IVIDIYO

Perfil

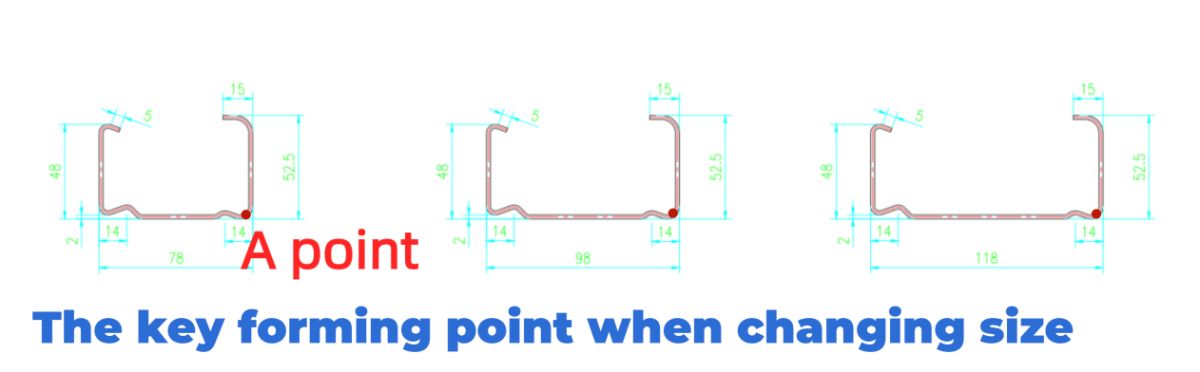

Umqa webhokisi umi njengokhetho oluqinileyo olulungiselelweumsebenzi onzimaizicelo. Ngokukodwa, sinika aumqadi webhokisi wodidi lwesiqwenga ezibiniukucingela wena. Ngokuqhelekileyo yenziwe ngentsimbi epholileyo okanye eshushu-eshushu enobunzima obusuka kwi-1.5 ukuya kwi-2mm, ihamba ngokuthe ngqo.ukwenza umqulungaphambi kokuba igqunywe ukuqinisekisa ukulungelelana kwesibheno esibonakalayo kunye namandla okunyamezela. Indibano ibandakanya ukudibanisa ngokukhuselekileyoiziqwenga ezibini zeprofayili zentsimbi ezimile okwe-C, okubangelwa isakhiwo sombhobho esomeleleyo. Ukuveliswa kweebhokisi zebhokisi, umatshini wokwenza umqulu obandayo uvela njengokhetho olukhethiweyo, olunikezela ngokufanelekileyo kunye nokuchaneka.

Ityala lokwenyani-Iiparamitha zoBuchule eziPhambili

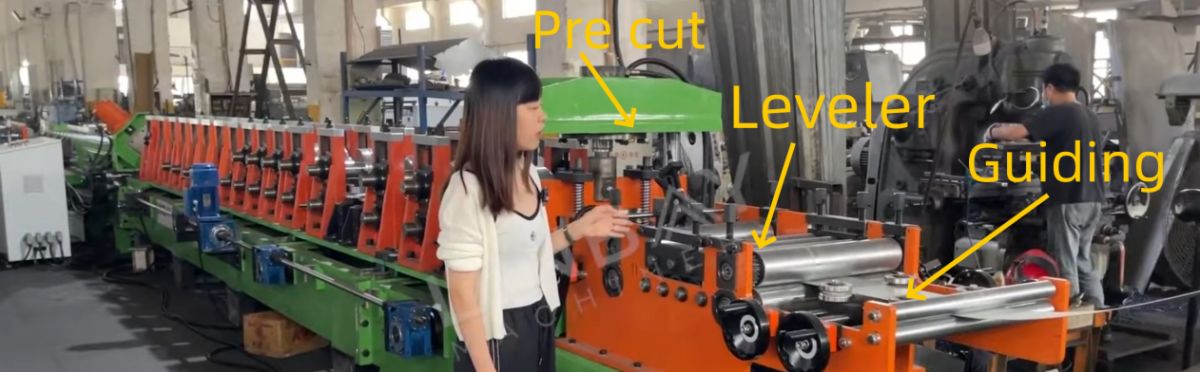

Iirola ezikhokelayo zibalulekile ekubambeni ulungelelwaniso phakathi kwekhoyili yentsimbi kunye noomatshini, ngokufanelekileyoukuthintela ukugqwethekayebhokisi yebhokisi. Zikwadlala indima ebalulekileyo kwinkqubo yokuqulunqa, ukuthintela ukuguqulwa kwe-rebound ye-coil yensimbi.Ukuthi tyeUmqa webhokisi ubambe ukuguquguquka okukhuluumgangatho wemveliso kunye nokukwazi ukuthwala umthwaloyeshelufu yonke. Ibekwe ngobuchule ecaleni komgca wokwenza, iirola ezikhokelayo ziqinisekisa ulungelelwaniso olucokisekileyo.ImilinganiseloUmgama werola ekhokelayo nganye ukuya emphethweni ubhalwe ngobuchule kwincwadana, eyenza ulungelelwaniso olungenamthungo olusekwe kule datha, naxa kukho ukufuduswa okungephi ngexesha lothutho okanye imveliso.

Umgangatho

Ukulandela isigaba esandulelayo, i-coil yensimbi iqhubela phambili kwinkqubo yokulinganisa. Apha, umatshini wokulinganisa ngenkuthalokuphelisa nayiphi na i-curvature ekhoyo kwikhoyili yensimbi, ngaloo ndlela iphucula i-flatness yayo kunye nokuhambelana kwayo, ngenxa yoko ukunyusa umgangatho wemveliso yokugqibela - ibhokisi yebhokisi. Ukuxhotyiswa ngee-2 eziphezulu kunye ne-3 ezisezantsi zokulinganisa, umatshini wokulinganisa uqinisekisa ukuchaneka okucokisekileyo ekulungiseleleni i-coil yensimbi kumanyathelo okuvelisa alandelayo.

I-Hydraulic Pre-Cut

Lo mgca wemveliso incorPoratesisixhobo sokusika kwangaphambili sehydraulic,ukwenza lula ukutshintshwa kweekhoyili zetsimbi ezinobubanzi obuhlukeneyo kunye nobukhulu, ngelixa ngaxeshanyeukunciphisa inkunkuma yekhoyili.

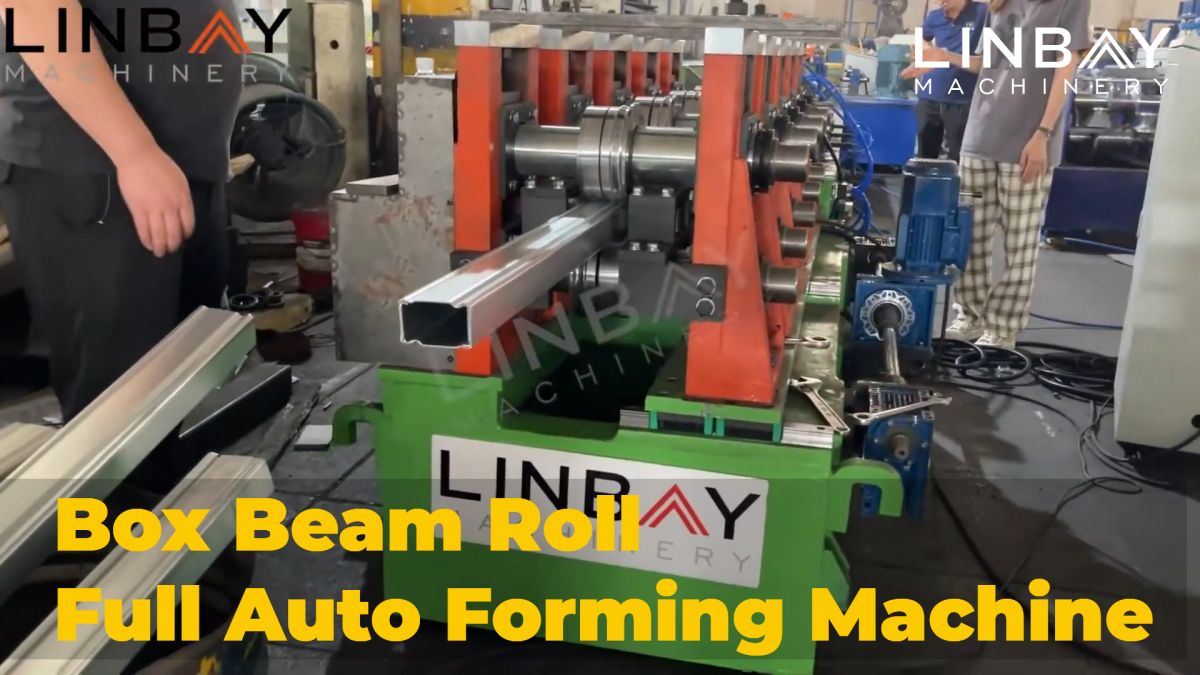

Umatshini wokwenza umqulu

Itshathi equkuqelayo

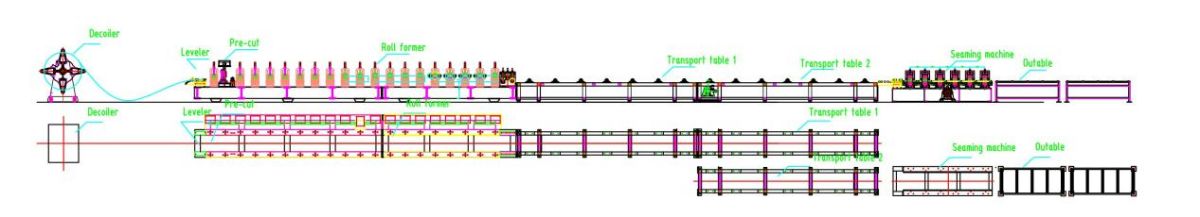

Idecoiler ngesandla--Isikhokelo--Leveler--Hydraulic pre cut--Roll forming machine--Flying hydraulic cut--Platform--Seaming machine--Out table

IiParameters ezingundoqo zobuGcisa

Isantya se-1.Umgca: 0-4 m / min, ukulungiswa

Iiprofayili ezi-2: Ubukhulu obuninzi-ubude obufanayo be-50mm, kunye nobubanzi obahlukeneyo be-80, 100, 120mm.

3.Ubukhulu bezinto: 1.5-2mm

I-4.Izinto ezifanelekileyo: Intsimbi eshushu eqengqelekayo, intsimbi eqengqelekayo ebandayo, intsimbi efakwe igalvanized

Umatshini wokwenza i-5.Roll: I-Cast-iron stru

Inkqubo yokuqhuba ikhonkco kunye nekhonkco.

6. Hayi. Kwisikhululo esakhayo: 18

I-7.Inkqubo yokusika: Ukusika kwe-hydraulic, umqulu wangaphambili awuyeki xa usika.

8.Ukutshintsha ubungakanani: ngokuzenzekelayo.

Ikhabhinethi ye-9.PLC: inkqubo ye-Siemens.

Imeko yokwenyani-Inkcazo

I-Decoiler Manual

I-decoiler ye-manuwali ifakwe ainkqubo yokuqhoboshayenziwe ngobunono ukulawula ukunyanzeliswa komqulu okhululayo kunye nokuqinisekisa inkqubo yokuphumla egudileyo. Ukunciphisa umngcipheko wokubuyela umva ngequbuliso, ngakumbi kwiikhoyili zentsimbi ezingaphezu kwe-1.5mm ubukhulu,ingalo yokucinezelaisetyenziselwe ukubamba ngokukhuselekileyo ikhoyili yentsimbi kwindawo. Ngaphaya koko, amagqabi okhuseleko lwentsimbi afakelwe ngobuchule ukuthintela ukutyibilika kwekhoyili ngexesha lokukhulula. Olu yilo lucingisisiweyo aluphuculi ukhuseleko kuphela kodwa lubonelelaukusebenza kweendleko eziphezulu, ukuqinisekisa ukusebenza okuthembekileyo nokusebenzayo.

Kule meko, i-decoiler manualngaphandle komthombo wayo wamandlauyasebenza. Ukufumana iimfuno zesantya esiphezulu semveliso, sinikezela ngokuzikhethelai-hydraulic decoileriqhutywa sisikhululo samanzi.

Ukukhokela

Embindini walo lonke umgca wemveliso kukho umatshini wokwenza umqulu, icandelo eliyimfuneko. Yakhiwe kwiqhekeza eliqinileyoJula i-ayini, lo matshini uqhayisa isakhiwo esomeleleyo kwaye siqhutywa ngumntu othembekileyoinkqubo yekhonkco. Ukuguquguquka kwayo kwenza ukuveliswa kobukhulu obahlukeneyo kunye nobude obuhambelanayo. Abaqhubi bafaka imilinganiselo ecwangcisiweyo ngokukhawuleza kwisikrini solawulo lwe-PLC, ibangelauhlengahlengiso oluzenzekelayoyokwenza izikhululo kwiindawo ezichanekileyo. Ngokuqhelekileyo, abasebenzi abanamava bafuna malunga nemizuzu engama-60 ukuba baqhube inkqubo epheleleyo yokutshintsha i-dimensional, ebandakanya ukuhamba okuzenzekelayo kwezikhululo zokwenza izikhululo kunye nokutshintshwa kwesandla kwikhoyili yensimbi.

IInqakuisebenza njengendawo ebalulekileyo yokwakheka kuhlengahlengiso lobubanzi. Njengoko izikhululo ezenza umqulu zihamba ecaleni koololiwe, zitshintsha ngamandla indawo yokwakheka kwale ndawo ibalulekileyo, nto leyo evumela ukuveliswa kololiwe.ibhokisi imiqadi enobubanzi obahlukeneyo.

Kwizinto zokwenza ii-rollers, i-Gcr15 ikhethiwe-intsimbi ephezulu ye-carbon chromium edume ngobulukhuni bayo obukhethekileyo kunye nokumelana nokunxiba. Ezi ziqengqelezi zifumana i-chrome-plating ukuze ziphucule ubomi bazo obude, ngelixa i-shafts, eyilwe ukusuka kwi-40Cr imathiriyeli, ifumana unyango lobushushu ukwenzela ukuqina okongeziweyo.

I-Flying Hydraulic Cut

Emva kokwenza inkqubo yokwenza umqulu, i-coil yensimbi ngokuthe ngcembe ihambelana neprofayili ene-C. Emva koko inqunywe ngokuchanekileyo ubude obufunekayo ngumatshini wokusika i-hydraulic, ukugcina aimpazamo yobude bokusika ngaphakathi kwe-1mm. Le nkqubo yokusika ngokufanelekileyo inciphisa ukuchithwa kwe-coil yensimbi kwaye ivumelanise kunye nesantya sokuvelisa umatshini wokwenza umqulu, ukuqinisekisa ukusebenza ngokungenamthungo kunye nokungaphazamiseki.

Iqonga

Iprofayili yokuqala ye-C igqithiselwa kwiqonga eliphezulu kwaye emva koko ityhalelwe kwiqonga elisezantsi. Emva koko, iprofayile ye-C yesibini ityhalelwa ngononophelo kwithambeka eliphakathi, apho isixhobo sokuphethula siyijikelezisa. Esi senzo silungelelanisa kwaye sibeka ngokucocekileyo iiprofayili ze-C ezimbini ngokuthe nkqo.

Iirola ezikhokelayo ziqinisekisa ukulungelelaniswa kweeprofayili ezimbini ze-C, kwaye iintonga zokutyhala umoya zityhala kumatshini wokuthunga.

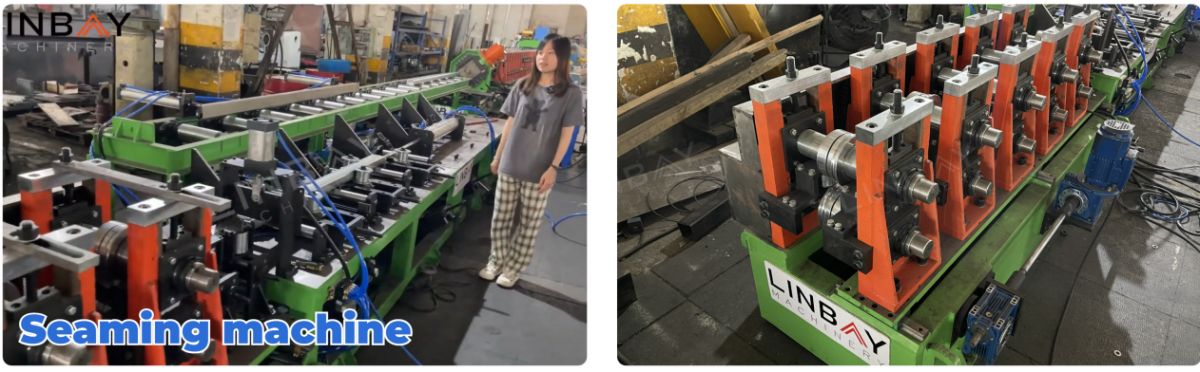

Umatshini wokuthunga

Umatshini wokuthunga ubonisa isakhiwo somatshini wokwenza umqulu, uqhayisa aulwakhiwo lwentsimbi kunye nenkqubo yokuqhuba ikhonkco. Ilungisa ngokuzimeleyo izithuba zesikhululo sokuthunga ngokobubanzi bebhokisi yebhokisi. Olu tshintshokuphelisa imfuneko yokutshisela, njengesiqhelo, umsebenzi wayefuneka ukuba adibanise i-C-profiles ezimbini kwibhokisi ye-post-roll yokwenza.

I-Encoder & PLC

Umatshini wokwenza umqulu uxhotyiswe ngeIsifaki khowudi saseJapan seKoyo, eguqula ngokuchanekileyo ubude bekhoyili kwiimpawu zombane kwikhabhinethi yokulawula ye-PLC. Oku kuchanekileyo kuyaqinisekisaiimpazamo zokusika zikhawulelwe kwi-1mm, ukuqinisekisa ukuba iibhokisi zebhokisi ezikumgangatho ophezulu kunye nokunciphisa inkunkuma. Abaqhubi banokulawula isantya semveliso, ukubeka imilinganiselo, ukusika ubude, kunye nokunye ngesikrini se-PLC. Ikhabhinethi iphinda igcine iiparamitha ezisetyenziswa ngokuqhelekileyo kwaye inikezela ngokhuseleko ekugqithiseni, isiphaluka esifutshane, kunye nokulahleka kwesigaba. Iisetingi zolwimi kwiscreen sePLC zinokulungiswa ukuze zihambelane nezinto ezikhethwa ngumthengi.

Isitishi seHydraulic

Isikhululo sethu se-hydraulic, esixhotyiswe ngabalandeli bombane bokupholisa, ngokufanelekileyo sichitha ubushushu, siqinisekisa ukusebenza okwandisiweyo kunye nokuthembekileyo kunye nezinga eliphantsi lokungaphumeleli.

Iwaranti

Ekuthunyelweni, i-nameplate ibonisa ngokucacileyo umhla wokuhanjiswa, ukubonelela aisiqinisekiso seminyaka emibini yawo wonke umgca wemveliso kunye newaranti yeminyaka emihlanu echukumisayo yeerola kunye neeshafti.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile