ividiyo

Inkangeleko yesimo

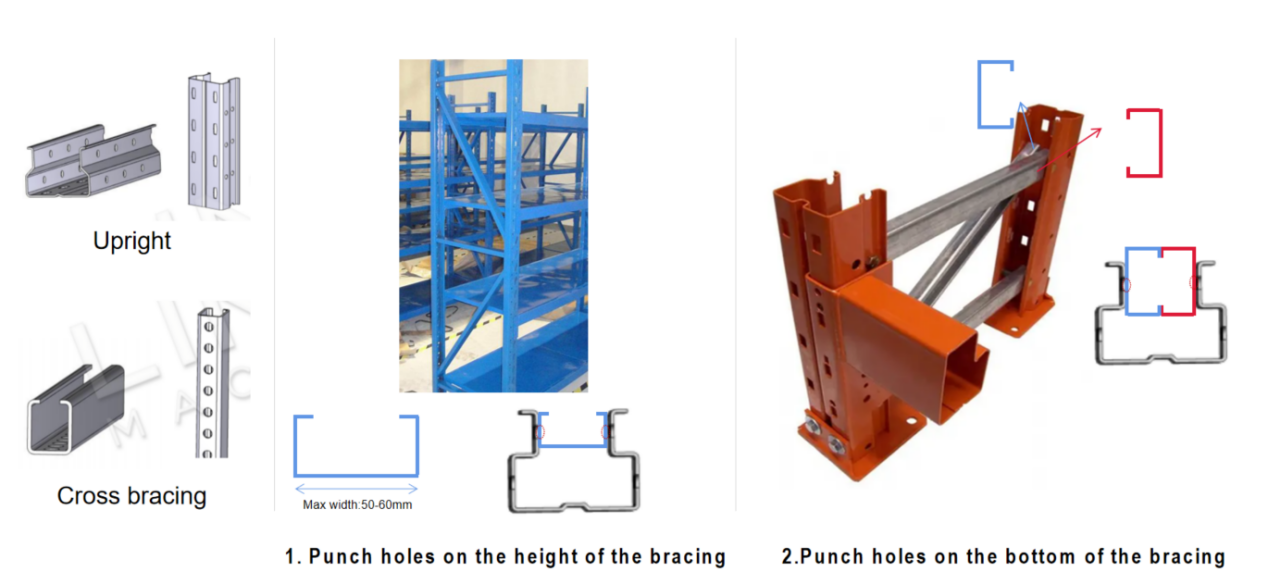

I-cross bracing idlala indima ebalulekileyo kwiinkqubo zokubeka iishelufu, ukuqinisa ubume beshelufu ngokubanzi. Ibekwe ngaphakathi kwirekhi ime nkqo, inika inkxaso eyongezelelweyo. Ngokuxhomekeke kwindlela yokufakela ekhethiweyo, imingxuma yoqhagamshelo ibekwe ngobuchule ukuze incamathele ngokukhuselekileyo.

*Ufakelo lweNdlela yoku-1: I-brace enye ifakwe ngaphakathi kwi-rack ethe tye, efuna imingxuma efakwe ngaphambili ekuphakameni kwe-bracing yofakelo lwe-screw.

*Ufakelo lweNdlela yesi-2: Iibracing ezimbini zifakwe ngaphakathi kwi-rack ethe tye, ekwafuna imingxuma efakwe ngaphambili ezantsi kwe-bracing yokufakela isikrufu.

Kule meko, sasebenzisa indlela yokufakela i-1. Siphinde sinikeze isisombululo esilungelelanisiweyo esivumela ukubethelwa ngaxeshanye phantsi kunye namacala aphakamileyo okubhobhoza ukunyusa ukuguquguquka.

Inkcazo

Itshathi equkuqelayo

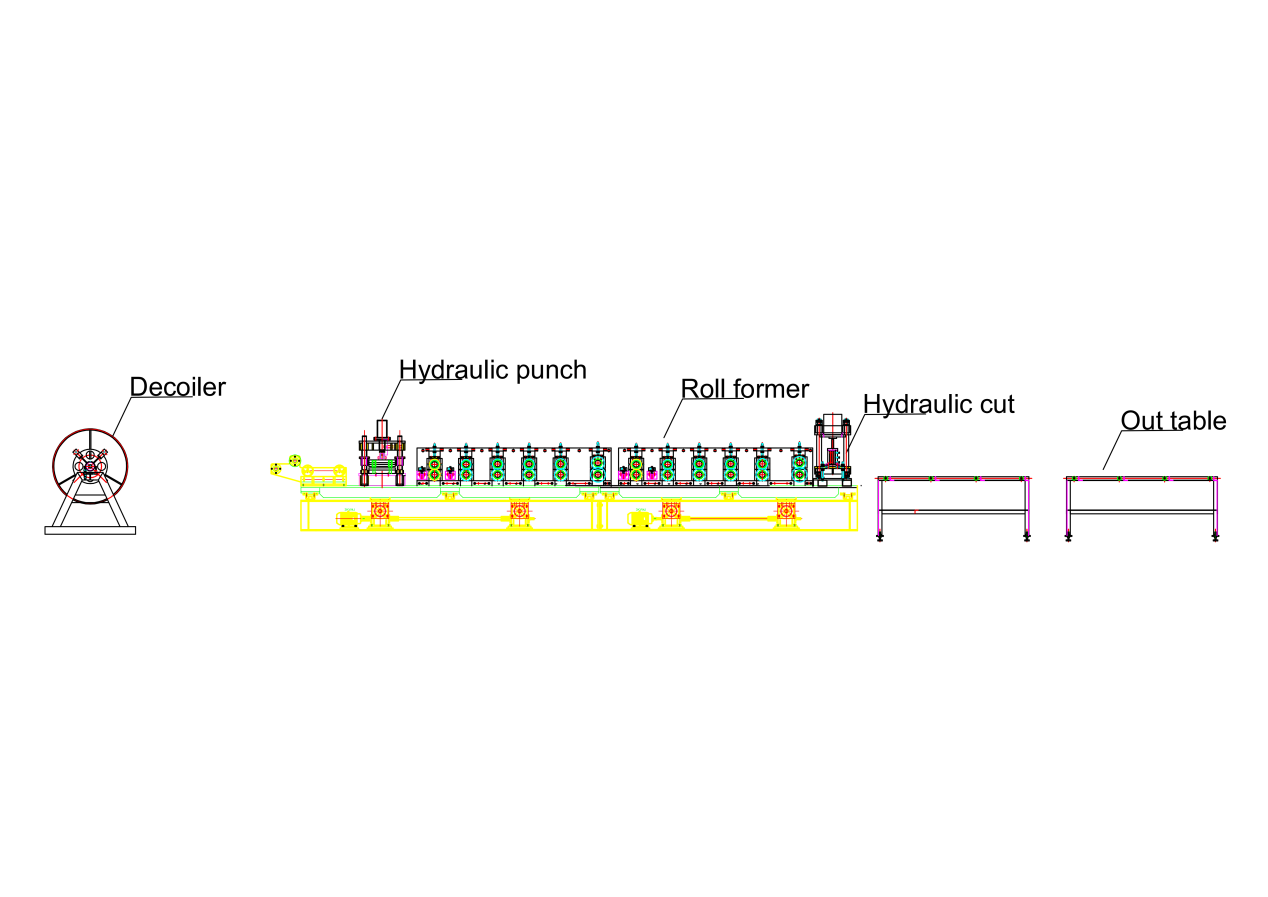

I-Decoiler--Isikhokelo--Leveler--Hydraulic punch--Roll forming machine--Hydraulic cut--Out table

I-Decoiler

I-decoiler ixhotywe ngengalo yokushicilela ukuze ikhusele ngokuqinileyo i-coil yensimbi ngexesha lokutshintshwa, ukunciphisa umngcipheko wokukhululwa ngokukhawuleza kunye nokulimala okunokwenzeka kubasebenzi. Ikwanayo nesixhobo sokuqhawuka esilawula ukunyanzeliswa kweerola zokutya, ukuqinisekisa isantya esingagungqiyo sokukhulula. Ngaphezu koko, iintsimbi ezikhuselayo zetsimbi zifakwe ukukhusela i-coil yensimbi ukuba ingabikho ngexesha lokuchithwa kwenkqubo, ukuphucula kokubili ukhuseleko kunye nokusebenza kakuhle kweendleko.

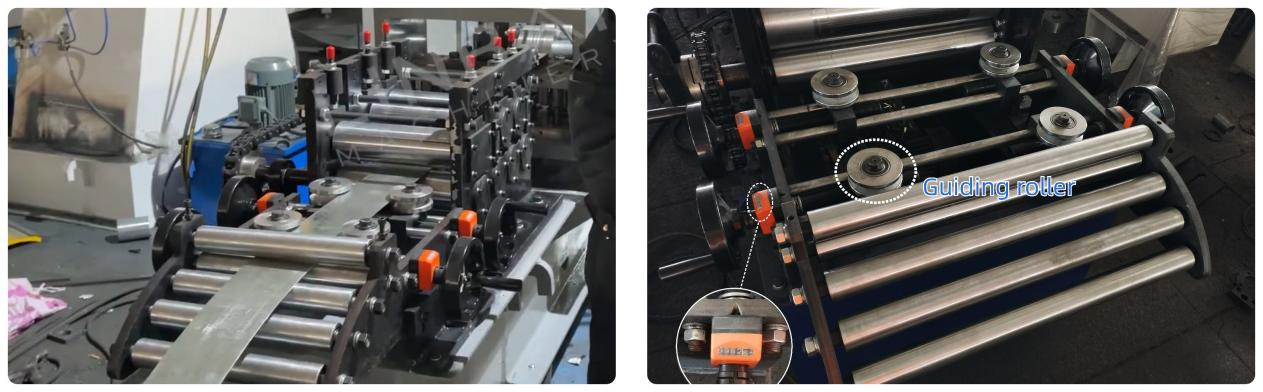

Ukukhokela

Iirola ezikhokelayo zidlala indima ebalulekileyo ekuqinisekiseni ulungelelwaniso phakathi kwekhoyili yentsimbi kunye nomatshini, ukuzigcina ecaleni kwendlela efanayo yokuthintela ukuphazamiseka kweeprofayili ezenziweyo. Ezi rollers zibekwe ngokucwangcisekileyo kungekhona kwindawo yokungena kuphela kodwa nakuwo wonke umgca wokwenza. Imigama ukusuka kwi-roller ekhokelayo ukuya kumda ibhalwe ngokucokisekileyo kwincwadana yemigaqo, eyenza abasebenzi benze izilungiso ezichanekileyo ngokusekelwe kwidatha enikeziweyo. Oku kuqinisekisa ulungelelwaniso oluchanekileyo, nokuba ukufuduswa okuncinci kwenzeka ngexesha lothutho okanye uhlengahlengiso lwemveliso olwenziwe ngabasebenzi.

Umgangatho

Umatshini wokulinganisa udlala indima ebalulekileyo ekuphuculeni i-flatness kunye ne-parallelism ye-coil yensimbi, ukuqinisekisa iziphumo eziphezulu zemveliso. Idityaniswe kumatshini wokwenza umqulu, iquka iiroli ezi-2 zomgangatho ophezulu kunye ne-3 ye-roller leveling rollers. Kungenjalo, abathengi abafuna isantya esiphezulu banokukhetha umatshini wokulinganisa ozimeleyo, nangona unomgca wemveliso omkhudlwana.

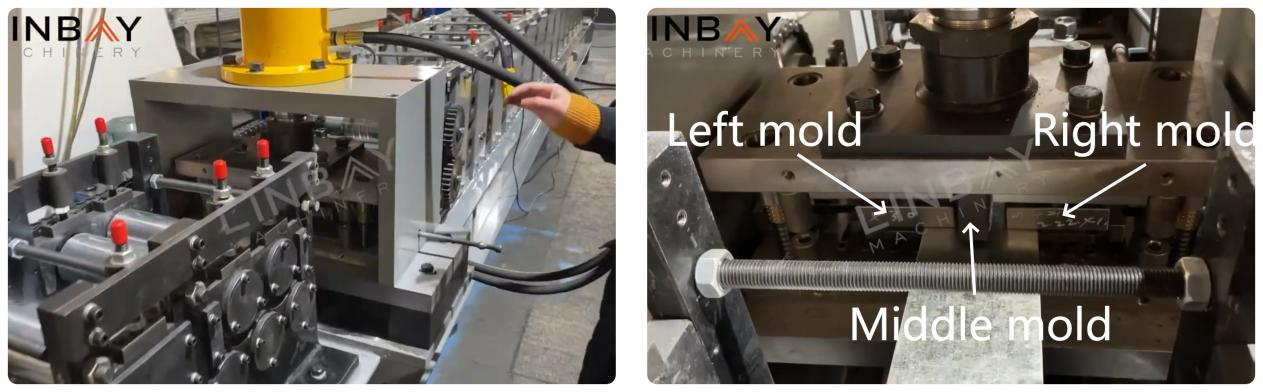

I-Hydraulic Punch

Umatshini we-hydraulic punch, onikwa amandla sisikhululo samanzi, usebenzisa ukubumba okusekhohlo nasekunenegqobhoza imingxuma ngokuchanekileyo kumgca osembindini wamacala okuphakama emva kokwenza. Ukulandela ukusika, kukho imingxunya emibini kwisiphelo ngasinye somnqamlezo wokufaka isikrufu. Ukongeza, umngundo ophakathi kwipunch yehydraulic unakoprinta ilogo yomthengikwi-coil yensimbi ngaphandle kokungena, ukuququzelela ukukhuthazwa kwe-brand kunye nokwandiswa kweemarike.

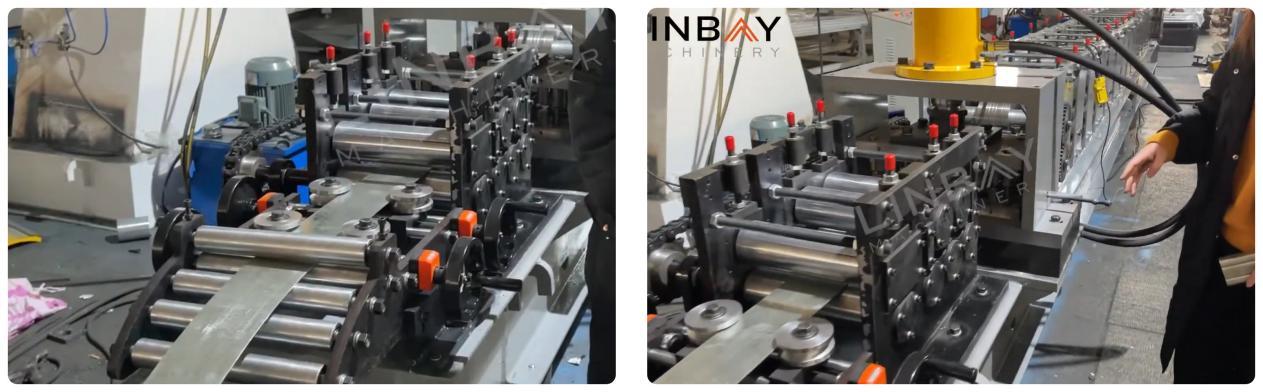

Umatshini wokwenza umqulu

Umatshini wokwenza umqulu, oquka aUlwakhiwo lwepaneli yodonga kunye nenkqubo yokuqhuba ikhonkco, idlala indima ebalulekileyo kumgca wemveliso. Ilungiselelwe abathengi abasebenzisa450MPaisivuno amandla iikhoyili zentsimbi, iqulatheIzikhululo ezingama-22 ezenza. Ukuqinisekisa ukulungelelaniswa kwemveliso ngokukhawuleza ekuhanjisweni, umatshini wokwenza umqulu uvavanywa usebenzisa iikhoyili zetsimbingamandla esivuno esifanayo (450MPa)njengazo zisetyenziswa kwimveliso yabathengi.

Iirola eziqulunqayo zenziwe ukusukaGcr15, intsimbi enekhabhoni ephezulu yechromium edume ngobulukhuni bayo obukhethekileyo kunye nokumelana nokunxiba. I-Chrome plating kumphezulu we-roller yandisa ubomi bayo, incediswa ngeeshafti ezenziwe ngobushushu.40Crimpahla.

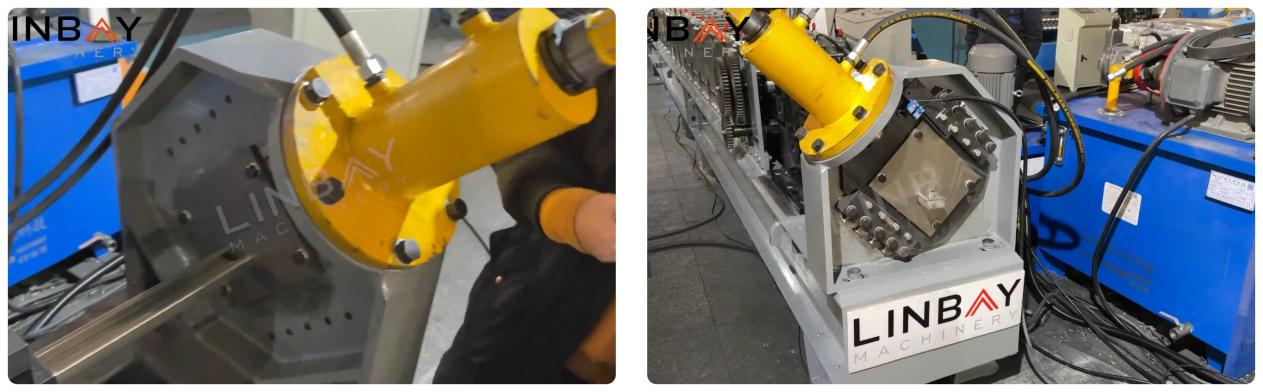

Ukusika kweHydraulic & Encoder

Ukudityaniswa kwe-encoder yaseJapan ye-Koyo ivumela ukuguqulwa kobude be-coil yensimbi evakalelwa kwimiqondiso yombane, idluliselwe kwikhabhinethi yokulawula ye-PLC. Le nkqubo ichanekileyo iqinisekisaukuchaneka kokusika ngaphakathi kwe-1mm,ngokwenza njalo kuqinisekisa iimveliso ezikumgangatho ophezulu ngeli lixa ucutha inkunkuma ebangelwa kukunqunyulwa okungalunganga.

Isitishi seHydraulic

Isikhululo se-hydraulic sixhotyiswe ngefeni yokupholisa ukutshatyalaliswa kobushushu ngokufanelekileyo, ukuqinisekisa ukusebenza kwexesha elide, eliphantsi kunye nokuqina.

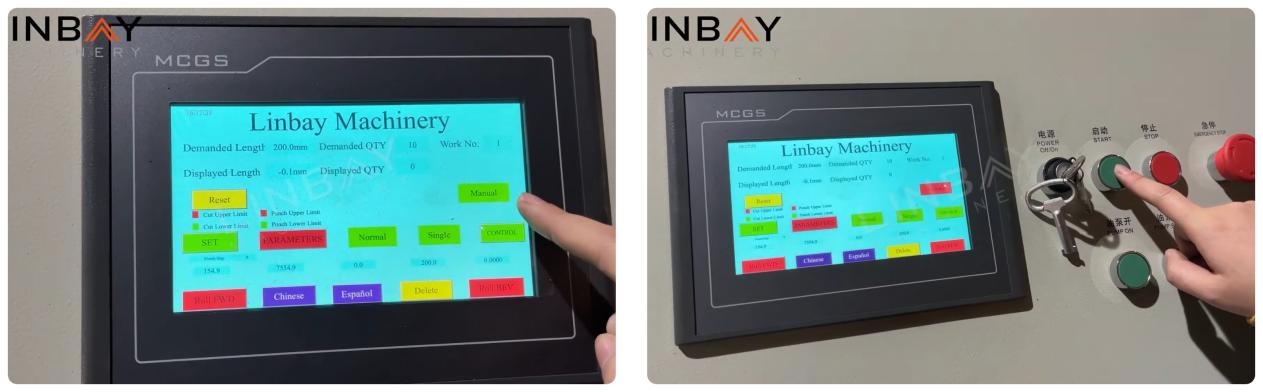

IKhabhinethi yoLawulo lwePLC

Abaqhubi banamandla okulawula isantya semveliso, ukuseka imilinganiselo yemveliso, kunye nokumisela ubude bokusika ngesikrini se-PLC. Ikhabhinethi yokulawula ye-PLC ixhotyiswe ngeempawu zokukhusela ezifana nokugqithiswa, isiphaluka esifutshane, kunye nokukhusela ilahleko yesigaba. Ukongeza, ulwimi oluboniswe kwisikrini se-PLCinokwenziwa ngokweelwimi ezithile okanye iilwimi ezininziukuhlangabezana nezinto ezikhethwa ngumthengi.

Iwaranti

Umhla wokuhanjiswa ubonisiwe kwi-nameplate, ukuqalaisiqinisekiso seminyaka emibini yomgca wemveliso wonke kunye newaranti yeminyaka emihlanu yeerola kunye neeshafti.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile