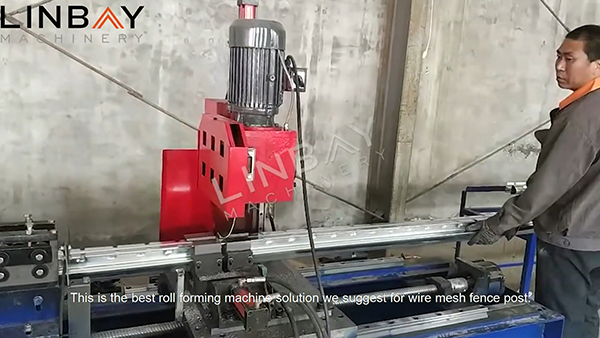

ividiyo

Inkangeleko yesimo

Ipali yocingo olunomnatha wocingo, edla ngokubizwa ngokuba yipali yepesika, ifumana igama layo kwimilo yayo engaphandle efana neyepesika. Ngokuqhelekileyo yenziwe ukusuka kwikhabhoni ephantsi okanye i-coil yentsimbi eshushu, i-peach post ihamba ngokuqengqeleka okubandayo ukufezekisa ukumila kwayo okwahlukileyo.

Imiphetho yentsimbi yentsimbi igobe ngaphandle ukuze yenze i-hook efana ne-U, iphucula ukuzinza xa ukhusela i-wire mesh. Iindawo zokubeka iinotshi zibekwe ngobuchule kumacala omabini epasika yepesika ukuququzelela ukufakelwa komnatha wocingo lwesinyithi, kunye nemilinganiselo yeslot elungiselelwe ukulingana ubungakanani bemesh.

Umgca wemveliso opheleleyo uquka ukubethelwa kweenotshi kunye neenkqubo zokwenza umqulu. Ii-roller zokwenza kunye ne-punch dies zilungiselelwe ukuqinisekisa ukubunjwa okuchanekileyo kunye nokubekwa kwenotshi ngokuchanekileyo.

Ityala lokwenyani-Iiparamitha zoBuchule eziPhambili

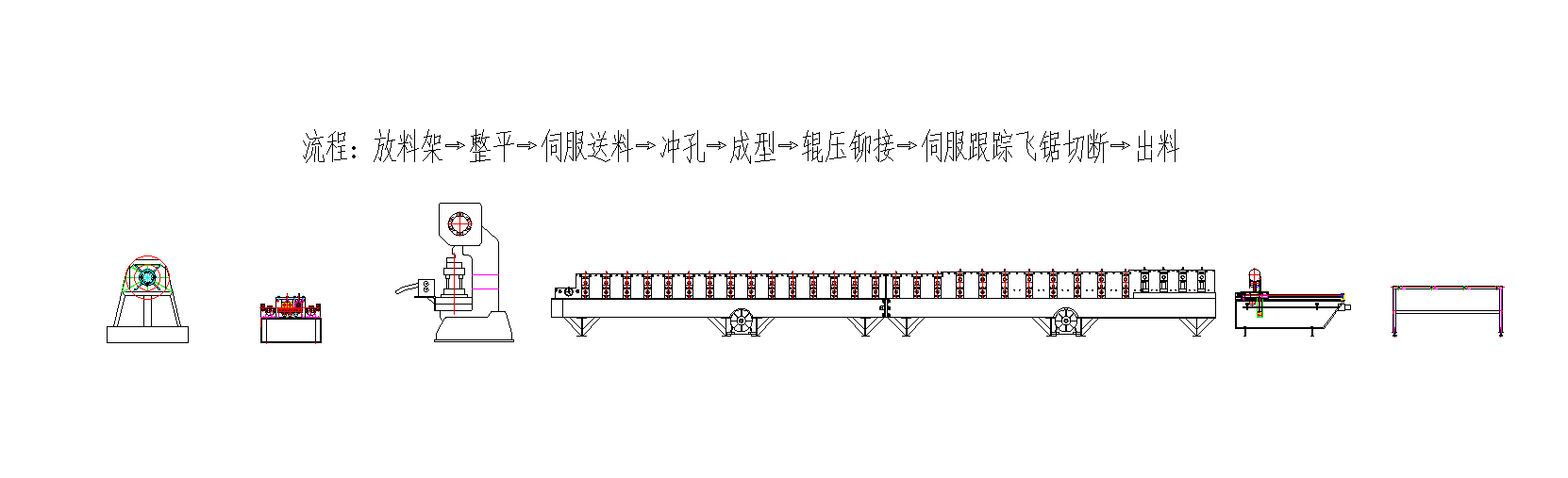

Itshathi equkuqelayo

Hydraulic decoiler-Leveler-Servo feeder-Punch press-Pit-Roll yangaphambili-Flying saw cut-out table

IiParameters ezingundoqo zobuGcisa:

1. Isantya somgca: Ukulungelelaniswa ukusuka kwi-0 ukuya kwi-6 m / min

2. Iiprofayili: Ubungakanani obunye bepali yocingo olunomnatha

3. Ubukhulu beMaterial: 0.8-1.2mm (kule sicelo)

4. Izinto ezifanelekileyo: Intsimbi eshushu, intsimbi epholileyo

5. Umatshini wokwenza umqulu: Isakhiwo sephaneli yodonga kunye nenkqubo yokuqhuba ikhonkco

6. Inani lezikhululo ezenzayo: 26

7. Inkqubo ye-Riveting: Uhlobo lwe-roller; Uluhlu lwangaphambili luhlala lusebenza ngexesha le-riveting

8. Inkqubo yokusika: I-Saw cut; Uluhlu lwangaphambili luhlala lusebenza ngexesha lokusika

9. Ikhabhinethi ye-PLC: Ixhotyiswe ngenkqubo ye-Siemens

Imeko yokwenyani-Inkcazo

I-Hydraulic decoiler

I-decoiler ibonelela ngezinto eziguquguqukayo kunye neenketho zemisebenzi yezandla, yombane, kunye ne-hydraulic. Ukukhethwa kohlobo kuxhomekeke kubunzima bekhoyili kunye nobukhulu bokuqinisekisa ukuchithwa okugudileyo kunye nokungenamthungo.

Le hydraulic decoiler inomthamo wokulayisha owomeleleyo weetoni ezi-5 kwaye ixhotyiswe ngezigcini zekhoyili zangaphandle ukuthintela ukutyibilika. I-motor iqhuba isixhobo sokwandisa, ivumela ukwandiswa kunye nokucutha ukuze kuhlaliswe i-coil yangaphakathi yeedayamitha ezahlukeneyo ukusuka kwi-460mm ukuya kwi-520mm.

Umgangatho

I-level ibeka ngokufanelekileyo i-coil, ikhupha uxinzelelo lwangaphakathi kunye noxinzelelo, ngaloo ndlela iphucula ukubethelwa kunye nokwenza iinkqubo.

I-Servo feeder kunye ne-Punch press

I-servo feeder yethu, ephawulwa ngokulibaziseka okuncinci kokuqala, inika ulawulo oluchanekileyo kwi-feeder. Oku kuqinisekisa ubude bokutya kwekhoyili echanekileyo kunye nezikhundla zepunch, ukuphucula ukuchaneka kwemveliso kunye nokusebenza kakuhle.

Iipali zocingo ezinomnatha ogqityiweyo zixhotyiswe ngeenotshi ezininzi eziyilelwe ukudityaniswa komnatha wocingo.

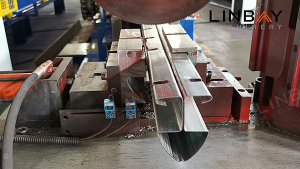

Umatshini wokwenza umqulu

Lo matshini wokwenza umqulu wakhiwe ngesakhiwo sepaneli yodonga kwaye usebenza usebenzisa inkqubo yokuqhuba ikhonkco. Kuyo yonke inkqubo yokwenza, i-coil iguqula ngokuthe ngcembe phantsi kwamandla, ibambelele kwi-"peach shape" echazwe kwimizobo enikeziweyo.

Ukuthintela ukuhlukana kweekhoyili kwi-post junction ngexesha lokusetyenziswa okwandisiweyo, amanyathelo okukhusela aphunyezwa. Ukulandela ukwenziwa komqulu, iiroli ezijikelezayo zicofa ukugqithelana kwekhoyili, zenza imbonakalo yerivet exhasa uzinzo lwesithuba kunye nokwandisa ubomi.

Ngaphezu koko, ngenxa yoyilo lwesetyhula yee-riveting rollers, i-roll yangaphambili ingakwazi ukuqhubeka nokusebenza kwayo ngokuqhubekayo njengoko i-coil iqhubela phambili ngexesha le-riveting, isusa imfuno yokubeka esinye isiseko esishukumisayo kwisixhobo se-riveting.

I-Flying saw cut

Ngenxa yobume obuvaliweyo beposti ye-peach, i-saw cutting iphuma njengendlela efanelekileyo kakhulu, ukuthintela nayiphi na i-coil deformation kwimida yokusika. Ngaphezu koko, inkqubo yokusika ayivelisi inkunkuma. Ukwandisa umthamo womgca wokuvelisa, isiseko somatshini wokusika sinokuhlengahlengiswa ngasemva nangaphambili ukuvumelanisa kunye nesantya somatshini wokwenza umqulu, ukuqinisekisa ukusebenza okungaphazanyiswa.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile