Inkangeleko yesimo

Umzila kaloliwe we-DIN ngumzila wentsimbi oqhelekileyo osetyenziswa rhoqo kubunjineli bombane. Uyilo lwayo luququzelela ukufakwa lula kunye nokususwa kwamalungu, abonisa uthotho lweendawo zokubeka okanye imingxuma yokuncamathisela kusetyenziswa izikrufu okanye izixhobo ze-snap-on. Imilinganiselo eqhelekileyo yeereyili ze-DIN yi-35mm x 7.5mm kunye ne-35mm x 15mm, kunye nobukhulu obuqhelekileyo be-1mm.

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

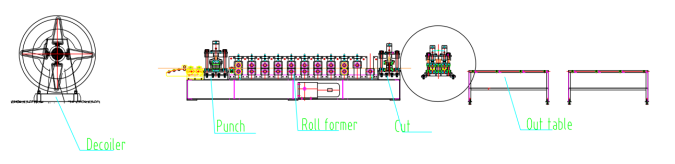

Itshathi equkuqelayo: I-Decoiler--Isikhokelo--Hydraulic punch--Roll forming machine--Umatshini wokusika weHydraulic

Isantya se-1.Umgca: 6-8m / min, ukulungiswa

2.Izinto ezifanelekileyo:Intsimbi eshushu eqengqelekayo, intsimbi eqengqelekayo ebandayo

3.Ubukhulu bezinto eziphathekayo: Ubukhulu obuqhelekileyo yi-1mm, kwaye umgca wokuvelisa unokwenziwa ngokwezifiso ngaphakathi koluhlu lwe-0.8-1.5mm.

I-4.Umatshini wokwenza i-Roll: Isakhiwo sephaneli yodonga

I-5.Inkqubo yokuqhuba: inkqubo yokuqhuba ikhonkco

I-6.Inkqubo yokusika: Yeka ukusika, ukuqengqeleka kwangaphambili ukumisa xa usika.

Ikhabhinethi ye-7.PLC: inkqubo ye-Siemens.

Oomatshini

1.I-Decoiler*1

2.Umatshini wokwenza umqulu*1

3.Ngaphandle kwetafile*2

4.PLC iKhabhinethi yolawulo*1

5.Isikhululo samanzi*1

6.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

Ubungakanani bomgqomo: 1x20GP

Imeko yokwenyani-Inkcazo

I-Decoiler

I-decoiler yinxalenye yokuqala yomgca wemveliso. Ukunikezelwa kobukhulu obuncinci kunye nobukhulu beereyile ze-DIN, ii-decoilers ezenziwe ngesandla zanele ukuhlangabezana neemfuno zemveliso. Nangona kunjalo, kwizantya eziphezulu zemveliso, sikwabonelela ngezisombululo ngee-decoilers zombane kunye ne-hydraulic.

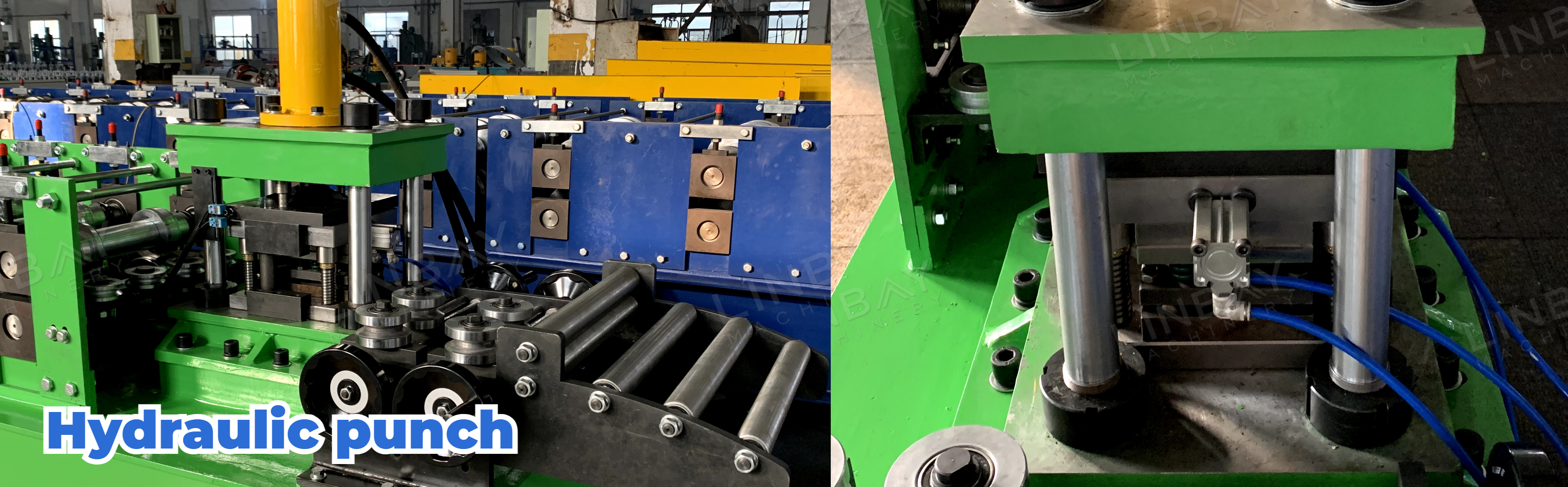

I-hydraulic punch

Kulo cwangciso, i-punch ye-hydraulic idibaniswe nomatshini wokwenza oyintloko, ukwabelana ngesiseko esifanayo. Ngexesha lokubetha, i-coil yensimbi iyeka okwethutyana ukungena kumatshini wokwenza. Kwizicelo ezifuna isantya esiphezulu semveliso, ii-standalone hydraulic punch machines ziyafumaneka.

Ukukhokela

I-roller ekhokelayo iqinisekisa ukulungelelaniswa phakathi kwekhoyili yensimbi kunye nomatshini, ukuthintela ukuphazamiseka ngexesha lokuqulunqa.

Umatshini wokwenza umqulu

Lo matshini wokwenza umqulu usebenzisa isakhiwo sepaneli yodonga kunye nenkqubo yokuqhuba ikhonkco. Uyilo lwemiqolo emibini luvumela ukuveliswa kweesayizi ezimbini ze-DIN kaloliwe. Nangona kunjalo, kufuneka kuqatshelwe ukuba yomibini imiqolo ayikwazi ukusebenza ngaxeshanye. Kwiimfuno eziphezulu zemveliso, sincoma ukuseta umgca wemveliso owahlukileyo kwisayizi nganye.

Kufuneka kugxininiswe ukuba ubude bokusika ukuchaneka komatshini wokwenza umqulu kunye nesakhiwo se-double-row ngaphakathi kwe-± 0.5mm. Ukuba imfuno yakho echanekileyo ingaphantsi kwe-± 0.5mm, akukhuthazwa ukuba usebenzise ulwakhiwo lwemiqolo emibini. Kunoko, isisombululo sokuba nomgca wokuvelisa ozimeleyo kwisayizi nganye sifanelekile ngakumbi.

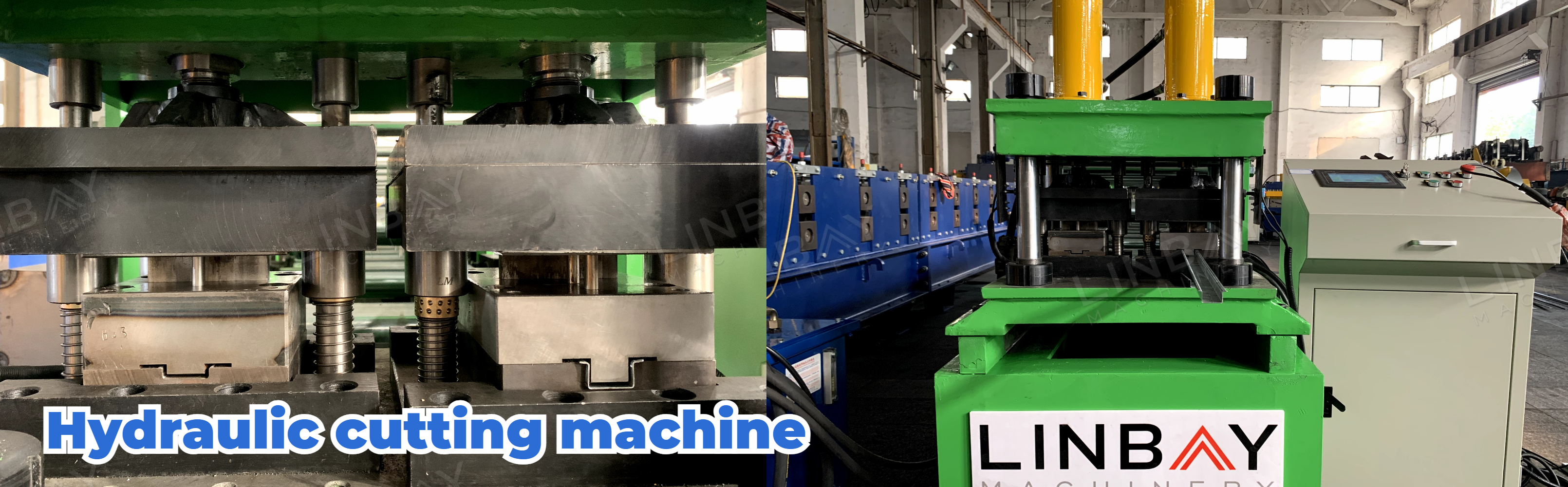

Umatshini wokusika we-hydraulic

Isiseko somatshini wokusika sihlala simile ngexesha lokusebenza, okwenza ukuba i-coil yensimbi imise ukuqhubela phambili kwayo ngexesha lokusika.

Ukufezekisa isantya esiphezulu semveliso, sinikezela ngomatshini wokusika ondizayo. Igama elithi "flying" libonisa ukuba isiseko somatshini wokusika sinokuhamba emva naphambili. Olu luyilo lwenza ukuba i-coil yensimbi iqhubele phambili ngokuqhubekayo ngomatshini wokubumba ngexesha lokusika, ukuphelisa isidingo sokumisa umatshini wokwenza kwaye ngaloo ndlela kuphuculwe isantya somgca wemveliso jikelele.

Imibumbo ye-blade yokusika ekupheleni komqolo ngamnye ilungiselelwe ukufanisa ubume bobungakanani obufanelekileyo be-DIN kaloliwe.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile