ividiyo

Inkangeleko yesimo

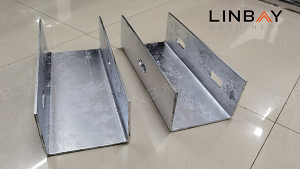

Iitshaneli zeStrut zisetyenziswa rhoqo kwizicelo ezifana nokunyuswa kweepaneli zelanga, ukufakela imibhobho nemibhobho, kunye neenkqubo zeHVAC. Umphakamo wesiteshi se-strut esisemgangathweni ubandakanya21mm, 41mm, 52mm, 62mm, 71mm, kunye 82mm.Ububanzi bee-roller zokwenza utshintsho kunye nokuphakama kweshaneli ye-strut, kunye neziteshi ezide ezifuna izikhululo ezininzi zokwenza. Ezi tshaneli zenziwa ngokwesiqhelointsimbi eqengqelekayo eshushu, intsimbi eqengqelekayo ebandayo, intsimbi enamava, okanye intsimbi engatyiwa,ezinobunzima obuqala ukusukaI-12 yegeyiji (2.5mm) ukuya kwi-16 yegeji (1.5mm).

Qaphela: Ngenxa yobuninzi besivuno samandla ensimbi engenasici, amandla okwenza amandla afunekayo makhulu xa kuthelekiswa nentsimbi ephantsi-alloy kunye nentsimbi yekhabhoni eqhelekileyo yobukhulu obufanayo. Ngoko ke, oomatshini bokwenza i-roll eyenzelwe insimbi engenasici bahluke kwezo zisetyenziselwa i-carbon steel eqhelekileyo kunye nentsimbi.

I-LINBAY inikezela ngemigca yokuvelisa ekwazi ukuvelisa imilinganiselo eyahlukeneyo, ehlelwe kwiintlobo ze-manual kunye ne-automated kuxhomekeke kwinqanaba lokuzenzekelayo elifunekayo ukulungiswa komlinganiselo.

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

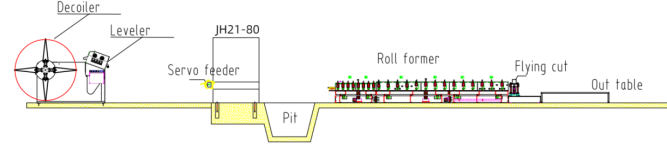

Itshathi equkuqelayo: I-Decoiler--Servo feeder--Punch press--Guiding--Roll forming machine--Flying saw cut--out table

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

Isantya se-1.Umgca: 15m / min, ukulungiswa

I-2.Izinto ezifanelekileyo: Intsimbi eshushu eqengqelekayo, intsimbi eqengqelekayo ebandayo, intsimbi efakwe igalvanized

3.Ubukhulu bezinto: 1.5-2.5mm

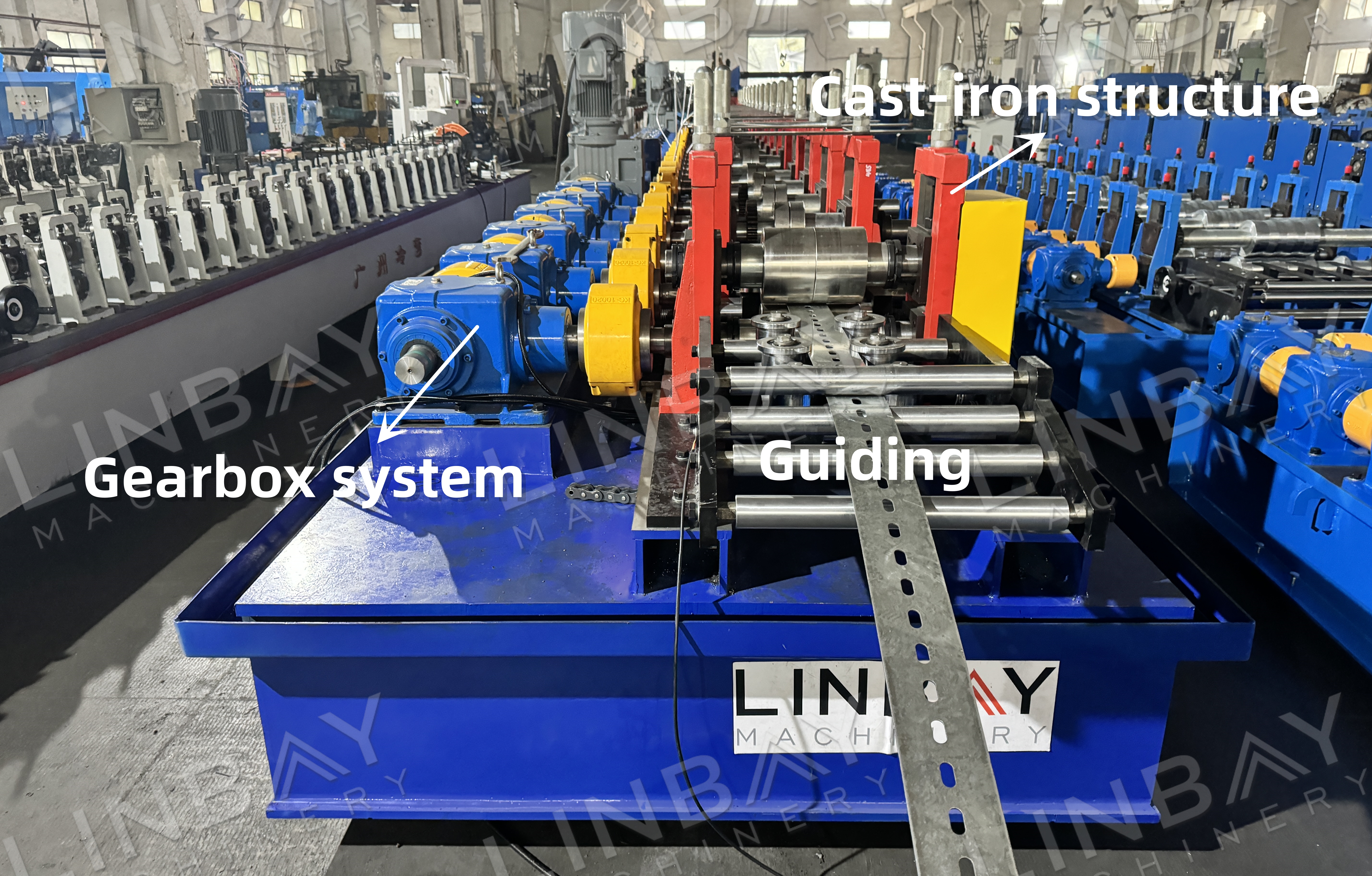

Umatshini wokwenza i-4.Roll: Isakhiwo se-Cast-iron

I-5.Inkqubo yokuqhuba: Inkqubo yokuqhuba i-Gearbox

I-6.Inkqubo yokusika: I-Flying saw cut. Umatshini wokwenza umqulu akayeki xa usika

Ikhabhinethi ye-7.PLC: inkqubo ye-Siemens

Ityala lokwenyani-oomatshini

1.I-Hydraulic decoiler eneleveli*1

2.I-Servo feeder*1

3.Cofa ngenqindi*1

4.Umatshini wokwenza umqulu*1

5.Flying wabona umatshini wokusika *1

6.PLC iKhabhinethi yolawulo*2

7.Isikhululo samanzi*2

8.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

Ubungakanani bomgqomo: 2x40GP + 1x20GP

Imeko yokwenyani-Inkcazo

I-Decoiler ene-Level

Lo matshini udibanisa imisebenzi ye-decoiler kunye ne-level, ukwandisa ukusetyenziswa kwendawo yomgangatho. Ukulinganisa iikhoyili zentsimbi ezityebileyo kune-1.5mm kubalulekile, ngakumbi xa kugqobhozwa rhoqo imingxuma kwiitshaneli ze-strut. I-leveler iqinisekisa ukuba i-coil yensimbi ihamba kakuhle kwaye ikhulula uxinzelelo lwangaphakathi, iququzelele ukubunjwa lula kunye nokuqulunqa ngokuthe tye.

I-Servo Feeder

I-servo feeder ibizwa ngokuba kukusetyenziswa kwe-servo motor. Ngenxa yokulibaziseka okuncinci kokuyeka ukuqalisa kwe-servo motor, inika ngokuchanekileyo okukhethekileyo ekondleni iikhoyili zentsimbi. Oku kuchanekileyo kubalulekile ekugcineni ukunyamezelana okuqinileyo kunye nokunciphisa inkunkuma yensimbi yentsimbi ngexesha lokuveliswa kwesiteshi se-strut. Ukongeza, izithinteli ze-pneumatic ngaphakathi kwe-feeder ziqhubela phambili ikhoyili yentsimbi ngelixa ikhusela umphezulu wayo kwimikrwelo.

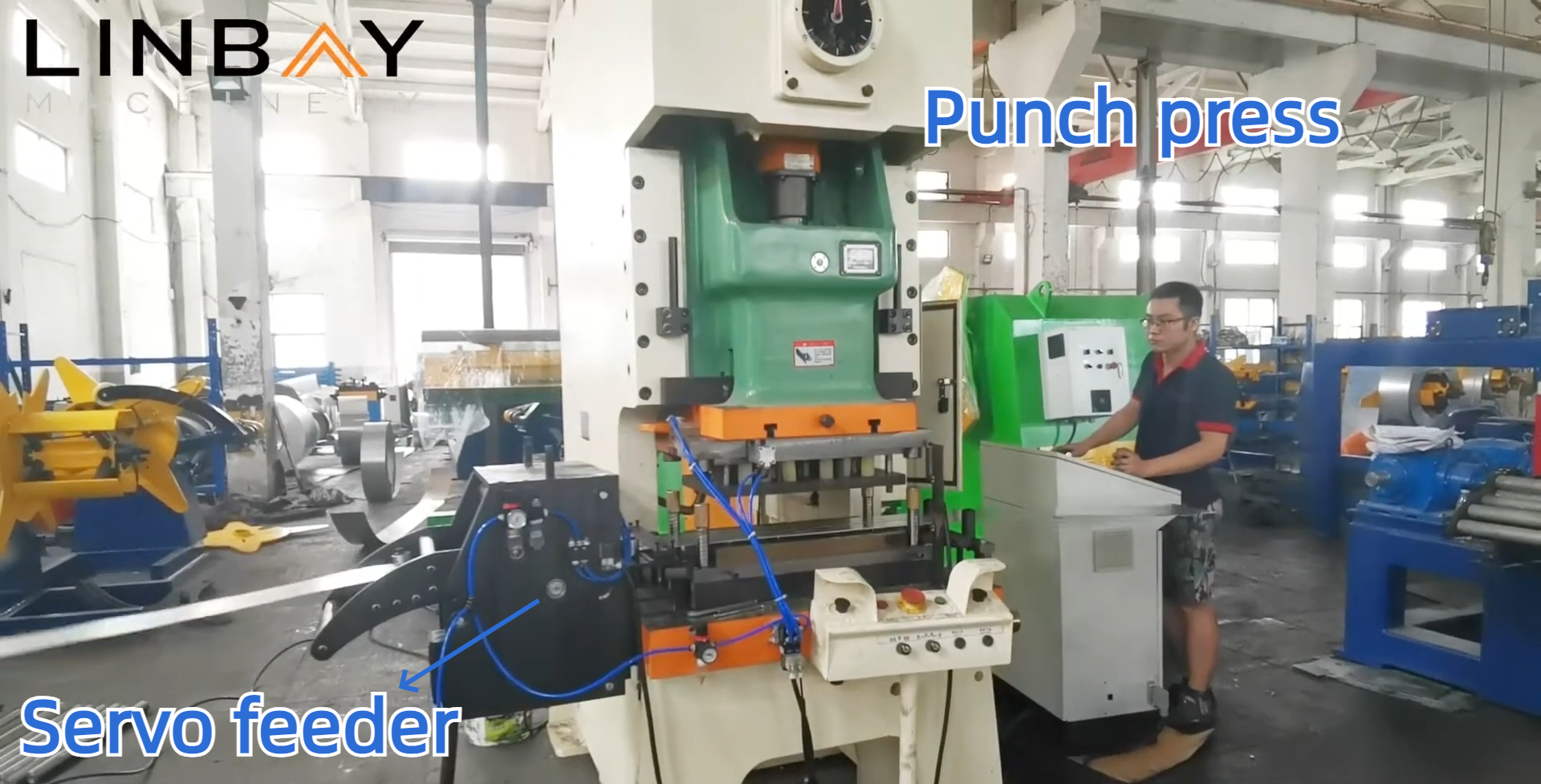

Punch Press

I-punch press isetyenziselwe ukudala imingxuma kwikhoyili yentsimbi, eyimfuneko ekufakeni izikrufu kunye namandongomane ukukhusela iziteshi ze-strut. Olu shicilelo lwe-punch lusebenza ngokukhawuleza kune-punch edibeneyo ye-hydraulic (efakwe kwisiseko esifanayo njengomatshini wokwenza umqulu) kunye ne-standalone hydraulic punch. Sisebenzisa i-punch press evela kwi-brand yaseTshayina eyaziwayo, i-Yangli, eneofisi ezininzi zehlabathi, iqinisekisa inkonzo efanelekileyo emva kokuthengisa kunye nokufikelela ngokulula kwiindawo ezitshintshileyo.

Ukukhokela

Ii-roller zesikhokelo zigcina i-coil yensimbi kunye noomatshini balungelelaniswa kunye ne-centerline efanayo, ukuqinisekisa ukuthe tye kwe-channel ye-strut. Olu lungelelwaniso lubalulekile ekufaniseni iziteshi ze-strut kunye nezinye iiprofayili ngexesha lofakelo, oluchaphazela ngokuthe ngqo ukuzinza kwesakhiwo sonke sokwakha.

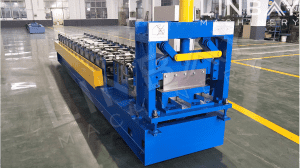

Umatshini wokwenza umqulu

Umatshini wokwenza umqulu uqhayisa isakhiwo sentsimbi esenziwe kwisiqwenga esinye sentsimbi, esinika ukuqina okukhethekileyo. Iirola eziphezulu nezisezantsi zisebenzisa amandla okubumba ikhoyili yentsimbi, eqhutywa yibhokisi yegiya ukuhambisa amandla awoneleyo kwinkqubo yokubumba.

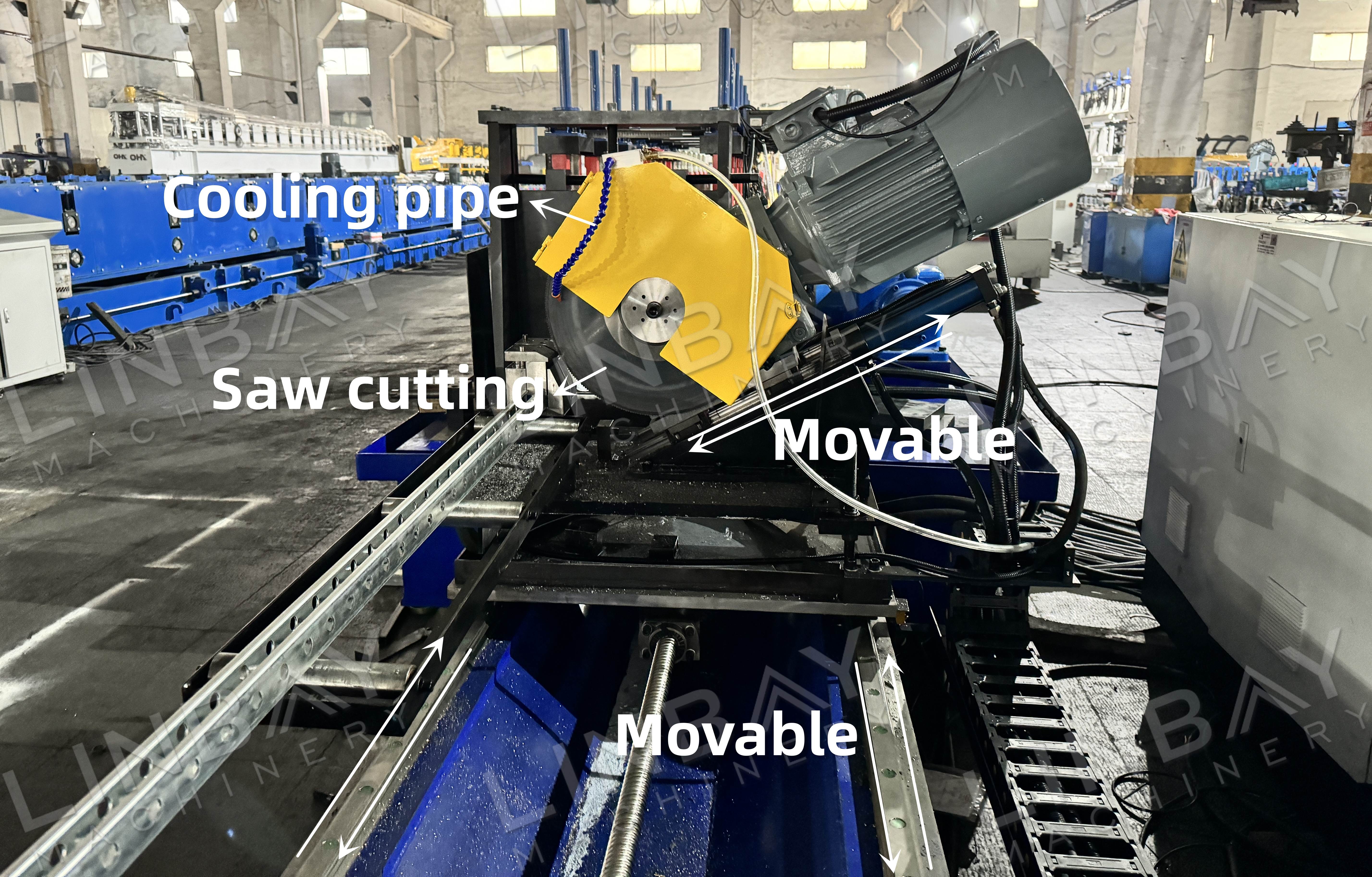

I-Flying Saw Cutting

Inqwelo ebhabhayo yesarha yomsiki ikhawuleza ukuvumelanisa kunye nesantya semijelo ye-strut ehambayo, ekwayisantya somatshini wokwenza umqulu. Oku kwenza ukusika ngaphandle kokumisa inkqubo yokuvelisa. Esi sisombululo sisebenza kakhulu sokusika sifanelekile kwimisebenzi yesantya esiphezulu kwaye sivelisa inkunkuma encinci.

Ngexesha lenkqubo yokusika, amandla e-pneumatic ahambisa isiseko se-saw blade ngokubhekiselele kumjelo we-strut, ngelixa amandla e-hydraulic avela kwisikhululo se-hydraulic eqhuba ukujikeleza kwe-saw blade.

Isitishi seHydraulic

Isikhululo se-hydraulic sinika amandla afunekayo kwizixhobo ezifana ne-hydraulic decoiler kunye ne-hydraulic cutter kwaye sixhotyiswe ngeefeni zokupholisa ukuqinisekisa ukuchithwa kobushushu okusebenzayo. Kwiimozulu ezishushu, sicebisa ukwandisa i-hydraulic reservoir ukuphucula ukuchithwa kobushushu kunye nokwandisa umthamo wolwelo olukhoyo lokupholisa. La manyathelo anceda ukugcina ukushisa okuzinzileyo kokusebenza ngexesha lokusetyenziswa ixesha elide, ngaloo ndlela kuqinisekiswe ukuthembeka kunye nokusebenza kakuhle komgca wokuvelisa umqulu.

IKhabhinethi yoLawulo lwe-PLC kunye ne-Encoder

Iikhowudi zidlala indima ebalulekileyo ekunikezeni ingxelo ngesikhundla, isantya, kunye nongqamaniso. Baguqula ubude obulinganisiweyo bekhoyili yensimbi kwiimpawu zombane, ezithi zithunyelwe kwikhabhinethi yokulawula ye-PLC. Abaqhubi basebenzisa umboniso wekhabhinethi yokulawula ukulungisa iiparameters ezifana nesantya sokuvelisa, isiphumo somjikelezo ngamnye, kunye nobude bokusika. Ngombulelo kwimilinganiselo echanekileyo kunye nempendulo evela kwii-encoders, umatshini wokusika unokufezekisa ukuchaneka kokusika ngaphakathi kwe-± 1mm.

I-Flying hydraulic cutting VS Flying isarha yokusika

I-Blade yokusika: Umlinganiselo ngamnye we-flying hydraulic cutter ufuna i-blade yokusika eyahlukileyo. Nangona kunjalo, ukusika i-sawh akuthintelwanga yimilinganiselo yeetshaneli ze-strut.

Ukunxiba kunye nokukrazula: Iiblade zesarha zihlala zikhawuleza ukunxiba xa kuthelekiswa neeblade zokusika zehydraulic kwaye zifuna ukutshintshwa rhoqo.

Ingxolo: Ukusika i-saw kuthande ukuba phezulu kune-hydraulic cut, enokuthi ifune amanyathelo ongezelelweyo okukhusela isandi kwindawo yemveliso.

Inkunkuma: Isisiki sehydraulic, nokuba silinganiswe kakuhle, sikholisa ukukhokelela kwinkunkuma engenakuthintelwa ye-8-10mm ngokusikwa. Kwelinye icala, umsiki wesarha ukhupha inkunkuma ephantse ibe yiqanda.

Ugcino: Iisarha iibhleyidi zifuna isixokelelwano sokupholisa ukulawula ubushushu obuveliswa kukukhuhlana, ukuqinisekisa ukusika ngokuqhubekayo nangokufanelekileyo. Ngokwahlukileyo, ukusika kwe-hydraulic kugcina ubushushu obuhambelanayo.

Unyino lweMathiriyeli: Intsimbi engatyiwayo inamandla esivuno esiphezulu kunentsimbi yekhabhoni eqhelekileyo. Xa usebenza ngensimbi engenasici, i-saw cut cut ifanelekile ukusetyenzwa kwezinto.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile