IVIDIYO

Perfil

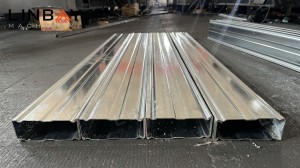

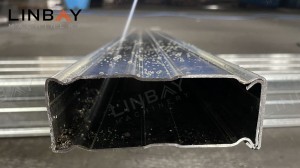

I-beam-piece-piece yinxalenye ebalulekileyoi-rack enzimaiinkqubo, ezibonisa ibhokisi yoxande-njengecandelo lomnqamlezo. Idityaniswe kusetyenziswa iipleyiti zokudibanisa kunye nezikrufu, ukwenza isakhelo esomeleleyo esineendawo zokubeka. Olu luyilo luqinisekisa uzinzo kunye nokomelela kweshelufu, ekwaziyo ukuxhasa imithwalo enzima.

Kwimveliso, i-coil enye yensimbi isetyenziselwa ukudala ibhokisi yebhokisi enye.Intsimbi epholileyo eqengqelekayo, intsimbi eshushu eqengqelekayo, okanye intsimbi efakwe igalvanized enobunzima obuyi-1.5-2mm.iqhele ukusetyenziselwa imveliso.

Ityala lokwenyani-Iiparamitha zoBuchule eziPhambili

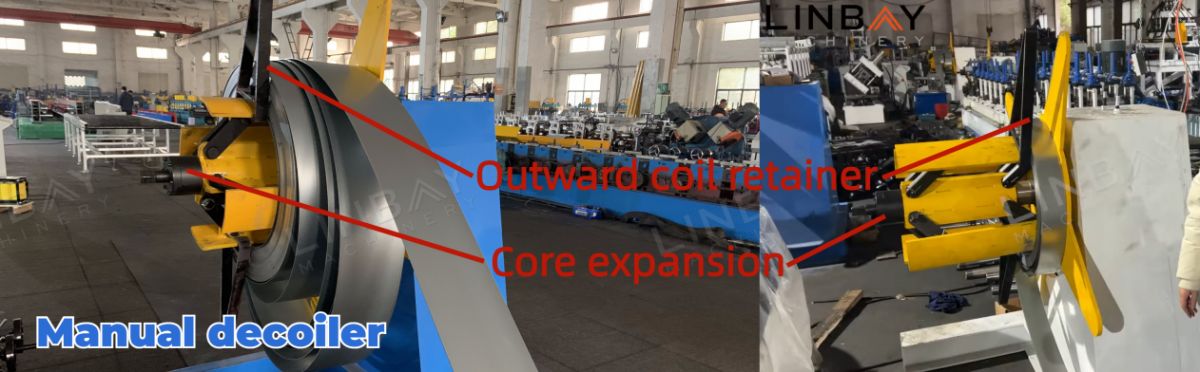

I-decoiler ye-manual yenzelwe kunye nesixhobo se-brake ukulungelelanisa ukwandiswa kunye nokuqinisekisa ukuchithwa okugudileyo ngaphakathi koluhlu lwe-φ460-520 mm. Ingalo yokushicilela ifakwe ukuthintela ubuninzi be-coil yensimbi, ngelixa amaqabunga okukhusela insimbi ekhusela i-coil slippage, ephucula zombini iindleko-ukusebenza kunye nokhuseleko.

Kulo mzekelo, i-decoiler ye-manual ngaphandle komthombo wayo wamandla iyasetyenziswa. Ukonyuka komthamo wemveliso, sinikezela ngesixhobo sokwenza oko kusenziwa ngoxinzelelo lwehydraulic oqhutywa sisikhululo samanzi.

Ukukhokela

Ii-roller ezikhokelayo ziyimfuneko ekugcineni ukulungelelaniswa phakathi kwekhoyili yensimbi kunye nomatshini, ukukhusela ukuphazamiseka kwe-tube beam. Bakwanceda ukukhusela i-rebound deformation ye-coil yensimbi ngexesha lenkqubo yokuqulunqa. Ukuthe tye kwebhokisi yebhobho yebhobho kuchaphazela kakhulu umgangatho wemveliso kunye nomthamo wokuthwala umthwalo wenkqubo yokukhwela. Iirola ezikhokelayo zibekwe ngobuchule ecaleni kwawo wonke umgca wokubumba ukuze kuqinisekiswe ulungelelwaniso oluchanekileyo. Imilinganiselo yomgama we-roller ekhokelayo ukuya emphethweni ibhalwe ngokucokisekileyo kwincwadana, uhlengahlengiso olulula olusekelwe kule datha, nokuba ukufuduka okuncinci kwenzeka ngexesha lokuthutha okanye imveliso.

Umgangatho

Emva koko, i-coil yensimbi iqhubela phambili kwi-level, apho i-curvature yayo isuswe ngokufanelekileyo ukuphucula i-flatness kunye ne-parallelism, iqinisekisa iimveliso zokugqibela eziphezulu. Umgangatho ubonisa i-3 ephezulu kunye ne-4 ye-roller yokulinganisa ephantsi ukufezekisa lo msebenzi ngokufanelekileyo.

Itshathi equkuqelayo

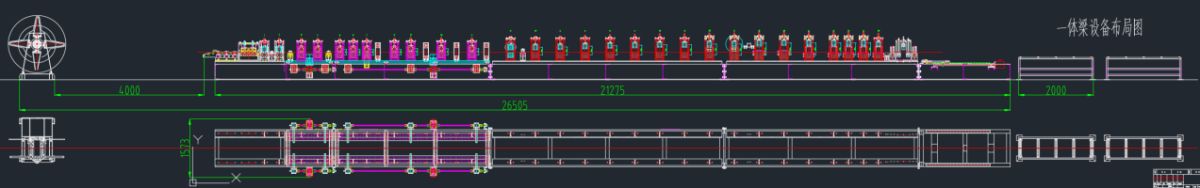

I-decoiler yeManuwali--Isikhokelo--I-Leveler--Umatshini wokwenza umqengqelelo--Isarha esikiweyo esikiweyo--Itafile

IiParameters ezingundoqo zobuGcisa

I-1.Isantya somgca: 5-6meters / min kuxhomekeke kubude bokusika

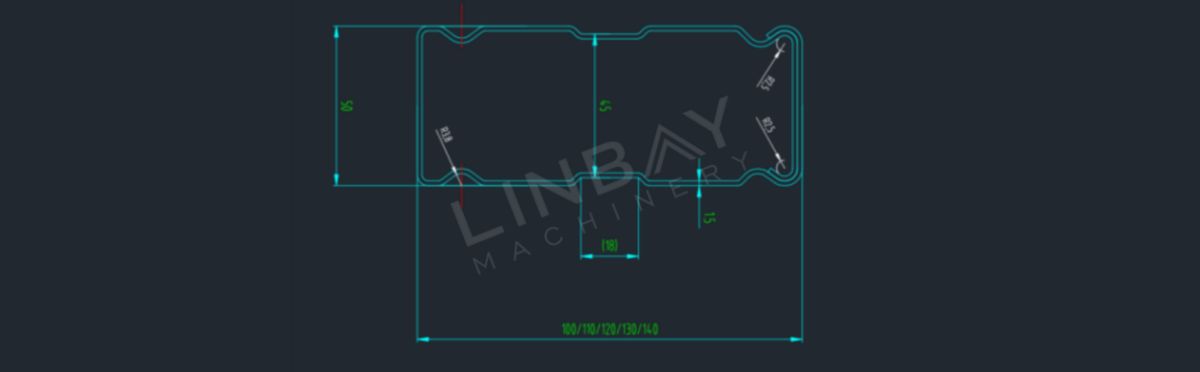

Iiprofayili ezi-2: Ubukhulu obuninzi-ubude obufanayo be-50mm, kunye nobubanzi obahlukeneyo be-100, 110, 120, 130, 140mm.

3.Ubukhulu beMaterial:1.9mm (kule meko)

I-4.Izinto ezifanelekileyo: Intsimbi eshushu eqengqelekayo, intsimbi eqengqelekayo ebandayo, intsimbi efakwe igalvanized

Umatshini wokwenza i-5.Roll: Isakhiwo se-Cast-iron kunye nenkqubo yokuqhuba i-chain.

6. Hayi. Kwisikhululo esakhayo: 28

I-7.Inkqubo yokusika: I-Saw cut, i-roll yangaphambili ayiyeki xa usika.

8.Ukutshintsha ubungakanani: ngokuzenzekelayo.

Ikhabhinethi ye-9.PLC: inkqubo ye-Siemens.

Imeko yokwenyani-Inkcazo

I-Decoiler Manual

Umatshini wokwenza umqulu

Umatshini wokwenza umqulu umi njengelitye lembombo lomgca wemveliso, uqhayisa iiseti ezingama-28 zezikhululo zokwenza kunye nesakhiwo esiqinileyo sentsimbi. Iqhutywa yinkqubo yekhonkco eyomeleleyo, ivelisa ngokufanelekileyo imiqadi yebhokisi yeesayizi ezahlukeneyo ezinobude obufanayo kunye nobubanzi ukusukaukusuka kwi-100 ukuya kwi-140mm. Abasebenzisi banokufaka ngokulula ubungakanani obunqwenelekayo ngesikrini solawulo se-PLC, oko kubangela uhlengahlengiso oluzenzekelayo lwezikhululo zokubeka indawo echanekileyo. Le nkqubo ezenzekelayo, kubandakanywa utshintsho lobungakanani, ithatha malunga nemizuzu eyi-10, iququzelelwe ukuhamba kwezikhululo ezenza izikhululo kunye nomzila wesitimela, ukulungelelanisa i-4 amanqaku abalulekileyo okwenza ububanzi obuhlukeneyo.

Ukuqulunqa ii-roller zenziwa ukusuka kwi-Gcr15, intsimbi ephezulu ye-carbon chromium exabiswayo ngenxa yobunzima bayo kunye nokumelana nokunxiba. Ezi ziqengqelezi zine-chrome-plated ukuze zihlale ixesha elide, ngelixa i-shafts, eyenziwe nge-40Cr imathiriyeli, iphathwa ngokucokisekileyo ubushushu bomelele.

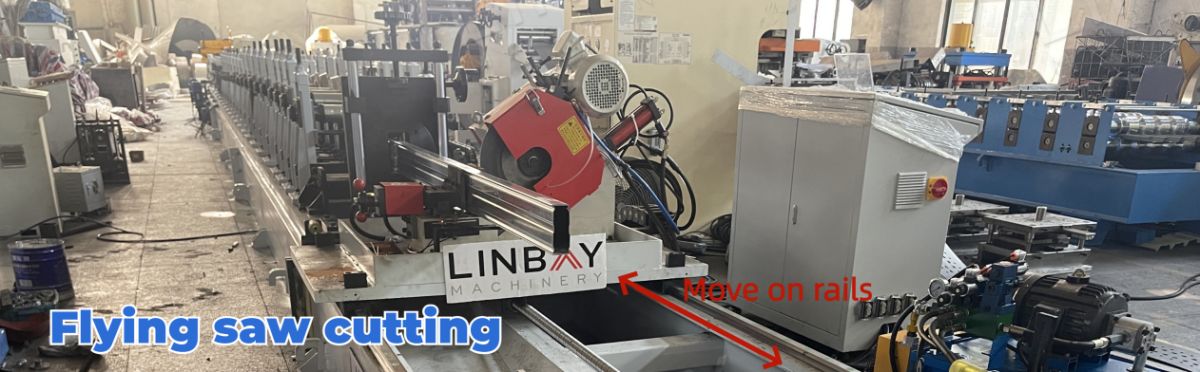

I-Flying Saw Cut

Imilo evaliweyo yebhokisi yebhokisi ifuna ukusika okuchanekileyo ukugcina ingqibelelo yesakhiwo kunye nokuthintela ukuguqulwa kwemiphetho eqingqiweyo. Le ndlela inciphisa inkunkuma ye-coil yensimbi, iqinisekisa iindawo zokusika ezigudileyo ngaphandle kwee-burrs. Iincakuba zeesarha ezikumgangatho ophezulu ziqinisekisa ukuchaneka kunye nobulukhuni, ngelixa inkqubo yokupholisa ikhulisa ubomi bayo ukuze isebenze ngokuqhubekayo.

Nangona isantya sokusika sabona sicotha kancinci kunokucheba nge-hydraulic, umsebenzi wethu ophathwayo uqinisekisa ulungelelwaniso kunye nesantya sokuvelisa umatshini wokwenza, okwenza umsebenzi ongaphazamisekiyo kunye nokuhamba kakuhle komsebenzi.

I-Encoder & PLC

Umatshini wokwenza umqulu udibanisa i-encoder yaseJapan ye-Koyo ukuguqulela ngokuchanekileyo ubude bekhoyili kwiimpawu zombane kwikhabhinethi yokulawula ye-PLC. Umlawuli oshukumayo ngaphakathi uqinisekisa ukunyakaza okungenamthungo komatshini wokucheba, ukugcina ubude obuchanekileyo bokusika ngaphandle kokukhawuleza okanye ukuncipha. Oku kubangela amanqaku e-welding agudileyo kwaye azinzile, ukuthintela ukuqhekeka kweprofayili kunye nokuqinisekisa ukuveliswa kwemitha ye-premium-grade.

Abaqhubi banolawulo olupheleleyo kwiiparitha zemveliso ngokusebenzisa isikrini sekhabhinethi ye-PLC yokulawula, kuquka isantya sokuvelisa, imilinganiselo yeprofayili, ubude bokusika, kunye nobuninzi. Ngenkumbuloyokugcinakwiiparamitha ezisetyenziswa ngokuqhelekileyo, abaqhubi banokulungelelanisa imveliso ngaphandle kokuphindaphinda ukungena kweparameter. Ukongeza, ulwimi lwesikrini se-PLC lunokwenziwa ngokwezifiso ukuze luhambelane nokhetho lomntu.

Isitishi seHydraulic

Isikhululo sethu se-hydraulic, esixhotyiswe ngabalandeli bombane bokupholisa, ngokufanelekileyo sichitha ubushushu, siqinisekisa ukusebenza ixesha elide kunye nokuthembekileyo kunye nezinga eliphantsi lokungaphumeleli.

Iwaranti

Ngomhla wokuthunyelwa, umhla wangoku uya kubhalwa kwi-nameplate yensimbi, ephawula ukuqala kwesiqinisekiso seminyaka emibini yomgca wemveliso yonke kunye newaranti yeminyaka emihlanu ye-roller kunye ne-shafts.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile