ividiyo

Inkangeleko yesimo

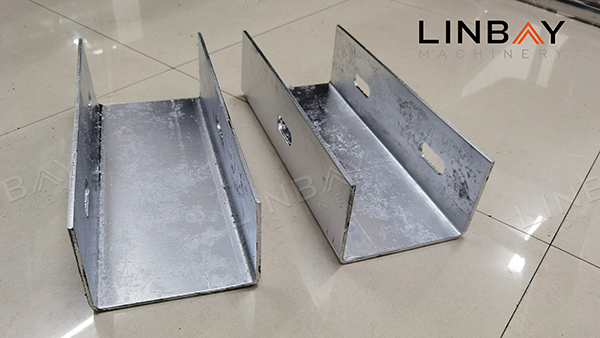

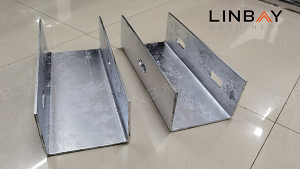

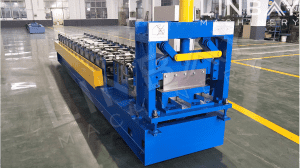

Iiprofayili eziveliswe kulo mgca wemveliso zizonke kwiifom ze-U, ngokukodwa i-U post kunye ne-spacer block ngaphakathi kwenkqubo yokulinda. Ibhloko yesikhenkcezisi isebenza njengebhloko yokumelana ebekwe phakathi kweposti kunye nomqadi wesitrayile, enikezela ngempembelelo phezu kwempembelelo.

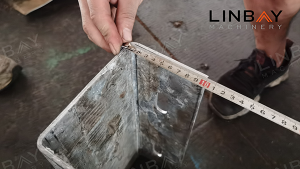

Ngokuqhelekileyo, izithuba ze-U kunye neebhloko ze-spacer zenziwe nge-5mm yentsimbi epholileyo okanye eshushu-eshushu, kunye ne-punching yemingxuma eyenziwa ngaphambi kwenkqubo yokwenza. Le mingxuma ilungiselelwe iinjongo zokufakela isikrufu kunye namantongomane.

Ityala lokwenyani-Iiparamitha zoBuchule eziPhambili

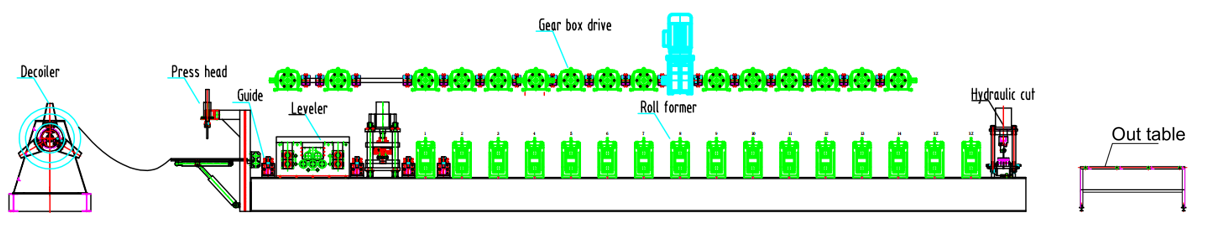

Itshathi equkuqelayo

5I-T Hydraulic decoiler--Isikhokelo--Umgangatho--Amanzipunch--Roll forming machine--Hydraulic cut--Out table

IiParameters ezingundoqo zobuGcisa:

1. Isantya somgca: Ukulungelelaniswa ukusuka kwi-0 ukuya kwi-6m / min

2. Iiprofayili: I-post channel kunye ne-Spacer

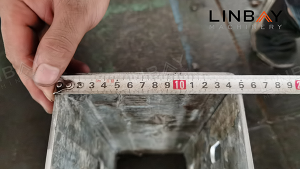

3. Ubukhulu beMaterial: 5mm (kolu setyenziso)

4. Izinto ezifanelekileyo: Intsimbi eshushu, intsimbi epholileyo

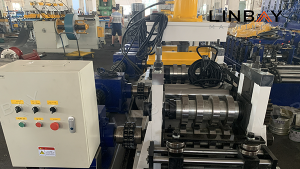

5. Umatshini wokwenza i-Roll: Isakhiwo se-Cast-iron kunye nenkqubo yokuqhuba i-gearbox

6. Inani lezikhululo ezenzayo: 16

7. Inkqubo yokugqobhoza: Hydraulic; qengqeleka iindawo zokumisa ngaphambili ngexesha lokubetha

8. Inkqubo yokusika: Hydraulic; roll yangaphambili yokumisa ngexesha lokusika

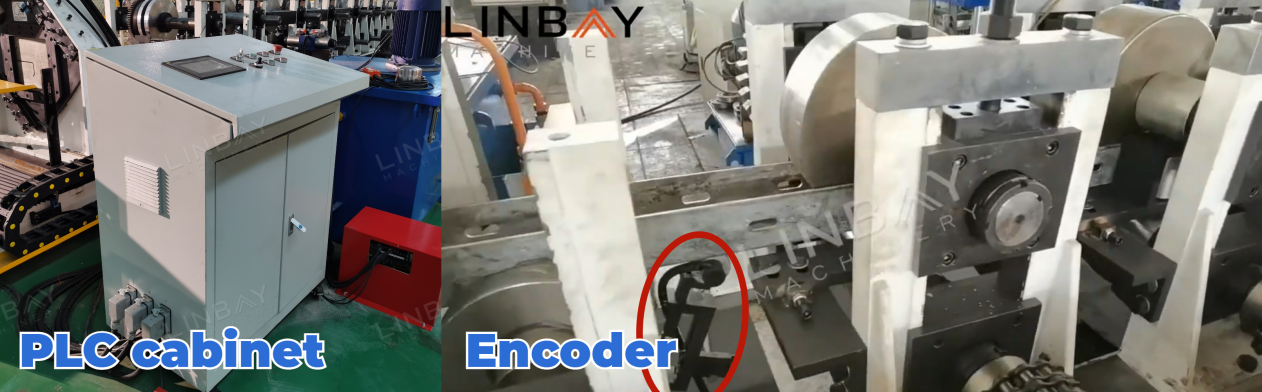

9. Ikhabhinethi ye-PLC: Ixhotyiswe ngenkqubo ye-Siemens

Imeko yokwenyani-Inkcazo

I-Hydraulicdi-ecoiler

Eyenziwe ngokusebenza ngokufanelekileyo kunye nokhuseleko engqondweni, i-hydraulic decoiler inikwe amandla sisikhululo esiqinileyo se-hydraulic. Ukuxhotyiswa nge-coil retainer yangaphandle, ikhusela ngokufanelekileyo i-coil yensimbi ekuphumeni ngexesha lokusebenza. Ukongezelela, ingalo yokushicilela ibambe ngokukhuselekileyo ikhoyili kwindawo, ngaloo ndlela iqinisekisa ukhuseleko lwabasebenzi ngokuthintela nayiphi na intwasahlobo engalindelekanga.

Umgangatho

Ngokunciphisa uxinzelelo lwangaphakathi ngaphakathi kweekhoyili, i-leveler iwalungisa ngokubetha kunye nokwenza iinkqubo. Idityaniswe nesiseko somatshini wokwenza, i-level ayiphuculi nje ukusebenza kakuhle kodwa igcina indawo enexabiso eliphantsi kwaye inciphisa iindleko zomhlaba ekusekweni komgca wakho wokuvelisa.

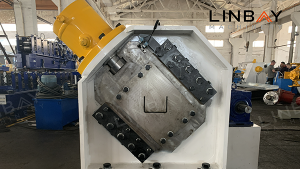

I-Hydraulicpunch

I-punch ye-hydraulic inokubhoboza ngokufanelekileyo imingxuma kwiikhoyili zentsimbi ukuya kuthi ga kwi-5mm ubukhulu, ilungiselele ukufakela isikrufu. Idityaniswe nesiseko somatshini wokwenza umqulu, iqinisekisa ukusebenza okuchanekileyo, nangona ifuna unqumamo olufutshane ngexesha lokubetha.

Kwizantya zemveliso ezongeziweyo, isisombululo se-hydraulic punch esizimeleyo sikwakhona.

Rolformingmhayi

Embindini womgca wemveliso ngumatshini wokwenza umqulu, oqhayisa ngesakhiwo esomeleleyo sentsimbi esikwaziyo ukuphatha icoil yentsimbi eshinyeneyo eyi-5mm. Zonke iiroli ezenza umqulu zinikwe amandla yinkqubo yebhokisi yegiya kwaye zenziwe zisuka kwi-Gcr15, intsimbi enekhabhoni ephezulu yechromium, ebonelela ngobulukhuni obukhethekileyo kunye nokunganyangeki kokunxiba, yongezwa ngakumbi nge-chrome plating. Ukongeza, i-shafts ye-40Cr ephathwa ngobushushu iqinisekisa ukuhlala kunye nokuthembeka naphantsi kweemeko ezinzima kakhulu.

I-Encoder & PLC

Ukuchaneka kunye nolawulo zidityaniswe ngaphandle komthungo kunye ne-encoder kunye nenkqubo ye-PLC. Ukuguqula ubude bekhoyili yensimbi kwimiqondiso yombane, i-encoder inikezela ngempendulo echanekileyo kwikhabhinethi yokulawula ye-PLC. Iiparamitha ezinje ngesantya sokuvelisa, ubuninzi bomjikelo ngamnye, kunye nobude bokusika zonke zinokulungiswa kwikhabhinethi yolawulo ye-PLC, ukuqinisekisa ukuba iimpazamo zokusika zilinganiselwe ngaphakathi.±1mm. Abathengi banokubeka ubude bokusika ngokweemfuno zabo ngepaneli yokusebenza.

I-Hydrauliccut

Ukusikwa ngakunye kuvelisa imiphetho egudileyo, engenazo i-burr, ukuphelisa inkunkuma kunye nokuqinisekisa ukuchaneka okugqibeleleyo, okugcina konga iindleko kubathengi. Kuyafaneleka ukuba uqaphele ukuba umatshini wokwenza umqulu uyeka ngexesha lomsebenzi ngamnye wokusika.

Sikwabonelela ngesisombululo sesantya esiphezulu apho umatshini wokwenza umqulu ungayeki ngexesha lokusika, ukuba uyawufuna.

I-Hydraulicsunikezelo

Ukusebenza kakuhle kudityaniswa nokuthembeka ngesikhululo sethu somphetho we-hydraulic. Ibandakanya iifeni zombane zokupholisa, ikhupha ngokufanelekileyo ubushushu, igcine amaqondo obushushu afanelekileyo okusebenza ixesha elide. Ngamazinga amancinci okusilela, izikhululo zethu ze-hydraulic ziqinisekisa ukuhlala kunye nokuphila ixesha elide, ziqinisekisa ukuhamba komsebenzi okungaphazamisekiyo.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile