ividiyo

Inkangeleko yesimo

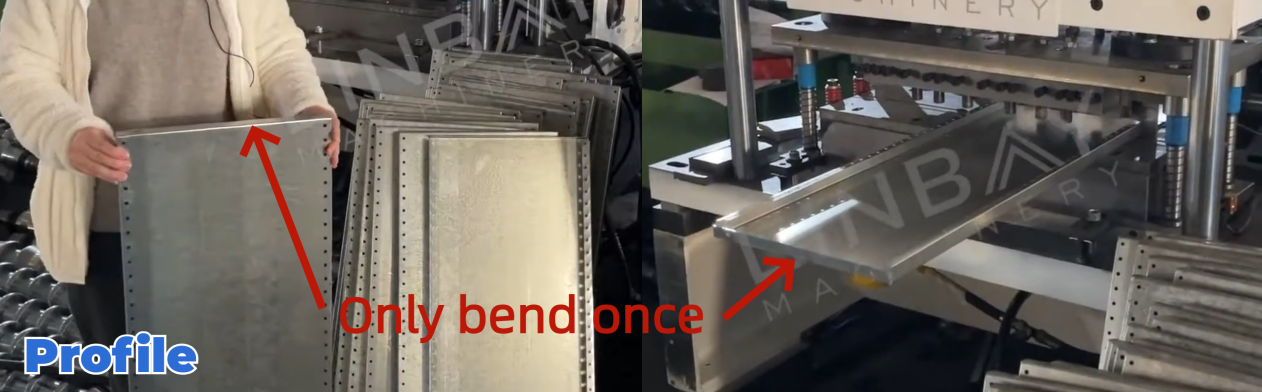

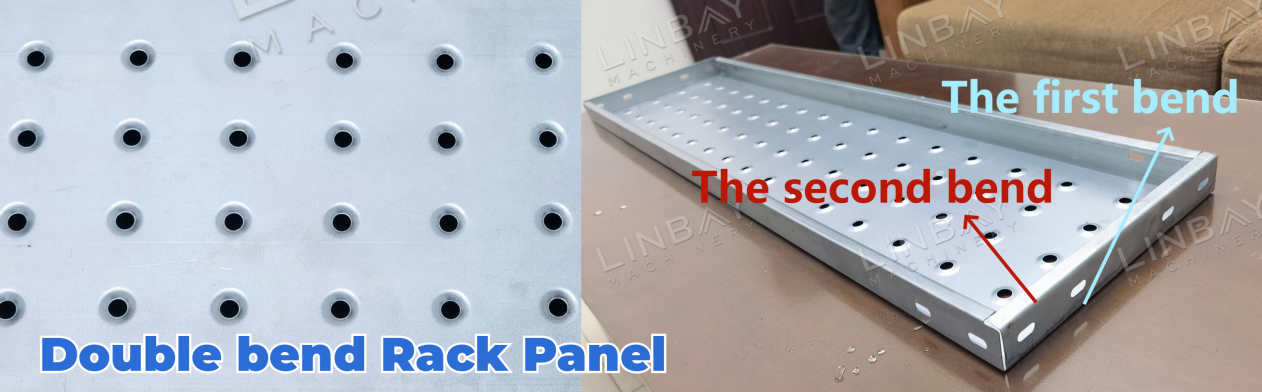

Iphaneli yeshelufu yinxalenye ebalulekileyo yenkqubo yokurhaxa, eyilelwe ukubamba iimpahla. Ngokuqhelekileyo yenziwe ngentsimbi enezingqimba ezinobunzima ukusuka kwi-1 ukuya kwi-2 millimeters. Le panel ifumaneka kububanzi nobude obahlukeneyo, ngelixa ubude bayo buhlala buhleli. Ikwabonisa igophe elinye kwicala elibanzi.

Ityala lokwenyani-Iiparamitha zoBuchule eziPhambili

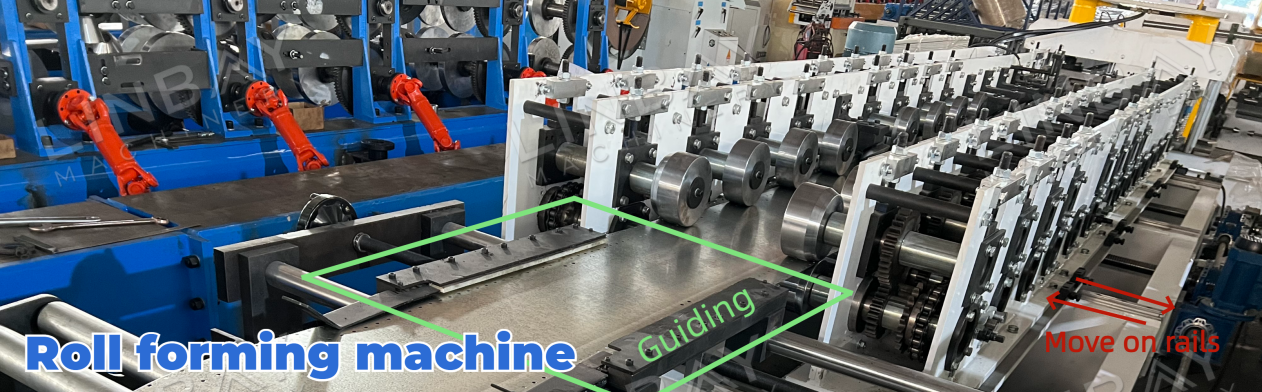

Itshathi equkuqelayo

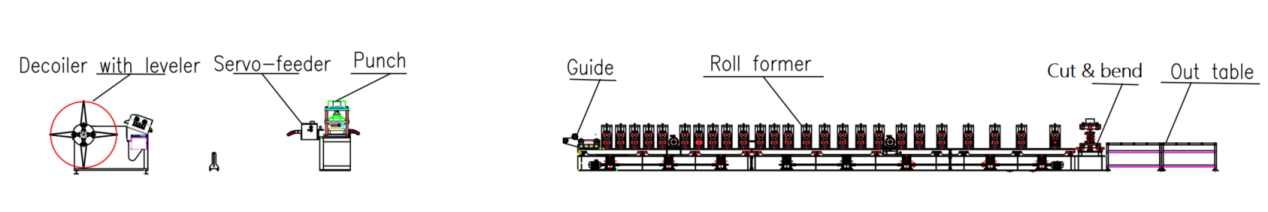

I-Hydraulic decoiler ene-level--Servo feeder--Hydraulic punch--Isikhokelo--Umatshini wokwenza umqengqelezi--Ukusika kunye nomatshini wokugoba--Itafile engaphandle

IiParameters ezingundoqo zobuGcisa

1. Isantya somgca: Ukulungelelaniswa phakathi kwe-4-5 m / min

2. Iiprofayili: Ububanzi obahlukeneyo kunye nobude, kunye nobude obuhambelanayo

3. Ubukhulu beMaterial: 0.6-1.2mm (kule sicelo)

4. Izinto ezifanelekileyo: Intsimbi eshushu, intsimbi epholileyo

5. Umatshini wokwenza umqulu:Cantilevered Isakhiwo sephaneli ephindwe kabini kunye nenkqubo yokuqhuba ikhonkco

6. Inkqubo yokusika kunye nokugoba: Ukusika kunye nokugoba ngaxeshanye, kunye nokumiswa kwangaphambili ngexesha lenkqubo.

7. Uhlengahlengiso lobungakanani: ngokuzenzekelayo

8. Ikhabhinethi ye-PLC: Inkqubo ye-Siemens

Imeko yokwenyani-Inkcazo

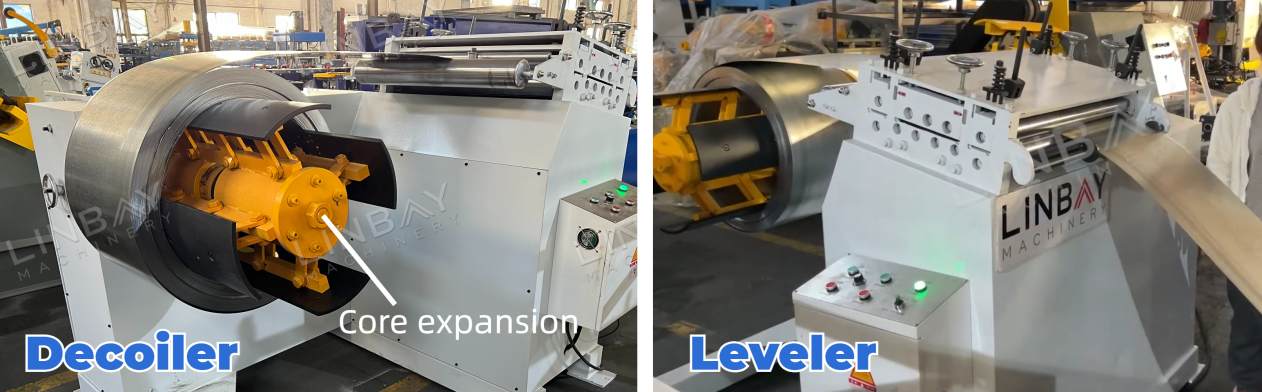

I-Hydraulic Decoiler ene-Level

Lo matshini udibanisa i-decoiler kunye ne-level, ukwandisa indawo yomgangatho wefektri kunye nokunciphisa iindleko zomhlaba. Indlela yokwandisa ingundoqo inokulungelelanisa ukuze ilingane iikhoyili zentsimbi ezinobubanzi bangaphakathi phakathi kwe-460mm kunye ne-520mm. Ngethuba lokuqhawula, izigcini zekhoyili zangaphandle ziqinisekisa ukuba i-coil yensimbi ihlala ikhuselekile, iphucula ukhuseleko lwabasebenzi.

I-leveler ithoba i-coil yensimbi, ikhulula uxinzelelo lwangaphakathi kwaye yenza ukuba i-punching esebenzayo kunye nokwenza umqulu.

I-Servo Feeder kunye ne-Hydraulic Punch

I-hydraulic punch isebenza ngokuzimeleyo, ihluke kwisiseko somatshini wokwenza umqulu. Olu luyilo luvumela umatshini wokwenza umqulu ukuba uqhubeke nokusebenza ngelixa ukubetha kuyaqhubeka, ukuphucula ukusebenza kakuhle komgca wemveliso. I-servo motor inciphisa ukulibaziseka kwexesha lokuqalisa, inika ulawulo oluchanekileyo kubude bentsimbi yentsimbi yobude bokubethelwa ngokuchanekileyo.

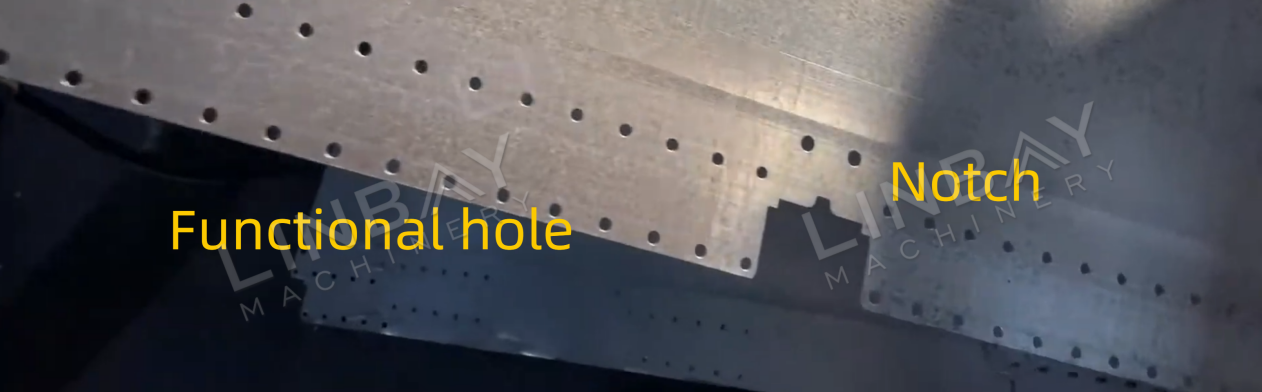

Ngethuba lenqanaba lokubhoboza, iinotshi zenziwa ngaphezu kwemingxuma esebenzayo yokufakela isikrufu. Ekubeni i-coil yensimbi yentsimbi iya kuqulunqwa ibe yiphaneli ye-dimensional-dimensional panel, ezi zinotshi zibalwe ngokuchanekileyo ukuthintela ukugqithiswa okanye izithuba ezinkulu kwiikona ezine zepaneli yeshelufu.

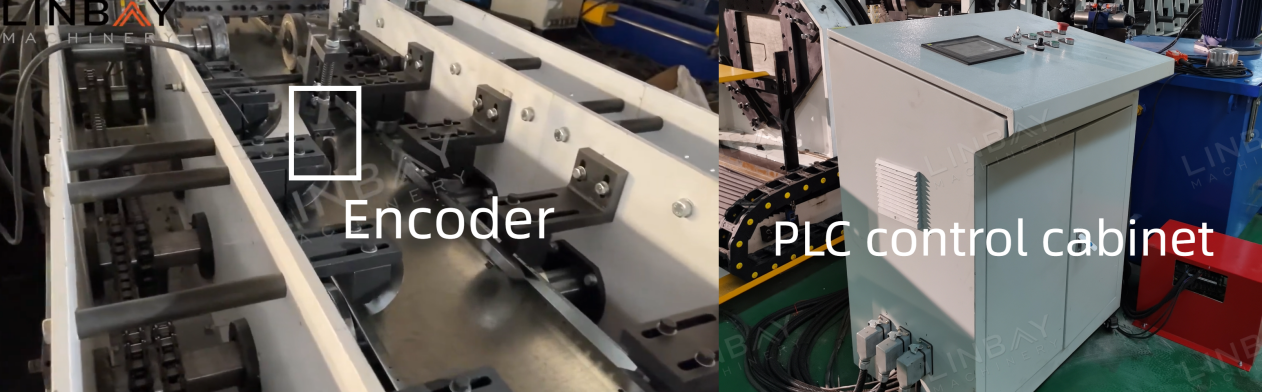

I-Encoder & PLC

I-encoder iguqula ubude obufunyenweyo bekhoyili yensimbi ibe ngumqondiso wombane, othi ke udluliselwe kwikhabhinethi yokulawula ye-PLC. Ngaphakathi kwekhabhinethi yokulawula, iiparamitha ezifana nesantya sokuvelisa, ubuninzi bemveliso, ubude bokusika, njl., Inokulawulwa ngokuchanekileyo. Ngombulelo kumlinganiselo ochanekileyo kunye nengxelo enikezelwe yi-encoder, i-hydraulic cutter inokugcina ukuchaneka kokusika ngaphakathi.±1mm, ukunciphisa iimpazamo.

Umatshini wokwenza umqulu

Ngaphambi kokungena kumatshini wokwenza, i-coil yensimbi ikhokelwa ngemivalo ukugcina ukulungelelaniswa kunye ne-centerline. Ukunikezelwa kwimilo yepaneli yeshelufu, kuphela amacala e-coil yensimbi afuna ukubunjwa. Ke ngoko, siqesha i-double wall panel cantilever structure ukunciphisa ukusetyenziswa kwezinto, ngaloo ndlela sigcina iindleko ze-roller material. I-Chain-drive rollers yenza uxinzelelo kwi-coil yensimbi ukuququzelela ukuqhubela phambili kunye nokwenza.

Umatshini wokwenza unako ukuvelisa iipaneli zeshelufu zobubanzi obuhlukeneyo. Ngokufaka imilinganiselo efunekayo kwiphaneli yolawulo ye-PLC, isikhululo sokwenza ngokuzenzekelayo sihlengahlengisa indawo yaso ecaleni koololiwe xa sifumana iimpawu. Njengoko isikhululo sokubumba kunye ne-roller sihamba, iindawo zokubumba kwikhoyili yensimbi zitshintsha ngokufanelekileyo. Le nkqubo yenza ukuba umatshini wokwenza umqulu uvelise ngokufanelekileyo iipaneli zeshelufu ezinobungakanani obahlukeneyo.

I-encoder ifakwe ukukhangela ukuhamba kwesikhululo esenzayo, ukuqinisekisa ukulungiswa kobukhulu obuchanekileyo. Ngaphaya koko, abenzi boluvo bendawo ezimbini-ezona zivamvo zangaphandle nezingaphakathi-baqeshelwe ukuthintela ukunyakaza okugqithisileyo ecaleni kweereyili, ngaloo ndlela kuthintelwa ukutyibilika okanye ukungqubana phakathi kweerola.

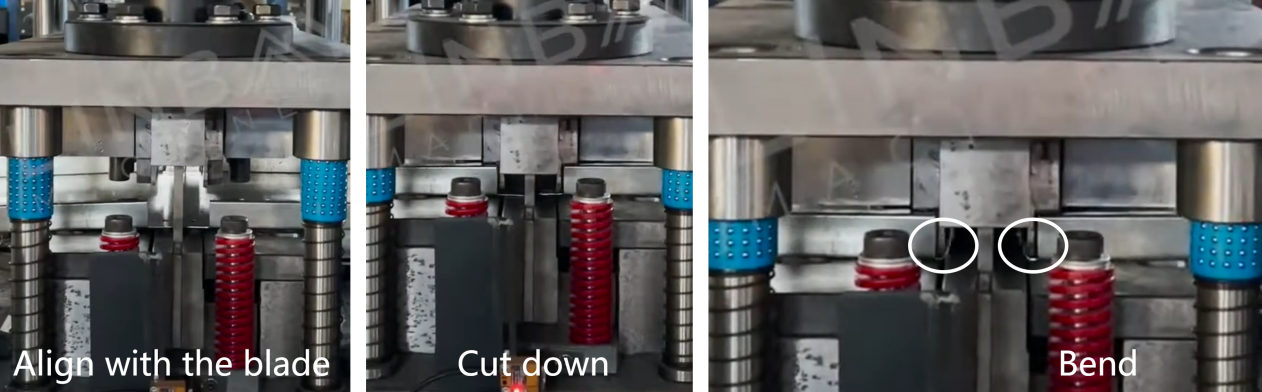

Umatshini wokusika kunye nokugoba

Kule meko, apho iphaneli yeshelufu idinga ukugoba okukodwa kwicala elibanzi, senze ubunjineli bomatshini wokusika ukwenza ukusika kunye nokugoba ngaxeshanye.

I-blade yehla ukwenza ukusika, emva koko i-mold yokugoba ihambela phezulu, igqibe ngokufanelekileyo ukugoba komsila wepaneli yokuqala kunye nentloko yepaneli yesibini ngendlela efanelekileyo.

Olunye uhlobo

Ukuba uyothuswa ziipaneli zeshelufu ezinamagophe amabini kwicala elibanzi, cofa ngokulula kumfanekiso ukuze ungene nzulu kwinkqubo yokuvelisa eneenkcukacha kwaye ubukele ividiyo ekhaphayo.

Umahluko ophambili:

Uhlobo lwe-double-bend lunikeza ukuqina okongeziweyo xa kuthelekiswa nohlobo lwe-bend enye, ukuqinisekisa ukusetyenziswa ixesha elide. Nangona kunjalo, uhlobo olulodwa lwe-bend luhlangabezana ngokwaneleyo neemfuno zokugcina. Ukongezelela, imida yohlobo lokugoba kabini ayibukhali, iphucula ukhuseleko ngexesha lokusetyenziswa, kanti i-single-bend inokuba nemiphetho ebukhali.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile