ividiyo

Iphrofayela

Udoti:Amagatha ensimbi ajwayele ukusetshenziselwa ukukhipha amanzi emaphethelweni ophahleni lwezakhiwo, ikakhulukazi ukuqoqa nokushanela amanzi emvula. Izitayela ezivamile zihlanganisahi-alf-nxazonkeuhlobokanye no-K-isitayelauhlobo. Ngokuvamile zenziwa ngezinto zensimbi ezisukela ku-0.3-0.8mm, njenge-aluminium, insimbi ependwe ngaphambili, noma insimbi.

I-Ridge cap:Umqansaisigqokokuyintosethalapho izinhlangothi zombiliezimbiliuphahlaamaphanelimeet, eyaziwa nangokuthi ophahleni sikaphezulu. Kujwayelekilesebenzisad ukuthuthukisa ukuvala kanye nobuhle bophahla. Amakepisi ama-Ridge ngokuvamile aklanywa ngensimbi ependwe ngaphambili noma insimbi ethathiwe kusukela ku-0.3-0.8mm.

Ikesi langempela-Amapharamitha Obuchwepheshe Abalulekile

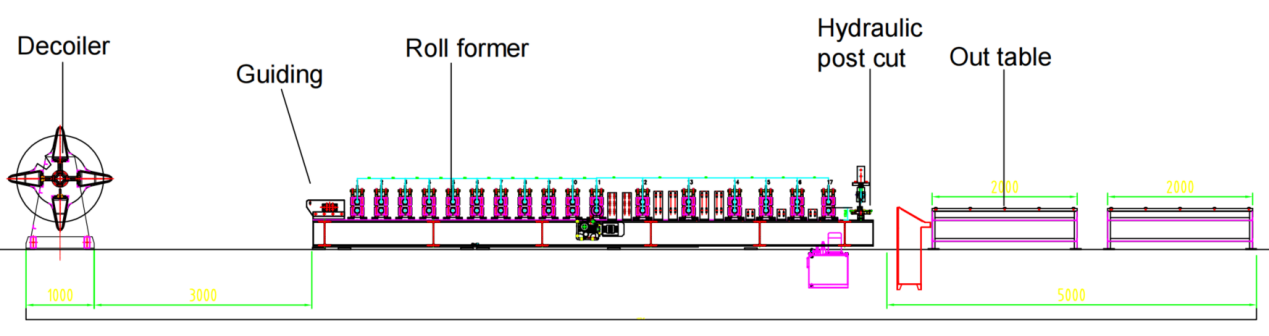

Ishadi eligelezayo: I-Decoiler--Guiding--Roll forming machine--Hydraulic cut--Out table

- 1.Ridge cap-Line isivinini: 0-12m/min, adjustable

- Isivinini se-2.Gutter-Line: 0-4m/min, siyalungiseka

- 3.Suiimpahla yetafula:Insimbi engaphekiwe, insimbi ependwe ngaphambilini, i-aluminium

- 4.Material ukujiya: 0.3-0.8mm

- I-5.Umshini wokwenza umqulu: Isakhiwo sephaneli yodonga kanye nesistimu yokushayela iketango

- I-6.Isistimu yokusika: Yeka ukusika ngemva komshini wokwenza umqulu, ugoqe izitobhi zangaphambili lapho usika.

- Ikhabhinethi ye-7.PLC: Uhlelo lwe-Siemens.

Uhlu Lwangempela Lokupakisha

- 1.I-Hydraulic decoiler*2

- 2.Umshini wokwenza amarowu amabili*1

- 3.Umshini wokusika we-hydraulic wemigqa emibili*1

- 4.Ithebula elingaphandle*2

- 5.PLC control cabinet*1

- 6.Isiteshi samanzi*1

- 7.Ibhokisi lezingxenye ezisele (Mahhala)

Ikesi langempela-Incazelo

- I-Decoiler

Ngesivalo se-ridge kanye ne-gutter, ukumiswa kwe-decoiler kucishe kufane, kusetshenziswa ama-hydraulic decoilers anomthamo womthwalo wamathani ama-3 lilinye. Uma kubhekwa ububanzi obuhlukahlukene bamakhoyili ensimbi asetshenziselwa ukuvala i-ridge cap kanye ne-gutter, kungcono ukwaba i-decoiler ezinikele emgqeni ngamunye wokukhiqiza. Le ndlela inciphisa isikhathi sokuphumula ngesikhathi sokushintsha ikhoyili futhi ithuthukisa ukusebenza kahle komugqa ngamunye wokukhiqiza.

Ukuqondisa

Iama-roller aqondisayo aqinisekisa ukuhambisana phakathi kwekhoyili yensimbi ne- ukwakha umquluumshini, ukuvimbela ukuhlanekezela ngesikhathi sokwenza inqubo.

Umshini wokwenza ama-roll

Lo mshini wokwenza ama-roll usebenzisa isakhiwo sephaneli yodonga kanye nesistimu yokushayela ngamaketango. Ngokungafani nokusetha okuvamile kwemigqa emibili okufaka osayizi ababili abahlukene bephrofayela efanayo, lo mshini uphatha amaphrofayela ahluke ngokuphelele kumugqa ngamunye.

Kubalulekile ukuqaphela ukuthi imigqa emibili ayikwazi ukusebenza ngesikhathi esisodwa. Sincoma ukuthi unikezele ngomugqa wokukhiqiza ohlukile wephrofayela ngayinye uma unezidingo eziphezulu zokukhiqiza.

Ukwengeza, kuye kwafakwa izembozo zensimbi phezu kwamaketango ukuze kuvikelwe izisebenzi ekuthinteni ngengozi ngamaketango ajikelezayo nokuvikela amaketango emonakalweni othulini nemfucumfucu.

Ukusika kweHydraulic

Imishini yokusika igxilile kulo mugqa wokukhiqiza, imisa ukunyakaza kwekhoyili yensimbi ngesikhathi sokusika. Kumakhasimende adinga isivinini sokukhiqiza esiphezulu, sinikeza umshini wokusika endizayo ukuthi isisekelo singahamba ngokushelela phambili nangemuva kuma-rails ngesivinini esifanayo somshini wokwenza umqulu. Lo mklamo omusha wenza ikhoyili yensimbi iqhubekele phambili emshinini wokwakha ngaphandle kweziphazamiso ngesikhathi sokusika, ngaleyo ndlela ikhulise ngokuphawulekayo ukusebenza kahle okuphelele komugqa wokukhiqiza.

Ekupheleni kwayo yomibili imigqa, ama-blade okusika aklanywe ngobunono ukuze afane ngokunembile nama-contour amaphrofayili afanele. Lokhu kuqinisekisa ukuthi amaphethelo kumaphrofayela awahlanekezelwe, kugcina amazinga aphezulu okunemba nekhwalithi.

Isiteshi samanzi

Inikeza amandla okuqala kumsiki ngethangi likawoyela elivaliwe. Ivaliwe ngaphandle kokusika, okungasindisa amandla.

Isiteshi se-hydraulic sifakwe isiphephetha-moya esipholile, esenza kube lula ukulahlwa kokushisa okusebenzayo ukuze kuqinisekiswe ukusebenza isikhathi eside nokufanele. Ngezinga eliphansi lokwehluleka nokuqina okukhethekile, isiteshi esisebenza ngaphansi kwamanzi siqinisekisa ukusebenza okuthembekile esikhathini eside.

Ikhabhinethi yokulawula ye-PLC ne-Encoder

Ulayini okhiqiza umqulu uhlotshiswe ngefomu le-encoder yaseJapan i-KOYO. Isifaki khodi silokhu sihumusha ubude obutholiwe bamakhoyili ensimbi kumasiginali kagesi, buwathumele kukhabhinethi yokulawula ye-PLC. Abasebenzisi bangalungisa isivinini sokukhiqiza, inani, nobude bokusika. Umshini wokusika uzuza ukunemba okumangalisayo ngenxa yokulinganisa okunembayo nempendulo yesifaki khodi, ugcina amaphutha okusika ngaphakathi kuka-±1mm.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle