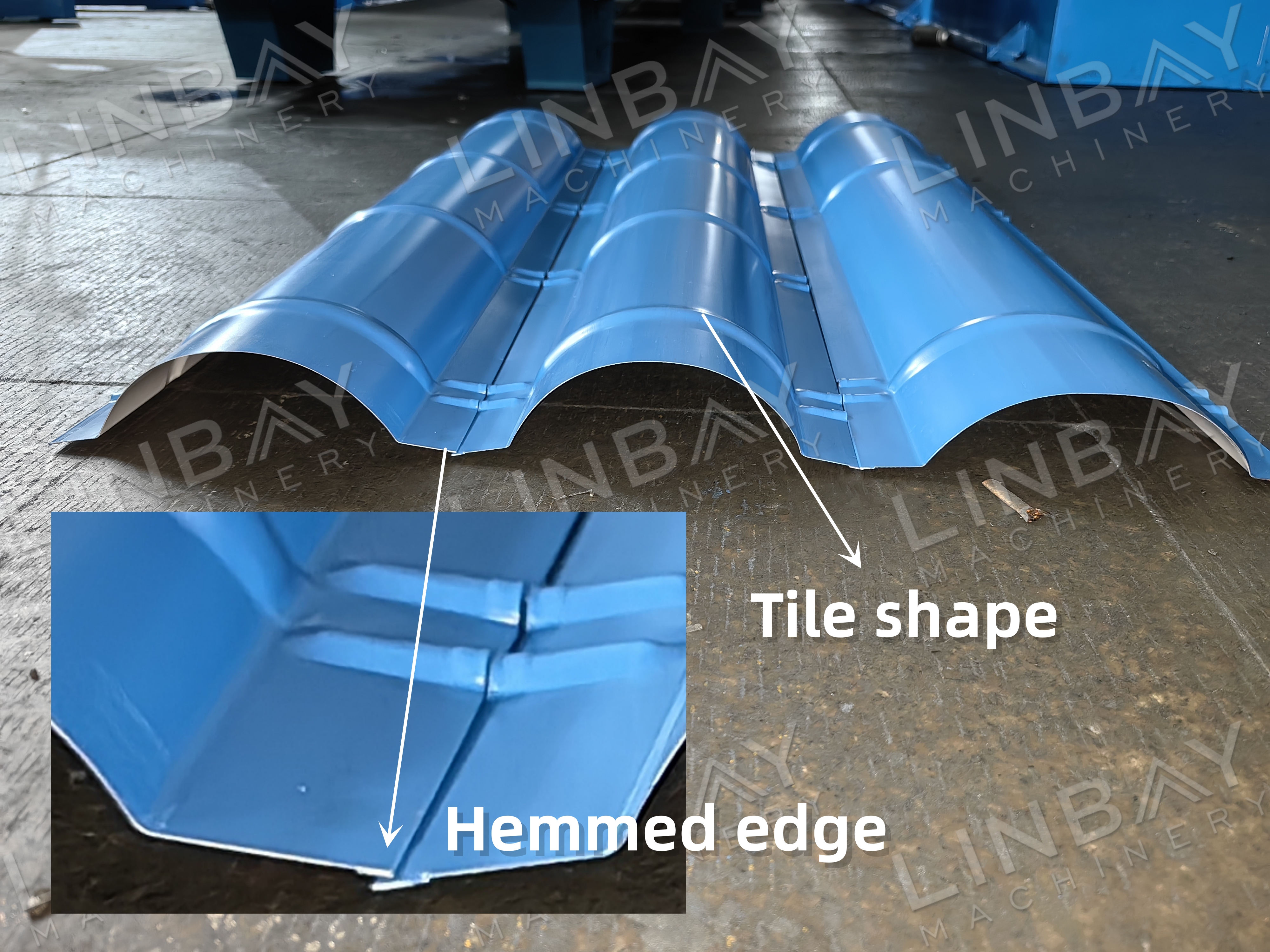

Inkangeleko yesimo

I-ridge cap ikhusela i-seam apho amathambeka amabini ophahla adibana khona, ngokufanelekileyo ukukhusela indawo emvuleni kunye nothuli. Ezi zigqoko zifumaneka kwiimilo ezahlukahlukeneyo zokuncedisa izitayela ezahlukeneyo zeepaneli zokuphahla zetsimbi kwaye zenziwe kwi-0.3-0.6mm yentsimbi efakwe umbala, i-PPGI, kunye nentsimbi ye-galvanized.

Ityala lokwenyani-Iiparamitha zoBuchule eziPhambili

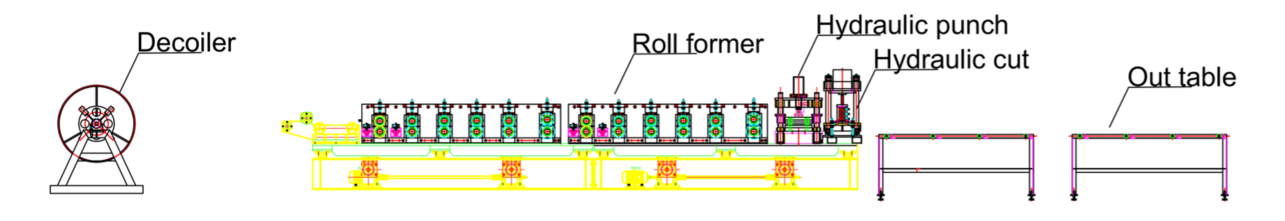

Itshathi equkuqelayo: I-Decoiler--Isikhokelo--Umatshini wokwenza umqengqelezi--Hydraulic punch--Hydraulic cut--Out table

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

· Isantya somgca ohlengahlengiswayo: 0-10m/min

· Izinto ezihambelanayo: Intsimbi efakwe ngombala, intsimbi yegalvanized, kunye nePPGI

· Uluhlu lwezinto eziphathekayo: 0.3-0.6mm

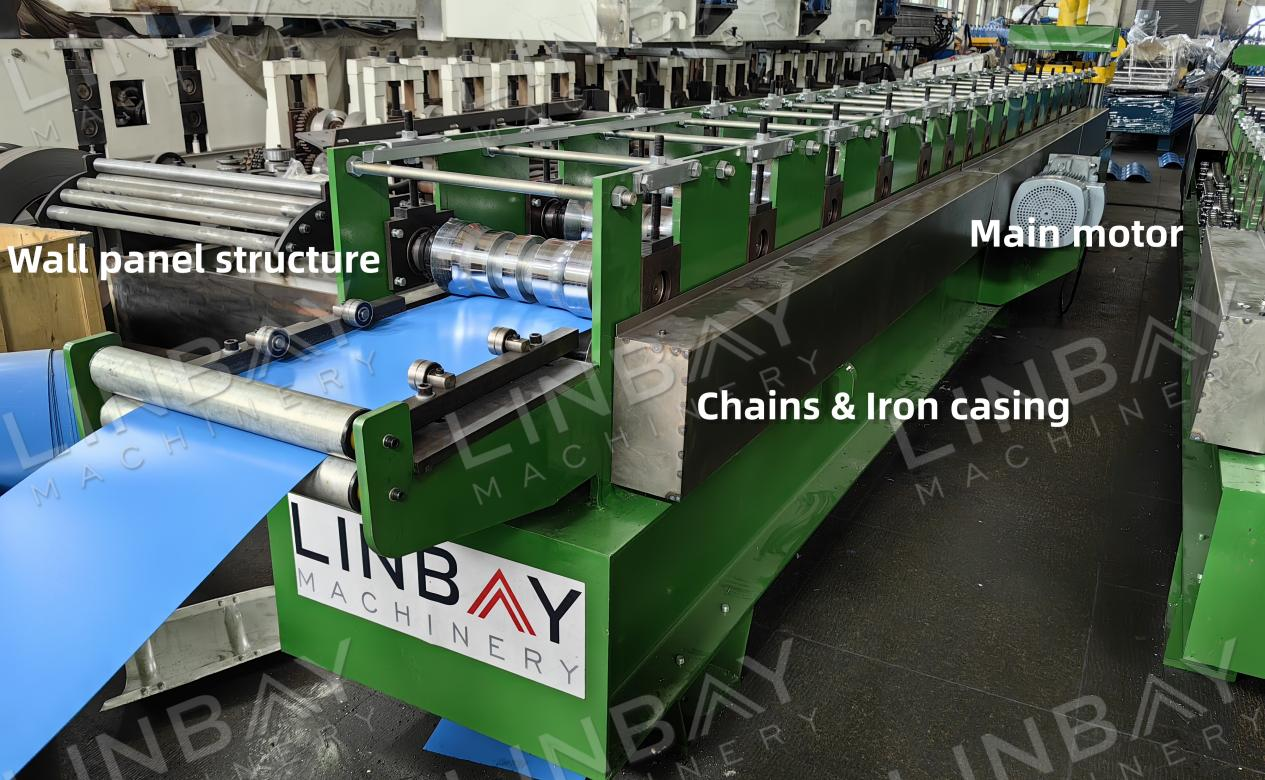

· Uhlobo lomatshini wokwenza umqulu: Isakhiwo sephaneli yodonga

· Inkqubo yokuqhuba: Inkqubo yetsheyini

· Inkqubo yokusika: Ukusika kwe-hydraulic, kunye ne-roll yangaphambili yokumisa ngexesha lokusika

· Ulawulo lwe-PLC: Inkqubo ye-Siemens

Ityala lokwenyani-oomatshini

I-1.Manual decoiler*1(Sikwabonelela nge-decoiler yombane kunye ne-hydraulic, yazi ngakumbi kwi-DESCRIPTION ngezantsi)

2.Umatshini wokwenza umqulu*1

3.Umatshini wepunch oHaydraulic*1

4.Umatshini wokusika i-Hydraulic * 1

5.Ngaphandle kwetafile*2

6.PLC iKhabhinethi yolawulo*1

7.Isikhululo samanzi*1

8.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

Imeko yokwenyani-Inkcazo

I-Decoiler

I-decoiler ifumaneka kwiinguqulelo zemanyuwali, zombane, kunye ne-hydraulic, ekhethwe ngokobunzima bentsimbi, ububanzi kunye nobunzima. I-decoiler ye-manual yanele ukuxhasa ngokukhuselekileyo ikhoyili engqindilili ye-0.6mm, iqinisekisa ukukhululeka kunye nokungagungqi.

I-shaft ephakathi ye-uncoiler, eyaziwa ngokuba sisixhobo sokwandisa i-core, yenzelwe ukubamba i-coil yensimbi, ekwazi ukwandisa okanye inkontileka ukulungiselela i-diameters yangaphakathi ukusuka kwi-460-520mm, iqinisekisa ukhuseleko olukhuselekileyo kunye nokungagungqi. Ukongeza, i-coil retainer yangaphandle ibandakanyiwe ukuthintela ukutyibilika kwekhoyili, okomeleza ukhuseleko lwabasebenzi.

Ukukhokela

Iirola ezikhokelayo zinceda i-coil yentsimbi ingene ngokutyibilikayo kumatshini wokwenza umqulu, iqinisekisa ulungelelwaniso kunye ne-centralline yabanye oomatshini. Olu lungelelwaniso lubalulekile ekugcineni ukuthe tye kwe-ridge cap kunye nokuqinisekisa iindawo zoxinzelelo ezichanekileyo.

Umatshini wokwenza umqulu

Ulwakhiwo lwepaneli yodonga oludityaniswe nenkqubo eqhutywa ngetyathanga ngokufanelekileyo imilo yamaphepha amancinci ukusuka kwi-0.3-0.6mm ubukhulu, inika isisombululo esineendleko. Ikhonkco livalelwe kwintsimbi yentsimbi, inika ukhuseleko kubasebenzi kunye nokukhusela amatyathanga kumonakalo wenkunkuma. Njengoko i-coil yensimbi idlula kwii-rollers eziqulunqayo, iphantsi koxinzelelo kunye nemikhosi enqabileyo, okubangelwa ukumila okufunayo.

Inkqubo ibandakanya izikhululo ezenza izikhululo ezili-16, ngasinye senziwe ngokuchanekileyo ngokusekelwe kwiinkcukacha zomthengi, kuthathelwa ingqalelo ukuphakama kwamaza, i-arc radius, kunye nemiphetho ethe tye kumacala omabini e-ridge cap. Ezi zikhululo zenzelwe ukuthintela nakuphi na ukukrwela umphezulu wekhoyili okanye umonakalo kwipeyinti yokwaleka.

Lo mnqwazi womphetho uquka imiphetho erhangiweyo ukomeleza ukhuseleko ngokunciphisa ububukhali kunye nokukhusela abasebenzi ekwenzakaleni. Idizayini ene-hemmed iphinda ifihle umda wesinyithi, ikhusela i-edge creep kunye nokunciphisa umngcipheko wokwakheka komhlwa kwi-ridge cap edge.

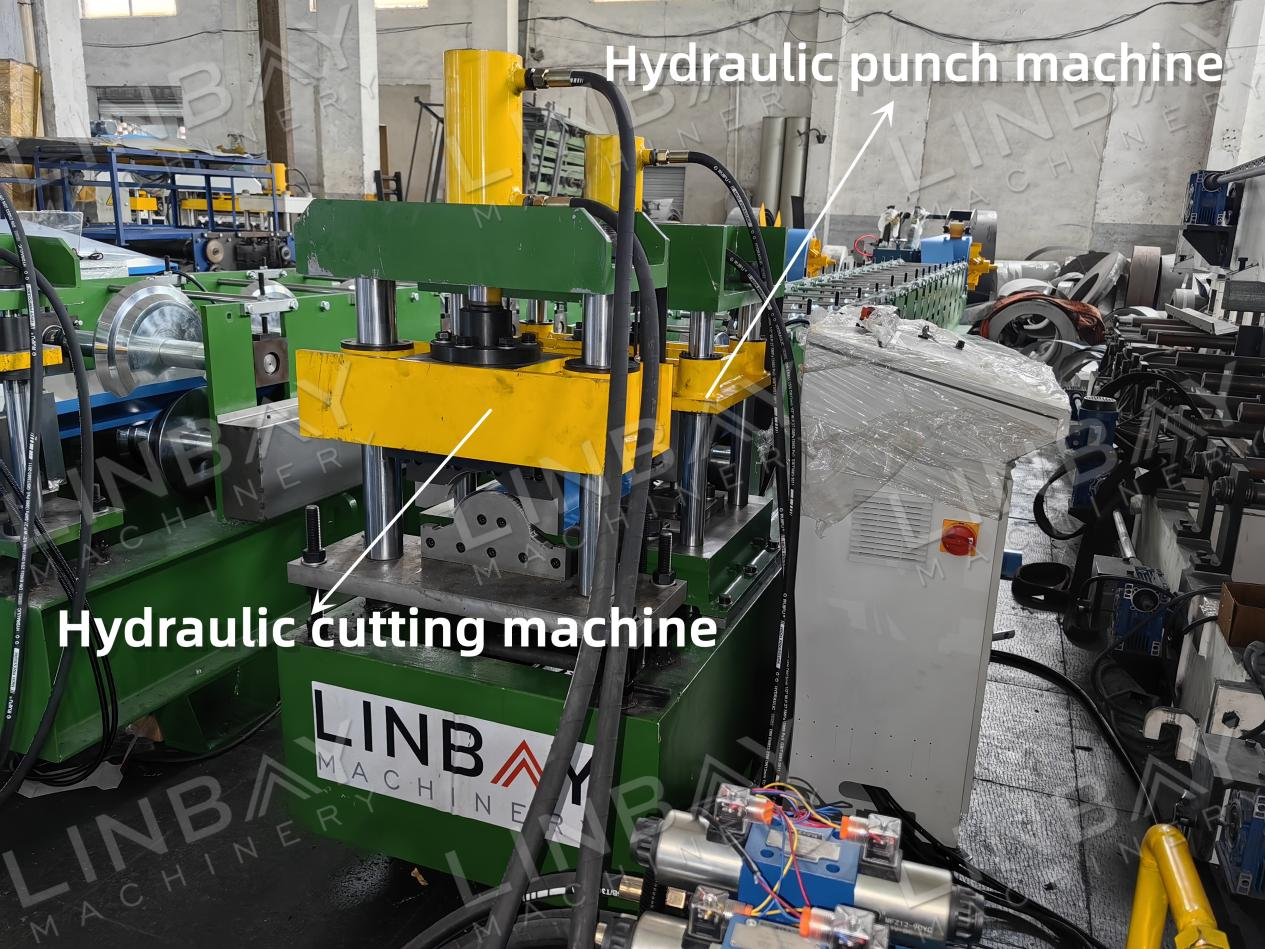

Isitampu

Xa sele yenziwe, i-coil yensimbi ithatha i-semi-circular shape. Emva koko, kuqeshwe umatshini we-hydraulic punch ukuze ugximfize ipateni ephakanyisiweyo kwithayile. Le nkqubo ayigcini nje ngokubumba i-tile kodwa iphinda ikhulise amandla e-longitudinal ye-ridge cap. I-frequency stamping inokulungiswa ngesikrini se-PLC, kwaye ukubumba kwesitampu kunokwenziwa ngokwezifiso ukuhambelana neenkcukacha zakho.

I-Encoder, iKhabhinethi yoLawulo lwe-PLC, kunye nokusika kweHydraulic

I-encoder ilinganisa ngokuchanekileyo ubude bekhoyili yensimbi eqhubela phambili kwaye iguqula lo mlinganiso ube ngumqondiso wombane othunyelwe kwikhabhinethi yokulawula ye-PLC. Abaqhubi banokuqwalasela isantya sokuvelisa, ubungakanani bebhetshi, kunye nobude bokusika ngokuthe ngqo kwisikrini sekhabhinethi yePLC. Ngombulelo kwingxelo echanekileyo evela kwi-encoder, umatshini wokusika i-hydraulic unokugcina impazamo yokusika ubude ngaphakathi kwe-± 1mm. Ukongezelela, ii-blades zokusika zenziwe ngokwesiko ngokwemizobo ebonelelweyo, ukuqinisekisa ukucoceka, imiphetho engabonakaliyo kunye nokuphelisa i-burrs.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile