Iphrofayela

I-DIN rail iyisitimela sensimbi esimisiwe esivame ukusetshenziswa kubunjiniyela bakagesi. Idizayini yayo isiza ukufakwa kalula nokususwa kwezingxenye, ngokuvamile ezifaka uchungechunge lwezikhala noma izimbobo zokunamathisela kusetshenziswa izikulufu noma izinsimbi ezisheshayo. Ubukhulu obujwayelekile bomzila we-DIN bungu-35mm x 7.5mm kanye no-35mm x 15mm, obunogqinsi obujwayelekile obungu-1mm.

Ikesi langempela-Amapharamitha Obuchwepheshe Abalulekile

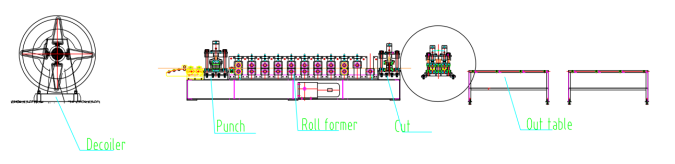

Ishadi eligelezayo: I-Decoiler--Guiding--Hydraulic punch--Roll forming machine--Hydraulic cutting machine

1.Isivinini somugqa: 6-8m/min, iyalungiseka

2.Impahla efanelekile:Insimbi egoqiwe eshisayo, insimbi egoqiwe ebandayo

3.Ubukhulu bezinto ezibonakalayo: Ubukhulu obujwayelekile bungu-1mm, futhi umugqa wokukhiqiza ungenziwa ngokwezifiso ngaphakathi kobubanzi obuyi-0.8-1.5mm.

I-4.Umshini wokwenza umqulu: Isakhiwo sephaneli yodonga

I-5.Isistimu yokushayela: uhlelo lokushayela ngamaketanga

I-6.Isistimu yokusika: Yeka ukusika, gingqa izitobhi zangaphambili lapho usika.

Ikhabhinethi ye-7.PLC: Uhlelo lwe-Siemens.

Imishini

1.I-Decoiler*1

2.Umshini wokwenza umqulu*1

3.Ithebula elingaphandle*2

4.PLC control cabinet*1

5.Isiteshi samanzi*1

6.Ibhokisi lezingxenye eziyisipele(Mahhala)*1

Usayizi wesiqukathi: 1x20GP

Ikesi langempela-Incazelo

I-Decoiler

I-decoiler iyingxenye yokuqala yomugqa wokukhiqiza. Uma kubhekwa ubukhulu obuncane obuncane kanye nosayizi wamareyili e-DIN, ama-decoiler okwenziwa ngesandla anele ukuhlangabezana nezidingo zokukhiqiza. Kodwa-ke, ngesivinini esiphezulu sokukhiqiza, siphinde sinikeze izixazululo ngama-decoiler kagesi nama-hydraulic.

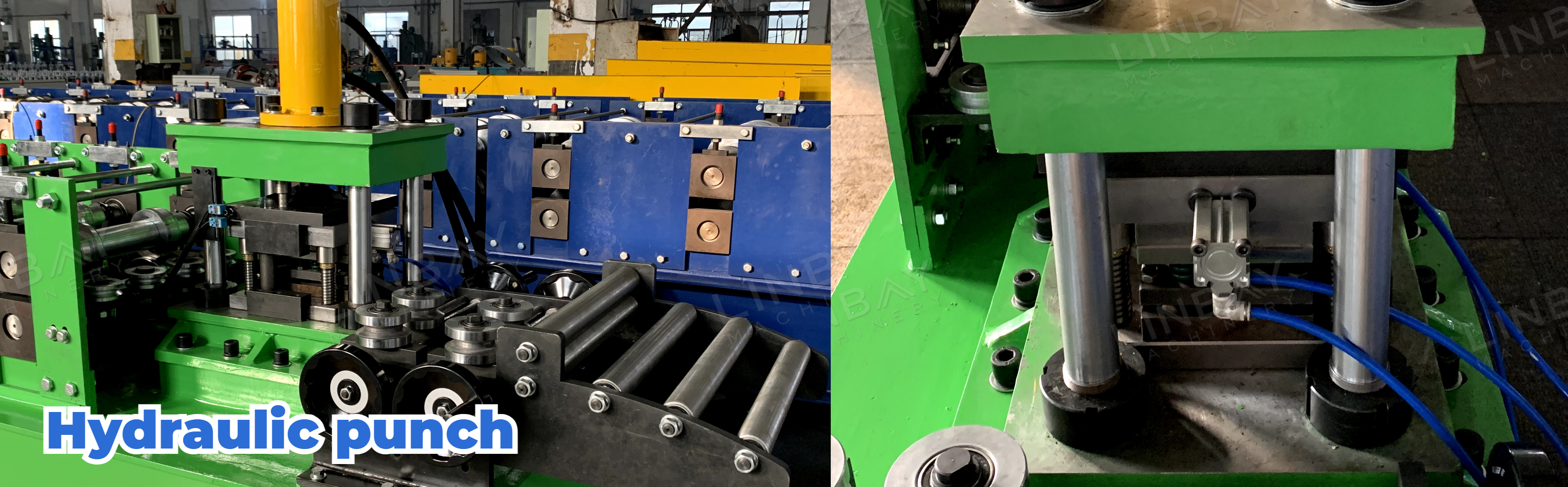

I-punch ye-hydraulic

Kulokhu kusetha, i-punch ye-hydraulic ihlanganiswe nomshini wokwenza oyinhloko, ukwabelana ngesisekelo esifanayo. Ngesikhathi sokubhoboza, ikhoyili yensimbi iyama okwesikhashana ukungena emshinini wokwakha. Kuzinhlelo zokusebenza ezidinga isivinini sokukhiqiza esiphezulu, imishini ye-standalone hydraulic punch iyatholakala.

Ukuqondisa

Ama-roller aqondisayo aqinisekisa ukuqondanisa phakathi kwekhoyili yensimbi nomshini, ukuvimbela ukuhlanekezela ngesikhathi sokwenza inqubo.

Umshini wokwenza ama-roll

Lo mshini wokwenza ama-roll usebenzisa isakhiwo sephaneli yodonga kanye nesistimu yokushayela ngamaketango. Idizayini yayo enemigqa emibili yenza ukuthi kukhiqizwe osayizi ababili besitimela se-DIN. Nokho, kufanele kuqashelwe ukuthi yomibili imigqa ayikwazi ukusebenza ngesikhathi esisodwa. Ngezidingo eziphezulu zokukhiqiza, sincoma ukuthi umise umugqa wokukhiqiza ohlukile wosayizi ngamunye.

Kufanele kugcizelelwe ukuthi ukunemba kobude bokusika komshini wokwenza umqulu onesakhiwo semigqa emibili kungaphakathi kuka ± 0.5mm. Uma isidingo sakho sokunemba singaphansi kuka-±0.5mm, akunconywa ukusebenzisa isakhiwo semigqa emibili. Esikhundleni salokho, isisombululo sokuba nomugqa wokukhiqiza ozimele wesayizi ngamunye sifaneleka kakhulu.

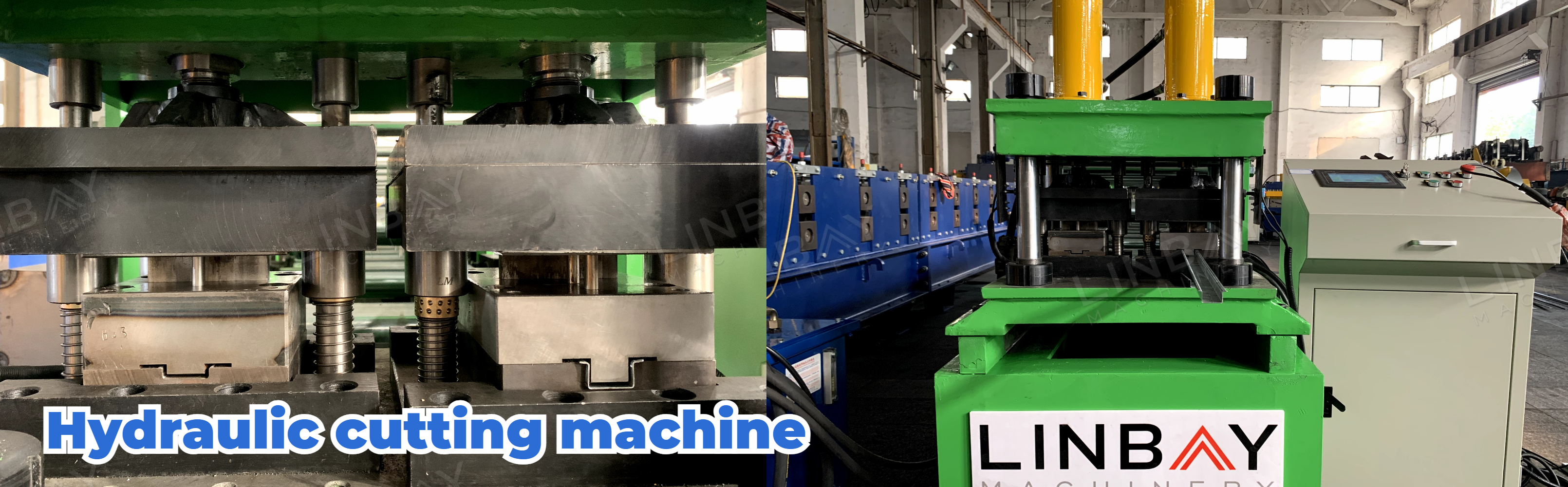

Umshini wokusika we-Hydraulic

Isisekelo somshini wokusika sihlala simile ngesikhathi sokusebenza, okwenza ikhoyili yensimbi ime isikhashana ukuthuthuka kwayo ngesikhathi sokusika.

Ukuze sifinyelele isivinini sokukhiqiza esiphezulu, sinikeza umshini wokusika endizayo. Igama elithi "flying" libonisa ukuthi isisekelo somshini wokusika singaya emuva naphambili. Lo mklamo wenza ikhoyili yensimbi iqhubekele phambili ngokuqhubekayo ngomshini wokwenza ngesikhathi sokusika, iqede isidingo sokumisa umshini wokwakha futhi ngaleyo ndlela ithuthukise isivinini somugqa wokukhiqiza.

Izibunzi ze-blade zokusika ekugcineni komugqa ngamunye zenziwe ngendlela oyifisayo ukuze zifane nosayizi ofanele wesitimela se-DIN.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle