Inkangeleko yesimo

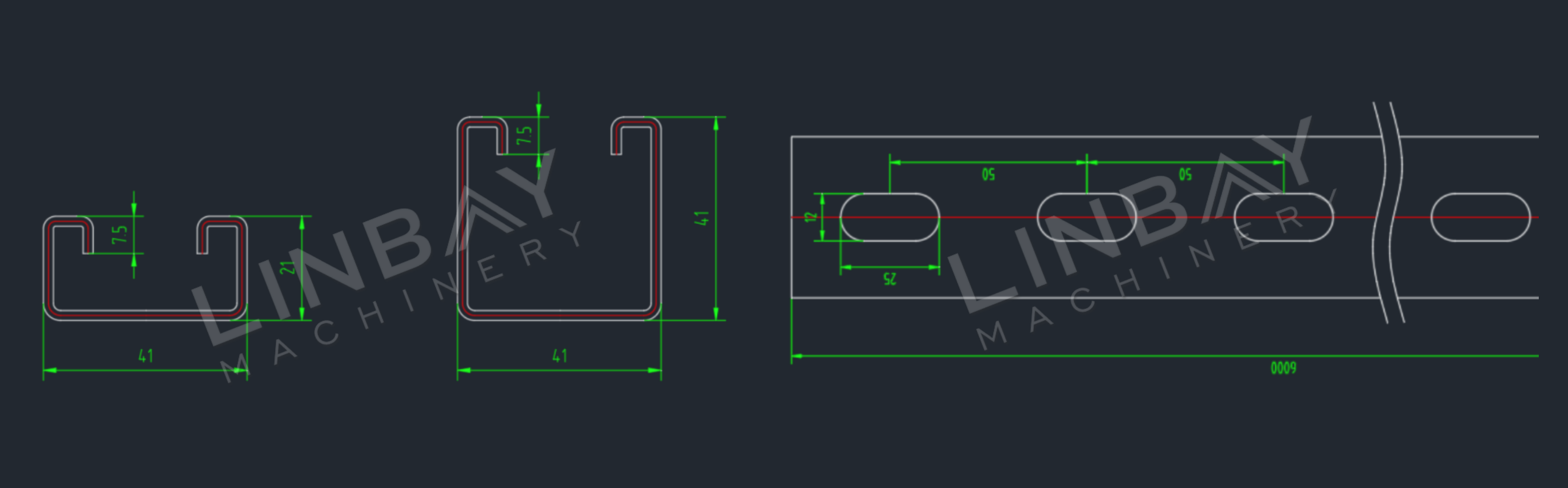

Imijelo ye-Strut yenziwe ngentsimbi enezingqimba ezinobunzima be-1.5-2.0mm okanye 2.0-2.5mm, okanye intsimbi engenasici enobunzima be-1.5-2.0mm. Ziyilwe ngemingxunya ehlala izithuba okanye iindawo zokubeka ecaleni ubude bazo, ziququzelela ukuncamatheliswa lula kweebholiti, iinati, okanye ezinye izinto zokubopha.

Umgca wemveliso kunye nokulungelelaniswa kwesayizi ngokuzenzekelayo ulungele ukuvelisa ubukhulu obuninzi, njengemilinganiselo eqhelekileyo efana ne-41 * 41, 41 * 21, 41 * 52, 41 * 62, 41 * 72, kunye ne-41 * 82mm. Ukuphakama kwesiteshi se-strut, izikhululo zokwenza ngakumbi ziyafuneka, eziye zandisa ixabiso lomatshini wokwenza umqulu.

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

Itshathi equkuqelayo

I-hydraulic decoiler ene-level--Servo feeder--Punch press--Isikhokelo--Roll forming machine--Flying hydraulic cut--Out table

IiParameters ezingundoqo zobuGcisa

Isantya se-1.Umgca: 15m / min, ukulungiswa

2.Ubungakanani: 41 * 41mm kunye ne-41 * 21mm.

3.Ubukhulu bezinto: 1.5-2.5mm

I-4.Izinto ezifanelekileyo: intsimbi yentsimbi

I-5.Umatshini wokwenza i-Roll: Isakhiwo se-Cast-iron kunye ne-gearbox drive system.

I-6.Ukusika kunye nenkqubo yokugoba: I-Flying hydraulic cut. Umqulu wangaphambili awuyeki xa usika.

7.Ukutshintsha ubungakanani: ngokuzenzekelayo.

Ikhabhinethi ye-8.PLC: inkqubo ye-Siemens.

Imeko yokwenyani-Inkcazo

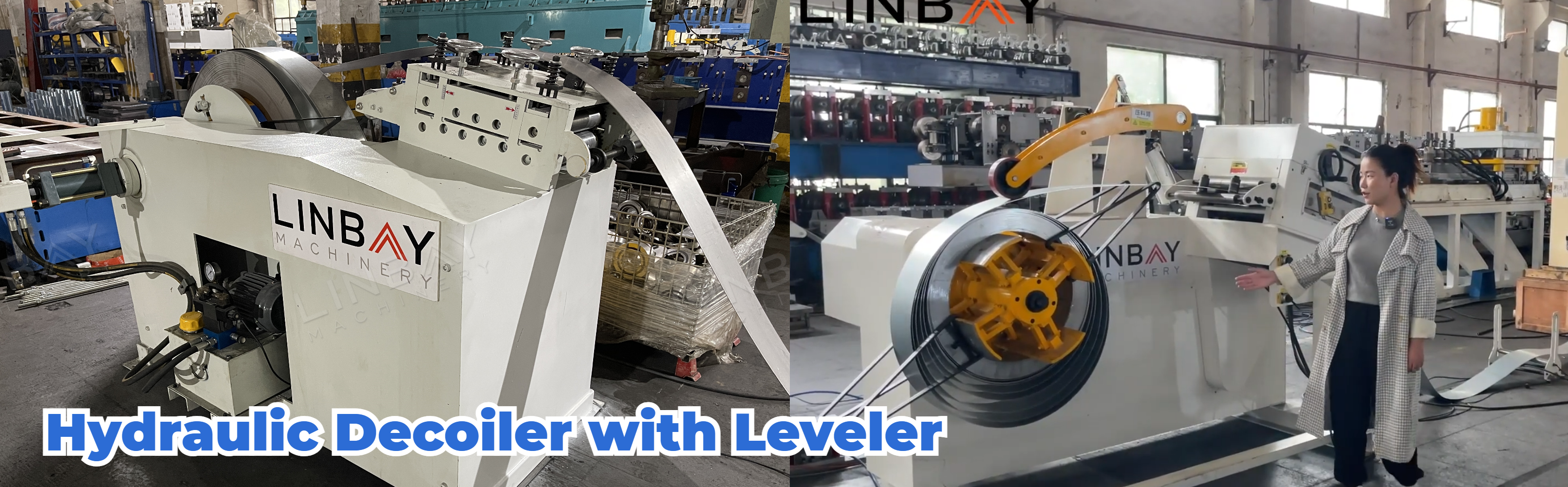

I-Hydraulic decoiler ene-level

Olu hlobo lwe-decoiler, ekwaziwa ngokuba yi "2-in-1 decoiler kunye neleveli," ibonakalisa uyilo olubambeneyo olunokugcina ukuya kuthi ga kwi-3 yeemitha zendawo yomgca wemveliso, ngaloo ndlela kuncitshiswe iindleko zomhlaba wefektri kubathengi bethu. Ukongeza, umgama omfutshane phakathi kwe-decoiler kunye neleveli yehlisa ubunzima bokuseta, yenza ukondla ikhoyili kunye nokusebenza kube lula ngakumbi.

I-Servo Feeder kunye ne-Punch Press

I-servo motor isebenza phantse akukho kulibaziseka kwexesha lokuqala, ivumela ulawulo oluchanekileyo lobude bokutya kwekhoyili ukuze kubethelwe ngokuchanekileyo. Ngaphakathi, ukondla nge-pneumatic ngaphakathi kwe-feeder ikhusela ngokufanelekileyo umphezulu wekhoyili kwi-abrasion.

Ngokuqhelekileyo, isithuba somngxuma wetshaneli ye-strut yi-50mm, kunye ne-punching pitch ye-300mm. Xa kuthelekiswa noomatshini be-punch be-hydraulic abanamandla alinganayo okubhobhoza, i-punch press ifezekisa isantya sokubethelwa ngokukhawuleza malunga namaxesha angama-70 ngomzuzu.

Ngelixa iindleko zokuqala zotyalo-mali kwii-punch presses zinokuba phezulu kune-hydraulic punches, zibonelela ngeendleko ezingcono zexesha elide, ngakumbi kwimveliso ephezulu. Ukongezelela, iindleko zokugcinwa kwe-punch presses zinokuba ngaphantsi ngenxa yezinto ezilula zoomatshini.

Sikhethe i-Yangli brand punch press evela e-China njengokhetho lwethu oluphambili kunye nexesha elide kuba iYangli ineeofisi ezininzi kwihlabathi jikelele, inikezela ngenkxaso emva kokuthengisa kunye nenkonzo kubathengi bethu.

Ukukhokela

Ii-roller ezikhokelayo ziqinisekisa ukuba i-coil kunye nomatshini zilungelelaniswa kunye ne-centerline efanayo, eqinisekisa ukuba i-coil ihlala ingabonakali kuyo yonke inkqubo yokwenza.

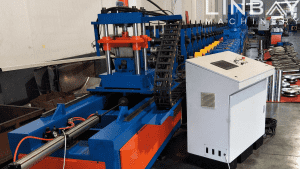

Umatshini wokwenza umqulu

Lo matshini wokubumba usebenzisa i-cast-iron kunye ne-gearbox yokuqhuba inkqubo. I-coil yensimbi idlula kwizikhululo ze-28 ezenza izikhululo, i-deformation deformation de ihambelane neenkcukacha kwimizobo.

Nje ukuba abasebenzi babeke imilinganiselo kwiphaneli yokulawula ye-PLC, izikhululo ezenza umatshini wokwenza umqulu ziya kulungelelanisa ngokuzenzekelayo kwiindawo ezichanekileyo, kunye neendawo zokubumba ezihamba nge-tandem kunye ne-roller.

Ukukhuseleka ngexesha lokuhamba kwezikhululo zokwenza izitishi, iisensi ezimbini zomgama zibekwe kumacala omabini asekhohlo nasekunene. Ezi zinzwa zihambelana neendawo ezingaphandle kunye nezingaphakathi apho izikhululo ezenzayo zinokuhlengahlengiswa. Babona isiseko sezikhululo zokwenza izikhululo: i-sensor yangaphakathi ikhusela izikhululo zokwenza ukuba zisondele kakhulu kwaye zibangele ukungqubana kwe-roller, ngelixa i-sensor yangaphandle ikhusela izikhululo zokwenza izitishi ukuba zingabikho kwimizila kunye nokuwa.

Umphezulu we-roller obumba i-chrome-plated ukuyikhusela kunye nokwandisa ixesha lokuphila kwee-roller.

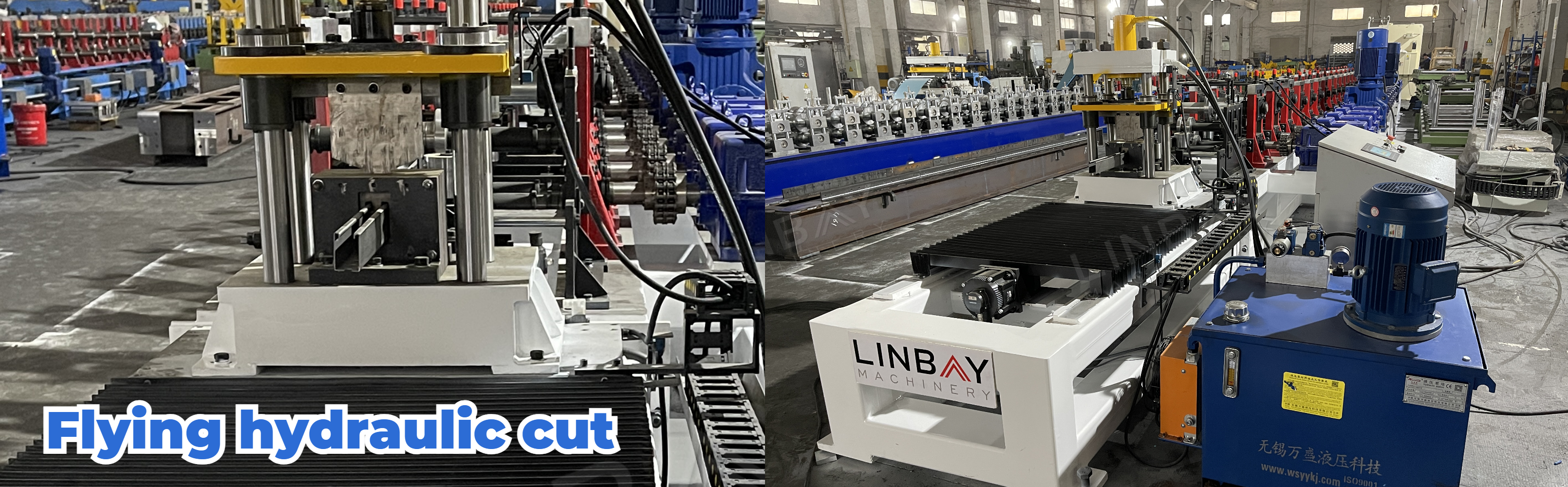

Ukunqunyulwa kwe-hydraulic cut

Isiseko somatshini wokusika sinokuhamba ngasemva nangaphezulu kumzila, okwenza ukuba i-coil yensimbi iqhube phambili ngokuqhubekayo ngomatshini wokwenza umqulu. Olu cwangciso luphelisa isidingo sokumisa umatshini wokwenza umqulu, ngaloo ndlela ukwandisa isantya esipheleleyo somgca wemveliso.I-molds ye-blade yokusika ilungiselelwe ukuhambelana nesimo seprofayili ethile. Ngoko ke, ubukhulu ngamnye bufuna isethi yayo yokubumba i-blade.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile