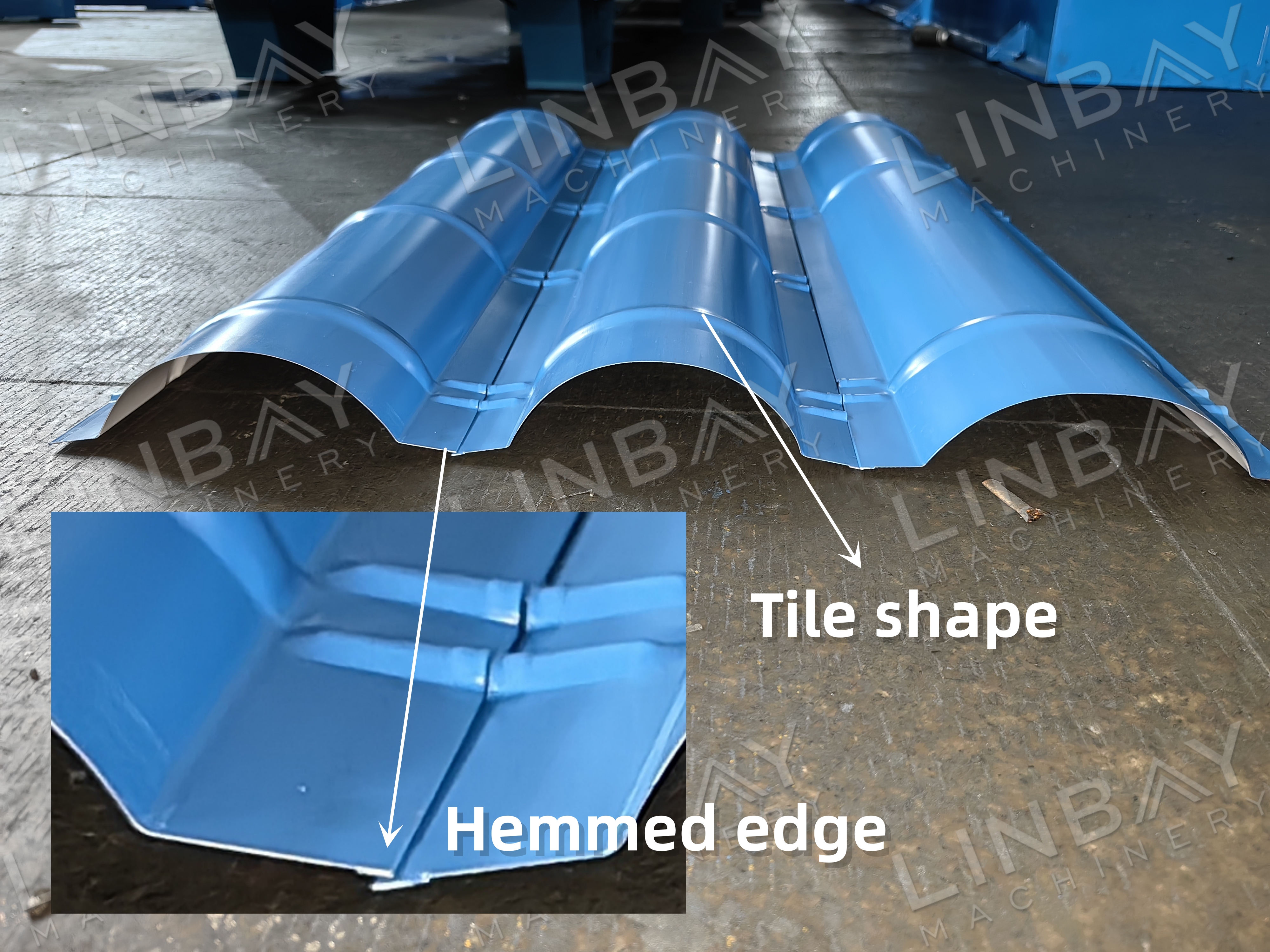

Profile

Sekoahelo se tiisa seam moo matsoapo a mabeli a marulelo a kopanang, ho sireletsa sebaka ka katleho puleng le leroleng. Likatiba tsena li fumaneha ka libopeho tse fapaneng ho tlatselletsa mekhoa e fapaneng ea liphanele tsa marulelo a tšepe 'me li entsoe ka tšepe e koahetsoeng ka mebala ea 0.3-0.6mm, PPGI le masenke.

