IVIDIYO

Perfil

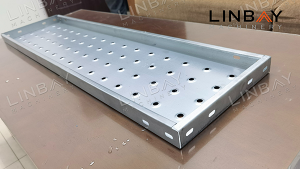

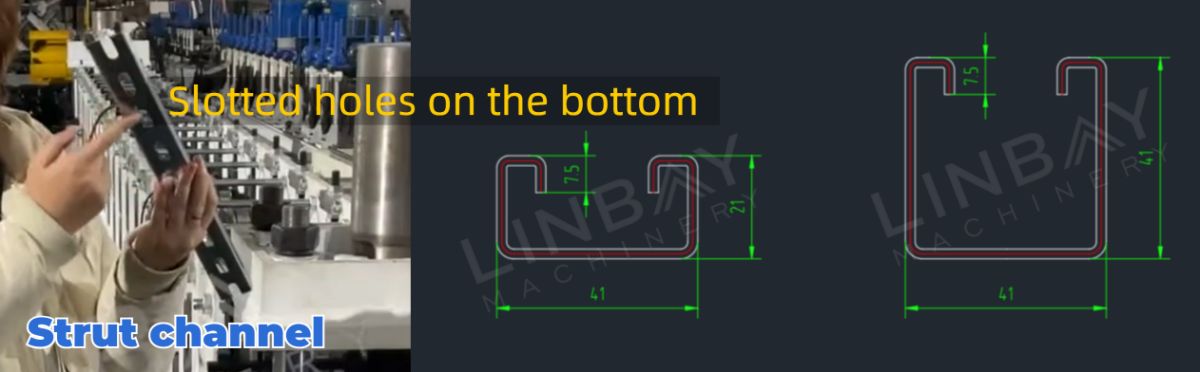

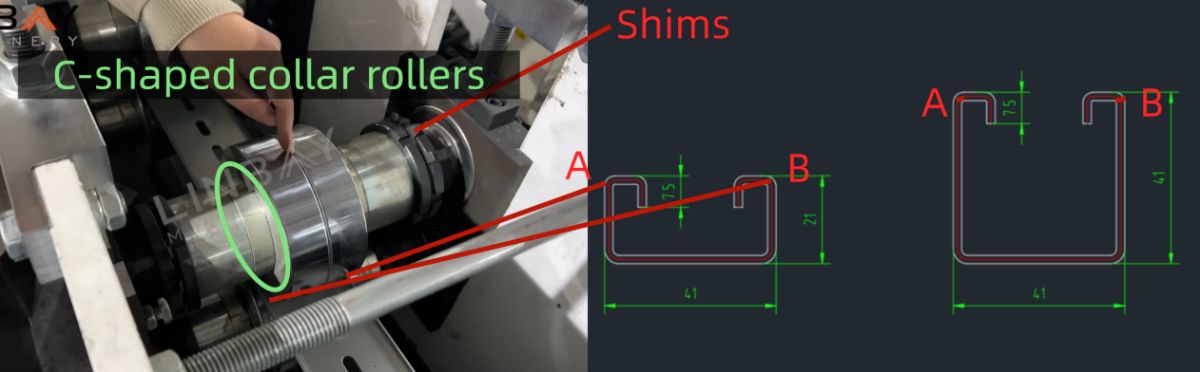

Ijelo le-Strut lisebenza njengenxalenye ebalulekileyo yokuxhasa kunye nokudibanisa imithwalo yesakhiwo esilula ekwakhiweni kwesakhiwo. Imilinganiselo esemgangathweni yeetshaneli ze-strut zihlala zibandakanya41*21mmkwaye41*41mm. Ezi tshaneli zidla ngokuyilwa kwizinto ezifanaintsimbi eqengqelekayo eshushu, intsimbi eqengqelekayo ebandayo, okanye intsimbi efakwe igalvanized, ebonisa ubukhulu obuqhele ukuqala ukusuka1.5mm ukuya 2mm.

Ityala lokwenyani-Iiparamitha zeTechinical eziPhambili

Itshathi equkuqelayo

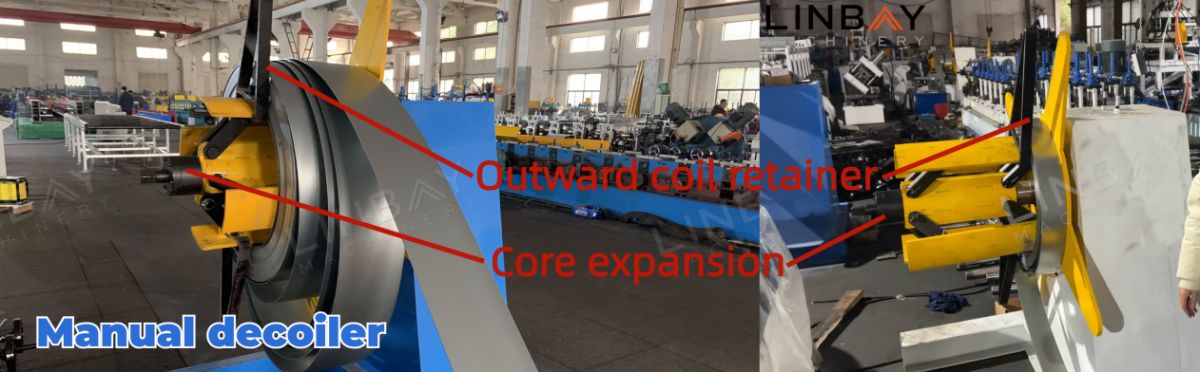

I-decoiler ye-manual ixhotyiswe ngesixhobo se-brake, evumela ukulungiswa kolwandiso olungundoqo phakathi kwe-φ490-510 mm,ukuqinisekisa ukuqhawuka okugudileyo. Ngaphezu koko, i-coil retainer yangaphandle ikhusela ukutyibilika kwekhoyili, inyusa ukusebenza kakuhle kunye nokhuseleko. Kwimeko ye-hydraulic decoiler, ingalo yokushicilela ikhusela i-coil yensimbi, ukunciphisa umngcipheko we-coil spring-up kunye nokulimala kwabasebenzi. Ukuhlangabezana neemfuno ezongezelelekileyo zemveliso, sibonelela ngesixhobo sokwenza oko kusenziwa ngoxinzelelo loxinzelelo olukhulu olwenziwa sisikhululo samanzi aphantsi komhlaba.

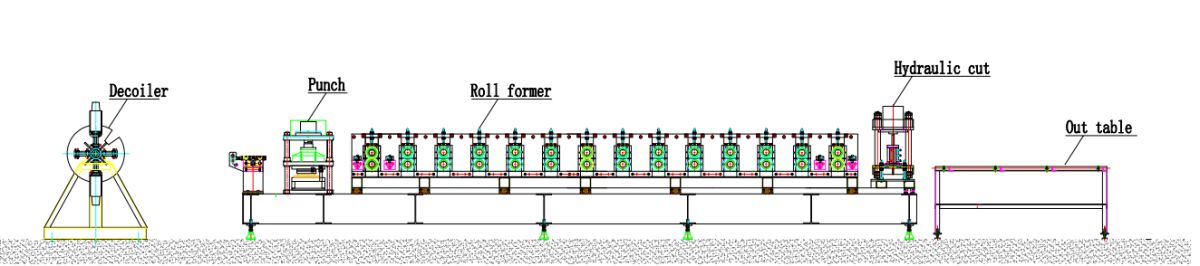

Idecoiler ngesandla--Isikhokelo--Hydraulic punch--Roll forming machine--Hydraulic cut--out table

IiParameters ezingundoqo zobuGcisa

I-1.Isantya somgca: 0-12m / min ngaphandle kokubetha, i-3m / min ngokubetha.

2.Ubukhulu bezinto eziphathekayo: 2mm kule meko.

3.Izinto ezifanelekileyo: Intsimbi eshushu, intsimbi epholileyo, intsimbi epholileyo.

I-4.Umatshini wokwenza i-Roll: Isakhiwo sephaneli yodonga kunye nenkqubo yokuqhuba ikhonkco.

5. Hayi. Kwisikhululo esakhayo: 20

Inkqubo ye-6.Punching: I-Hydraulic, i-roll yangaphambili iyayeka xa ubetha.

I-7.Inkqubo yokusika: I-Hydraulic, i-roll yangaphambili iyayeka xa usika.

8.Ukutshintsha ubungakanani: iiyure ze-2-3 ngesandla.

Ikhabhinethi ye-9.PLC: inkqubo ye-Siemens.

Imeko yokwenyani-Inkcazo

I-Decoiler ye-Manual

Ukukhokela

Iirola ezikhokelayo zidlala indima ebalulekileyo ekugcineni ulungelelwaniso phakathi kwekhoyili yentsimbi kunye nomatshini, ukuthintela ukugqwethwa komjelo we-strut.

Iirola ezikhokelayo zidlala indima ebalulekileyo kwinkqubo yokuqulunqa, ukuthintela ukuguqulwa kwe-rebound yentsimbi. Ukuthe tye kombhobho wetyhubhu kubalulekile kumgangatho wemveliso, okuchaphazela ukusebenza kwenkxaso yesakhelo sokufakela sonke. Iirola ezikhokelayo zifakwe ngobuchule ecaleni komatshini wokwenza umqulu wonke, hayi nje kwindawo yokungena. Ngaphambi kokuthunyelwa, silinganisa umgama ukusuka kwisikhokhelo ngasinye ukuya kumda womatshini kwaye sibhale le milinganiselo kwincwadana. Kwimeko yokufuduka okuncinci ngexesha lokuthutha okanye inkqubo yokuvelisa, abasebenzi banokusebenzisa le datha erekhodiweyo ukuze baphinde babeke ii-roller ngokuchanekileyo.

I-Hydraulic Punch

I-punch ye-hydraulic, enikwe isikhululo se-hydraulic, ibekwe phambi komatshini wokwenza umqulu, odinga ukuphumla kwinkqubo yokwenza umqulu ngexesha lokubetha. Umatshini we-hydraulic punch ulungelelaniswe kunye nesinyathelo se-punch ye-400 mm. Ukonyuka kwesantya sokuvelisa, sicebisa isisombululo esizimeleyo se-hydraulic punching esilungiselelwe imizobo yokubhoboza enikiweyo.

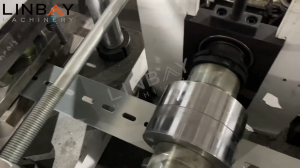

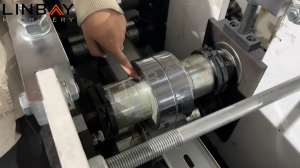

Umatshini wokwenza umqulu

Umatshini wokwenza umqulu ubonisa isakhiwo sepaneli yodonga kunye nenkqubo yokuqhuba ikhonkco, ukubonelela ngesisombululo esineendleko zokutshintsha ubungakanani bezandla kunye nexesha lokutshintshwa malunga.2-3 iiyure.

Ukulungelelanisa iindawo zokuyila kubalulekile ekutshintsheni ubungakanani. Ukukhulula i-shims ekupheleni kwee-roller kunye nokutshintsha okanye ukongezaIirola zekhola ezimile njengo-C (imikhono)kwindawo efanelekileyo tshintsha indawo yokwenza isayizi entsha yeprofayile. Ukongeza, sibonelela ngeutshintsho lwesayizi oluzenzekelayo isisombululokunye nexesha lokutshintshwa kwemalunga nemizuzu eli-10.

Ikhonkco levidiyo ukuya -【Ukuhlohla】Linbay Guqula imikhono yomatshini wokwenza umqulu

Ukusika kweHydraulic

Umatshini wokusika we-hydraulic, osebenza kwisikhululo se-hydraulic, unobuchule bokusika ii-coil zetsimbi ezi-2mm. Iincakuba zayo zokusika zilungelelaniswe kwimilo yeprofayile, zivelisa malunga ne-8mm yenkunkuma ngokusikwa ngokusikwa ngelixa igcina indawo yokusika ephantse yangena-burr.

I-Encoder & PLC

Umatshini wokwenza umqulu ubandakanya uphawu lwaseJapan lwe-Koyo encoder, oluguqulela ubude bekhoyili eboniweyo kwiimpawu zombane ezithunyelwa kwikhabhathi yolawulo yePLC. Le nkqubo echanekileyo iqinisekisa ukuba iimpazamo zokusika zigcinwangaphakathi kuluhlu ±1mm, ukuqinisekisa ukuveliswa kweemveliso eziphezulu ngelixa unciphisa inkunkuma ekusikeni okungalunganga. Abaqhubi banokulawula ngokulula isantya semveliso, ubungakanani bemveliso, ubude bokusika, kunye nokunye ngesikrini sePLC. Ukongeza, i-PLC yokulawula iKhabhinethi ineempawuukugcinwa kwememorikwiiparamitha ezisetyenziswa ngokuqhelekileyo kwaye ibonelela ngemisebenzi yokukhusela efana nokugqithisa, isiphaluka esifutshane, kunye nokulahleka kwesigaba.

Ulwimi olukwisikrini se-PLC lunokwenziwa ngokwezifiso ngokusekelwe kwizinto ezikhethwa ngumthengi.

Isitishi seHydraulic

Isikhululo sethu se-hydraulic sixhotyiswe ngabalandeli bombane bokupholisa ngokufanelekileyo ukutshabalalisa ubushushu, ukuqinisekisa ukusebenza ixesha elide kunye nokuthembekileyo kunye nesantya esisezantsi sokungaphumeleli, ukulungelelanisa kwindawo yokusebenza eshushu.

Iwaranti

Ngomhla wokuthunyelwa, umhla wangoku uya kubhalwa kwi-nameplate yensimbi, ephawula ukuqala kwesiqinisekiso seminyaka emibini yomgca wemveliso yonke kunye newaranti yeminyaka emihlanu ye-roller kunye ne-shafts.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile