ividiyo

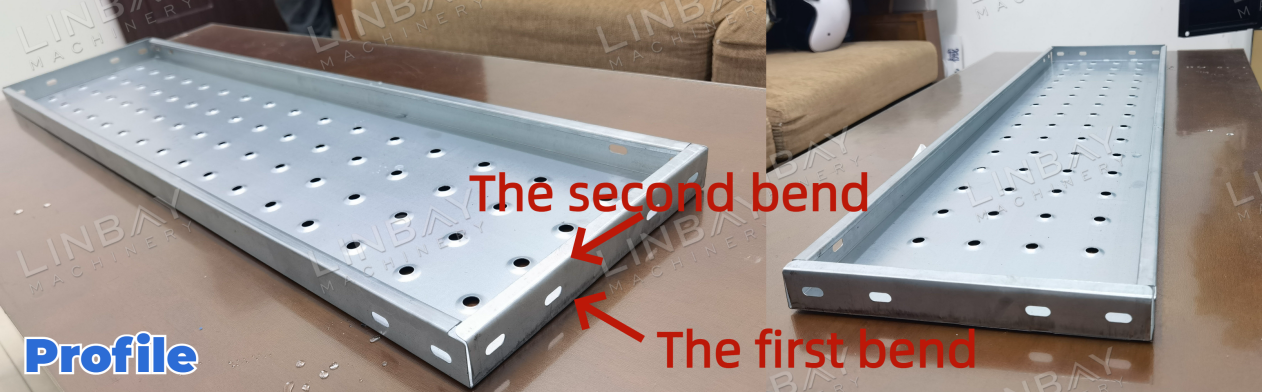

Inkangeleko yesimo

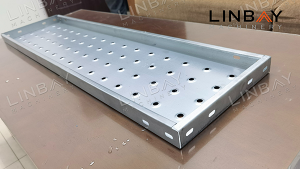

Iphaneli yeshelufu, emi kwimiqadi yesixokelelwano sokurhangqa, isebenza njengeqonga elomeleleyo lokugcina iimpahla ngokukhuselekileyo. Ubuchwephesha bethu bokuvelisa bugxile ekuveliseni iipaneli zeshelufu ezigobileyo eziphindwe kabini, ezibonelela ngokuqina okuphezulu xa kuthelekiswa nohlobo lokugoba olunye. Ngaphezu koko, olu luyilo luphelisa imiphetho ebukhali eveziweyo, ibeka phambili ukhuseleko lomsebenzisi.

Ityala lokwenyani-Iiparamitha zoBuchule eziPhambili

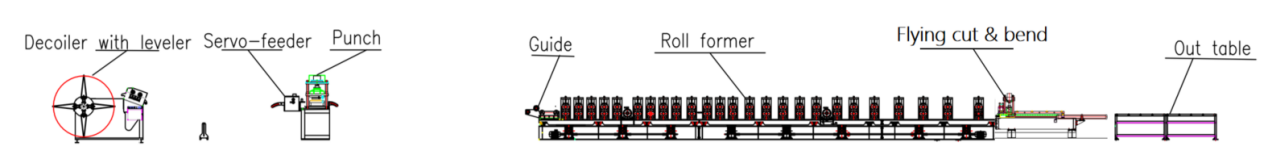

Itshathi equkuqelayo

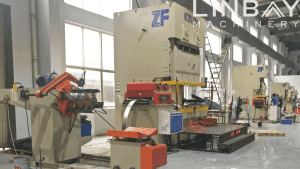

I-Hydraulic decoiler ene-level--Servo feeder--Hydraulic punch--Roll forming machine--Hydraulic cut and stamping-- Out table

IiParameters ezingundoqo zobuGcisa:

1. Isantya somgca: Ukulungelelaniswa ukusuka kwi-0 ukuya kwi-4 m / min

2. Iiprofayili: Iisayizi ezahlukeneyo ezinobude obuhambelanayo, ezahlukeneyo ngobubanzi kunye nobude

3. Ubukhulu beMaterial: 0.6-0.8mm (kolu setyenziso)

4. Izinto ezifanelekileyo: Intsimbi yentsimbi

5. Umatshini wokwenza umqulu: Usebenzisa i-cantilevered double-wall panel structure kunye ne-chain drive system.

6. Inani lezikhululo ezenzayo: 13

7. Inkqubo yokusika: Ukusika kunye nokugoba ngaxeshanye; Uluhlu lwangaphambili luhlala lusebenza ngexesha lenkqubo

8. Uhlengahlengiso lobungakanani: ngokuzenzekelayo

9. Ikhabhinethi ye-PLC: Ixhotyiswe ngenkqubo ye-Siemens

Imeko yokwenyani-Inkcazo

I-Hydraulic Decoiler ene-Level

Ukwandiswa okungundoqo kunokulungiswa ukuze kulingane i-coil yentsimbi yeedayamitha zangaphakathi ukusuka kwi-460mm ukuya kwi-520mm. Ngexesha lokuqhawula, izigcini zekhoyili zangaphandle ziqinisekisa ukuba i-coil yensimbi ihlala ikhuselekile kwi-decoiler, iphucula ukhuseleko lwabasebenzi ngokuthintela i-coil ukuba ihambe.

I-level ixhotyiswe ngoluhlu lwee-roller eziqhubela phambili ngokucolisa i-coil yensimbi, ngokufanelekileyo ukususa iingcinezelo eziseleyo.

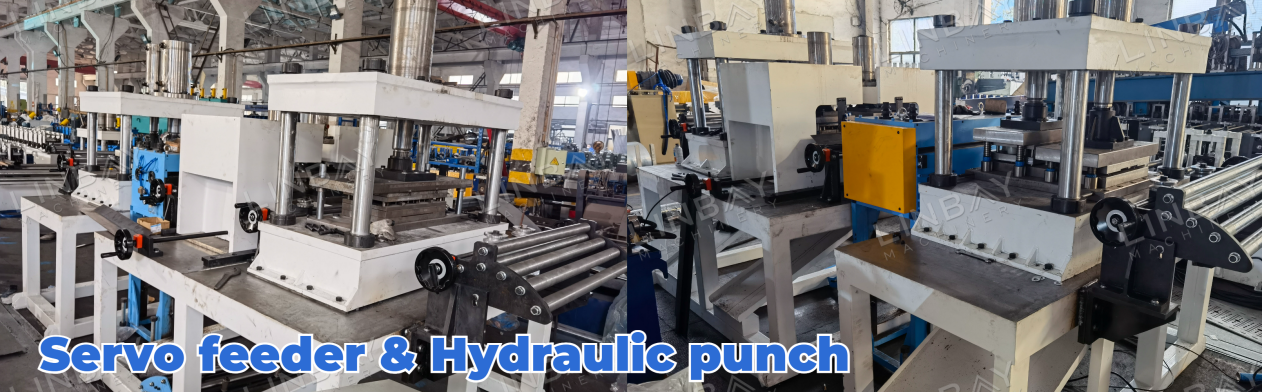

I-Servo Feeder kunye ne-Hydraulic Punch

(1)I-Independent Hydraulic Punching

Le nkqubo ye-punching isebenza ngokuzimeleyo, ingabelananga ngesiseko somatshini ofanayo kunye nomatshini wokwenza umqulu, ukuqinisekisa ukusebenza okungenamthungo kunye nokungaphazanyiswa kwenkqubo yokwenza umqulu. I-feeder inikwe amandla yi-servo motor, enokulibaziseka kwexesha lokuqala lokumisa. Oku kuvumela ulawulo oluchanekileyo kwinkqubela phambili yentsimbi kwi-coil feeder, ukuqinisekisa ukubethelwa okuchanekileyo kunye nokusebenzayo.

(2)Isisombululo sokungunda esilungiselelweyo

Imingxuma ephothiweyo kwiphaneli yeshelufu ihlelwe ngokweenotshi, imingxuma esebenzayo, kunye nemingxuma esezantsi eqhubekayo. Ngenxa yokwahluka kwee-frequencies ezi ntlobo zemingxuma kwipaneli yeshelufu enye, umatshini we-hydraulic punch uxhotyiswe ngeemold ezine ezinikezelweyo, nganye yenzelwe uhlobo oluthile lomngxuma. Olu seto lwenzelwe ukugqibezela ngokufanelekileyo uhlobo ngalunye lokubetha, ngaloo ndlela luphucula ukusebenza kakuhle kunye nemveliso.

I-Encoder & PLC

I-encoder iguqulela ubude bekhoyili yentsimbi kwimiqondiso yombane, ethi emva koko ithunyelwe kwikhabhinethi yolawulo ye-PLC. Ngaphakathi kwikhabhinethi yokulawula, abaqhubi banokulawula isantya sokuvelisa, imveliso yokuvelisa enye, ubude bokusika, kunye nezinye iiparitha. Ngemilinganiselo echanekileyo kunye nempendulo evela kwi-encoder, umatshini wokusika unokugcina iimpazamo zokusika ngaphakathi±1mm.

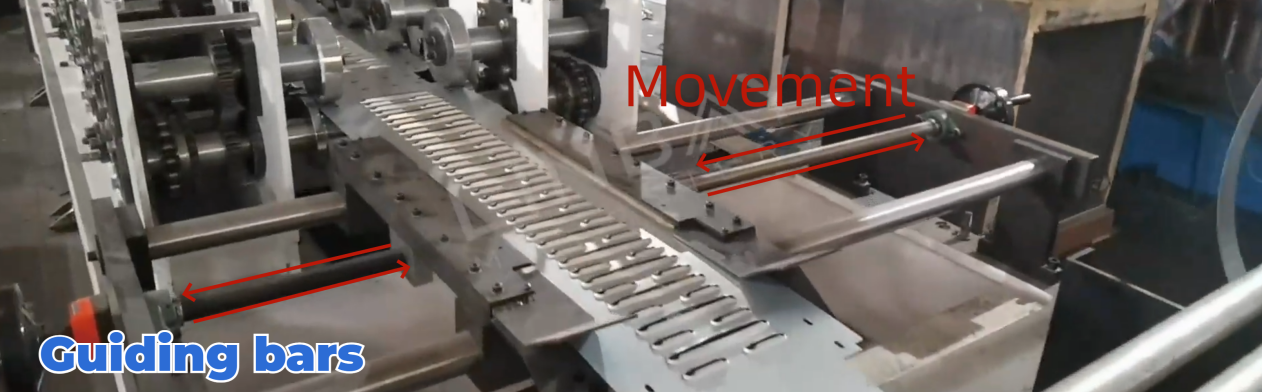

Umatshini wokwenza umqulu

Ngaphambi kokungena kumatshini wokwenza umqulu, ikhoyili yentsimbi idlula kwimivalo ekhokelayo ehlengahlengiswayo. Le mivalo ilungelelaniswe ngokobubanzi bekhoyili yensimbi, iqinisekisa ukuba ihambelana ngokuchanekileyo kunye nomatshini wokuvelisa umgca kunye nomgca ophakathi. Olu lungelelwaniso luyimfuneko ekugcineni ukuthe tye kunye nomthamo wokuthwala umthwalo wephaneli yeshelufu.

Lo matshini wokubumba usebenzisa i-cantilever ephindwe kabini. Ekubeni ukubunjwa kufunwa kuphela kumacala amabini ephaneli, idizayini ye-cantilever roller isetyenziselwa ukulondoloza izinto eziphathekayo. Inkqubo yokuqhuba i-chain ihambisa ii-roller kwaye isebenzise amandla kwi-coil yensimbi, eyenza ukuqhubela phambili kwayo kunye nokwenza.

Umatshini unokuvelisa iipaneli zeshelufu zobubanzi obahlukeneyo. Abasebenzi bafaka imilinganiselo efunekayo kwiphaneli yekhabhinethi yolawulo yePLC. Emva kokuba umqondiso ufunyenwe, isikhululo esenzayo kwicala lasekunene sihamba ngokuzenzekelayo kwiireyile. Amanqaku okwenza kwi-coil yensimbi alungelelanisa kunye nokuhamba kwesikhululo sokwenza kunye nokwenza i-rollers.

I-encoder ifakwe kwakhona ukubona umgama wentshukumo yesikhululo esenzayo, iqinisekisa ukuchaneka xa utshintsha ubungakanani. Ukongeza, abenzi boluvo ababini bendawo babandakanyiwe: enye yokufumanisa owona mgama ukude kwaye enye ingowona mgama ukufutshane isikhululo esenzayo sinokuhamba kwiireyili. I-sensor yendawo ekude kakhulu ikhusela ukunyakaza okugqithisileyo kwesikhululo sokwenza, ukuphepha ukutyibilika, ngelixa i-sensor ye-position esondeleyo ikhusela isikhululo sokwenza ukuba sihambe kakhulu ngaphakathi, ngaloo ndlela sigweme ukungqubana.

Ukusika kunye nokugoba kwe-hydraulic

Iipaneli zeshelufu eziveliswe kulo mgca wemveliso zibandakanya ukugoba kabini kwicala elibanzi. Siyile ukubumba okudityanisiweyo kunye nokugoba, okwenza ukuba zombini ukusika kunye nokugoba kabini kumatshini omnye. Olu yilo alugcini nje kuphela ubude bomgca wemveliso kunye nendawo yomgangatho wefektri kodwa kunciphisa ixesha lokuvelisa.

Ngexesha lokusika kunye nokugoba, isiseko somatshini wokusika sinokubuyela ngasemva kwaye siqhubele phambili ngokuvumelanisa kunye nesantya sokuvelisa umatshini wokuqulunqa. Oku kuqinisekisa imveliso engaphazanyiswa kwaye kwandisa ukusebenza kakuhle.

Esinye isisombululo

Ukuba unomdla kwiipaneli zeshelufu ezigobileyo, cofa ngokulula emfanekisweni ukuze ungene nzulu kwinkqubo yokuvelisa eneenkcukacha kwaye ubukele ividiyo ehamba nayo.

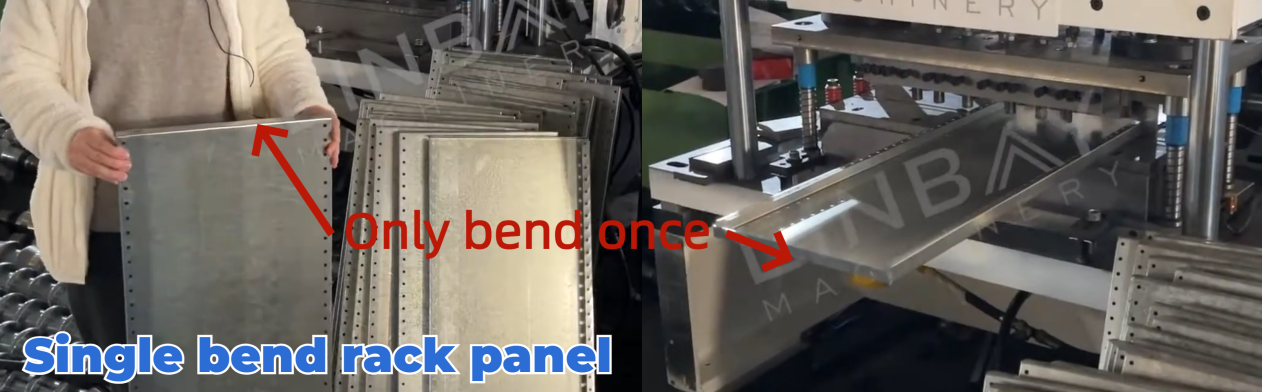

Umahluko ophambili:

Uhlobo lwe-double-bend lunikeza ukuqina okuphezulu, ngelixa uhlobo olulodwa lwe-bend lukwahlangabezana ngokwaneleyo neemfuno zokugcina.

Amaphethelo ohlobo lwe-double-bend ayibukhali, ukwandisa ukhuseleko, kanti uhlobo olulodwa lwe-bend lunokuba nemiphetho ebukhali.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile