etsang mochini ho fana ka mokhoa o baballang chelete le o loketseng.

Mochini oa ho etsa Roll

· Tlhahiso e fapaneng: Mohala ona o khona ho etsa li-square tubes tse nang le litekanyo ho tloha ho 50-100mm ka bophara le 100-200mm ka bolelele. (Linbay e ka boela ea fana ka mokhoa oa ho iketsetsa mefuta e meng ea boholo.)

· Phetoho ea boholo bo ikemetseng: Ka ho beha le ho netefatsa boholo bo lakatsehang skrineng sa PLC, liteishene tsa ho etsa li fetoha ka tsela e iketsang ho latela liporo tsa tataiso ho ea maemong a nepahetseng, ho lokisa sebaka sa ho theha ka nepo. Boiketsetso bona bo ntlafatsa ho nepahala le boiketlo, ho fokotsa tlhoko ea litokiso tsa matsoho le litšenyehelo tse amanang.

· Lateral Movement Detection: Sesebelisoa sa encoder se latela hantle motsamao oa morao-rao oa liteishene tse etsang 'me hang-hang se fetisetsa data ena ho PLC, se boloka liphoso tsa motsamao ka har'a mamello ea 1mm.

· Li-Sensors tsa Moeli oa Tšireletso: Li-sensor tse peli tsa moeli oa polokeho li behiloe ka mahlakoreng a ka ntle a liporo tsa tataiso. Sensor e ka hare e thibela liteishene tsa ho theha hore li se ke tsa atamela haufi haholo, li qoba ho thulana, ha sensor ea ka ntle e tiisa hore ha e tsamaee hole haholo.

· Foreime e tiileng ea Cast-iron: E na le foreimi e ikemetseng e otlolohileng e entsoeng ka tšepe e entsoeng ka tšepe, mohaho ona o tiileng o loketse litlhoko tse phahameng tsa tlhahiso.

· Sistimi e Matla ea Drive: Lebokose la li-gearbox le lenonyeletso la bokahohle li fana ka matla a matla, a nolofalletsang ts'ebetso e bonolo ha li-coil li ntse li tsoela pele ho feta 2mm kapa ka lebelo la ho theha le fetang 20m/min.

· Lirolara tse tšoarellang: Chrome-plated le mocheso-chelete, li-roller tsena li hanela mafome le ho bola, ho etsa bonnete ba hore nako e telele ea bophelo.

· Main Motor: Tlhophiso e tloaelehileng ke 380V, 50Hz, 3-mohato, e nang le likhetho tsa ho ikhethela tse fumanehang.

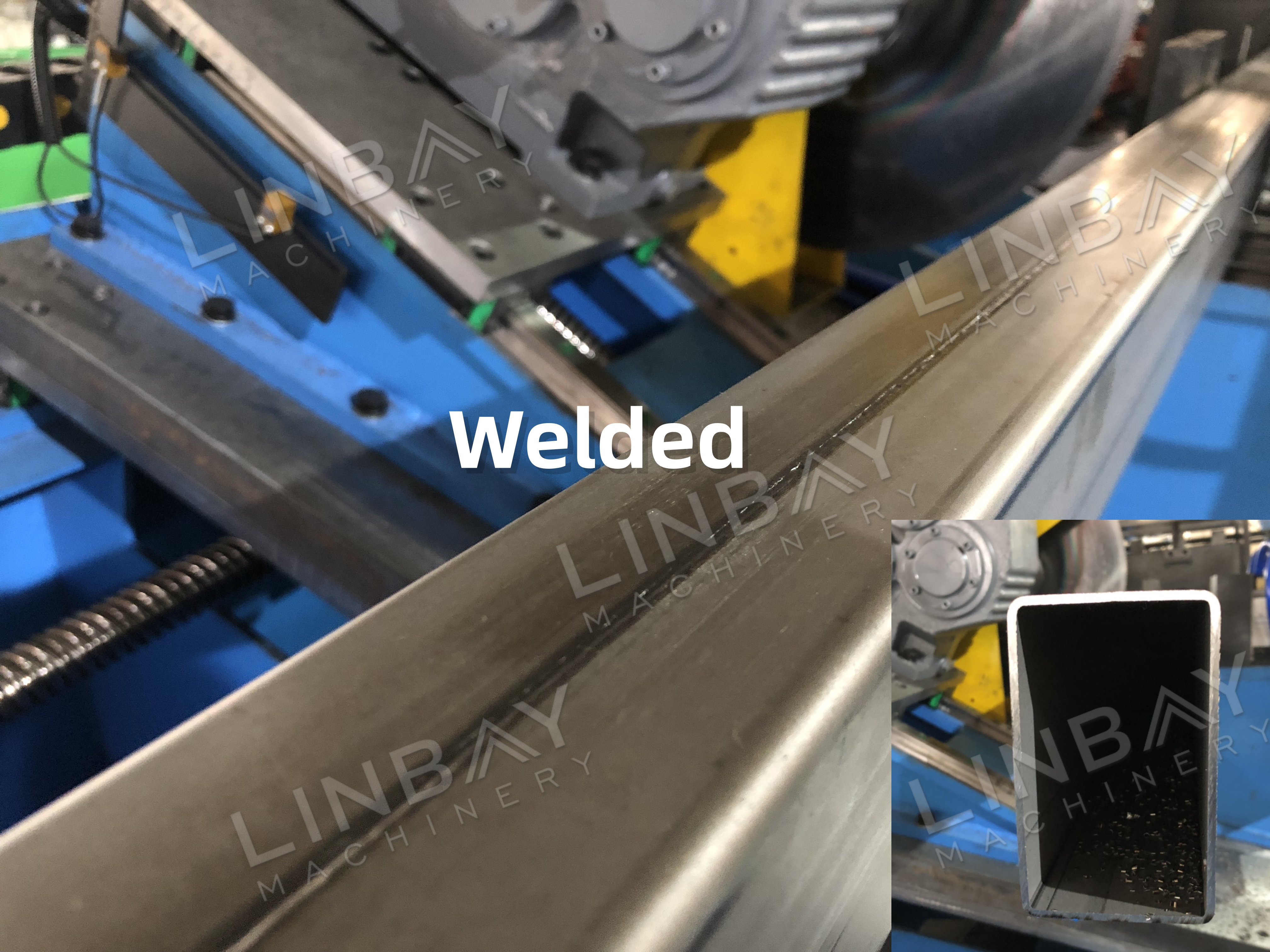

Laser Weld

· Boleng bo Ntlafetseng le Bonepehi: E fana ka ho nepahala ho holimo le khokahano e matla.

· Lenonyello le Makhethe ebile le hloekisitsoe: E netefatsa pheletso e hloekileng, e boreleli lenonyeletsong.

Welding Fume Purifier

• Taolo ea Monko le Mosi: E tšoara le ho tlosa menko le mosi o hlahisoang nakong ea ho cheselletsa, ho netefatsa tikoloho e sireletsehileng ea feme le ho sireletsa bophelo ba basebetsi.

Flying Saw Cut

· Flying Cut: Setsi sa ho itšeha se lumellana le lebelo la mochini o etsang roll nakong ea ts'ebetso, se matlafatsa tlhahiso le tlhahiso.

· Precision Cutting: Ka mochine oa servo le molaoli oa tsamaiso, mochine oa ho itšeha o boloka ho nepahala ha ± 1mm.

· Mokhoa oa ho Sawing: E fana ka likheo tse nepahetseng ntle le ho senya likarolo tsa liprofaele tse koetsoeng ka lisekoere.

· Tšebeliso e Ntle ea Lintho: Ho khaola ka 'ngoe ho hlahisa litšila tse fokolang, ho fokotsa litšenyehelo tsa thepa.

·Flexible Tshebetso: Ho fapana le mekhoa e meng ea ho itšeha e hlokang li-blades tse khethehileng bakeng sa boholo bo fapaneng, ho khaola li-saha hoa fetoha, ho fana ka chelete ea ho boloka li-blades.

1. Decoiler

2. Ho fepa

3.Ho phunya

4. Litomo tsa ho etsa roll

5. Mokhoa oa ho khanna

6. Mokhoa oa ho khaola

Ba bang

Tafole e kantle