Iphrofayela

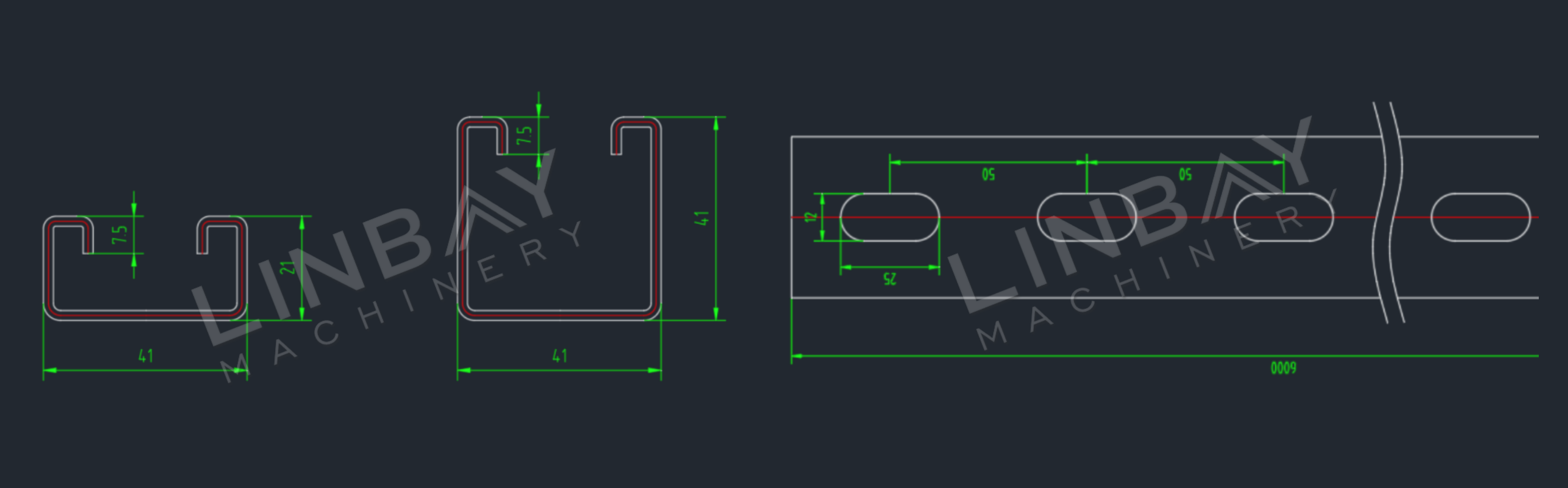

Amashaneli e-Strut ngokuvamile enziwe ngensimbi enothayela obungu-1.5-2.0mm noma 2.0-2.5mm, noma insimbi engagqwali enogqinsi luka-1.5-2.0mm. Aklanywe ngezimbobo ezihlala zihlukene noma izikhala ngobude bazo, asiza ukunamathiselwa kalula kwamabhawodi, amantongomane, noma ezinye izibophelelo.

Ulayini wokukhiqiza onokulungiswa kosayizi okuzenzakalelayo ulungele ukukhiqiza osayizi abaningi, njengobukhulu obuvamile njengo-41*41, 41*21, 41*52, 41*62, 41*72, kanye no-41*82mm. Uma kuphakeme ukuphakama kwesiteshi se-strut, kudingeka iziteshi eziningi zokwakha, okubuye kwenyuse intengo yomshini wokwenza ama-roll.

Ikesi langempela-Amapharamitha Obuchwepheshe Abalulekile

Ishadi eligelezayo

I-hydraulic decoiler ene-level--Servo feeder--Punch press--Guiding--Roll forming machine--Flying hydraulic cut--out table

Main Techinical Amapharamitha

Isivinini se-1.Line: 15m/min, siyalungiseka

2.Ubukhulu: 41*41mm no-41*21mm.

3.Ubukhulu bezinto: 1.5-2.5mm

I-4.Impahla efanelekile: insimbi yama-galvanized

5.Umshini wokwenza i-Roll: Isakhiwo se-Cast-iron kanye nesistimu yokushayela i-gearbox.

I-6.Isistimu yokusika nokugoba: Ukusika kwe-hydraulic endizayo. I-Roll yangaphambili ayimi lapho isika.

7.Ukushintsha usayizi: Ngokuzenzakalelayo.

Ikhabhinethi ye-8.PLC: Uhlelo lwe-Siemens.

Ikesi langempela-Incazelo

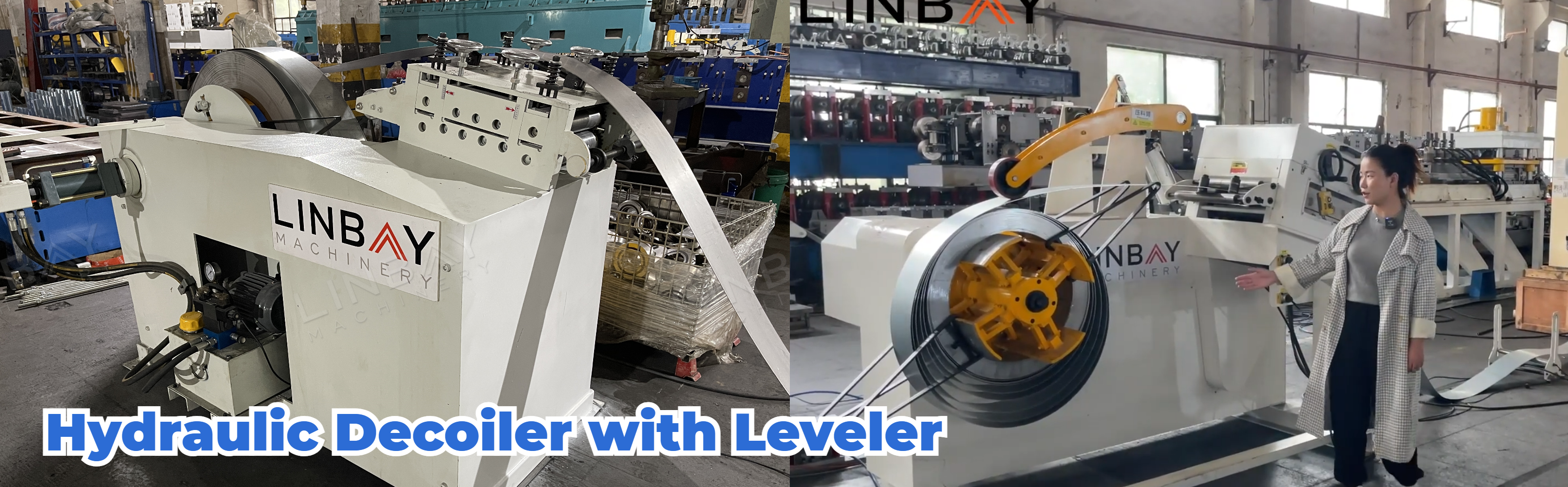

I-Hydraulic decoiler ene-level

Lolu hlobo lwe-decoiler, olwaziwa nangokuthi "i-2-in-1 decoiler kanye neleveli," luhlanganisa umklamo ohlangene ongagcina cishe amamitha angu-3 wesikhala somugqa wokukhiqiza, ngaleyo ndlela kwehlise izindleko zomhlaba wefekthri kumakhasimende ethu. Ukwengeza, ibanga elifushane phakathi kwe-decoiler neleveli linciphisa ubunzima bokusetha, okwenza ukondla ikhoyili nokusebenza kube lula.

I-Servo Feeder & Punch Cindezela

I-servo motor isebenza cishe akukho ukubambezeleka kwesikhathi sokuqalisa, okuvumela ukulawula okunembile ubude besiphakeli sekhoyili ukuze kushaye ngokunembile. Ngaphakathi, ukuncelisa umoya ngaphakathi kwesiphakeli kuvikela ngempumelelo indawo yekhoyili ekuhuzukeni.

Ngokuvamile, isikhala sembobo sesiteshi se-strut singama-50mm, ne-punching pitch engu-300mm. Uma kuqhathaniswa nemishini yokubhoboza ye-hydraulic enamandla alinganayo okubhoboza, i-punch press ifinyelela izinga lokushaya elisheshayo cishe izikhathi ezingu-70 ngomzuzu.

Nakuba izindleko zokuqala zokutshala izimali zomshini wokunyathelisa zingase zibe phezulu kunezingqimba ze-hydraulic, zinikeza ukusebenza kahle kwezindleko zesikhathi eside, ikakhulukazi ukukhiqizwa kwevolumu ephezulu. Ukwengeza, izindleko zokunakekelwa kwe-punch press zingase zibe phansi ngenxa yezingxenye zabo zemishini ezilula.

Sikhethe umshini wokunyathelisa we-punch womkhiqizo we-Yangli ovela e-China njengento yethu yokuqala neyesikhathi eside ngoba i-Yangli inamahhovisi amaningi emhlabeni wonke, enikeza ukusekelwa okufika ngesikhathi ngemva kokuthengisa kanye nenkonzo kumakhasimende ethu.

Ukuqondisa

Amarola aqondisayo aqinisekisa ukuthi ikhoyili kanye nomshini kuhambisana nomugqa ophakathi nendawo, okuqinisekisa ukuthi ikhoyili ihlala ingaguquki ngesikhathi sokubunjwa.

Umshini wokwenza ama-roll

Lo mshini wokubumba usebenzisa i-cast-iron kanye nesistimu yokushayela i-gearbox. Ikhoyili yensimbi idlula isamba seziteshi ezakhayo ezingama-28, ishintshashintsha ize ifane nokucaciswa kwemidwebo.

Uma abasebenzi sebesethe izilinganiso kuphaneli yokulawula ye-PLC, iziteshi ezakha umshini wokwenza ama-roll zizozivumelanisa ngokuzenzakalelayo nezindawo ezifanele, nendawo yokubumba ihamba ngokuhambisana namarola.

Ukuze uphephe ngesikhathi sokunyakaza kweziteshi ezakhayo, izinzwa ezimbili zebanga zimi nhlangothi zombili kwesokunxele nakwesokudla. Lezi zinzwa zihambisana nendawo engaphandle kanye nengaphakathi impela lapho iziteshi ezakhayo zingalungiswa khona. Babona isisekelo seziteshi ezakhayo: inzwa engaphakathi impela ivimbela iziteshi ezakhayo ukuthi zingasondeli eduze kakhulu futhi zibangele ukungqubuzana kwama-roller, kuyilapho inzwa yangaphandle ivimbela iziteshi ezakhayo ekuhlukaneni nezinsimbi nokuwa.

Ingaphezulu lama-roller akha i-chrome-plated ukuyivikela futhi yandise isikhathi sokuphila sama-roller.

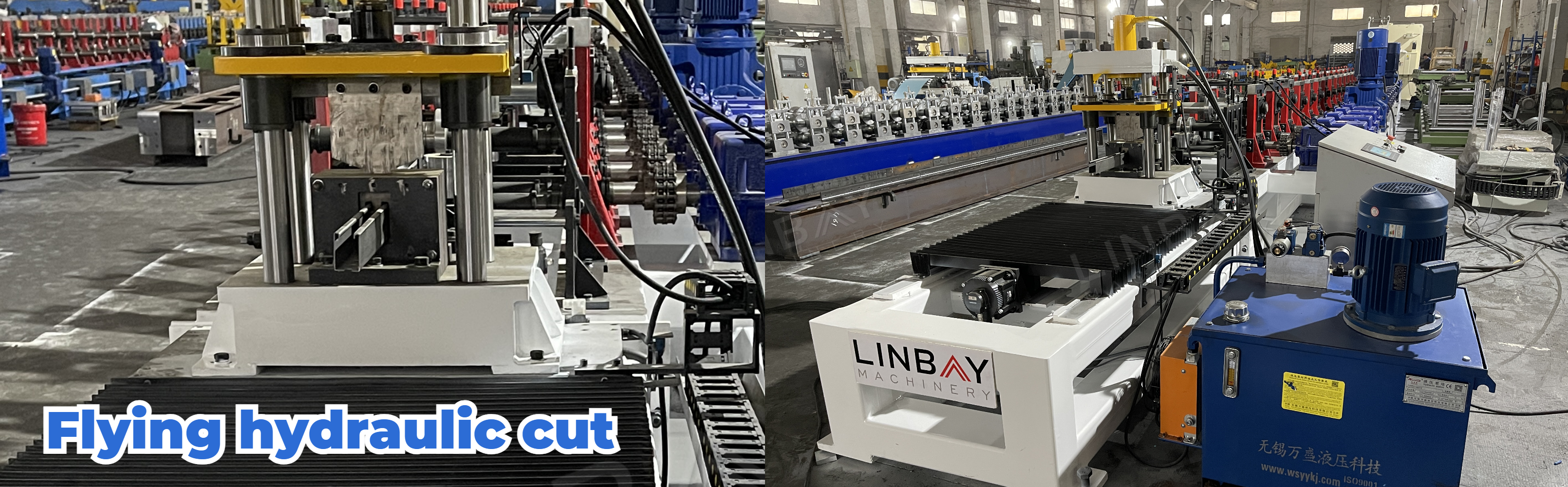

Ukusikwa kwe-hydraulic endizayo

Isisekelo somshini wokusika singahamba siye emuva naphambili kuthrekhi, senze ikhoyili yensimbi iqhubekele phambili ngokuqhubekayo ngomshini wokwenza umqulu. Lokhu kusetha kuqeda isidingo sokumisa umshini wokwenza umqulu, ngaleyo ndlela kwandisa isivinini esiphelele somugqa wokukhiqiza.Izibungu zokusika ze-blade zenzelwe ukufanisa ukuma kwephrofayili ngayinye ethile. Ngakho-ke, usayizi ngamunye udinga isethi yawo yokusika isikhunta se-blade.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle