INGXELO YOBOMI

Iityhubhu ezingqukuva ze-awning zizinto eziyimfuneko kwi-awnings, edla ngokwakhiwa nge-aluminiyam okanye intsimbi. Iidiameters eziqhelekileyo ziquka i-60/63/70/78/80/85mm, kwaye zixhaphake ngokufumaneka kubude be-4, 5, 6, okanye i-7 yeemitha.

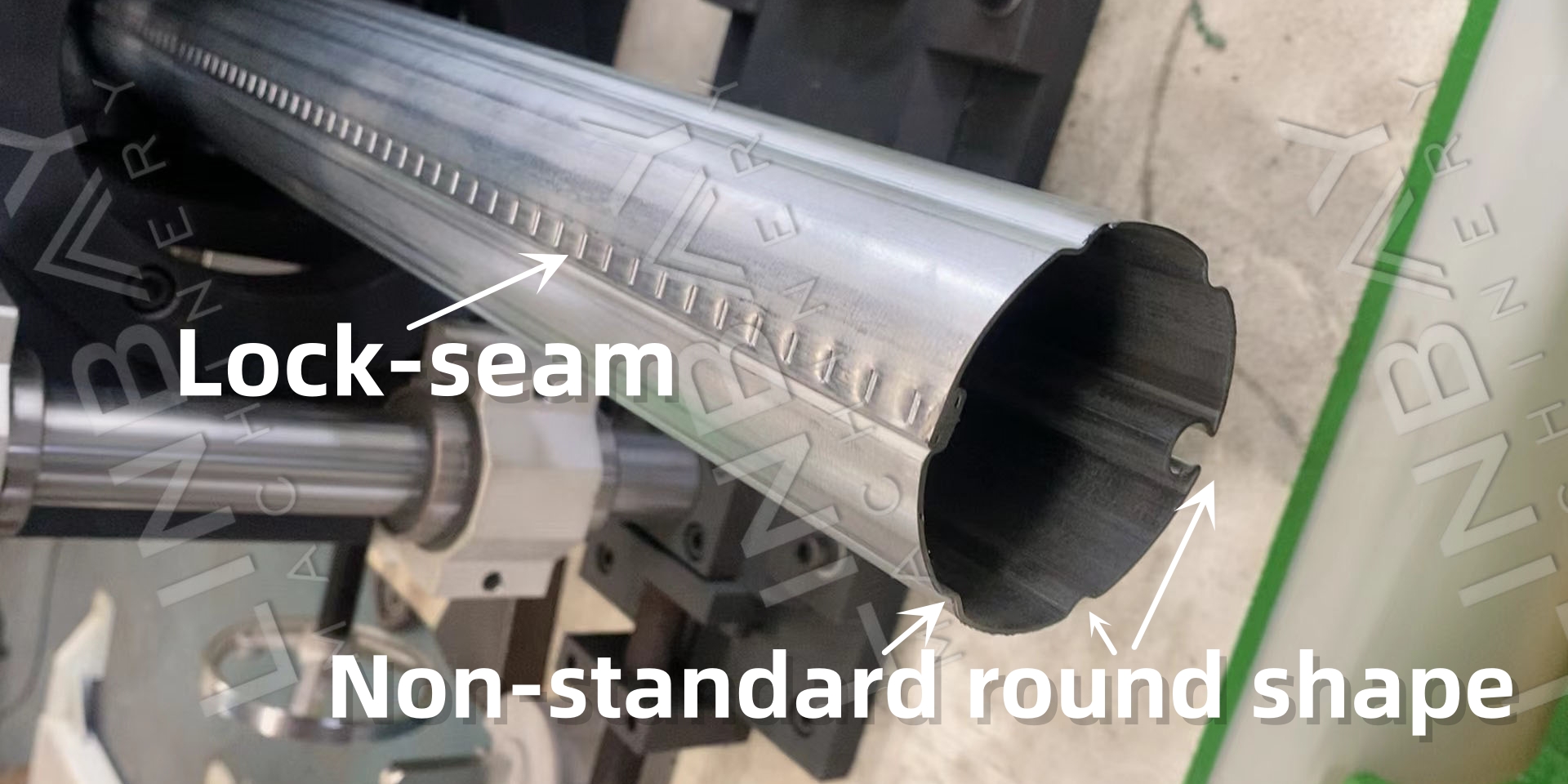

Indlela yokuvelisa eqhelekileyo: Iikhoyili zentsimbi zijijwa kwi-cylindrical mold kwaye zicinezelwe ukwenza ityhubhu engqukuva. Le ndlela ibangela ukusabalalisa kwamandla angalinganiyo, ukusebenza kakuhle okuphantsi, kunye nokulinganiselwa kwimibhobho yomibini ubude kunye nobukhulu obuncinci. Ngapha koko, kunzima ukwenza iityhubhu ezinoyilo olujikelezileyo olungelulo oluqhelekileyo, njengoko kubonisiwe kumfanekiso ongezantsi.

Indlela entsha: Umatshini wokwenza umqulu.Inkqubo yokwenza umqulu ngokuthe ngcembe ibumba izinto eziphathekayo kunye ne-roller nganye, ngokuyigoba ngokunyukayo de ibe yityhubhu engqukuva, evaliweyo. Oku kuhanjiswa kwamandla afanayo kunciphisa i-springback. Iikhoyili zetsimbi zinokuthi zityiswe ngokuqhubekayo ngaphandle kokufuna ukusika kwangaphambili, kwaye ubude betyhubhu bunokunqunyulwa ngokuchanekileyo ngokuchaneka kwe-± 1mm. Le ndlela ilungele ukuvelisa iityhubhu ezincinci zedayamitha kunye noyilo oluqhelekileyo lomphetho. Sisisombululo esisebenzayo nesinoqoqosho kubathengi.

I-CASE YOKWENENE-I-PARAMETER ZOBUGCISA

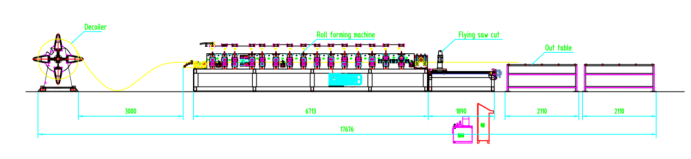

Itshathi equkuqelayo: I-Decoiler--Isikhokelo--Roll yangaphambili--Isarha yokubhabha isikiwe--Itafile

I-CASE YOKWENENE-I-PARAMETER ZOBUGCISA

Isantya se-1.Umgca: 0-10m / min, ukulungiswa

I-2.Izinto ezifanelekileyo: Intsimbi ye-galvanized, i-aluminium

3.Ubukhulu bezinto: 0.8-1mm

Umatshini wokwenza i-4.Roll: Isakhiwo se-Cast-iron

I-5.Inkqubo yokuqhuba: Inkqubo yokuqhuba i-Gearbox ene-universal joint cardan shaft.

Inkqubo ye-6.Cutting: I-Flying saw cut, i-roll yangaphambili ayiyeki xa usika.

Ikhabhinethi ye-7.PLC: inkqubo ye-Siemens.

I-CASE-MACHINERY YOKWENENE

1.Manual Decoiler*1

2.Umatshini wokwenza umqulu*1

3.Flying isarha umatshini wokusika *1 (Kuquka isarha isarha *1)

4.Ngaphandle kwetafile*2

5.PLC iKhabhinethi yolawulo*1

6.Isikhululo samanzi*1

7.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

INGCACISO YOKWENENE

I-Decoiler ye-Manual

· Isakhelo esomeleleyo:Isakhelo sakhiwe ukuba somelele kwaye sizinzile, siqulunqwe ngokukodwa ukuxhasa iikhoyili zentsimbi ngokukhuselekileyo.

· Ukwandiswa kweMandrel:I-mandrel okanye i-arbor ingalungiswa ngesandla ukuze yandise kwaye ifake iikhoyili zentsimbi kunye nobubanzi obungaphakathi ukusuka kwi-490-510mm. Oku kuqinisekisa ukuba ikhoyili ibanjwe ngokuqinileyo ukuze i-decoiling egudileyo.

· Isigcini sekhoyili:Eli candelo lenzelwe ukuthintela icoil yentsimbi ekutyibilikeni kwi-mandrel. Kulula ukuncamathela kunye nokususa.

· Ukhetho olukhoyo:Ukongezwa kombane kunye ne-automation, iinguqulelo zombane okanye zehydraulic zesixhobo esingundoqo sokwandiswa ziyafumaneka. Nangona kunjalo, inguqulo ye-manual ikhethwa kwi-awning round tubes ngenxa ye-coil yensimbi encinci kunye nencinci echaphazelekayo.

Ukukhokela

· Indima yokuqala: Ukugcina ulungelelwaniso oluchanekileyo lwekhoyili yensimbi kunye ne-centerline yomatshini, ukuthintela imiba efana nokujija, ukugoba, kunye nokwakheka kwe-burr. Ulungelelwaniso oluchanekileyo lubalulekile ekuqinisekiseni ukuba imithungo yetyhubhu engqukuva ye-awning iqinile kwaye ikhuselekile.

· Iinkqubo ezininzi zokuKhokela: Ayifumaneki nje kwindawo yokutya kodwa nakuwo wonke umatshini wokwenza ukuqinisekisa ukuba ityhubhu ihlala ithe tye ngexesha lemveliso.

· Ulungelelwaniso lweMimiselo: Ukulungelelaniswa rhoqo kweenkqubo ezikhokelayo ziyimfuneko, ngakumbi emva kokuthutha okanye ixesha elide lokusetyenziswa.

· Amaxwebhu athunyelwa kwangaphambili: Iqela laseLinbay lilinganisa ngononophelo kwaye lirekhode ububanzi besikhokelo ngaphambi kokuthunyelwa, ukubonelela ngezi nkcukacha kwincwadana yomsebenzisi ukuququzelela ukulinganisa ngokuchanekileyo kwirisithi yomxhasi.

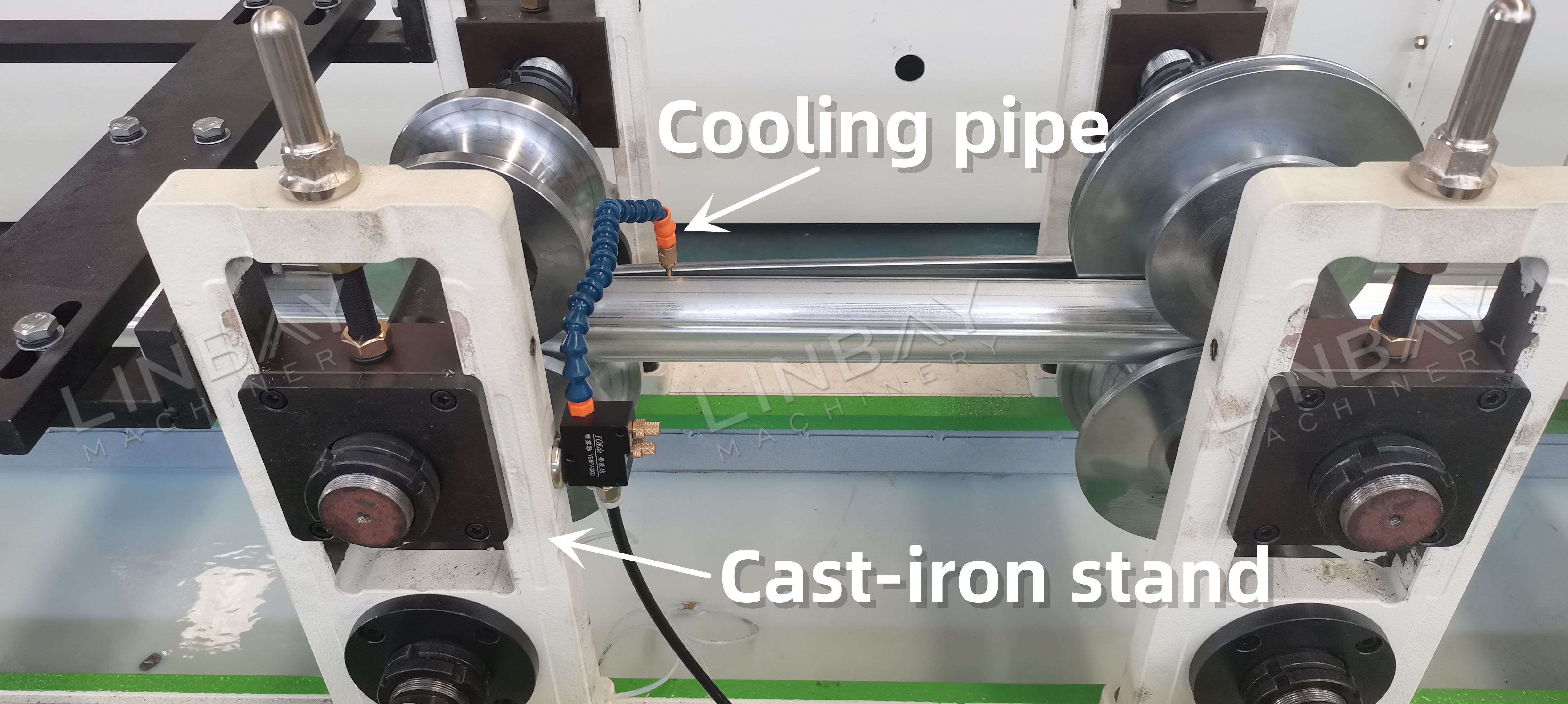

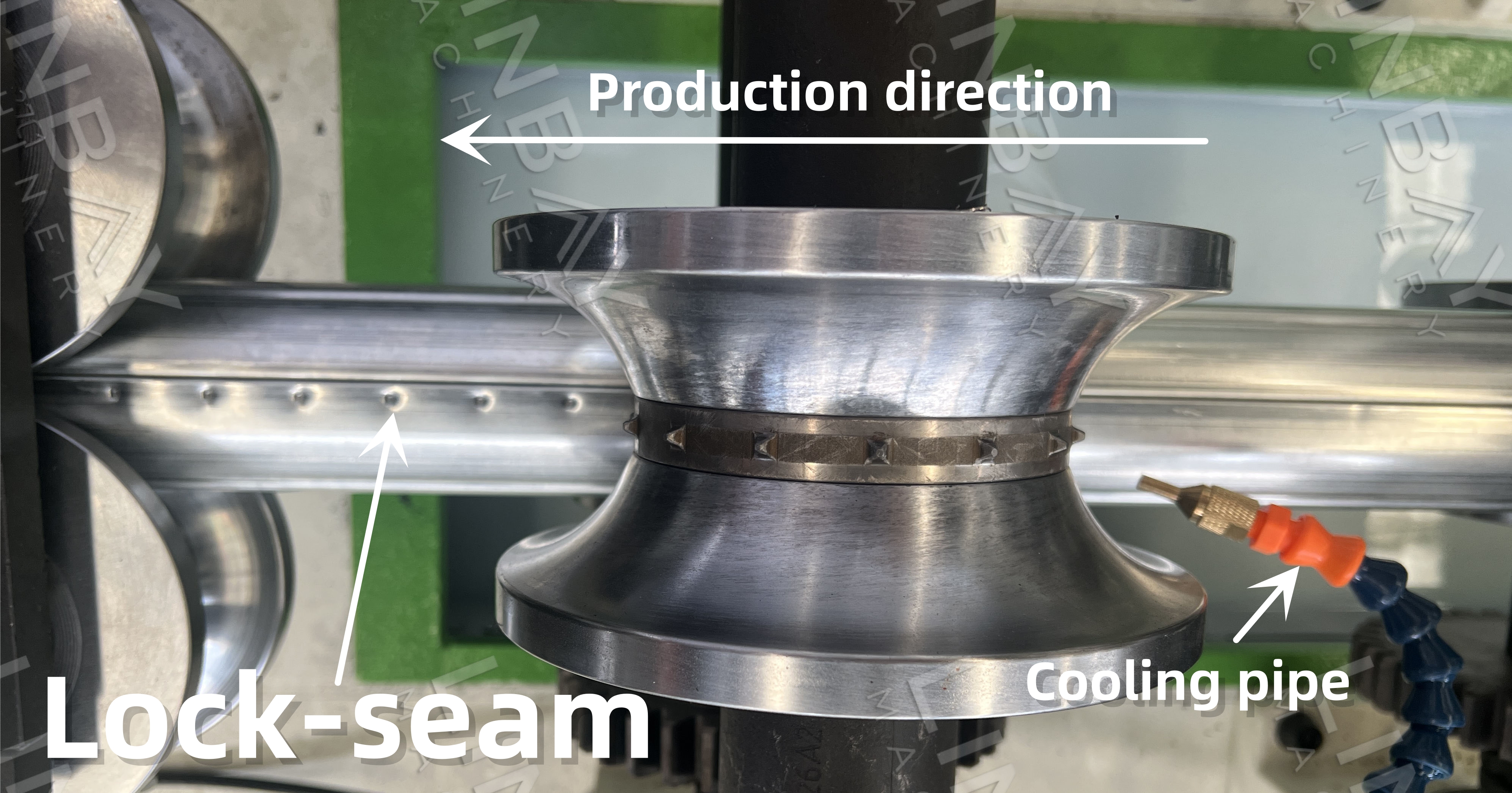

Roll Former

· Ulwakhiwo olomeleleyo: Ifaka i-cast-iron stand yokuqina okuphuculweyo.

· Inkqubo yokuqhuba ngamandla: Ixhotyiswe ngebhokisi yegiya kunye nendibaniselwano yendalo yonke ehambisa amandla okuqhuba awomeleleyo kwiirola, iqinisekisa ukwakheka okugudileyo kunye nokungaguqukiyo kweekhoyili zentsimbi.

· Imveliso eguquguqukayo: Isiseko somatshini wokwenza umqulu omnye sithatha iikhasethi ezahlukeneyo, nganye ilungiselelwe kwiidiameters ezithile ezijikelezayo. Ukutshintsha ngokulula iikhasethi ukuvelisa iityhubhu ezinobukhulu obahlukeneyo.

· Ukusebenza kakuhle kweendleko: Inika isisombululo esinoqoqosho ngakumbi ngokuphelisa imfuno yemigca yokuvelisa eyahlukileyo kwiidayimitha zetyhubhu ezahlukeneyo.

· Seam Seam: Iqinisekisa umthungo wokutshixa oqinileyo ohlala unjalo, unqanda nakuphi na ukusilela okunokwenzeka komthungo.

· Inkqubo yokupholisa eZinzileyo: Isebenzisa isixokelelwano sokupholisa esijikelezayo ukugcina amaqondo obushushu e-roller esezantsi, ephucula umgangatho wokwakheka kunye nokwandisa ubomi berola.

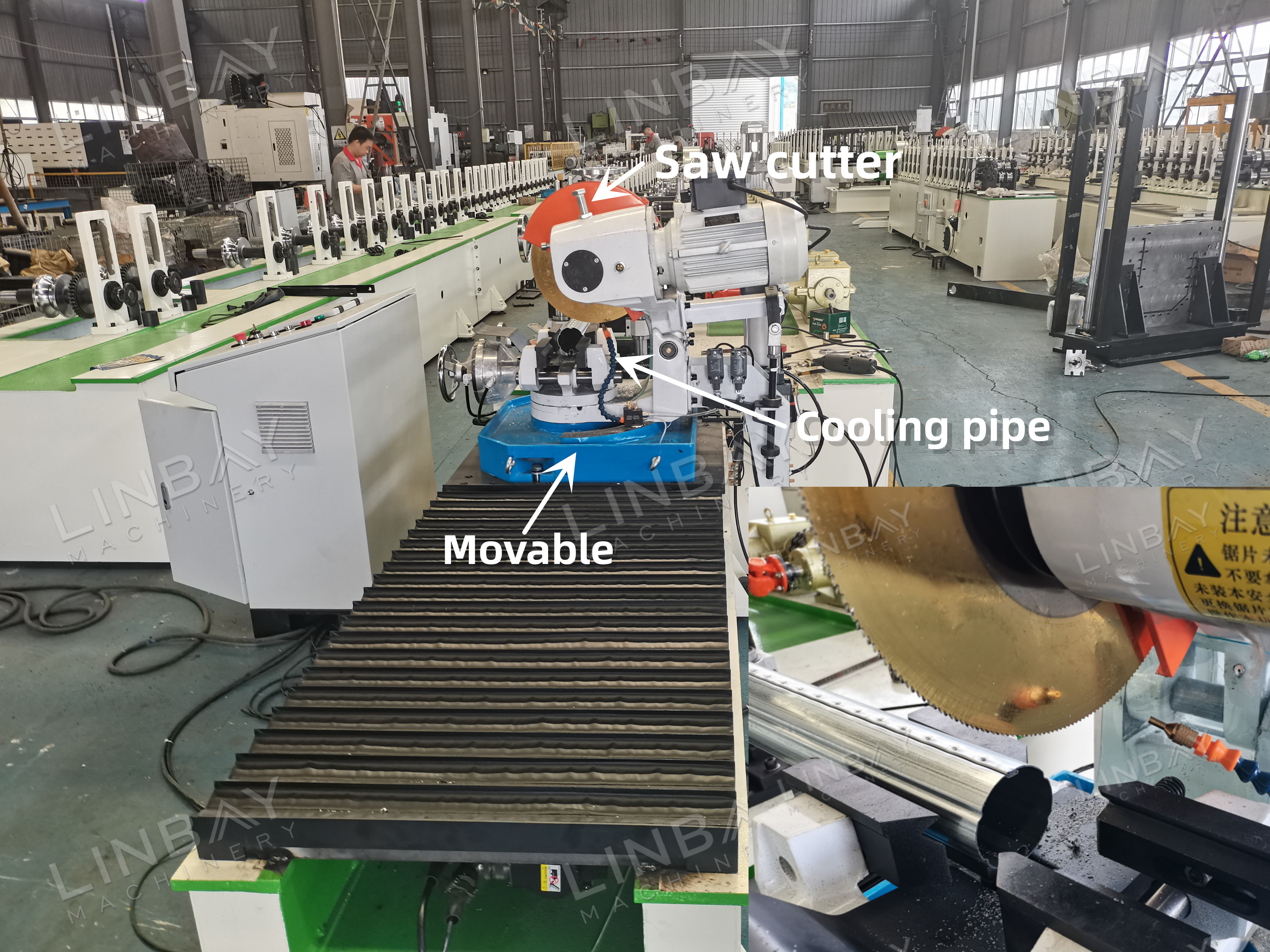

I-Flying Saw Cut

· Multi-Diameter Saw: Yenzelwe ukulungiselela ubungakanani betyhubhu eyahlukahlukeneyo engqukuva, inceda ukunciphisa iindleko zokutshintshwa kweblade.

· Ukusika ngokuchanekileyo: Iqinisekisa ukusika okucocekileyo, okungaguqukiyo kunye nemiphetho egudileyo, engenazo i-burr.

· Ucikizeko lweMathiriyeli: Ukuphelisa inkunkuma ngokusikwa nganye, ukwandisa ukusetyenziswa kweekhoyili zensimbi kunye nokunciphisa iindleko.

· Isantya soMveliso esongezelelweyo: Iyunithi ye-cutter ihamba kunye nomzila ngesantya esifanayo njengenkqubo yokubumba, ivumela ukusebenza okungaphazamisekiyo.

· Ukuchaneka okuphezulu: Idityaniswe ne-servo motor kunye nomlawuli wentshukumo, ukugcina ukuchaneka kokusika ngaphakathi kwe-± 1mm yokunyamezela.

· Inkqubo yokupholisa esebenzayo: Iphinda ijikeleze isisipholisi ukugcina iblade isarha ipholile, iqinisekisa ubulunga obungaguqukiyo bokusika ngexesha lokusetyenziswa rhoqo kunye nokwandisa ubomi bencakuba.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile