Iphrofayela

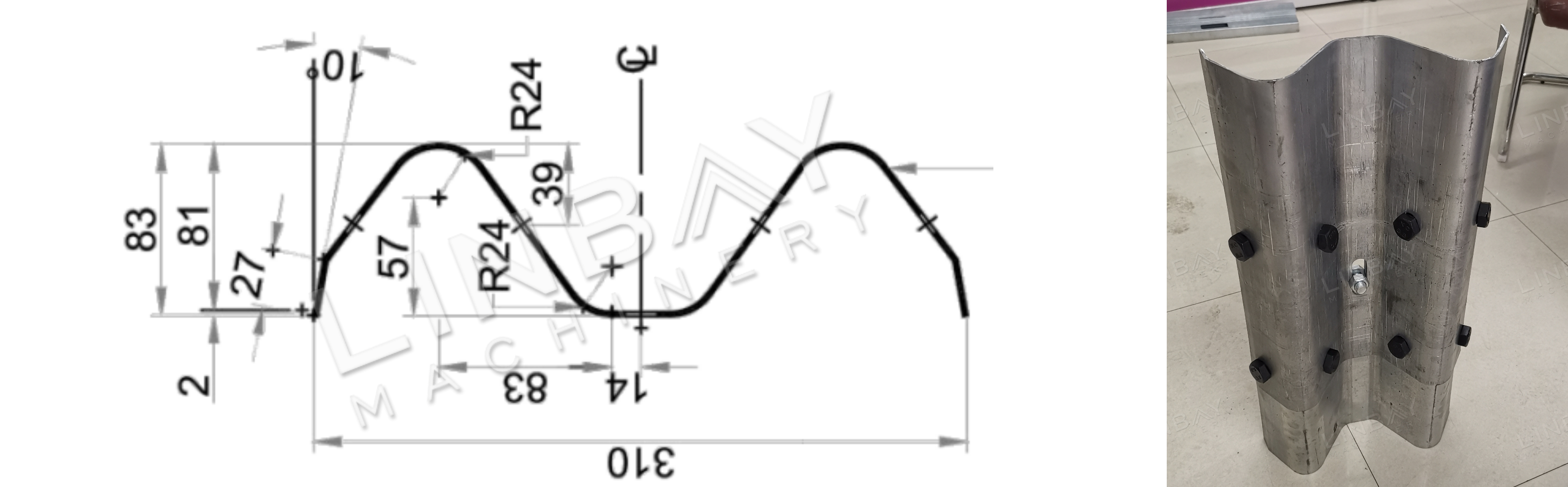

I-W-beam guardrail iyisici esibalulekile sokuphepha kumaphrojekthi wengqalasizinda yezokuthutha njengemigwaqo emikhulu, imigwaqo esheshayo, namabhuloho. Igama layo livela kusimo sayo esihlukile esithi "W", esineziqongo ezimbaxambili. Ivamise ukukhiqizwa ngensimbi egayiwe noma egoqwe ngokushisayo, i-W-beam guardrail isukela ku-2 kuye ku-4mm ngogqinsi.

Isigaba esijwayelekile se-W-beam sifinyelela ubude obungamamitha angu-4 futhi sinezimbobo ezishaywe ngaphambili kuzo zombili iziphetho ukuze zifakwe kalula. Ukuze kuhlangatshezwane nezidingo zamakhasimende ezihlukene zejubane lokukhiqiza nendawo yaphansi, sinikeza izixazululo ezenziwe ngokwezifiso zokubhoboza izimbobo ezihlanganisa ngaphandle komthungo emugqeni wokukhiqiza umshini wokwenza oyinhloko.

Ikesi langempela-Amapharamitha Obuchwepheshe Abalulekile

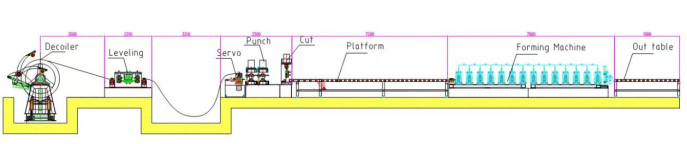

Ishadi eligelezayo: I-Hydraulic decoiler--Leveler--Servo feeder--Hydraulic punch--Pre Cut--Platform--Guiding--Roll former--Ithebula lokuphuma

1.Isivinini somugqa: 0-12m/min, siyalungiseka

2.Impahla efanelekile:Insimbi egoqiwe eshisayo, insimbi egoqiwe ebandayo

3.Material ukujiya: 2-4mm

Umshini wokwenza i-4.Roll: Isakhiwo se-Cast-iron kanye nokuhlangana kwendawo yonke

5.Isistimu yokushayela: Isistimu yokushayela ye-Gearbox ene-universal joint cardan shaft.

6.Isistimu yokusika: Sika ngaphambi kokwenza umqulu, umqulu wangaphambili awumi lapho usika.

Ikhabhinethi ye-7.PLC: Uhlelo lwe-Siemens.

Imishini

1.I-Decoiler*1

2.Izinga*1

3.Isiphakeli se-Servo*1

4.Umshini we-Hydraulic punch*1

5.Umshini wokusika amanzi*1

6.Inkundla*1

7.Umshini wokwenza iroll*1

8.Ithebula elingaphandle*2

9.PLC control cabinet*2

10.Isiteshi samanzi*2

11.Ibhokisi lezingxenye eziyisipele(Mahhala)*1

Usayizi wesiqukathi: 2x40GP

Ikesi langempela-Incazelo

I-Hydraulic decoiler

I-hydraulic decoiler ihlanganisa izingxenye ezimbili ezibalulekile zokuphepha: ingalo yokucindezela kanye ne-coil retainer yangaphandle. Lapho ushintsha amakhoyili, ingalo yokucindezela ibamba ngokuvikelekile ikhoyili endaweni yayo, ivimbele ukuthi ingaphumi ngenxa yokushuba kwangaphakathi. Ngesikhathi esifanayo, i-coil retainer yangaphandle iqinisekisa ukuthi ikhoyili ihlala iqinile ngesikhathi sokuqaqa.

Idivayisi yokunweba eyinhloko ye-decoiler iyalungiseka, ikwazi ukwenza inkontileka noma inwebe ukuze ikwazi ukufaka amadayamitha angaphakathi ekhoyili asuka ku-460mm kuya ku-520mm.

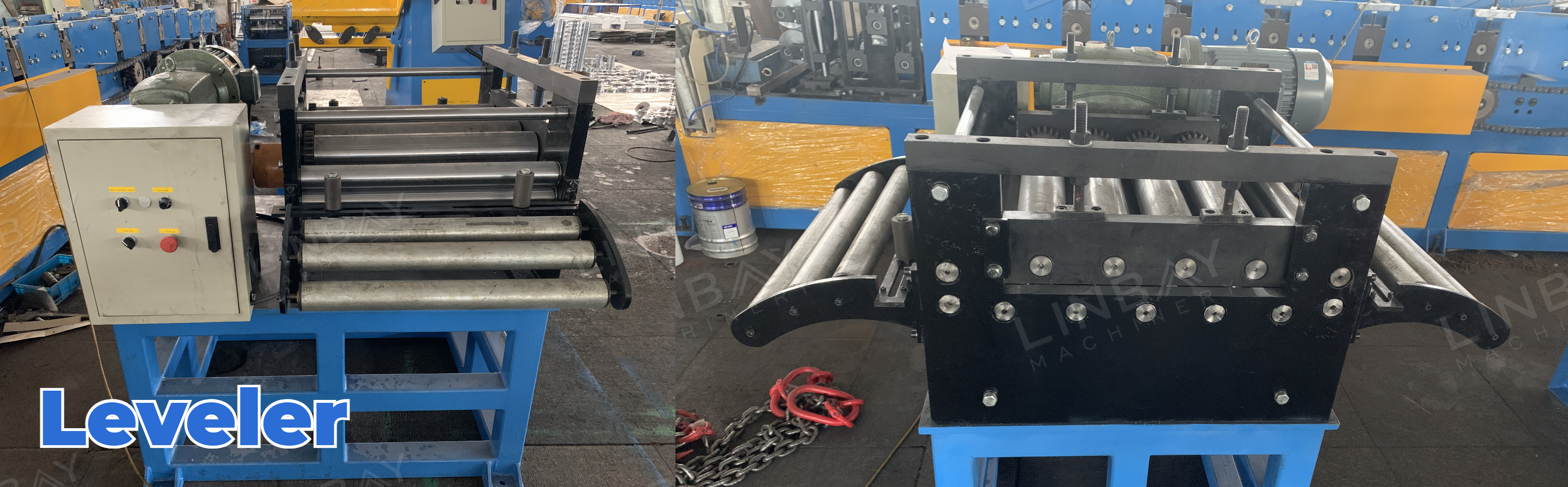

Ileveli

I-level ibalulekile ukuze wenze ikhoyili ibe isicaba kanye nokugcina ukujiya okungaguquki. Ukusebenzisa i-level ehlukile kuqinisekisa ukusebenza okuhle.

Siphinde sinikeze i-decoiler ehlanganisiwe ne-level (2-in-1 decoiler) ukuze wonge isikhala nezindleko. Lesi sixazululo esihlanganisiwe senza ukuqondana kube lula, ukuphakela, ukufakwa, nokulungisa iphutha.

I-Servo Feeder

Ifakwe injini ye-servo, i-feeder isebenza ngaphandle kokubambezeleka kokuqala, okuvumela ukulawula okunembile kobude besiphakeli sekhoyili ukuze kuhlatshwe ngokunembile. Ngaphakathi, ukuphakela umoya kuvikela ikhoyili ekuhuzukeni.

I-Hydraulic Punch & Pre-cut Hydraulic Cutting Machine

Ukuthuthukisa ukusebenza kahle nokusebenza kahle kwezindleko, inqubo yokubhoboza iphathwa iziteshi ezimbili zama-hydraulic (isikhunta ezimbili).

Isiteshi sokuqala esikhulu singabhoboza izimbobo eziyi-16 ngesikhathi. Izimbobo ezibhontshiwe esiteshini sesibili zivela kanye kuphela ensikeni ngayinye, okwenza isiteshi esincane sibe isisombululo esisebenza kahle.

Ukusika ngaphambili ngaphambi kokwakhiwa kwama-roll kuqinisekisa ukusebenza okungaphazamiseki komshini wokwenza ama-roll, ngaleyo ndlela kwandise isivinini sokukhiqiza. Ukwengeza, lesi sixazululo sinciphisa ukumosheka kwekhoyili yensimbi.

Ukuqondisa

Ama-roller aqondisayo abekwe ngaphambi komshini wokwenza ama-roll aqinisekisa ukuqondanisa phakathi kwekhoyili yensimbi nomshini, avimbele ukuhlanekezelwa kwekhoyili ngesikhathi sokwenza inqubo.

Umshini Wokwenza Roll

Lo mshini wokwenza ama-roll unokwakheka kwe-iron-cast, enama-universal shaft axhuma ama-roller akha nama-gearbox. Ikhoyili yensimbi idlula isamba seziteshi eziyi-12 ezakhayo, ishintshashintsha ize ihambisane nokuma kwe-W-beam ecaciswe emidwebeni yekhasimende.

Ingaphezulu lama-roller akhayo lifakwe nge-chrome ukuze liwavikele futhi andise ubude bempilo yawo.

Ongakukhetha: Isitaki esizenzakalelayo

Ekupheleni komugqa wokukhiqiza, ukusebenzisa isitaki esizenzakalelayo kunganciphisa izindleko zomsebenzi wezandla cishe ngabasebenzi ababili. Ukwengeza, ngenxa yesisindo se-W-beam engamamitha angu-4 ubude, ukuphatha ngezandla kubangela izingozi zokuphepha.

Isitaki esizenzakalelayo siyindlela evamile nephumelelayo emigqeni yokukhiqiza eyenza umqulu ukuze kuthuthukiswe kokubili ukusebenza kahle nokuphepha, ngezintengo ezisuselwe kubude. Amaphrofayili ahlukene adinga izindlela ezihlukene zokunqwabelanisa. Kulo mugqa wokukhiqiza, isitaki esizenzakalelayo esingamamitha angu-4 sifakwe izinkomishi ezintathu zokumunca ezenzelwe amaphrofayili amise okwe-W. Lezi zinkomishi zokumunca zibamba ngokuvikelekile i-W beam futhi ziyibeke kahle ku-conveyor ukuze zipakishwe ngendlela ehlelekile, kube lula ukuthuthwa.

Isixazululo esisike ngaphambili VS Isixazululo sokusika ngemuva

Isivinini Sokukhiqiza:Ngokuvamile, imishayo ye-Guardrail ingamamitha angu-4 ubude. Ukusika kuqala kusebenza ngesivinini esingamamitha ayi-12 ngomzuzu, okwenza ukukhiqizwa kwemishayo engu-180 ngehora. Ngemva kokusika, egijima ngamamitha angu-6 ngomzuzu, ikhiqiza imishayo engu-90 ngehora.

Ukuchithwa Kwemali:Ngesikhathi sokusika, isixazululo esinqunyiwe ngaphambili sikhiqiza imfucuza eyiziro noma ukulahleka. Ngokuphambene, isixazululo sangemuva kokusikwa sikhiqiza imfucuza engu-18-20mm ngokusikwa ngakunye, njengokucaciswa komklamo ngamunye.

Ubude besakhiwo somugqa:Esixazululweni esinqunyiwe ngaphambili, isiteji sokudlulisa siyadingeka ngemuva kokusika, okungase kuholele ekuhlelweni komugqa wokukhiqiza okude kancane uma kuqhathaniswa nesixazululo sokusika ngemuva.

Ubude obuncane:Esixazululweni esinqunyiwe, kunesidingo sobude obuncane bokusika ukuze kuqinisekiswe ukuthi ikhoyili yensimbi ihlanganisa okungenani amasethi amathathu ama-roller akhayo, okuhlinzeka ukungqubuzana okwanele ukuze iqhubekele phambili. Ngokuphambene, isixazululo sokusikwa asinawo umkhawulo wobude obuncane bokusika njengoba umshini wokwenza umqulu unikezwa ngokuqhubekayo ngekhoyili yensimbi.

Kodwa-ke, uma kubhekwa ukuthi ama-W beam ngokuvamile alinganisa amamitha angu-4 ubude, okweqa imfuneko yobude obuncane, ukukhetha phakathi kwezixazululo ezisikwe ngaphambilini nangemuva kokusikwa kuba bucayi kakhulu kulo mshini wokwenza umqulu oklanyelwe ama-W.

Iseluleko esinomusa:Sincoma ukuthi amaklayenti akhethe umugqa wokukhiqiza ngokusekelwe kuzidingo zabo zobuningi bokukhiqiza. Kubanikeli bamaphrofayili we-guardrail beam, isisombululo esisikiwe ngaphambili siyanconywa. Naphezu kwezindleko zayo eziphakeme kancane uma kuqhathaniswa nesixazululo sangemuva kokusika, amandla ayo athuthukisiwe okukhiphayo angasusa ngokushesha noma yimuphi umehluko wezindleko.

Uma uthengela iphrojekthi yokwakhiwa kwethrafikhi, isisombululo se-post-cut sifaneleka kakhulu. Ithatha indawo encane futhi ngokuvamile itholakala ngezindleko eziphansi.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle

1-300x168.jpg)