Taba ea 'nete-Mekhabiso e ka Sehloohong ea Techinical

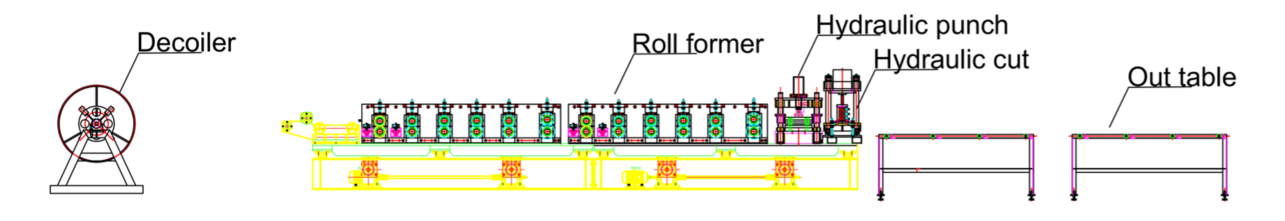

Chate e phallang: Decoiler--Tatai--Roll forming machine--Hydraulic punch--Hydraulic cut--Out table

Taba ea 'nete-Mekhahlelo e ka Sehloohong ea Tekheniki

· Lebelo le feto-fetohang la mohala: 0-10m / min

· Lisebelisoa tse lumellanang: Tšepe e koahetsoeng ka mebala, tšepe e entsoeng ka masenke le PPGI

· Botenya ba lintho tse bonahalang: 0.3-0.6mm

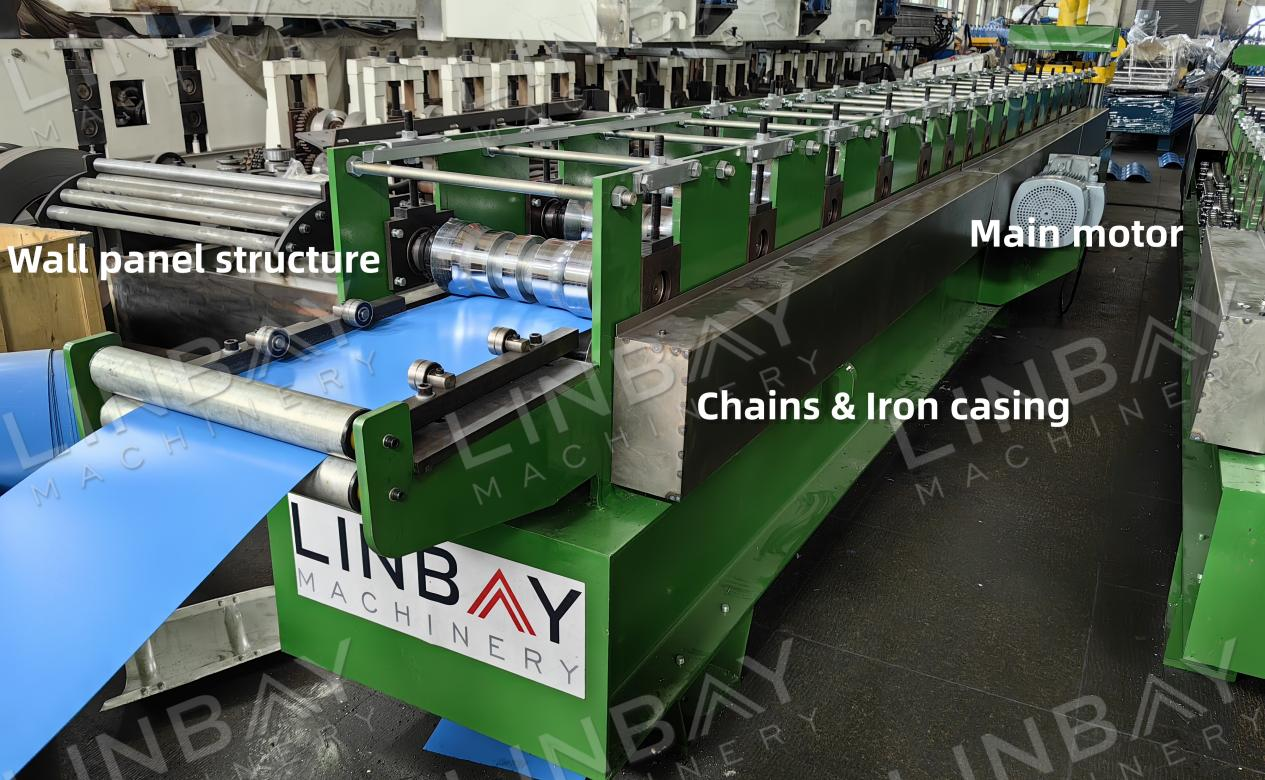

· Mofuta oa mochini o etsang roll: Sebopeho sa lebota-phanele

· Sistimi ea ho khanna: Mochini oa ketane

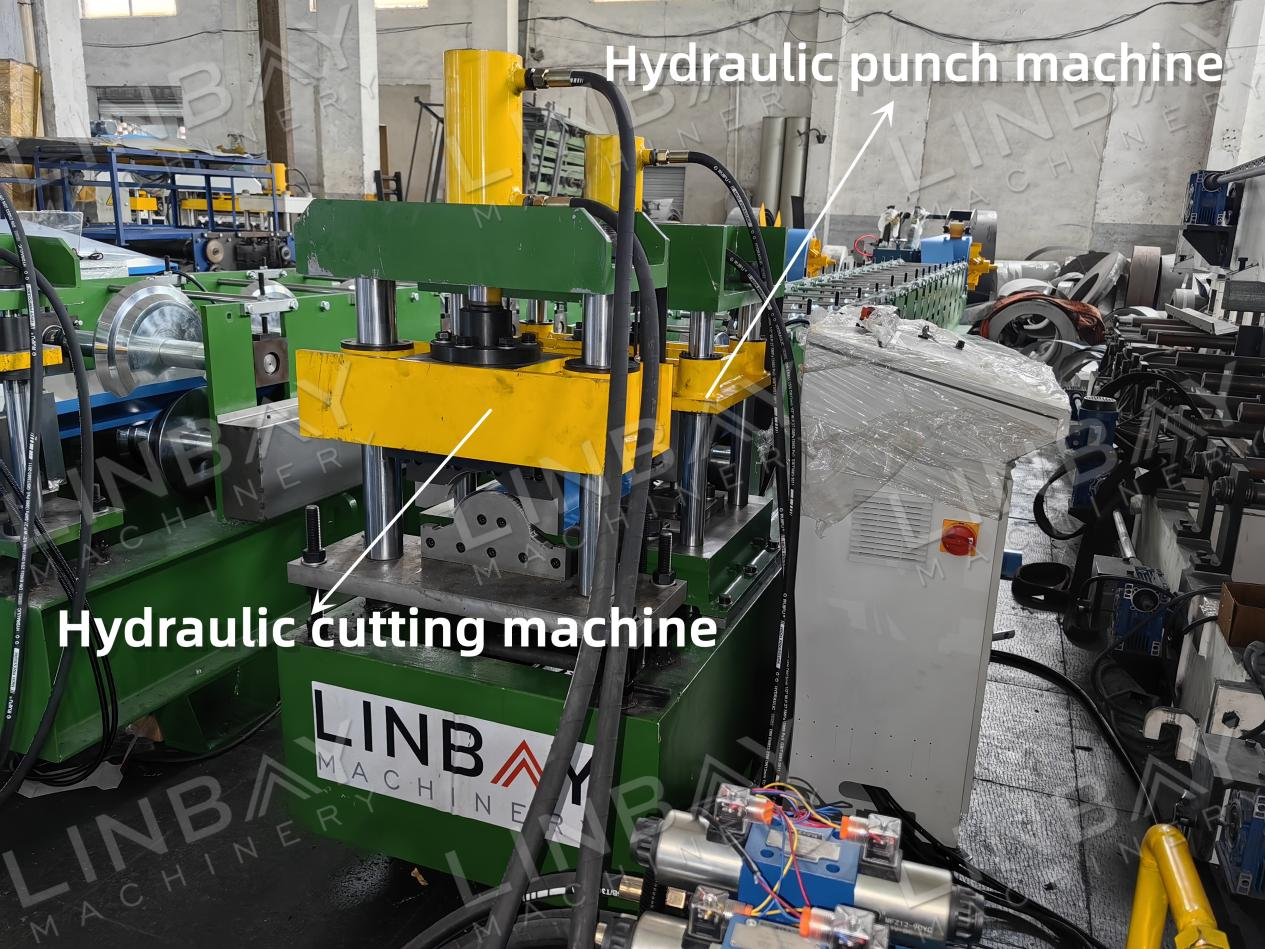

· Sisteme ea ho itšeha: Hydraulic cutting, le moqolo o kileng oa emisa nakong ea ho seha

· Taolo ea PLC: Sisteme ea Siemens

Mechini ea 'nete ea linyeoe

1.Manual decoiler*1(Re boetse re fana ka motlakase le hydraulic decoiler, tseba haholoanyane ho DESCRIPTION e ka tlase)

2.Roll forming machine*1

3.Mochini oa hydraulic punch*1

4.Mochini oa ho itšeha ka metsi *1

5.Ka ntle ho tafole*2

6.PLC taolo ea khabinete*1

7.Seteishene sa Hydraulic*1

8.Lebokose la likarolo tsa polokelo (Mahala)*1

Taba ea 'nete-Tlhaloso

Decoiler

Decoiler e fumaneha ka mefuta ea tataiso, ea motlakase le ea hydraulic, e khethiloeng ho latela botenya ba tšepe, bophara le boima ba eona. Decoiler e entsoeng ka letsoho e lekane ho ts'ehetsa ka mokhoa o sireletsehileng coil e teteaneng ea 0.6mm, e netefatsa hore ha e koalehe ha bonolo ebile e tsitsitse.

The shaft bohareng ba uncoiler, eo hape e tsejoang e le sesebelisoa sa mantlha sa katoloso, e etselitsoe ho ts'oara coil ea tšepe, e nang le bokhoni ba ho hola kapa konteraka ho amohela bophara ba ka hare ho tloha ho 460-520mm, ho netefatsa hore ha e koalehe ka mokhoa o sireletsehileng le o boreleli. Ho ekelletsa moo, ho kenyeletsoa sekontiri se ka ntle sa coil ho thibela khoele hore e se thelle, ho matlafatsa polokeho ea basebetsi.

Tataiso

Lirolara tse tataisang li thusa coil ea tšepe hore e kene hantle mochining oa ho etsa moqolo, e etsa bonnete ba hore e tsamaisana le mehala e bohareng ea mechini e meng. Ho tsamaisana hona ho bohlokoa bakeng sa ho boloka ho otloloha ha sekoahelo sa ridge le ho etsa bonnete ba hore ho na le libaka tsa khatello tse nepahetseng.

Mochine oa ho etsa roll

Sebopeho sa marako sa marako se kopantsoeng le tsamaiso e tsamaisoang ke ketane ka katleho se bōpa lipampiri tse tšesaane ho tloha ho 0.3-0.6mm ka botenya, ho fana ka tharollo e theko e tlaase. Ketane e koaletsoe ka mokotleng oa tšepe, ho fana ka tšireletso bakeng sa basebetsi le ho sireletsa liketane ho senya litšila. Ha tšepe ea tšepe e feta har'a li-rollers tse etsang, e tlas'a khatello le matla a thata, e leng se hlahisang sebopeho se lakatsehang.

Sistimi ena e kenyelletsa liteishene tse 16 tsa ho etsa, e 'ngoe le e 'ngoe e entsoe ka nepo ho latela se boletsoeng ke moreki, ho nahanoa ka bophahamo ba maqhubu, radius ea arc le likarolo tse otlolohileng mahlakoreng ka bobeli a sekoaelo sa maqhubu. Liteishene tsena li etselitsoe ho thibela leha e le efe ho khoasolla holim'a coil kapa ho senya pente ea pente.

Sekoahelo sena se na le mapheo a hemmed ho matlafatsa polokeho ka ho fokotsa bohale le ho sireletsa basebetsi kotsing. Moralo o nang le hemmed o boetse o pata karolo ea tšepe, o thibela ho phunyeha le ho fokotsa kotsi ea ho hlaha ha mafome moeling oa ridge cap.

Ho hatakela

Hang ha e etsoa, coil ea tšepe e nka sebopeho sa semi-chitja. Ka mor'a moo, mochine oa hydraulic punch o sebelisoa ho hatisa paterone e phahamisitsoeng holim'a tile. Ts'ebetso ena ha e bōpe lithaele feela empa e boetse e ntlafatsa matla a longitudinal a cap cap. Maqhubu a setempe a ka fetoloa ka skrineng sa PLC, 'me hlobo ea setempe e ka etsoa ka mokhoa o ikhethileng ho tsamaisana le litlhaloso tsa hau.

Encoder, PLC Control Cabinet, & Hydraulic cutting

Sesebelisoa se lekanya ka nepo bolelele ba tšepe e ntseng e tsoela pele ebe se fetola tekanyo ena hore e be lets'oao la motlakase le rometsoeng khabineteng ea taolo ea PLC. Basebelisi ba ka hlophisa lebelo la tlhahiso, boholo ba batch, le bolelele ba ho seha ka kotloloho ho tsoa skrineng sa khabinete ea PLC. Ka lebaka la maikutlo a nepahetseng a tsoang ho encoder, mochine oa ho itšeha oa hydraulic o ka boloka phoso ea bolelele ba ho itšeha ka hare ho ± 1mm. Ho feta moo, li-blades tsa ho itšeha li entsoe ka mokhoa o ikhethileng ho latela lits'oants'o tse fanoeng, ho etsa bonnete ba hore ho na le mapheo a hloekileng, a se nang deformation le ho tlosa li-burrs.

1. Decoiler

2. Ho fepa

3.Ho phunya

4. Litomo tsa ho etsa roll

5. Mokhoa oa ho khanna

6. Mokhoa oa ho khaola

Ba bang

Tafole e kantle