Inkangeleko yesimo

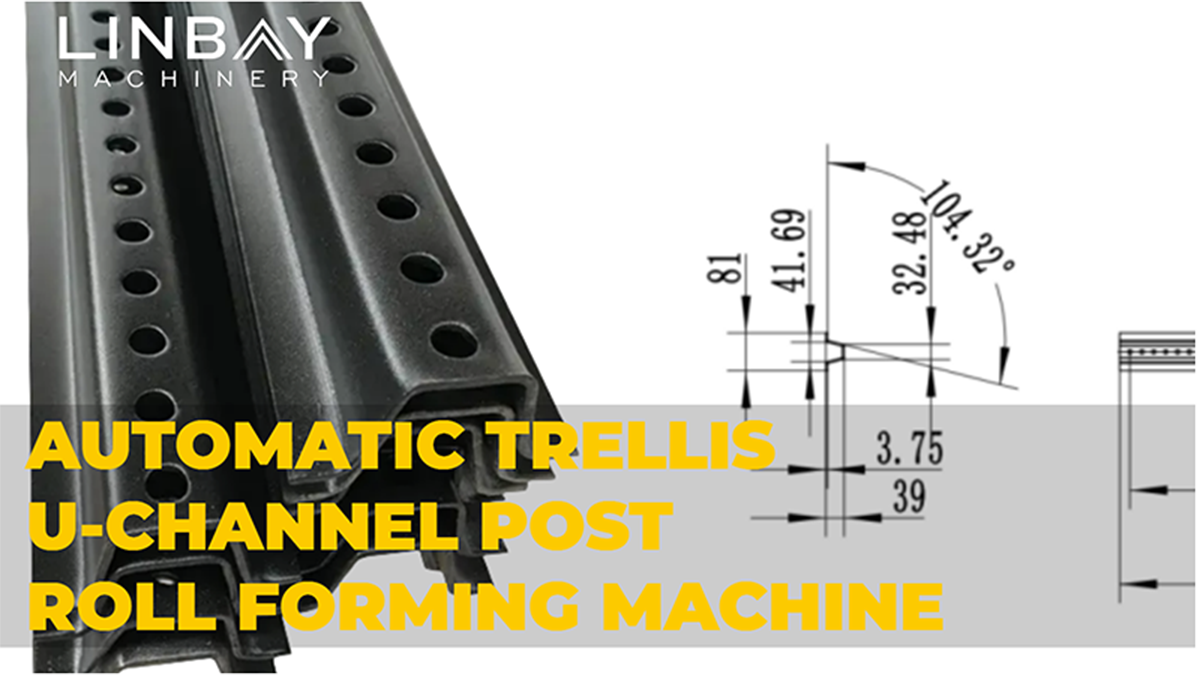

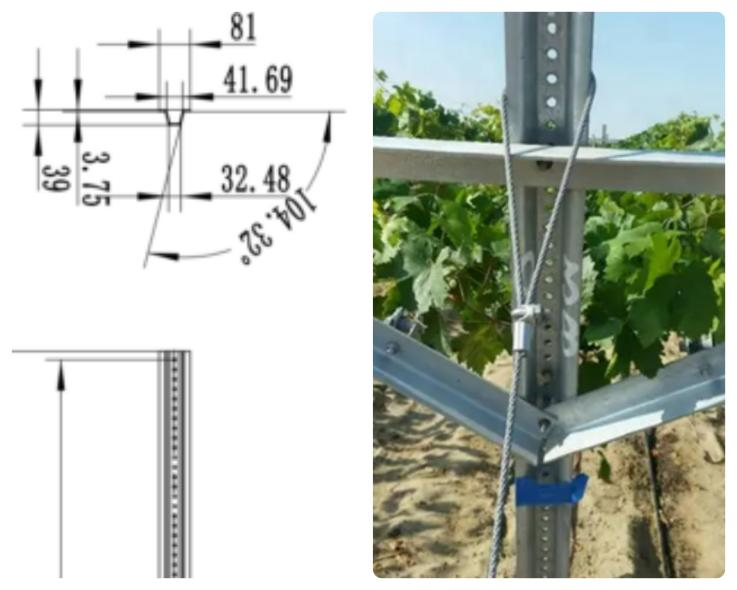

Isithuba seTrellis U-channel yipali yocingo emile okweminqwazi edla ngokusetyenziswa kwicandelo lezolimo, ingakumbi kwiitrellis zeediliya, iifreyimu zama-apile, nezinye izinto ezifanayo. Ibonisa ububanzi obuphezulu be-32.48mm, ububanzi obungaphantsi kwe-41.69mm, kunye nobubanzi obuyi-81mm, kunye nobude be-39mm. Isithuba ngasinye silinganisa i-2473.2mm ubude kwaye sixhotyiswe nge-107 esondelene ngokusondeleyo, imingxuma eqhubekayo ye-9mm ububanzi, evumela ukufakwa okuguquguqukayo kwezibiyeli kwiisayizi ezahlukeneyo.

Inkcazo

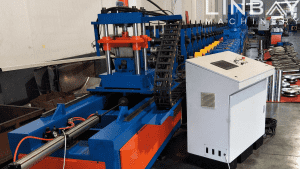

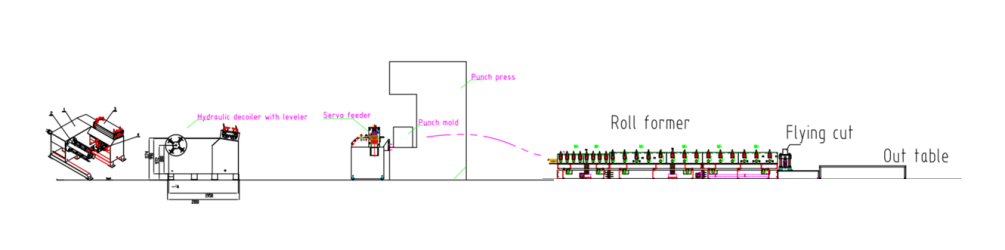

Itshathi equkuqelayo

I-Decoiler ene-level--Servo feeder--Punch press-Rola ngaphambili--Flying cut--out table

I-Decoiler ene-Level

Lo matshini udibanisa ukucima kunye nokusebenza komgangatho. I-decoiler yayo inesixhobo sokuqhawula ukulungelelanisa ukunyanzeliswa kwe-roller decoiling, iqinisekisa ukusebenza kakuhle. Amagqabi okukhusela isinyithi akhusela ukutyibilika kwekhoyili ngexesha lokuqhawula, ukwandisa ukhuseleko kunye nokusebenza kakuhle kweendleko ngelixa ugcina indawo yomgangatho womgangatho wokuvelisa.

Ukulandela i-decoiling, i-coil yensimbi iqhubela phambili kumatshini wokulinganisa. Xa kujongwe ubukhulu bekhoyili (2.7-3.2mm) kunye nokungqinwa kwekhoyili, i-level ibalulekile ekupheliseni ukugobeka kwekhoyili, kuphuculwe ukucaba kunye nokuhambelana. Umatshini wokulinganisa uxhotyiswe ngeeroli ezi-3 eziphezulu kunye ne-4 ezisezantsi zokulinganisa ukusebenza kakuhle.

I-Servo Feeder kunye ne-Punch Press

Ukwenzela le njongo, siqesha umatshini wokushicilela we-110-toni owenziwe luhlobo lweYangli, udityaniswa ne-servo feeder. I-servo motor yenza impendulo ekhawulezayo kunye nenkcitho encinci yokuyeka ukuqalisa, iqinisekisa ulawulo oluchanekileyo lwendawo. Ngobukho behlabathi bukaYangli kunye nokuzibophelela kwinkonzo ekumgangatho ophezulu emva kokuthengisa, abathengi banokulindela inkxaso ethembekileyo. Iimolds ezenziwe ngokwezifiso zilungiselelwe ngokusekelwe kwimizobo ebonelelwe ngabathengi, ngokufanelekileyo ukudala imingxuma ye-9mm ububanzi. I-punching iyafa, eyakhiwe ngentsimbi ye-SKD-11, inika ukuxhathisa okungaqhelekanga kunye nokuqina.

Kwinkqubo yokulawula ye-PLC, silungelelanisa igalelo lokubethelwa kwedatha ngokulawula ubuninzi bemingxuma yokubhoboza. Ukongezelela, umsebenzi wememori yeparameter unikezelwa ukugcina iiseti ezili-10 zeeparitha zokubetha, ezilungiselelwe iimfuno zokuvelisa. Olu phawu luvumela ukufunyanwa lula kunye nokusetyenziswa kweeparamitha ezigciniweyo ngaphandle kwesidingo sokufakwa kwakhona.

Umda

Ukulungelelanisa isantya semveliso, isithinteli sibekwe phakathi kwamacandelo okubhoboza kunye nomqulu. Xa i-coil yensimbi iqhagamshelana nomlinganiselo ophantsi, ibonakalisa isantya sokubhoboza esidlula isantya sokwenza umqulu, umatshini wokubhoboza ufumana uphawu lokuyeka. I-prompt ivela kwisikrini se-PLC, ikhuthaza ukuba umqhubi aqalise umsebenzi ngokucofa isikrini.

Ngokuchasene noko, ukuba i-coil yensimbi ichukumisa umda ophezulu, iphakamisa isantya sokwenza umqulu odlula isantya sokubetha, umatshini wokwenza umqulu uyamisa ukusebenza. Ngelixa umatshini wokwenza umqulu uqalisa kwakhona umsebenzi, umatshini wokubetha uyaqhubeka nokusebenza kwawo ngaphandle kokuphazamiseka.

Olu cwangciso luqinisekisa ukulungelelaniswa ngokubanzi kunye nokufana kwesantya semveliso kumgca wemveliso.

Ukukhokela

Ngaphambi kokungena kwisethi yokuqala yokwenza i-rollers, i-coil yensimbi iqondiswe kwicandelo lesikhokelo usebenzisa i-roller ekhokelayo. Ezi rollers ziqinisekisa ukulungelelaniswa phakathi kwekhoyili kunye ne-centerline yomatshini, ukuthintela ukuphazamiseka kweeprofayili ezenziwe. Iirola ezikhokelayo zibekwe ngobuchule kunye nomgca wokwenza yonke into. Imilinganiselo esuka kwi-roller ekhokelayo ukuya emphethweni ibhalwe kwincwadana yemigaqo, iququzelela ukubuyisela ngaphandle komgudu ukuba ukufuduka okuncinci kwenzeka ngexesha lokuthutha okanye ukulungiswa kwemveliso.

Umatshini wokwenza umqulu

Embindini womgca wemveliso kukho umatshini wokwenza umqulu, icandelo elibalulekileyo eliquka izikhululo eziyi-10. Iqhayisa ngolwakhiwo olomeleleyo lwentsimbi kunye nenkqubo yokuqhuba yebhokisi yegiya, ifikelela kwisantya esoyikekayo sokuya kuthi ga kwi-15m/min. Eyenziwe ngentsimbi ye-Cr12 ephezulu ye-carbon chromium-ethwele, i-roller eyenza i-roller igqwesa ngobunzima kunye nokumelana nokunxiba. Ukwandisa ubomi babo, ii-roller zihamba nge-chrome plating, ngelixa i-shafts yakhiwe ukusuka kwi-40Cr impahla.

IKhowuda yeLaser ephaphazelayo (Ngokhetho)

Ngaphambi kwenkqubo yokusika, i-coder ye-laser yokuzikhethela ingafakwa, ivumelaniswe nesantya somatshini wokusika ngaphandle kokuphazamisa ukusebenza okuqhubekayo komatshini wokwenza umqulu. Le nkqubo iphucukileyo ixhotyiswe ngescreen esichukumisayo, amehlo okwazisa, kunye nesibiyeli sokuphakamisa. Iququzelela ushicilelo lwelaser yezinto ezahlukeneyo ezinje ngokubhaliweyo, imizobo, iikhowudi zeQR, nokunye. Oku kuzenzekelayo kunceda ekulinganiseni iimveliso, ukulawula imveliso, kunye nokukhuthaza uphawu ngokufanelekileyo.

I-Flying Hydraulic Cutting & Encoder

Ngaphakathi kumatshini wokwenza, i-encoder ye-Koyo evela eJapan iguqula ubude obufunyenweyo bekhoyili yensimbi ibe ngumqondiso wombane, othi ke udluliselwe kwikhabhinethi yokulawula ye-PLC. Oku kuvumela ulawulo oluchanekileyo lweempazamo zokusika, ukuqinisekisa umgangatho wemveliso ngaphakathi komda we-1mm kunye nokunciphisa inkunkuma. Iimbumba zokusika zenzelwe ngokukodwa ukuhambelana neprofayili, ziqinisekisa ukusikwa okugudileyo, okungahambi kakuhle ngaphandle kwe-deformation. Igama elithi "flying" libonisa ukuba umatshini wokusika unokuhamba ngesantya esifanayo nenkqubo yokwenza umqulu, okwenza kube lula ukusebenza kunye nokunyusa ukusebenza kakuhle kwemveliso.

Isitishi seHydraulic

Isikhululo se-hydraulic sixhotyiswe ngeefeni ezidibeneyo zokupholisa ukuze zichithe ngokufanelekileyo ubushushu, ziqinisekisa ukusebenza okuqhubekayo kunye nokuphila ixesha elide. Eyaziwayo ngesantya esisezantsi sokungaphumeleli, isikhululo se-hydraulic senzelwe ukuqina okwandisiweyo.

Ikhabhinethi yokulawula ye-PLC

Ngesikrini se-PLC, abaqhubi banamandla okulawula isantya semveliso, ukuchaza imilinganiselo yemveliso, ukusika ubude, kunye nokunye. Iimpawu zokhuseleko ezibandakanyiweyo kwikhabhinethi yolawulo ye-PLC ibandakanya ukhuseleko ngokuchasene nokugcwala, isekethe emfutshane, kunye nokulahleka kwesigaba. Ngaphaya koko, ulwimi oluboniswe kwisikrini se-PLC lunokulungiswa ukuze luhambelane nezinto ezikhethwa ngabathengi.

Iwaranti

Umgca wemveliso unikezwa iwaranti yeminyaka emibini ukusuka kumhla wokuhanjiswa, oboniswe kwi-nameplate. Iirola kunye neeshafti zifumana iwaranti yeminyaka emihlanu.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile