INGXELO YOBOMI

Igatha yesinyithi isebenza njengenxalenye ebalulekileyo yokuhambisa amanzi efakwe ecaleni kwencam yophahla ukuze ibambe kwaye iqondise amanzi emvula kude nesakhiwo, inceda ukuthintela umonakalo onxulumene namanzi. Iigatha ziqhele ukwakhiwa ngezinto ezifana ne-aluminiyam, intsimbi, intsimbi egqunywe ngombala, ubhedu, kunye negalvalume, enobunzima obuphakathi kwe-0.4 kunye ne-0.6 mm.

Lo mgca wemveliso ubonisa isakhiwo semiqolo emibini, evumela ukuveliswa kobukhulu obuhlukeneyo be-gutter kumgca omnye, nangona kungekhona ngexesha elinye. Olu luyilo lukhulisa ukusetyenziswa kwendawo kwaye luthoba iindleko zoomatshini kumxhasi.

I-CASE YOKWENENE-I-PARAMETER ZOBUGCISA

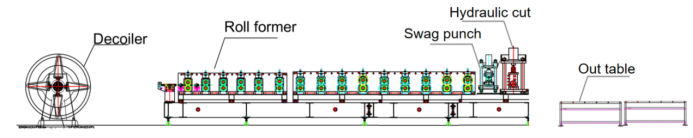

Itshathi equkuqelayo: I-Decoiler--Isikhokelo--Roll ngaphambili--Swag punching--Hydraulic cut--out table

I-CASE YOKWENENE-I-PARAMETER ZOBUGCISA

· Isantya somgca: Ukulungiswa, ukusuka kwi-0-12m / min.

· Izinto ezihambelanayo: Aluminiyam, intsimbi, intsimbi enombala, igalvalume, ubhedu.

· Ukutyeba kwezinto eziphathekayo: 0.4-0.6mm.

· Umatshini wokwenza umqulu: Uyilo lwemigca emibini enesakhiwo sodonga.

· Inkqubo yokuqhuba: Inkqubo eqhutywa ngamakhonkco.

· Inkqubo yokusika: Indlela yokumisa kunye nokusika, apho umqulu wangaphambili unqumama ngexesha lokusika.

· Ulawulo lwe-PLC: Inkqubo yeSiemens.

I-CASE-MACHINERY YOKWENENE

1.I-Hydraulic decoiler*1

2.Umatshini wokwenza umqulu*1

3.Umatshini we-Hydraulic swag punch*1

4.Umatshini wokusika i-Hydraulic * 1

5.Ngaphandle kwetafile*2

6.PLC iKhabhinethi yolawulo*1

7.Isikhululo samanzi*2

8.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

INGCACISO YOKWENENE

I-Hydraulic Decoiler

· Isakhelo: Isakhelo esomeleleyo senzelwe ukuxhasa ngokuthembekileyo iikhoyili zetsimbi, kunye ne-hydraulic-powered decoiler ephakamisa ukusebenza kakuhle kunye nokhuseleko ngexesha lokutya kwekhoyili kumgca wokuvelisa.

· Indlela yoKwandiswa okungundoqo: I-mandrel eqhutywe nge-hydraulic (okanye i-arbor) ilungelelanisa ukuhlalisa iintsimbi zetsimbi ezinobubanzi bangaphakathi be-490-510mm, ukukhusela i-coil ukuze i-coil igudiswe kwaye igxininise.

· Cinezela iArm: Ingalo yokucinezela nge-hydraulic iqinisekisa ukuba ikhoyili ihlala kwindawo, inciphisa umngcipheko wokubuyela ngokukhawuleza ngenxa yoxinzelelo lwangaphakathi kunye nokukhusela ukhuseleko lwabasebenzi.

· Ikhoyili yokugcina: Ikhuselwe kwi-mandrel blades nge-screws kunye namantongomane, i-coil retainer igcina i-coil yensimbi ekuphumeni, kwaye kulula ukuyifaka okanye ukususa njengoko kufuneka.

· Inkqubo yokulawula: Ukuxhotyiswa nge-PLC kunye nephaneli yokulawula ebandakanya iqhosha lokuyeka ngokukhawuleza, ukuphucula ukhuseleko lokusebenza.

·Iinketho ze-Decoiler zokwenziwa komqulu ombini: Kumatshini wokwenza umqulu wemiqolo emibini, i-decoiler enye-shaft ingasetyenziswa kwaye ibekwe ngokutsha ukuze kugcinwe iindleko, nangona ifuna ixesha elingakumbi. Ngenye indlela, i-decoilers ezimbini ze-shaft-shaft okanye i-decoiler ephindwe kabini ingasetyenziselwa ukuvelisa ngokufanelekileyo.

IiBha zokukhokela

· Ulungelelwaniso: Iqinisekisa ukuba i-coil yensimbi igxininiswe ngokufanelekileyo kunye ne-axis yomatshini, ukuthintela imiba yokutya enokubangela ukujija, ukugoba, i-burrs, okanye ukungachaneki kwe-dimensional kwimveliso egqityiweyo.

· Uzinzo: Ukuzinzisa imathiriyeli ngundoqo, kunye nemivalo ekhokelayo eqinisekisa ukondla okungaguqukiyo, okubalulekileyo ekuveliseni amacandelo asemgangathweni ophezulu.

· Isalathiso: Baqondisa izinto ngokutyibilikayo kwiseti yokuqala yokuqulunqa ii-roller, ezibaluleke kakhulu kwimilo echanekileyo yokuqala.

· Isondlo: Kubalulekile ukuhlaziya rhoqo izixhobo ezikhokelayo, ngakumbi emva kokuthutha okanye ukusetyenziswa ixesha elide. Ngaphambi kokuthunyelwa, i-Linbay irekhoda ububanzi besikhokelo kwincwadana yomsebenzisi, ivumela ukulinganisa okuchanekileyo xa umthengi efumana izixhobo.

Umatshini wokubumba umqulu

· Ixabiso-Ngempumelelo kuMveliso weGutter: Ibandakanya idizayini yepaneli yodonga kunye nenkqubo eqhutywa ngamakhonkco.

· Ukuguquguquka kweesayizi ezininzi: Ukuseta imiqolo emibini ixhasa ukuveliswa kweesayizi ezimbini ezahlukeneyo zegutter, ukwandisa indawo kunye nokunciphisa iindleko zoomatshini.

· Ukhuseleko lwekhonkco: Amatyathanga avalelwe ngaphakathi kwentsimbi yentsimbi, eqinisekisa ukhuseleko lwabasebenzi kunye nokukhusela amatyathanga emonakalweni ngenxa yenkunkuma yomoya.

·Ukusebenza kakuhle: Icutha ixesha lokucwangcisa xa lithelekiswa neenkqubo zomqolo omnye ezifuna utshintsho olwenziwa ngesandla.

· Ukwenza iiRoller: Ixhotyiswe ngama-20 okwenza imiqulu, kuquka i-2 engile-angle rolls yokuphucula ukwakhiwa kwamaza amancinci njengoko kubonisiwe kumfanekiso ohamba kunye.

·IiRola ezihlala zihleli: I-Roller ifakwe i-chrome-plated kwaye iphathwa ngokutshisa ngenxa ye-corrosion kunye ne-rust resistance, igalelo kubomi obude benkonzo.

· IMotor engundoqo: Ukucaciswa okusemgangathweni ngu-380V, 50Hz, isigaba se-3, kunye neenketho zokwenza ngokwezifiso ezikhoyo.

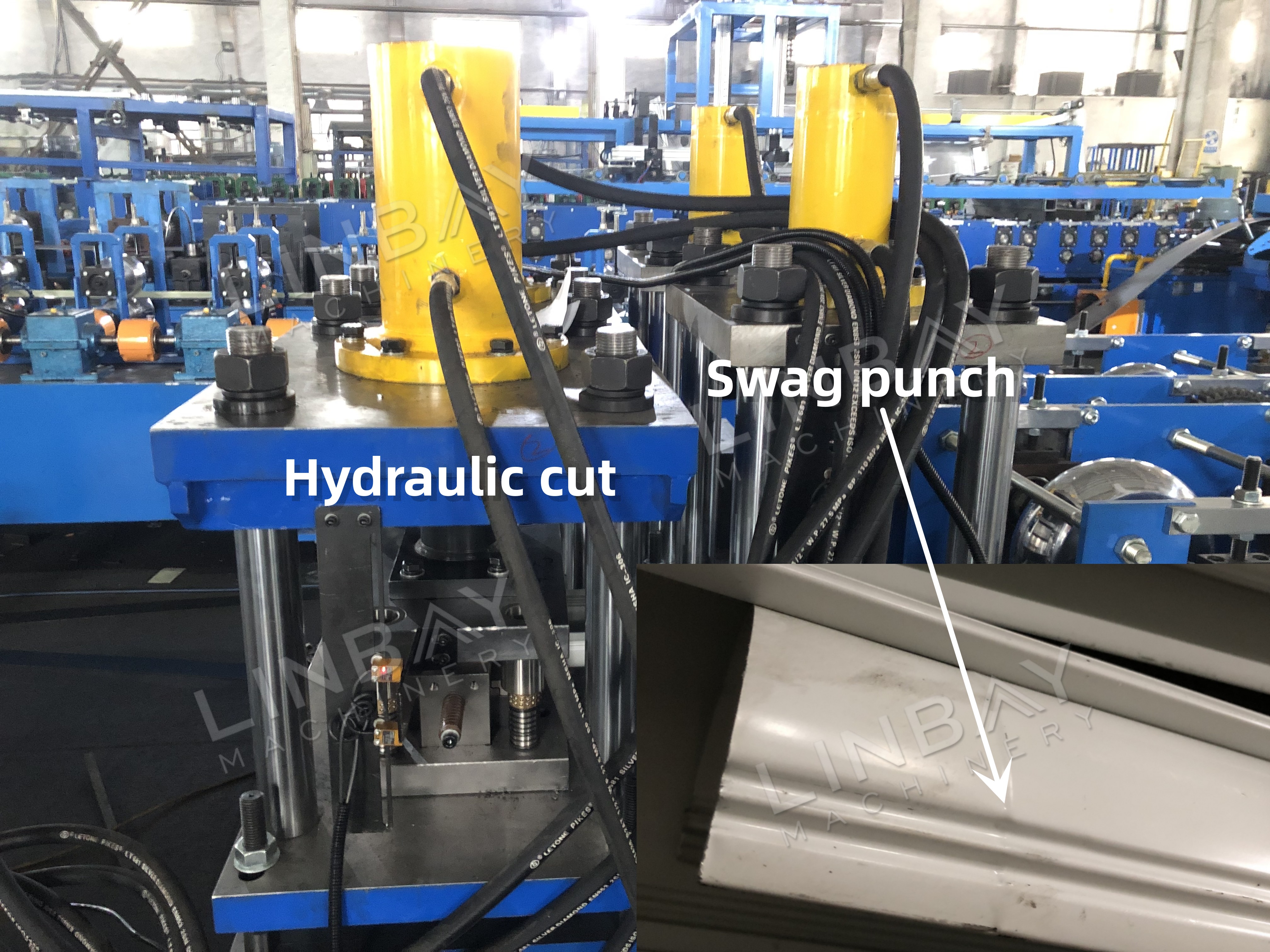

I-Swag Punching

· Uqwalaselo lweGutter: Isiphelo somjelo wentsimbi sicuthelwe ukunciphisa idiameter, sisenza ukuba sityibilike kwelinye icandelo legutter ukuze likhuseleke.

· Ubunakho bomatshini: Isebenzisa i-hydraulic punching die ukwenza umdibaniso wokugqibela, uqinisekisa ukudibanisa okugudileyo kunye nokukhuselekileyo phakathi kwamacandelo amabini e-gutter.

Ukusika kweHydraulic

· IiBladi zesiko: Yenzelwe ukuba ilingane iprofayile yomjelo, iqinisekisa ukusikwa okucocekileyo ngaphandle koguquko okanye iibhutsi.

· Ubude obuchanekileyo bokusika: Igcina unyamezelo lwe-±1mm. Oku kuchanekileyo kufezekiswa nge-encoder elinganisa ukuhamba kwekhoyili yensimbi, ukuguqula le datha kwiimpawu zombane ezithunyelwe kwikhabhinethi ye-PLC. Abaqhubi banokuhlengahlengisa ubude bokusika, ubuninzi bemveliso, kunye nesantya nge-interface ye-PLC.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile