ividiyo

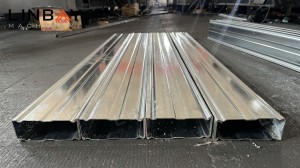

Inkangeleko yesimo

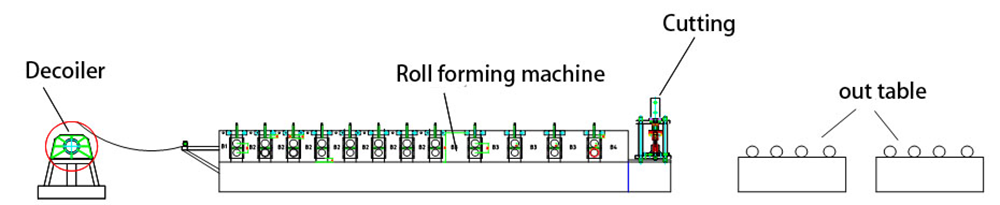

I-Decoiler--Roll yangaphambili--Hydraulic cut--Out table

7.5 Ton Hydraulic Decoiler

Kulo mgca wemveliso, siqesha i-hydraulic decoiler ekwazi ukuphatha imithwalo ukuya kwiitoni ezi-7.5. Ngenxa yemfuneko yeekhoyili zentsimbi ezibanzi ekuveliseni iipaneli zetrapezoidal, inkqubo yokutshintsha ikhoyili ibonakalisa ubungozi obunokubakho kubasebenzi. Ukunciphisa le mingcipheko, amagqabi entsimbi akhuselayo afakwe kwicala langaphandle lekhoyili ukuthintela ukutyibilika ngexesha lokubola,egxininisa ukubaluleka kokhuseleko lwabasebenzikwiingqwalasela zethu zoyilo.

Ukuzikhethelaukulayisha imotoikhona, inceda ekuthuthweni kweekhoyili kwi-decoiler. Esi sixhobo sinceda ukonga ixesha kwaye siphucula ukhuseleko lwabasebenzi, ngakumbi kumazikoukunqongophala kweekhreyini eziphezulu.

Umatshini wokwenza umqulu

Umatshini wokwenza umqulu usebenza njengenxalenye ebalulekileyo kulo mgca wemveliso, uqhayisa izikhululo ezingama-20 ezenza zonke. Isebenzisa isakhiwo sepaneli yodonga kunye nenkqubo yokuqhuba ikhonkco. Iirola eziqulunqayo, ezenziwe ngobuchule ukusukaGcr15, intsimbi ephezulu yekhabhoni yechromium, inikezelaubulukhuni obukhethekileyo kunye nokumelana nokunxiba. I-Chrome plating kumphezulu we-roller yandisa ubomi bayo, ngelixa i-shafts yakhiwe ngokuphathwa ngobushushu.40Crimpahla.

Izigqubuthelo ezikhuselayo kwikhonkco zikhusela ukwakhiwa kothuli okanye amaqhekeza ekonakaliseni amatyathanga, ngaloo ndlela eqinisekisa ukhuseleko lwabasebenzi. Umatshini wokwenza umqulu uyahambaukuvavanya usebenzisa iikhoyili zentsimbi kunye namandla afanayo esivunonjengezo zisetyenziselwa imveliso yabathengi, ukuququzelela imveliso efanelekileyo ekuhanjisweni.

I-Hydraulic Cut & Encoder

Umatshini wokwenza umqulu udibanisa i-encoder ye-Koyo evela eJapan, eguqula ubude bekhoyili yentsimbi evakeleyo ibe ziimpawu zombane ezithunyelwa kwikhabhathi yolawulo ye-PLC. Le nkqubo ichanekileyo yenzaumatshini wokusika ukugcina iimpazamo zokusika ngaphakathi kokunyamezela kwe-1mm, ukuqinisekisa umgangatho ophezulu wemveliso kunye nokunciphisa inkunkuma ekusikeni okungalunganga. Ixhaswe sisikhululo se-hydraulic, umatshini wokusika we-hydraulic uhambisa amandla okusika anamandla.Inkqubo yayo yokusika ayivezi nkunkuma, ishiya imiphetho egudileyo ngaphandle kwee-burrs.Sivavanya ngokucokisekileyo umatshini wokwenza umqulu de uvelise iprofayile ehambelana nomzobo, emva koko senza iimold blade ezisekelwe kwisampuli. Ngelixa le ndlela inokunyusa kancinci ixesha kunye neendleko zabasebenzi, umatshini wokusika onesiphumo ubonisa imiphetho egudileyo ngaphandle kwee-burrs.

Isitishi seHydraulic

Ixhotyiswe ngeefeni zombane zokupholisa, isikhululo sethu se-hydraulic siqinisekisa ukuchithwa kobushushu ngokufanelekileyo, sivumela ukusebenza okuqhubekayo kunye nokupholileyo, ngaloo ndlela siphucula ukusebenza kakuhle. Ngezinga eliphantsi lokungaphumeleli kunye nokuqina kwexesha elide, isikhululo sethu se-hydraulic sithembekile kwaye sakhelwe ukuhlala.

Ikhabhinethi yokulawula ye-PLC

Abasebenzi banamandla okulawula isantya semveliso, ukulungelelanisa imilinganiselo yemveliso, ukusika ubude, kunye nokunye ngesikrini se-PLC. Ikhabhinethi yolawulo ye-PLC ixhotyiswe ngeimisebenzi yokukhuselakubandakanywa ukugqithiswa, isiphaluka esifutshane, kunye nokukhusela ilahleko yesigaba. Ukongeza, ulwimi oluboniswe kwisikrini se-PLCingenziwa ngokwezifiso ukuhlangabezana neemfuno ezithile zabathengi, ukulungiselela ulwimi olunye okanye ezininzi njengoko kufuneka.

Itheyibhile ephuma rhoqo kunye noKhenketho: Isitaki esizenzekelayo

Le phaneli yetrapezoidal yinto eqhelekileyo yokuphahla kunye nezinto ezigqumayo ezisetyenziswa ngokubanzi eRomania kuzo zonke izicelo ezinje ngemizi mveliso kunye neeprojekthi zokwakha, iindawo zokugcina ezincinci, iishedi, kunye nezibonelelo zolimo.

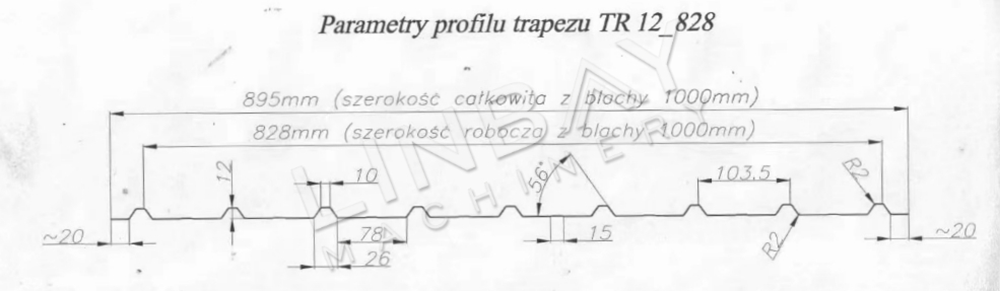

Yenziwe ngenkqubo yokwenza umqulu obandayo, le phaneli inobubanzi obupheleleyo be-895mm, ububanzi bekhava ye-828mm, kwaye ibonisa ukuphakama kwamaza e-12mm, kunye nobubanzi obuphezulu kunye nobubanzi be-wave ye-10mm kunye ne-26mm ngokulandelanayo. Ukuphakama kwamaza kumalunga ne-78mm. Ifumaneka kubukhulu obususela kwi-0.3mm ukuya kwi-0.6mm kwaye inokuveliswa ngokusebenzisa intsimbi, intsimbi ye-aluminium, okanye iikhoyili zetsimbi ezinombala. Intsimbi yeGalvalume ithandwa kakhulu ngenxa yeempawu zayo eziphezulu zokuchasa umhlwa xa kuthelekiswa nentsimbi ekhandiweyo.

Inkcazo

Itshathi equkuqelayo

Aitafile esemgangathweniibonelelwa kuthutho lwemveliso, inikezela aabangenamandlaisisombululo esinokuthi silungiselelwe ubude kunye nobubanzi ukuhlangabezana neemfuno ezithile zabathengi.

Kubaiiphaneli zetrapezoidal ezingaphezu kweemitha ezi-6 ubude, sicebisa ukuba usebenzise istacker autoukunciphisa iindleko zomsebenzi wezandla kunye nokuphucula ukusebenza kakuhle kunye nokhuseleko lomsebenzi. Ukulandela ukusika, iipaneli zetrapezoidal zigqithiselwa kwingalo yokujingi ye-stacker, apho zikhoyo.yalekwe ngononophelo. Emva koko, iipaneli zihanjiswa ngaphandle kunye ne-conveyor.

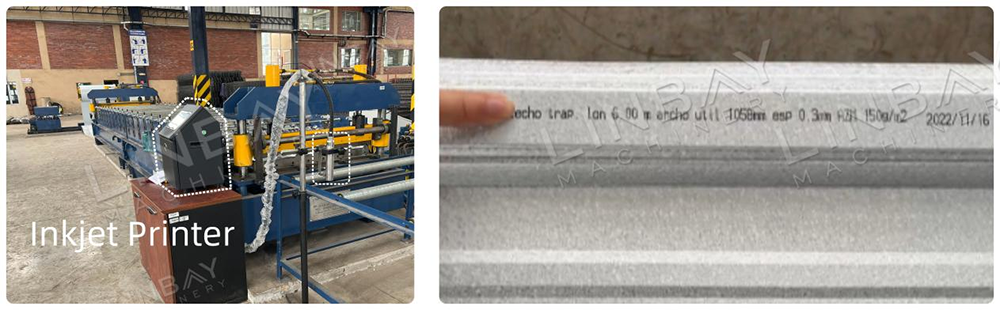

Olunye ukhetho: Umshicileli we-inki

Abathengi banokhetho lokusebenzisa umshicileli we-inkishicilela amagama enkampani, iilogo, amanani eprofayile, kunye nolunye ulwazi olubalulekileyo kumphezulu wephaneli.Oku kuququzelela ukwanda ngokukhawuleza kwemarike kunye nokwanda kokubonakala kweenkampani. Ii-inki yoma ngokukhawuleza kwaye ayifaki ingozi yokungcolisa umphezulu.

Iwaranti

Ngaphambi kokunikezelwa, umhla wokuhanjiswa uboniswa kwi-nameplate, ukuqalaisiqinisekiso seminyaka emibini kuwo wonke umgca wemveliso kunye newaranti yeminyaka emihlanu ye-roller kunye ne-shafts.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile