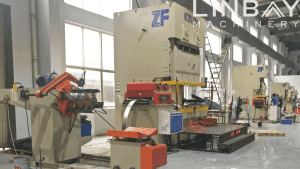

Inkangeleko yesimo

I-W-beam guardrail luphawu olubalulekileyo lokhuseleko kwiiprojekthi zeziseko zothutho ezifana nohola wendlela, iindlela zokuhamba, kunye neebhulorho. Igama layo livela kwimilo yayo eyahlukileyo "W", enencochoyi ezimbini. Ngokuqhelekileyo yenziwe ngentsimbi egobileyo okanye eshushu, i-W-beam guardrail inobubanzi obusuka kwi-2 ukuya kwi-4mm.

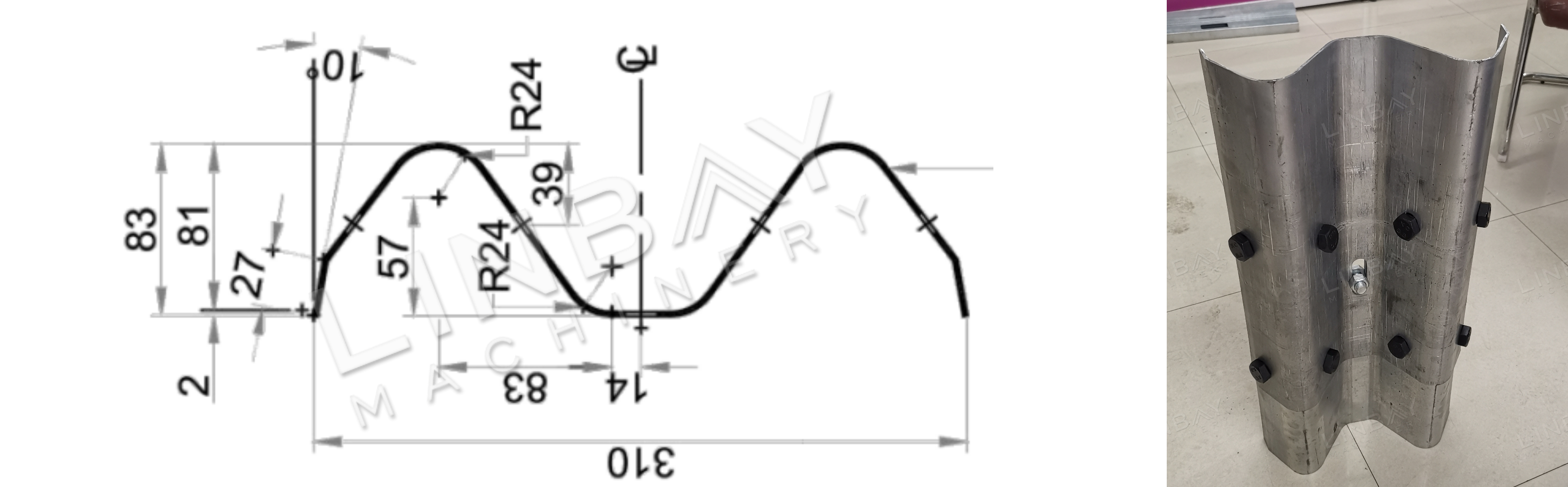

Icandelo eliqhelekileyo le-W-beam lifikelela kwiimitha ezi-4 ubude kwaye libonisa imingxuma efakwe ngaphambili kwiiphelo zombini ukuze kube lula ukufakwa. Ukubonelela ngeemfuno ezahlukeneyo zabathengi ngesantya sokuvelisa kunye nendawo yomgangatho, sibonelela ngezisombululo ezinokwenziwa ngokwezifiso zokugqobhoza umngxuma ezidityaniswa ngaphandle komthungo kumgca wokuqala wokuvelisa umatshini.

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

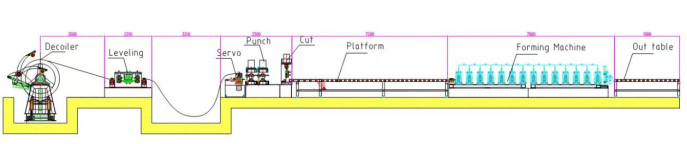

Itshathi equkuqelayo: I-Hydraulic decoiler--Leveler--Servo feeder--Hydraulic punch--Precut-Platform--Guiding--Roll former--out table

1.Isantya somgca: 0-12m / min, ukulungiswa

2.Izinto ezifanelekileyo:Intsimbi eshushu eqengqelekayo, intsimbi eqengqelekayo ebandayo

3.Ubukhulu bezinto: 2-4mm

I-4.Umatshini wokwenza i-Roll: Isakhiwo se-Cast-iron kunye ne-universal joint

I-5.Inkqubo yokuqhuba: Inkqubo yokuqhuba i-Gearbox ene-universal joint cardan shaft.

I-6.Inkqubo yokusika: Sika ngaphambi kokwenza umqulu, umqulu wangaphambili awuyeki xa usika.

Ikhabhinethi ye-7.PLC: inkqubo ye-Siemens.

Oomatshini

1.I-Decoiler*1

2.Inqanaba*1

3.I-Servo feeder*1

4.Umatshini we-Hydraulic punch*1

5.Umatshini wokusika i-Hydraulic * 1

6.Iqonga*1

7.Umatshini wokwenza umqulu*1

8.Ngaphandle kwetafile*2

9.PLC iKhabhinethi yolawulo*2

10.Isikhululo samanzi*2

11.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

Ubungakanani bomgqomo: 2x40GP

Imeko yokwenyani-Inkcazo

I-Hydraulic decoiler

I-hydraulic decoiler inezixhobo ezimbini ezibalulekileyo zokhuseleko: ingalo yokushicilela kunye ne-coil retainer yangaphandle. Xa utshintsha iikhoyili, ingalo yokushicilela ibambe ngokukhuselekileyo ikhoyili endaweni, ithintele ukuba ingavulwa ngenxa yoxinzelelo lwangaphakathi. Ngexesha elifanayo, i-coil retainer yangaphandle iqinisekisa ukuba i-coil ihlala izinzile ngexesha lenkqubo yokukhupha.

Isixhobo sokwandiswa kwesiseko se-decoiler sinokulungelelaniswa, sinakho ukwenza ikhontrakthi okanye ukwandiswa ukuze kuhlaliswe i-coil diameters yangaphakathi ukusuka kwi-460mm ukuya kwi-520mm.

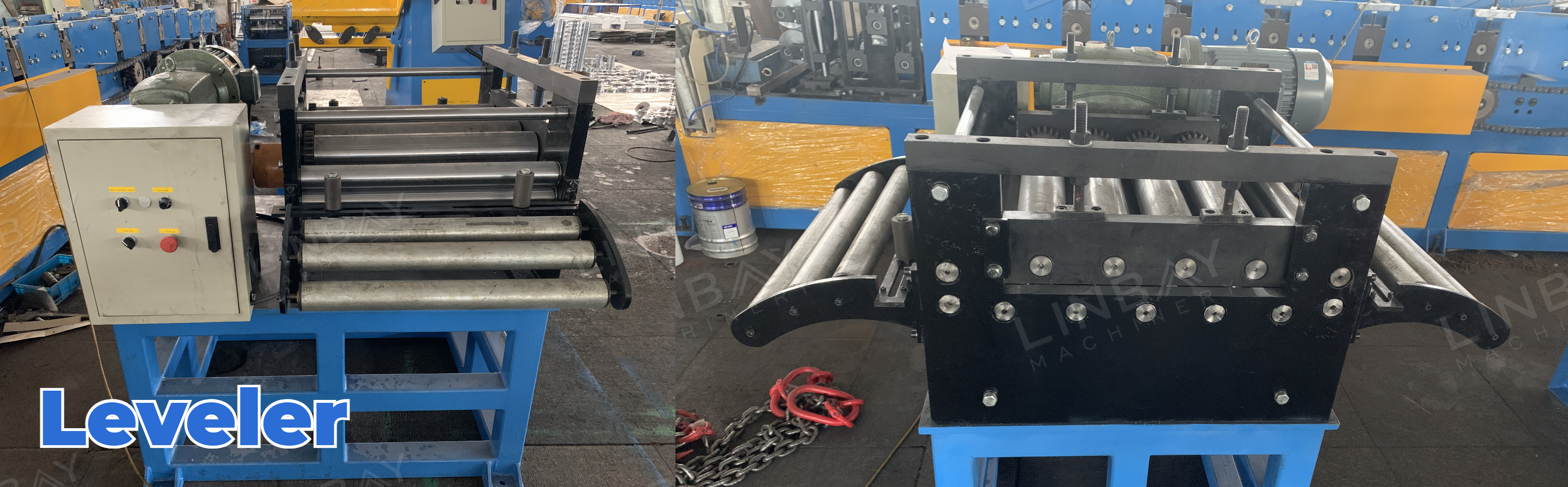

Umgangatho

I-level ibalulekile ekufakeni i-coil kunye nokugcina ubukhulu obuhambelanayo. Ukusebenzisa inqanaba elahlukileyo kuqinisekisa ukusebenza kakuhle.

Sikwanikezela nge-decoiler edibeneyo kunye ne-level (2-in-1 decoiler) ukugcina indawo kunye neendleko. Esi sisombululo sidityanisiweyo senza lula ulungelelwaniso, ukondla, ukufakela, kunye nokulungiswa kweempazamo.

I-Servo Feeder

Ixhotyiswe nge-servo motor, i-feeder isebenza ngaphandle kokulibaziseka kokuqalisa, ivumela ulawulo oluchanekileyo lwe-coil feed ubude ukwenzela ukubethelwa ngokuchanekileyo. Ngaphakathi, ukondla nge-pneumatic kukhusela umphezulu wekhoyili kwi-abrasion.

I-Hydraulic Punch & Pre-cut Hydraulic Cutting Machine

Ukuphucula ukusebenza kakuhle kunye nokusebenza kakuhle kweendleko, inkqubo yokubhoboza iphathwa zizikhululo ezibini ze-hydraulic (ezimbini zokubumba).

Isikhululo sokuqala esikhulu sinokugqobhoza imingxunya eyi-16 ngexesha. Imingxuma egqobhoziweyo kwisikhululo sesibini ibonakala kube kanye kuphela kumqadi ngamnye, nto leyo eyenza ukuba isitishi esincinci sibe sisisombululo esisebenzayo.

Ukusika kwangaphambili ngaphambi kokwenza umqulu kuqinisekisa ukusebenza okungaphazamisekiyo komatshini wokwenza umqulu, ngaloo ndlela ukwandisa isantya sokuvelisa. Ukongezelela, esi sisombululo sinciphisa ukuchithwa kweekhoyili zensimbi.

Ukukhokela

Ii-roller ezikhokelayo ezibekwe phambi kokuba umatshini wokwenza umqulu uqinisekisa ukulungelelaniswa phakathi kwe-coil yensimbi kunye nomatshini, ukuthintela ukuphazamiseka kwekhoyili ngexesha lenkqubo yokwenza.

Umatshini wokubumba umqulu

Lo matshini wokwenza umqulu ubonisa isakhiwo sentsimbi, kunye neeshafti zendalo yonke ezidibanisa ii-roller kunye neebhokisi zegiya. I-coil yensimbi idlula kwizikhululo ze-12 ezenza izikhululo, i-deformation deformation de ihambelane ne-W-beam shape echazwe kwimizobo yomthengi.

Umphezulu we-rollers eyenza i-chrome-plated ukukhusela kunye nokwandisa ubomi babo.

Ukuzikhethela: Isitaki esizenzekelayo

Ekupheleni komgca wemveliso, ukusebenzisa i-auto stacker kunokunciphisa iindleko zomsebenzi wezandla malunga nabasebenzi ababini. Ukongezelela, ngenxa yobunzima be-W-beam ubude beemitha ezi-4, ukuphathwa ngesandla kubangela imingcipheko yokhuseleko.

I-auto stacker lukhetho oluqhelekileyo nolusebenzayo kwimigca yokuvelisa yokwenza umqulu ukuze kuphuculwe ukusebenza kakuhle nokhuseleko, ngamaxabiso asekelwe kubude. Iiprofayili ezahlukeneyo zifuna iindlela ezahlukeneyo zokupakisha. Kulo mgca wemveliso, i-auto stacker ebude beemitha ezi-4 ixhotyiswe ngeekomityi ezintathu zokufunxa ezilungiselelwe iiprofayili ezimile okwe-W. Ezi komityi zokufunxa zibamba ngokukhuselekileyo umqadi we-W kwaye ziwubeke ngokucokisekileyo kwi-conveyor ukuze zipakishwe ngocwangco, ziququzelele uthutho.

Isisombululo esisikwe ngaphambili VS Isisombululo se-Post-cut

Isantya seMveliso:Ngokuqhelekileyo, imiqadi ye-guardrail i-4 yeemitha ubude. Ukusika kwangaphambili kusebenza ngesantya seemitha ezili-12 ngomzuzu, okwenza ukuveliswa kweentsimbi ze-180 ngeyure. I-Post-cutting, ehamba ngeemitha ezi-6 ngomzuzu, ivelisa i-90 beams ngeyure.

Ukusika Inkcitho:Ngexesha lokusika, isisombululo esinqunyelwe ngaphambili sivelisa inkunkuma ye-zero okanye ilahleko. Ngokwahlukileyo, isisombululo se-post-cut cut sivelisa inkunkuma ye-18-20mm ngokusikwa, ngokweenkcukacha zoyilo.

Ubude boyilo lomgca:Kwisisombululo esisikiweyo ngaphambili, iqonga lokudlulisa liyimfuneko emva kokusika, elinokuthi likhokelela kumgca wokuvelisa ixesha elide xa kuthelekiswa nesisombululo se-post-cut.

Ubuncinane Ubude:Kwisisombululo esinqunywe ngaphambili, kukho imfuneko yobude obuncinci bokusika ukuze kuqinisekiswe ukuba i-coil yensimbi idibanisa ubuncinane iiseti ezintathu zokubumba ii-roller, inikezela ukungqubuzana okwaneleyo ukuyiqhubela phambili. Ngokwahlukileyo, isisombululo se-post-cut cut asinayo umlinganiselo omncinci wokusika ubude ukususela ekubeni umatshini wokwenza umqulu uqhubeka usondliwe nge-coil yensimbi.

Nangona kunjalo, ngenxa yokuba ii-W beams zilinganisa ngokuqhelekileyo malunga neemitha ezi-4 ubude, ezidlula imfuneko yobude obuncinci, ukhetho phakathi kwezisombululo zokusika kwangaphambili kunye ne-post-cut cut luba lubaluleke kakhulu kulo mshini wokwenza umqulu owenzelwe imiqadi ye-W.

Ingcebiso enobubele:Sincoma ukuba abathengi bakhethe umgca wemveliso ngokusekelwe kwiimfuno zabo zobuninzi bemveliso. Kubaboneleli beeprofayili ze-guardrail beam, isisombululo esisikiwe kwangaphambili siyacetyiswa. Nangona ixabiso layo liphezulu kancinci xa lithelekiswa nesisombululo sasemva kokusikwa, amandla ayo okuphuma aphuculweyo anokuphelisa ngokukhawuleza nawuphi na umahluko weendleko.

Ukuba uthengela iprojekthi yokwakhiwa kwezithuthi, isisombululo se-post-cut cut sifanelekile ngakumbi. Ithatha indawo encinci kwaye ifumaneka ngexabiso eliphantsi kancinci.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile

1-300x168.jpg)