Inkangeleko yesimo

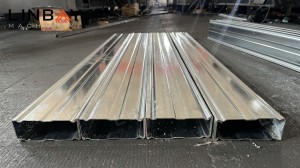

I-W-beam guardrail sisithintelo sokhuseleko esisetyenziswa rhoqo kwiiprojekthi zobunjineli bezothutho ezahlukeneyo, kubandakanya oohola bendlela, iindlela zokuhamba, kunye neebhulorho. Igama layo livela kwimilo "W", ephawulwa ngamawele ayo. Le ntsimbi yokugada iveliswa ngokubanzi ngentsimbi efakwe igalvanized okanye eshushu enobunzima obuyi-2-4mm.

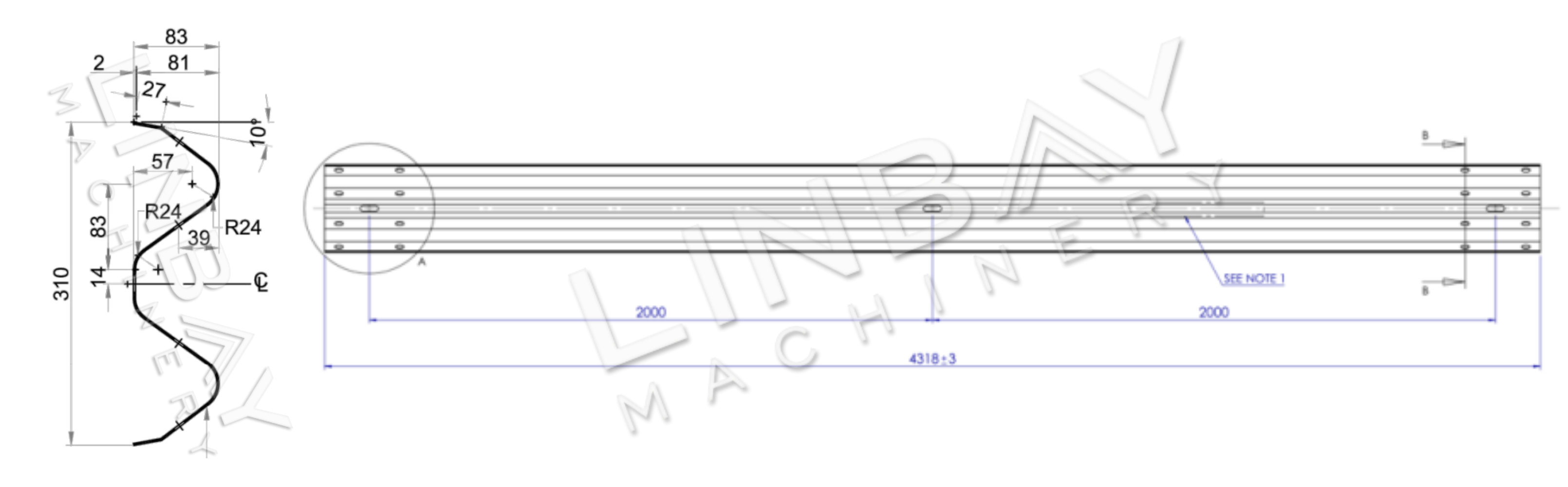

Icandelo ngalinye le-W-beam lihlala lilinganisa i-4 yeemitha ubude kwaye liza nemingxuma esele ifakwe ngaphambili kuzo zombini iziphelo ukuququzelela ukufakwa. Ngokusekwe kwiimfuno zabathengi malunga nesantya sokuvelisa kunye nesithuba esikhoyo somgangatho, sinikezela ngezisombululo ezinokwenziwa ngokwezifiso zokugqobhoza umngxuma ezinokudityaniswa ngokungenamthungo kumgca ophambili wokwenza umatshini wokuvelisa.

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

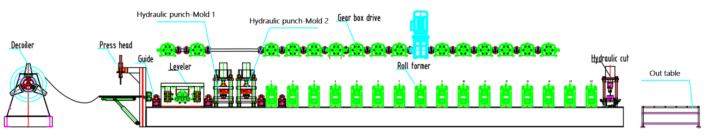

Itshati equkuqelayo: I-Hydraulic decoiler-Guiding-Leveler-Hydraulic punch-Roll yangaphambili-Hydralic cut-Out table

Isantya se-1.Umgca: 0-8m / min, ukulungiswa

2.Izinto ezifanelekileyo:Intsimbi eshushu eqengqelekayo, intsimbi eqengqelekayo ebandayo

3.Ubukhulu bezinto: 2-4mm

I-4.Umatshini wokwenza i-Roll: Isakhiwo se-Cast-iron kunye ne-universal joint

I-5.Inkqubo yokuqhuba: Inkqubo yokuqhuba i-Gearbox ene-universal joint cardan shaft.

I-6.Inkqubo yokusika: Sika ngaphambi kokwenza umqulu, umqulu wangaphambili awuyeki xa usika.

Oomatshini

1.I-Hydraulic decoiler*1

2.Leveler(Ixhotyiswe kumatshini wokwenza umqulu)*1

3.Umatshini wepunch oHaydraulic*1

4.Umatshini wokwenza umqulu*1

5.Umatshini wokusika i-Hydraulic * 1

6.Ngaphandle kwetafile*2

7.PLC iKhabhinethi yolawulo*1

8.Isikhululo samanzi*2

9.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

Ubungakanani bomgqomo: 2x40GP

Imeko yokwenyani-Inkcazo

I-Hydraulic Decoiler

I-decoiler iza nezinto ezimbini eziphambili zokhuseleko: ingalo yokushicilela kunye ne-coil retainer yangaphandle. Xa utshintsha iikhoyili, ingalo yokushicilela ibambe ikhoyili kwindawo ukuyithintela ukuba ingaphumi kwaye ibangele ukwenzakala kubasebenzi. I-coil retainer yangaphandle iqinisekisa ukuba i-coil ayityi kwaye iwe ngexesha lenkqubo yokukhulula.

I-decoiler ixhotyiswe ngomgangatho we-460mm ukuya kwi-520mm.

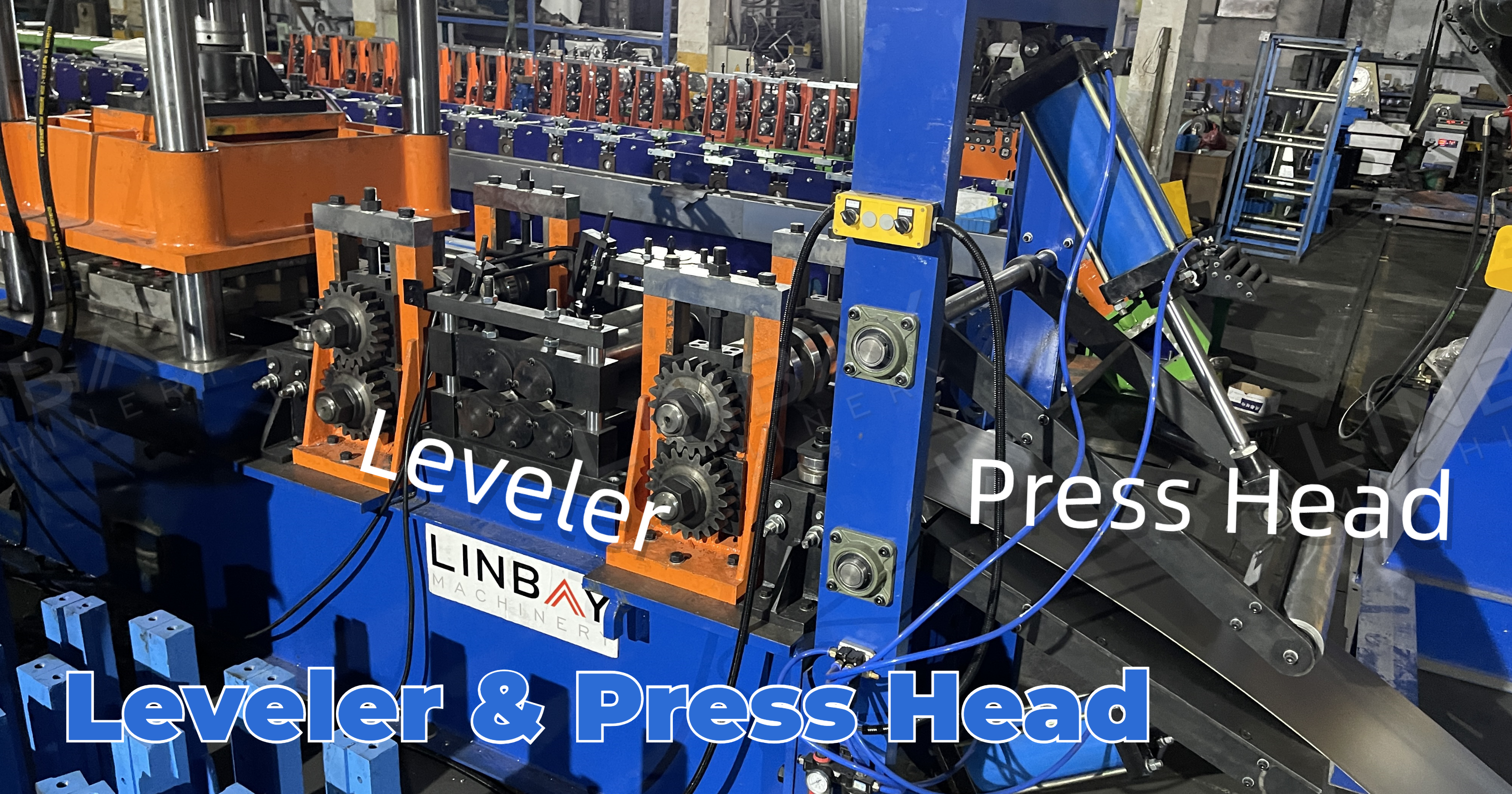

Inqanaba kunye neNtloko yeCofa

Iqonga elibekwe phambi kweleveli, lihlengahlengiswa ngokuthe nkqo ngebha yehydraulic, inceda ekukhokeleni ikhoyili kumgca wokuvelisa.

Kwiiprofayili ezingaphezulu kwe-1.5mm ubukhulu obufuna ukubethelwa ngenqindi, kubalulekile ukusebenzisa isilinganisi ukuthambisa ikhoyili kunye nokunciphisa uxinzelelo lwangaphakathi ukufezekisa ubukhulu obufanayo, okwandisa ukubethelwa kunye nokwenza umgangatho. Kule meko, i-leveler ifakwe kwi-main roll forming machine, ukwabelana ngesiseko esifanayo.

Ukuhlangabezana neemfuno zesantya esiphezulu semveliso, sibonelela ngenqanaba elizimeleyo elenyusa kancinci isantya somgangatho, nangona sandise ubude bubonke bomgca wemveliso malunga neemitha ezi-3.

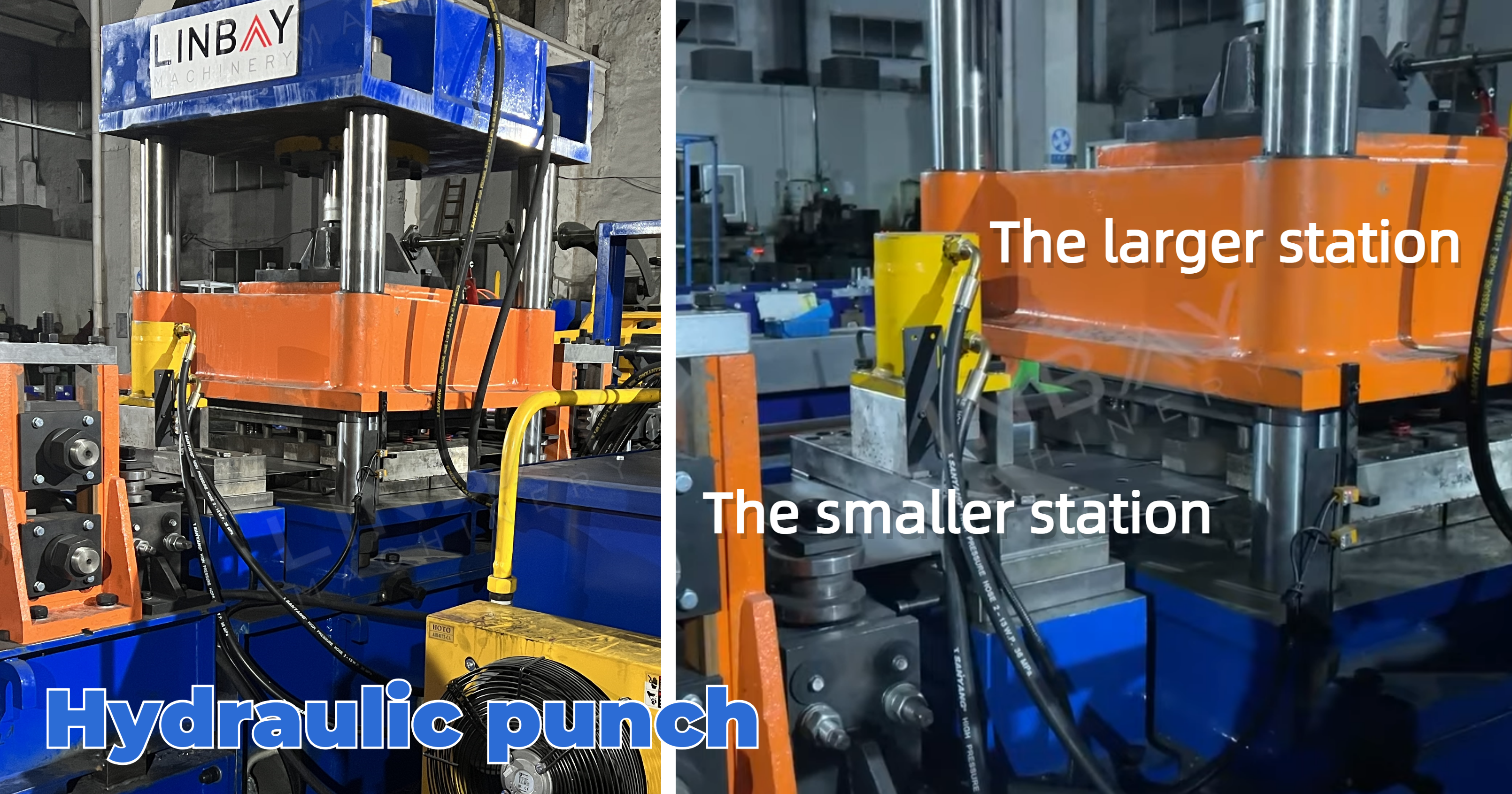

I-hydraulic punch

Ukusebenza kakuhle kunye nokusebenza kakuhle kweendleko, ukusebenza ngenqindi kunokwahlulwa phakathi kweefa ezimbini (izitishi ezibini). Isikhululo esikhulu sinokugqobhoza ukuya kutsho kwimingxuma eli-16 ngaxeshanye, ngelixa isikhululo sesibini siphethe imingxunya eyenzeka kube kanye kuphela ngomqadi ngamnye.

Umatshini wokwenza umqulu

Lo mqulu wangaphambili wakhiwe ngesakhelo sentsimbi, usebenzisa i-shafts jikelele ukudibanisa i-rollers eyenza i-roller kunye ne-gearbox. Olu yilo luqinisekisa ukuqina kwaye luhlangabezana ngokufanelekileyo neemfuno zokwenza iipaneli ze-guardrail ezinobunzima ukusuka kwi-2 ukuya kwi-4mm. I-coil yensimbi iqhubela phambili ngokulandelelana kwezikhululo ze-12 zokwenza ukuphumeza imilo echanekileyo echazwe kwimidwebo.

Umatshini wokusika we-hydraulic

Ekubeni ukusika kwenzeka emva kokuqulunqa, ukufa kokusika kufuneka kuhambelane nemilo ye-W-beam ukunciphisa i-burrs kunye ne-edge deformation. Eyenzelwe umsebenzi wokumisa kunye nokusika umatshini wokusika, inkqubo yokubumba iyayeka ngokufutshane ngexesha lokusika.

Isisombululo esisikwe ngaphambili VS Isisombululo se-Post-cut

Isantya seMveliso:Ngokuqhelekileyo, imiqadi ye-guardrail i-4 yeemitha ubude. Ukusika kwangaphambili kusebenza ngesantya seemitha ezili-12 ngomzuzu, okukhokelela kwisantya sokuvelisa i-180 beam ngeyure. I-Post-cutting ibaleka kwiimitha ezi-6 ngomzuzu, ivelisa iiplanga ezingama-90 ngeyure.

Ukusika Inkcitho:Ngexesha lokusika, indlela yokusika kwangaphambili ivelisa inkunkuma ye-zero okanye ilahleko. Ngokwahlukileyo, indlela yokusika i-post-cut ivelisa inkunkuma ye-18-20mm ngokusikwa, njengoko kuchaziwe kuyilo.

Ubude boyilo lomgca:Kwindlela yokunqunyulwa kwangaphambili, iqonga lokudluliselwa liyimfuneko emva kokusika, okunokubangela ukuba kubekho umgca wendlela yokuvelisa ixesha elide xa kuthelekiswa nendlela yokusika.

Impembelelo kubomi boluhlu:Indlela yokusika i-post-cut inika ubomi obungcono be-roller xa icutshungulwa i-gauge enzima kunye nentsimbi ephezulu, njengoko i-edge ephambili kwindlela yokunqunyulwa kwangaphambili ichaphazela ii-roller zokwenza kunye nenxalenye nganye.

Ubuncinane Ubude:

Kwindlela yokunqunyulwa kwangaphambili, kukho imfuneko yobude obuncinci bokusika ukuze kuqinisekiswe ukuba ubuncinane iiseti ezintathu zokubumba i-roller zidibene ne-coil yensimbi. Oku kuqinisekisa ukukhuhlana okwaneleyo ukuqhuba ikhoyili phambili. Nangona kunjalo, kwindlela yokusika i-post-cut, akukho mqobo kubude obuncinci bokusika ukususela ekubeni umatshini wokwenza umqulu uhlala uzaliswe nge-coil yensimbi. Ngenxa yokuba ubude be-W-beam buqhelekile malunga neemitha ezi-4, ukudlula imfuneko yobude obuncinci, akukho nkxalabo malunga nokukhetha phakathi kweendlela zokusikwa kwangaphambili kunye ne-post-cut cut kulo mshini wokwenza umqulu.

Ingcebiso enobubele:

Sincoma ukuba abathengi bethu bakhethe umgca wemveliso ofanelekileyo ngokusekelwe kwiimfuno zabo zobuninzi bemveliso. Kubaboneleli beeprofayili ze-guardrail beam, indlela yokusika kwangaphambili iyacetyiswa. Nangona indlela yokunqunyulwa kwangaphambili ineendleko eziphezulu kancinci xa kuthelekiswa nendlela yokunqunyulwa kweposi, iinzuzo zayo kwimveliso inokuphelisa ngokukhawuleza le ntswelo yexabiso.

Ukuba uthengela iprojekthi yokwakhiwa kwezithuthi, indlela yokusika i-post-cut ifanelekile ngakumbi. Ifuna indawo encinci kwaye iza ngexabiso eliphantsi kancinci.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile