SQUARE TUBE ROLL UKWENZA UMSHINI

Lo mgca wemveliso ulungiselelwe ukudala iibhubhu zesikwere ezinobunzima be-2mm, kunye nemilinganiselo ukusuka kwi-50-100mm ububanzi kunye ne-100-200mm ukuphakama.

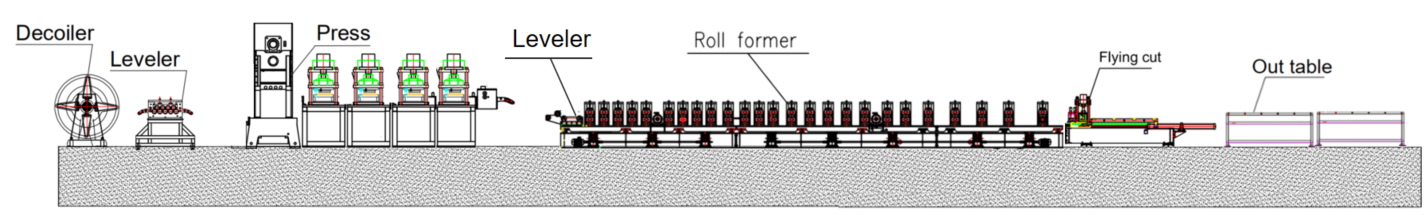

Umgca wemveliso uquka iinkqubo ezininzi eziphambili: ukuchithwa, ukulinganisa kwangaphambili, ukubetha, ukulinganisa emva kwepunch, ukwakhiwa kwe-roll, i-laser welding, i-fume extraction, kunye nokusika.

Kubandakanya ukuseta okubanzi kunye nokuzenzekelayo okuzenzekelayo, lo mgca wemveliso unikezela ngenye indlela ephezulu kumatshini oqhelekileyo we-welding welding, ngokukodwa kwimiqulu ephantsi yokuvelisa.

I-CASE YOKWENENE-I-PARAMETER ZOBUGCISA

Itshathi equkuqelayo: I-hydraulic decoiler enemoto elayishayo--Leveler--Servo feeder--Punch press--Hydraulic punch--Limiter--Guiding-Leveler--Roll former--Laser weld--Flying saw cut--Itafile

I-CASE YOKWENENE-I-PARAMETER ZOBUGCISA

· Isantya somgca olungiswayo: 5-6m / min kunye ne-laser welding

· Izinto ezihambelanayo: Intsimbi eshushu, intsimbi epholileyo, intsimbi emnyama

· Ubukhulu bezinto eziphathekayo: 2mm

· Umatshini wokwenza umqengqelezi: Ulwakhiwo lwentsimbi etyhidiweyo enejoyini yendalo yonke

· Inkqubo yokuqhuba: Inkqubo eqhutywa yi-Gearbox ene-universal joint cardan shaft

· Inkqubo yokusika: Ukusika isarha yokubhabha, kunye nomqulu wangaphambili oqhubeka nokusebenza ngexesha lokusika

· Ulawulo lwe-PLC: Inkqubo ye-Siemens

I-CASE-MACHINERY YOKWENENE

1.I-Hydraulic decoiler*1

2.Inqanaba elizimeleyo*1

3.Cofa ngenqindi*1

4.Umatshini we-Hydraulic punch*1

5.I-Servo feeder*1

6.Inqanaba elidibeneyo*1

7.Umatshini wokwenza umqulu*1

8.Laser welding machine*1

9.IWelding Fume Purifier*1

10.Umatshini wokusika i-Flying *1

11.Ngaphandle kwetafile*2

12.PLC iKhabhinethi yolawulo*2

13.Isikhululo samanzi*3

14.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

INGCACISO YOKWENENE

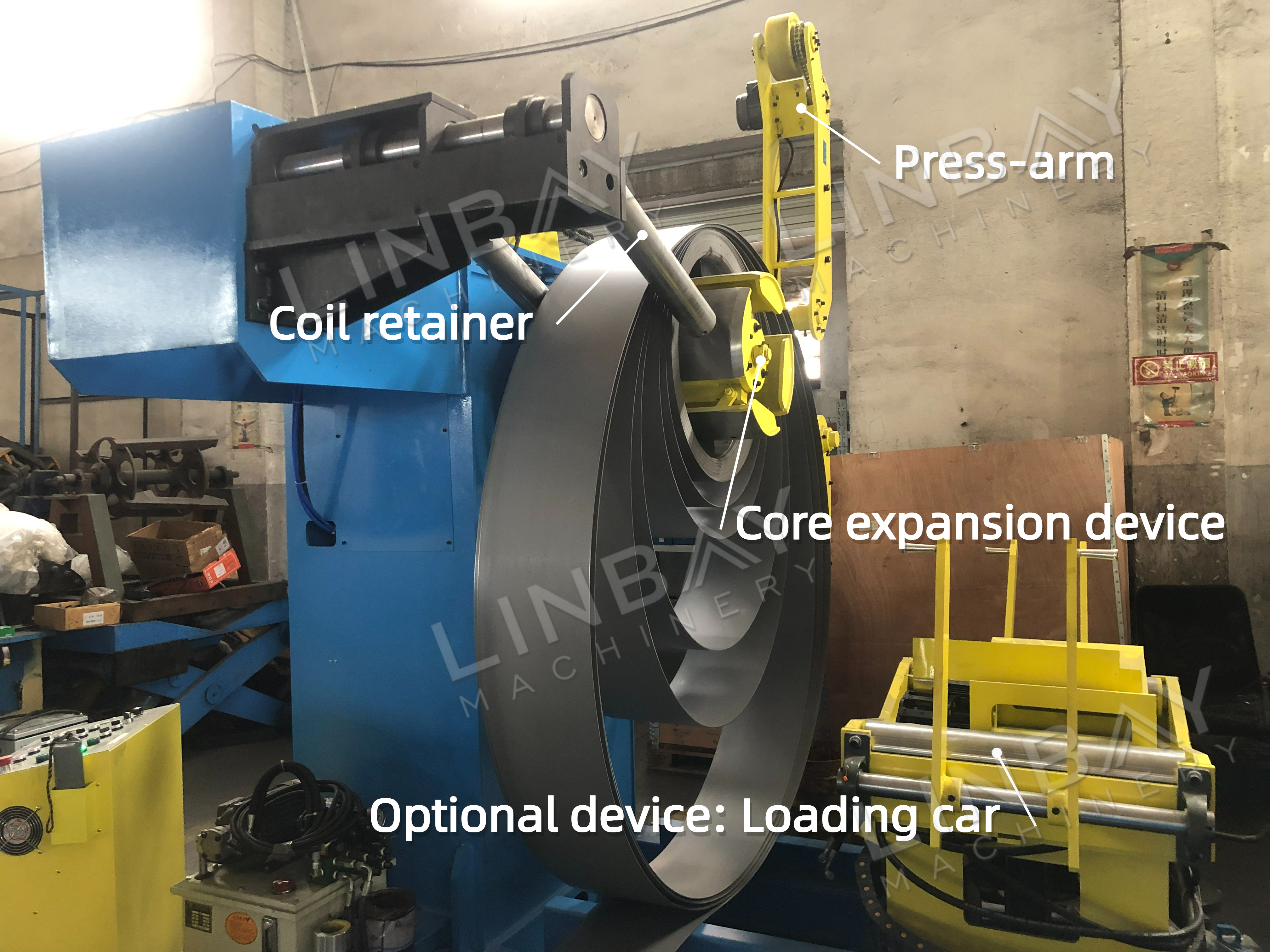

I-Hydraulic decoiler

•Umsebenzi: Isakhelo esomeleleyo sakhiwe ukuxhasa ukulayishwa kweekhoyili zentsimbi. I-decoiler ye-hydraulic iphucula ukusebenza kakuhle kunye nokhuseleko ekondleni iikhoyili zetsimbi kumgca wokuvelisa.

•Isixhobo soKwandiswa kweNqanaba: I-mandrel ye-hydraulic okanye i-arbor ilungelelanisa ukulungelelanisa iikhoyili zetsimbi kunye nobubanzi obungaphakathi be-490-510mm, ukwandisa kunye nekhontrakthi ukubamba ngokuqinileyo ikhoyili kunye nokuqinisekisa ukuchithwa okugudileyo.

•Cinezela-ingalo: Ingalo ye-hydraulic press arm ikhusela i-coil yensimbi, ikhusela ukukhulula ngokukhawuleza ngenxa yoxinzelelo lwangaphakathi kunye nokukhusela abasebenzi kukulimala okunokwenzeka.

•Ikhoyili yokugcina: Uyilo luqinisekisa ukuba ikhoyili ihlala ikhuselekile ngelixa ivumela ukuba kube lula ukufakwa kunye nokususwa.

•Inkqubo yokulawula: Inkqubo ibonisa i-PLC kunye nephaneli yokulawula, ebandakanya iqhosha lokumisa likaxakeka ukwenzela ukhuseleko olongezelelweyo.

Isixhobo esinoKhenketho: Ilayisha iMoto

•Ukutshintshwa kwekhoyili esebenzayo: Inceda ekutshintsheni iikhoyili zetsimbi ngokukhuselekileyo nangempumelelo, ukunciphisa iindleko zabasebenzi.

•Ulungelelwaniso lweHydraulic: Iqonga liyakwazi ukulungiswa nge-hydraulically phezulu nasezantsi ukulungelelanisa ne-mandrel. Ukongeza, imoto elayishayo, efakelwe amavili, inokuhamba ngombane ecaleni kwendlela.

•Uyilo loKhuseleko: Idizayini ye-concave ibambe ngokuqinileyo i-coil yensimbi, ikhusela nayiphi na i-sliding.

Umatshini ozikhethelayo: Shearer Butt Welder

· Idibanisa iikhoyili zentsimbi yokugqibela kunye nezintsha, ukunciphisa ixesha lokutya kunye namanyathelo okulungisa iikhoyili ezintsha.

· Ukunciphisa iindleko zabasebenzi kunye nenkcitho yezinto eziphathekayo.

· Uqinisekisa ukucheba okugudileyo, okungagungqiyo ukwenzela ulungelelwaniso oluchanekileyo kunye nokuwelda.

· Iquka ukuwelda kwe-TIG okuzenzekelayo kwi-welds engaguqukiyo kunye neyomeleleyo.

· Kubandakanya izibuko zokhuseleko kwitafile yewelding ukukhusela amehlo abasebenzi.

· Ukulawulwa kweenyawo kwenza ukubamba iikhoyili kube lula.

· Ukulungelelaniswa kobubanzi bekhoyili obahlukeneyo kwaye inokudityaniswa ngokulula kwimigca eyahlukeneyo yemveliso ngaphakathi kobubanzi bayo.

Inqanaba elizimeleyo

· Ukunciphisa uxinzelelo kunye nokungafezeki komphezulu kwiikhoyili zetsimbi ngokusebenzisa ukuguqulwa kweplastiki, ukuthintela iimpazamo zejometri ngexesha lenkqubo yokwenza.

• Umgangatho ubalulekile kwiikhoyili ezityebe kune-1.5mm ezifuna ukubethwa.

· Ngokungafaniyo neeleveli ezidityanisiweyo ezidityaniswe ne-decoilers okanye oomatshini bokwenza umqulu, iileveli ezizimeleyo zisebenza ngesantya esiphezulu.

Ukugqogqa Icandelo

• Kulo mgca wemveliso, sisebenzisa indibanisela yepunch press kunye nehydraulic punch ukugqobhoza emngxunyeni. Iqela lethu lobunjineli lenze indlela efanelekileyo yokuphatha iipateni zemingxuma enzima, ukulinganisa ukusebenza kakuhle kunye neendleko ngokudibanisa iingenelo zabo zombini oomatshini bokubhoboza.

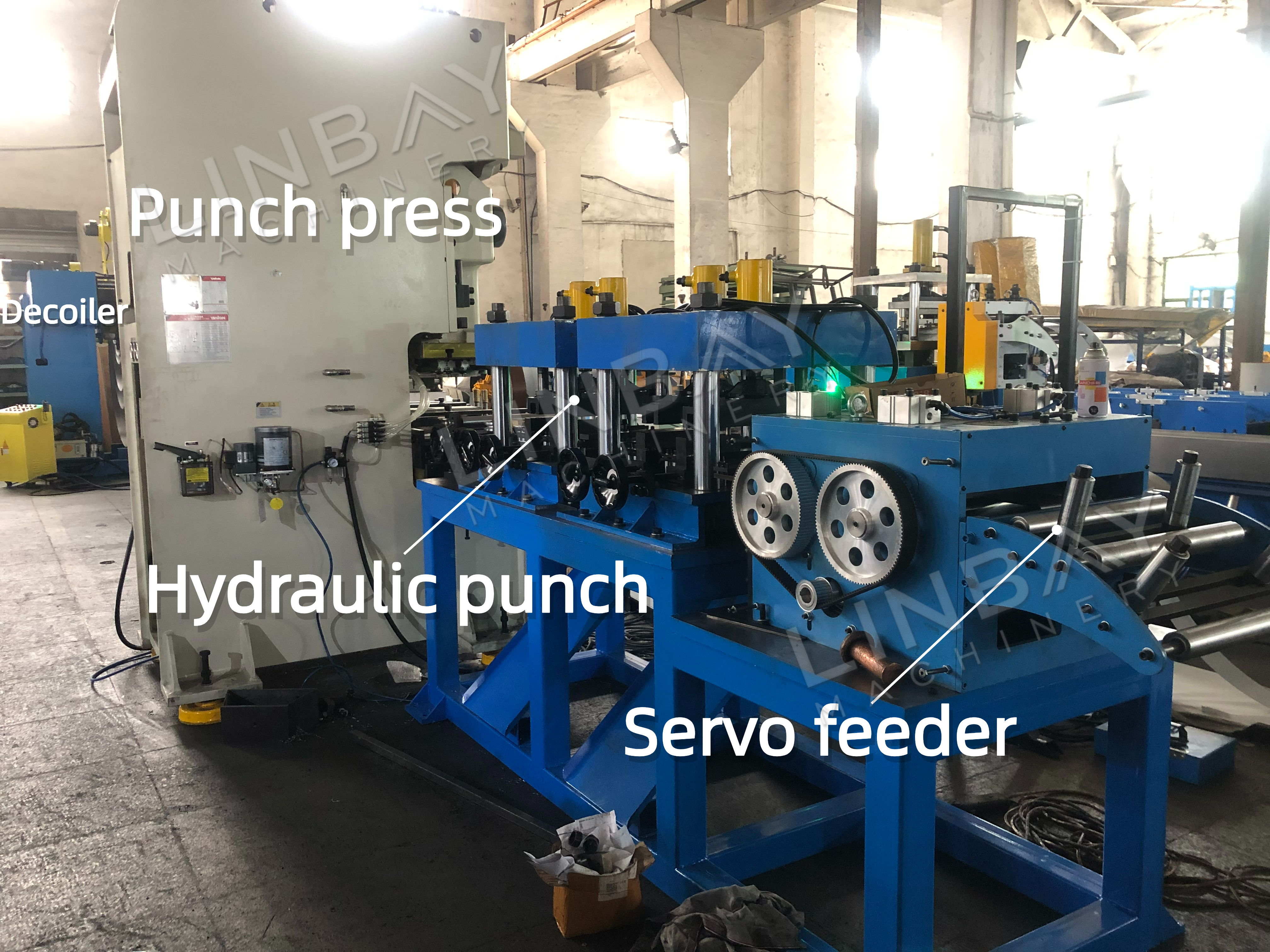

Punch Press

· Ukusebenza ngokukhawuleza.

· Ukuchaneka okuphezulu kwisithuba semingxuma ngexesha lokugqobhoza.

· Ilungele iipateni zemingxuma ezinzileyo.

I-Hydraulic Punch

• Inika ukuguquguquka okukhulu kwiipateni ezahlukeneyo zemingxuma. I-punch ye-hydraulic inokuziqhelanisa nemilo eyahlukeneyo yomngxuma, ilungelelanisa i-punching frequency ngokufanelekileyo kwaye ngokukhethayo ukubetha iimilo ezahlukeneyo nge-stroke nganye.

I-Servo Feeder

I-feeder, eqhutywa yi-servo motor, ilawula ngokuchanekileyo ukutyiswa kweekhoyili zentsimbi kwi-punch press okanye umatshini we-hydraulic punch. Ngamaxesha okuphendula ngokukhawuleza kunye nokulibaziseka okuncinci kokuqala, iimotor ze-servo ziqinisekisa ubude obuchanekileyo bokutya kunye nesithuba esingaguqukiyo somngxuma, ukunciphisa kakhulu inkunkuma evela kwiipuntshi ezingalunganga. Le nkqubo ikwasebenzisa amandla, ukutsala amandla kuphela ngexesha lokusebenza okusebenzayo, kunye nokugcina amandla ngamaxesha okungasebenzi. I-feeder icwangciswe ngokupheleleyo, ivumela uhlengahlengiso olukhawulezayo kumgama wenyathelo kunye nesantya sokubetha, ukucutha amaxesha okuseta xa utshintsha iipunch molds. Ukongezelela, i-internal pneumatic clamping mechanism ikhusela umphezulu we-coil yensimbi kuwo nawuphi na umonakalo onokwenzeka.

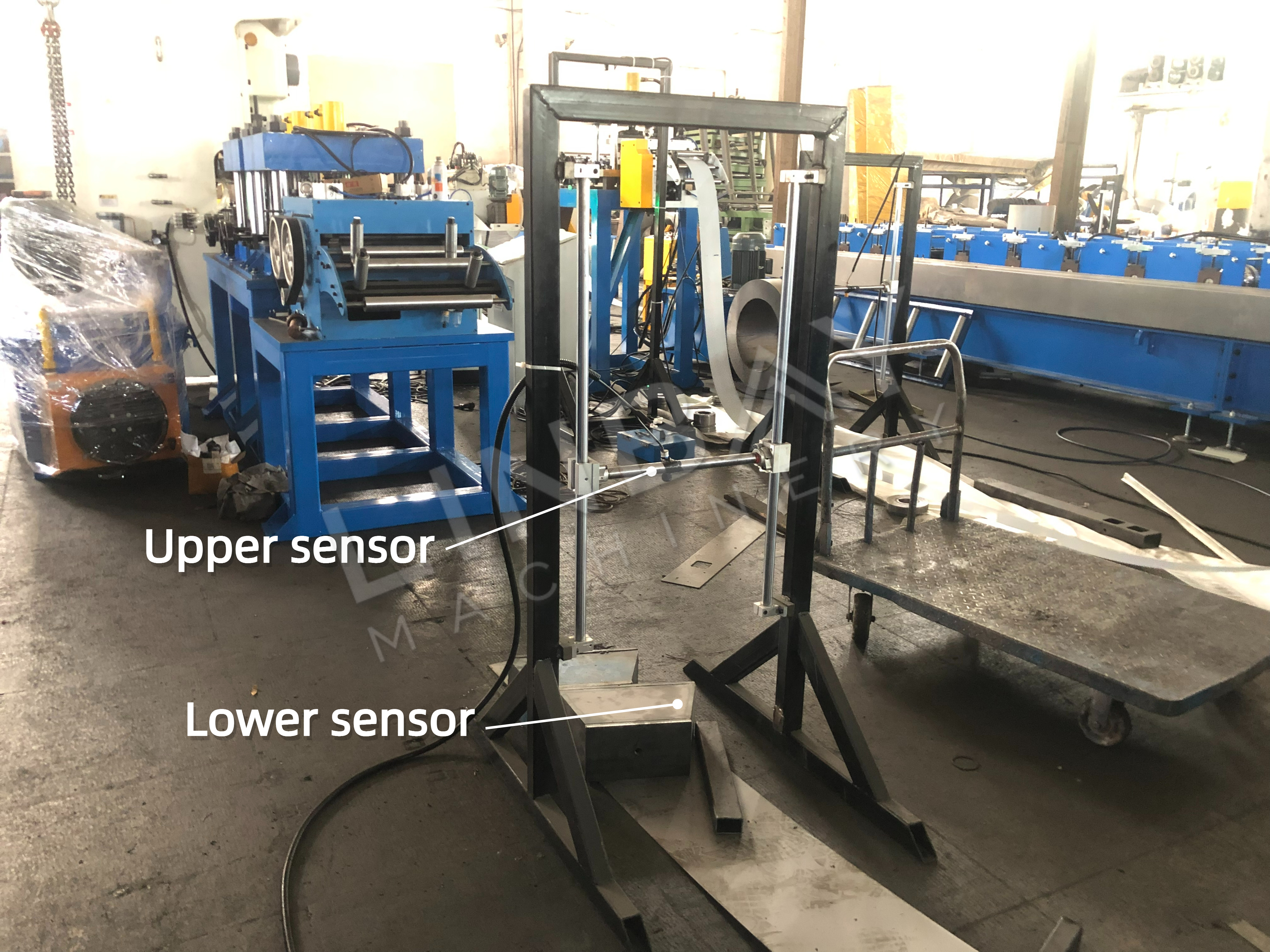

Umda

Ilawula isantya semveliso ukomeleza ukusebenza kakuhle kunye nokugcina ukusebenza okukhuselekileyo kwazo zombini iikhoyili zentsimbi kunye noomatshini. Ukuba i-coil idibana ne-sensor ephantsi, ithetha ukuba ukuchithwa, ukulinganisa, kunye neenkqubo zokubhoboza phambi kwe-limiter zisebenza ngokukhawuleza kunokwakheka okulandelayo, i-welding, kunye nezigaba zokusika. Ezi nkqubo zangaphambili kufuneka zinqumame ukulungelelanisa ukuhamba kwemveliso; ngaphandle koko, i-coil buildup ingenzeka, ithintele ukungena kwayo ngokugudileyo kumatshini wokwenza kwaye kunokubangela ukuguqulwa. Ngakolunye uhlangothi, ukuba i-coil ichukumisa inzwa ephezulu, ibonisa ukuba izigaba zamva zihamba ngokukhawuleza kunezo zangaphambili, zifuna ikhefu kwiinkqubo emva kokunciphisa. Ukungaphumeleli ukwenza oko kunokubangela ukuba ikhoyili itsalwe kumatshini wokwenza umqulu ngokukhawuleza, umngcipheko wokulimala kumatshini wokubhoboza kunye nokwenza iirola. Nakuphi na ukuphumla kuya kubangela isaziso kwi-PLC ehambelanayo nekhabhinethi umboniso, evumela abasebenzi ukuba baphinde baqalise ukusebenza ngokuvuma ukukhawuleza.

Ukukhokela

Injongo ephambili: Iqinisekisa ukuba i-coil yensimbi ihambelana ngokufanelekileyo kunye ne-centerline yomatshini, ukuphepha imiba efana nokujija, ukugoba, i-burrs, kunye nokungachaneki kwe-dimensional kwimveliso egqityiweyo. Iirola ezikhokelayo zibekwe ngokucwangcisekileyo kwindawo yokungena kunye nangaphakathi kumatshini wokwenza. Kubalulekile ukulungelelanisa ezi zixhobo zikhokelayo rhoqo, ngakumbi emva kokuthuthwa okanye ukusetyenziswa ixesha elide lomatshini wokwenza umqulu. Ngaphambi kokuthunyelwa, iqela likaLinbay lilinganisa ububanzi besikhokelo kwaye libandakanya le ngcaciso kwincwadi yomsebenzisi, evumela abathengi ukuba balinganise umatshini ekuhanjisweni.

Umgangatho weSekondari (Seta kwisiseko esifanayo kunye nomatshini wokwenza umqulu)

Ikhoyili egudileyo iqinisekisa ukulungelelaniswa okuphezulu kwe-seam post-forming, enceda kakhulu kwinkqubo ye-welding. Umgangatho wesibini usebenzela ukuqhubela phambili ukuphucula umgangatho wokulinganisa kunye nokunciphisa uxinzelelo kwiindawo ezibethelelweyo. Njengomlinganiselo owongezelelweyo, ukubeka le leveler kwisiseko somatshini wokwenza kunika indlela engabizi kakhulu nefanelekileyo.

Umatshini wokwenza umqulu

· IMveliso eNyenziwe ngezinto ezininzi: Lo mgca unako ukuvelisa iibhubhu zesikwere kunye nemilinganiselo ukusuka kwi-50-100mm ububanzi kunye ne-100-200mm ukuphakama. (ILinbay inokubonelela ngokwenziwa ngokwezifiso kolunye uluhlu lobungakanani.)

· Ukutshintsha ubungakanani obuzenzekelayo: Ngokucwangcisa kunye nokuqinisekisa ubungakanani obufunwayo kwisikrini se-PLC, izikhululo ezenza izikhululo zitshintshe ngokuzenzekelayo ecaleni kwendlela yesikhokelo ukuya kwiindawo ezichanekileyo, zilungelelanise indawo yokubumba ngokufanelekileyo. Oku kuzenzekelayo kwandisa ukuchaneka kunye nokulula, ukunciphisa imfuno yohlengahlengiso lwezandla kunye neendleko ezinxulumene nazo.

· Ukufunyanwa kweMovement yeLateral: I-encoder ilandelela ngokuchanekileyo ukunyakaza kwecala lezikhululo zokwenza kwaye ngokukhawuleza idlulisele le datha kwi-PLC, igcina iimpazamo zokuhamba ngaphakathi kwe-1mm yokunyamezela.

· Izivamvo zoMda woKhuseleko: Izinzwa ezimbini zomda wokhuseleko zibekwe emacaleni angaphandle eendlela zesikhokelo. I-sensor yangaphakathi ikhusela izikhululo zokwenza ukuba zisondele kakhulu kunye, zigweme ukungqubana, ngelixa i-sensor yangaphandle iqinisekisa ukuba ayihambi kakhulu.

· Isakhelo esiqinileyo seCast-iron: Kubandakanya isakhelo esizimeleyo esithe tye esenziwe kwintsimbi etyhidiweyo, esi sakhiwo esiqinileyo sifanelekile kwiimfuno zokuvelisa umthamo ophezulu.

· INkqubo yokuQhuba enamandla: Ibhokisi yegiya kunye nendibaniselwano yendalo yonke ihambisa amandla awomeleleyo, ivumela ukusebenza ngokutyibilikayo xa uqhubela phambili iikhoyili ezityebileyo kune-2mm okanye kwizantya zokwenza ezingaphezulu kwe-20m/min.

· IiRola ezihlala zihleli: I-Chrome-plated kunye ne-heat-treated, ezi ziqengqelezi zixhathisa i-rust kunye ne-corrosion, ziqinisekisa ubomi obude.

· IMotor engundoqo: Ubumbeko oluqhelekileyo luyi-380V, i-50Hz, i-3-isigaba, kunye neenketho zokwenza ngokwezifiso ezikhoyo.

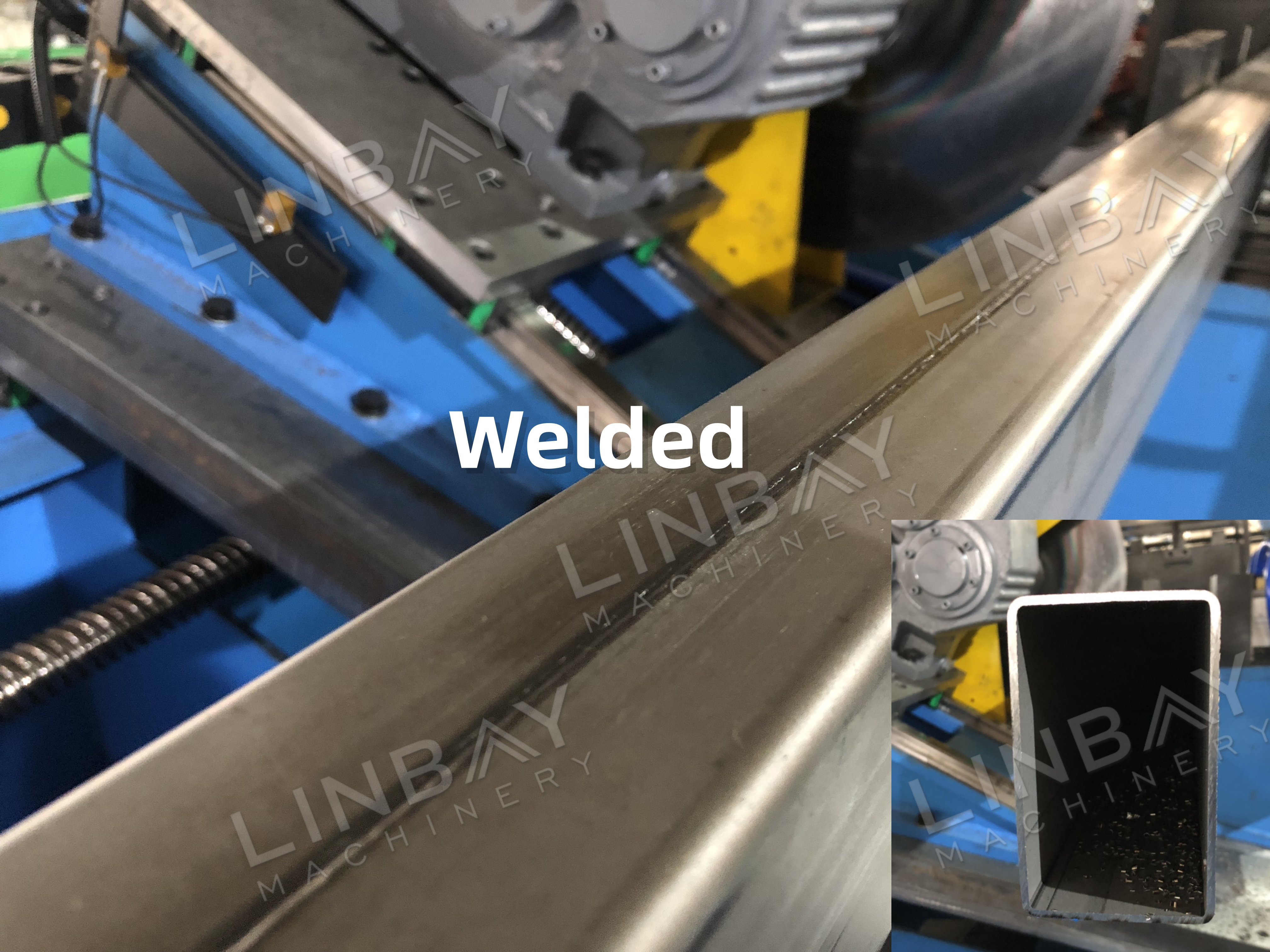

Laser Weld

· Umgangatho ophuculweyo kunye nokuchaneka: Ihambisa ukuchaneka okuphezulu kunye noqhagamshelo olomeleleyo.

· IJoyinti ecocekileyo kunye neGcwecwe: Iqinisekisa ukugqitywa okucocekileyo, okugudileyo kwindawo edibeneyo.

Welding Fume Purifier

• Ukulawula Ivumba kunye noMsi: Ibamba kwaye isuse ngokufanelekileyo ivumba kunye nomsi oveliswa ngexesha le-welding, iqinisekisa indawo ekhuselekileyo yefektri kunye nokukhusela impilo yabasebenzi.

I-Flying Saw Cut

· I-Flying Cut: Iyunithi yokusika idibanisa kunye nesantya somatshini wokwenza umqulu ngexesha lokusebenza, ukunyusa ukuveliswa kwemveliso kunye nemveliso.

· Ukusika okuchanekileyo: Nge-servo motor kunye nomlawuli wentshukumo, iyunithi yokusika igcina ukuchaneka kwe-± 1mm.

· Indlela yokuSarha: Ihambisa iinqunto ezichanekileyo ngaphandle kokuguqula imiphetho yeeprofayile ezivaliweyo.

· Ukusebenza kakuhle kwezinto: Ukusika nganye kuvelisa inkunkuma encinci, ukunciphisa iindleko zezinto eziphathekayo.

·Operation Flexible: Ngokungafaniyo nezinye iindlela zokusika ezifuna ii-blades ezithile zobukhulu obahlukeneyo, ukusika kweesarha kuyaguquguquka, kunika iindleko zokonga kwiiblades.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile