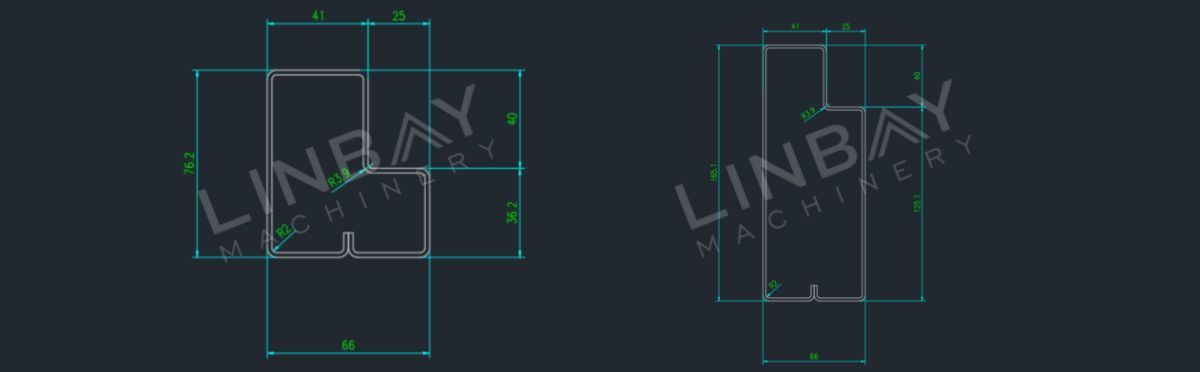

Perfil

Umqadi wenyathelo udlala indima ebalulekileyoIinkqubo zokurhangqa ipalethi enzima, ukuchaphazela ngokuthe ngqo amandla kunye nomthwalo wokuthwala umthamo wesakhiwo sonke.

Abavelisi ngokuqhelekileyo basebenzisa oomatshini bokwenza umquluI-1.5-2mm yentsimbi eshushu okanye ebandayoukuvelisa imiqadi yenyathelo. Ukuphucula ubomi babo kunye nokuthintela ukuguquka okubangelwa ukunyanzeliswa kwe-coil yensimbi, i-welding isetyenziswa kwi-coil joints. Iinkqubo ezimbini ze-welding eziqhelekileyo eziqeshwe kwishishiniI-MIG welder (njengale meko) kunye ne-laser full welder.

Zombini i-MIG welder kunye ne-laser i-welder epheleleyo inegalelo ekomelezeni imfezeko yesakhiwo. Nangona kunjalo, ngenxa yokhuselo olubanzi lwamalungu kwi-welding epheleleyo, ukusebenza kwayo kungaphezulu koko kwe-MIG welding. Abathengi banokukhetha indlela ye-welding ngokusekelwe kuhlahlo lwabiwo-mali kunye neemfuno zokulayisha i-rack.

Ityala lokwenyani-Iiparamitha zoBuchule eziPhambili

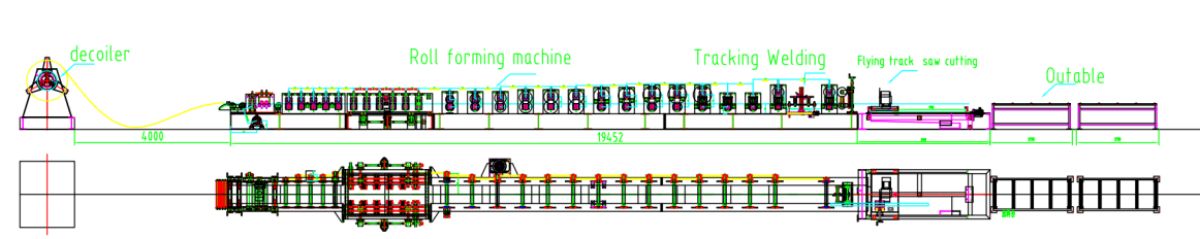

Itshathi equkuqelayo

I-decoiler ngesandla--Ukukhokela--I-Leveler--Umatshini wokwenza i-Roll--Iwelder ebhabhayo--Isarha ebhabhayo yokusika--Itafile

IiParameters ezingundoqo zobuGcisa

Isantya se-1.Umgca: 4-5 m / min, ukulungiswa

Iiprofayili ezi-2: Ubukhulu obuninzi-ububanzi obufanayo be-66mm, kunye nobude obahlukeneyo be-76.2-165.1mm

3.Ubukhulu beMaterial: 1.9mm (kule meko)

I-4.Izinto ezifanelekileyo: Intsimbi eshushu eqengqelekayo, intsimbi eqengqelekayo ebandayo, intsimbi efakwe igalvanized

Umatshini wokwenza i-5.Roll: Ubume be-Cast-iron kunye nenkqubo yokuqhuba ikhonkco.

6. Hayi. Kwisikhululo esakhayo: 26

I-7.Inkqubo ye-Welding: 2 * iitotshi ze-welding, i-roll yangaphambili ayiyeki xa i-welding.

I-8.Inkqubo yokusika: I-Saw cut, i-rollformer ayiyeki xa usika.

9.Ukutshintsha ubungakanani: ngokuzenzekelayo.

Ikhabhinethi ye-10.PLC: inkqubo ye-Siemens.

Imeko yokwenyani-Inkcazo

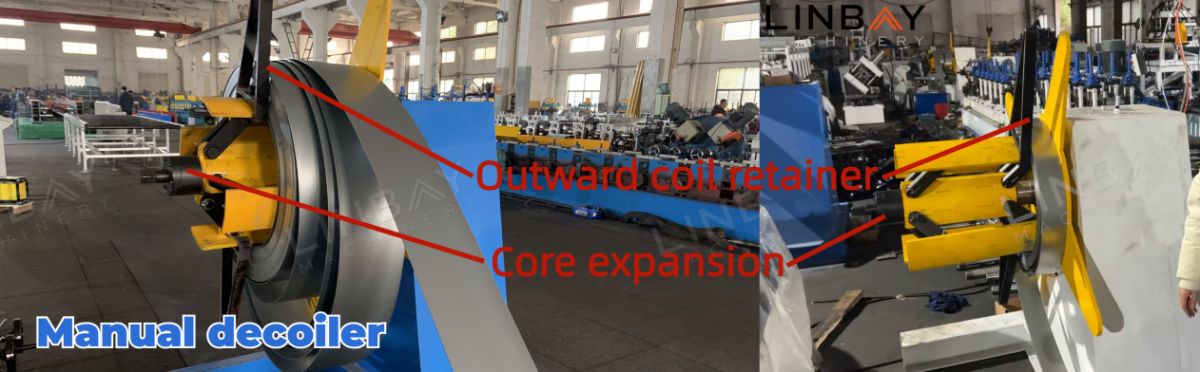

I-Decoiler Manual

I-decoiler yemanuwali ineempawu aisixhobo sokuqhoboshayenzelwe ukulungelelanisa i-core expansion tension ngaphakathi koluhlu lwe-φ490-510 mm, ukuqinisekisa ukusebenza kakuhle kokuvula. Ukunikezelwa kokusetyenziswa kwekhoyili yentsimbi eyi-1.9mm, kukho umngcipheko wokuvuleka ngokukhawuleza xa uvula.Ukujongana nolu khuselekoinkxalabo, ingalo yokushicilela ifakwe ukuze ibambe ngokukhuselekileyo i-coil yensimbi, ngelixa iintsimbi ezikhuselayo zongezwa ukukhusela i-coil slippage. Olu luyilo alunikezeli kuphela isisombululo esinexabiso eliphantsi kodwa lubeka phambili ukhuseleko kwinkqubo yokukhulula.

I-decoiler ye-manual ineakukho mandla. Kwiimfuno eziphezulu zomthamo wemveliso, sinikezela ngokuzikhethelai-hydraulic decoileriqhutywa sisikhululo samanzi.

IsiKhokelo kunye nomboniso weDijithali

Iirola ezikhokelayo zidlala indima ebalulekileyo ekugcineni ulungelelwaniso phakathi kwekhoyili yentsimbi kunye noomatshini, ngaloo ndlela kuthintela ukugqwethwa komqadi wesinyathelo kunye nokuthatha inxaxheba kwinkqubo yokwenza umquluthintela ukuguqulwa kwe-rebound yentsimbi. Ukuthi tyeUmqadi wenyathelo ubalulekile kumgangatho wemveliso kwaye unefuthe ekusebenzeni komthwalo wenkqubo yokurakhisa yonke. Iirola ezikhokelayo zibekwe ngobuchule kungekuphela nje ekuqaleni komatshini wokwenza umqulu kodwa kwakhonakwiindawo ezahlukeneyo kumgca wokwenza umqulu wonke, ukuqinisekisa ulungelelwaniso oluchanekileyo kuyo yonke inkqubo yokuvelisa.

Izixhobo zokubonisa idijithali ziququzelelaukurekhodwa okufanelekileyoyendawo echanekileyo yeerola ezikhokelayo. Kwayeimilinganiselo yomgamaukusuka kwi-roller nganye ekhokelayo ukuya kumaphethelo asekhohlo nasekunene kumatshini wokwenza umqulu abhalwe kwincwadana, evumela uhlengahlengiso olulula olusekwe kule datha nokuba ukufuduswa okuncinci kwenzeka ngexesha lothutho okanye imveliso.

Umgangatho

Emva koko, i-coil yensimbi iqhubela phambili kwi-level. Ngenxa yobukhulu bayo obuyi-1.9mm, kunyanzelekile ukubaphelisa nayiphi na i-curvature ekhoyo kwi-coil yensimbi, ngaloo ndlela iphucula i-flatness yayo kunye nokuhambelana kumgangatho we-step beam. Exhotyiswe ngeerola ezi-3 eziphezulu nezi-4 zomgangatho osezantsi, umdidiyeli uphumeza le njongo ngokufanelekileyo, eqinisekisa ukufiphala okugqwesileyo kunye nokuhambelana kwenkqubo yokuqulunqa uluhlu olulandelayo.

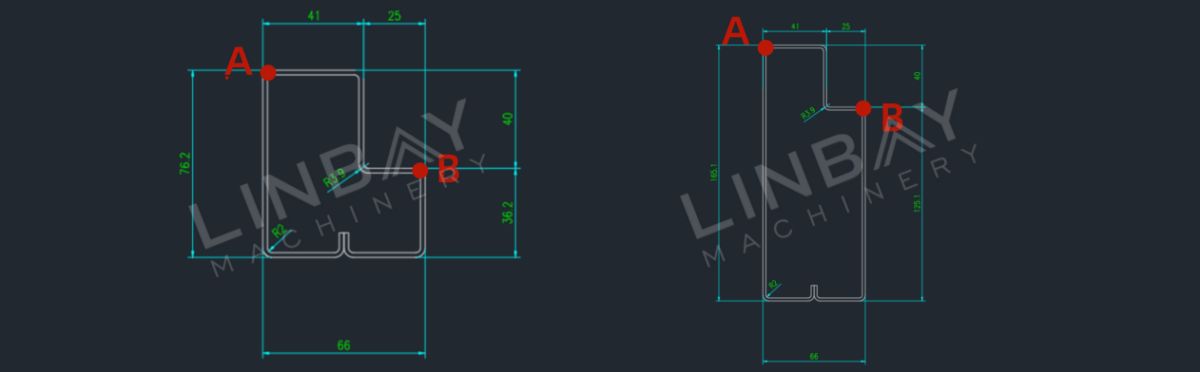

Umatshini wokwenza umqulu

Embindini wemveliso yonke kukho umatshini wokwenza umqulu. Ukuxhotyiswa ngesantya esiguquguqukayo sokulawulwa kwesantya esiququzelelwa yi-(brand yaseJapan) inverter ye-Yaskawa, umatshini unikeza uluhlu oluhlukeneyo lwesantya ukusuka kwi-0 ukuya kwi-10m / min, ukuqinisekisa ukulungelelaniswa kwiimfuno ezahlukeneyo zokuvelisa. Ibandakanya izikhululo ezingama-26 ezenzayo, iyasebenzisaisakhiwo sepaneli yodonga kunye nenkqubo yokuqhuba ikhonkco, yenziwe ngobuchwephesha ukuhambisa ukuchaneka kunye nokusebenza kakuhle kwinkqubo yokuqulunqa. Ngobugcisa bayo bokusika kunye noyilo oluqinileyo, umatshini wokwenza umqulu usebenza njengelitye lembombo lomgangatho kunye nemveliso ngaphakathi komgca wemveliso.

Ukukwazi ukuvelisaUbukhulu obahlukeneyo, ububanzi be-66mm kunye nobude obusuka kwi-76.2 ukuya kwi-165.1mm., le nkqubo inikezela ngokuguquguquka kwimveliso. Emva kokufaka ububanzi obufunekayo obusezantsi kunye nobude kwikhabhinethi yolawulo ye-PLC, izikhululo ezenza ngokuzenzekelayo zilungelelanisa izikhundla ezichanekileyo kwaye ziguqule.Amanqaku okubumba angundoqo (amanqaku A kunye no-B), ukuququzelela utshintsho lwesayizi malunga nemizuzu ye-10. Ukulungiswa kokuphakama kuhambelana nokuhluka kwamanqaku okubumba okuphambili (A kunye namanqaku e-B), okwenza ukuveliswa kwemigangatho yesinyathelo enobude obuhlukeneyo.

I-Gcr15, intsimbi enekhabhoni ephezulu yechromium edume ngobulukhuni kunye nokumelana nokunxiba, isetyenziselwa ukwenza iirola. Ukwandisa ukuqina, ii-roller zingena kwi-chrome plating. Ukongeza, i-shafts eyenziwe ngezinto ze-40Cr ifumana unyango lobushushu, ukomeleza amandla kunye nokuqinisekisa ulwakhiwo olomeleleyo.

Flying MIG Welder

Ukwandisa ixesha lokuphila kwe-beam yesinyathelo kunye nokuthintela ukuhlukana kwiintsimbi ze-coil zensimbi, i-welding iqeshwe kwiindawo ezidibeneyo zeentsimbi zetsimbi kwiphethini yechaphaza. Isithuba phakathi kwechaphaza ngalinye sihlengahlengiswa ngokweemfuno zabathengi. Ukongeza, iitotshi ezimbini ze-welding zifakwe ukunyusa isantya somgca. Ezi totshiinokuhamba ngaxeshanye kunye nesantya esenza umqulu, ukuqinisekisa ukusebenza okuqhubekayo komatshini wokwenza umqulu.

I-Flying Saw Cutting

Ukulandela ukuqulunqa umqulu, i-step beam iqhubela phambili ukuya kumatshini wokusika, isebenzisa umatshini wokusika ngenxa yesimo esivaliweyo somgca wesinyathelo. Iincakuba zeesarha ezikhethekileyo ziqinisekisa ukuchaneka okuphezulu kunye nobulukhuni, ngelixaisitshizi sokupholisaikhusela iincakuba zeesarha, yandisa ubomi bawo. Nangona isantya sokusika isarha sicotha kunokucheba ngehydraulic,umsebenzi ophathwayo udityaniswe ukuvumelanisa kunye nesantya sokuvelisa umatshini wokuqulunqa, ukuqinisekisa ukusebenza okungaphazanyiswa. Ngaphezu koko, umatshini wokusika uqinisekisa inkunkuma encinci ngexesha lokutshintshwa kwekhoyili yensimbi kunye nokusika iphrofayili.

I-Encoder & PLC

Ngaphakathi kumatshini wokwenza umqulu, i-encoder yaseJapan ye-Koyo iguqula ngokuchanekileyo ubude bekhoyili eboniweyo ibe ngumqondiso wombane, othi ke udluliselwe kwikhabhathi yolawulo ye-PLC. Umlawuli oshukumayo, ogcinwe ngaphakathi kwikhabhinethi yokulawula umbane, uqinisekisa ukukhawulezisa okungenamthungo kunye nokunciphisa ngexesha lokuhamba phambili nasemva komatshini wokusika, ngaloo ndlela ufezekise ukuchaneka kobude obuchanekileyo. Lo matshini wolawulo olucokisekileyo uqinisekisa amanqaku e-welding azinzileyo kwaye agudileyo, ukuthintela imiqadi yamanyathelo ekuqhekekeni nasekuqinisekiseni imveliso ezinzileyo, ekumgangatho ophezulu. Abaqhubi banokulawula ngokulula isantya semveliso, ukuseta imilinganiselo yemveliso, ukusika ubude, kunye nokunye ngesikrini se-PLC. Ngapha koko, ikhabhinethi yolawulo lwe-PLC inomsebenzi wokugcina imemori kwiiparamitha ezisetyenziswa ngokuqhelekileyo kwaye ibonelela ngokhuseleko ekugqithiseni, isekethe emfutshane, kunye nokulahleka kwesigaba, ukuqinisekisa ukuthembeka nokusebenza ngokukhuselekileyo.

Ulwimi olukwisikrini se-PLC lunokwenziwa ngokweemfuno zabathengi.

Isitishi seHydraulic

Isikhululo sethu se-hydraulic sibonisa i-fan yombane epholileyo ukutshabalalisa ubushushu ngokufanelekileyo, ukuqinisekisa ukusebenza ixesha elide kunye nokuthembekileyo kunye namazinga aphantsi okusilela.

Iwaranti

Ekuthunyelweni, umhla wokuhanjiswa ubonakaliswe kwi-nameplate yensimbi, ukubonelela ngesiqinisekiso seminyaka emibini kuwo wonke umgca wemveliso kunye newaranti yeminyaka emihlanu ye-roller kunye ne-shafts.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile

1-300x168.jpg)