ividiyo

Iphrofayela

I-cross bracing idlala indima ebalulekile ezinhlelweni zama-rack, iqinisa ukusekela nokuzinza phakathi kwamafreyimu amabili aqondile. Yakhiwe ngensimbi emnyama eqinile enogqinsi oluvame ukusuka ku-1.5 kuye ku-2.5mm, upende owenziwe ngemva kokwakhiwa usiza ekwengezeni ukugqwala nokumelana nokugqwala, iqinisekisa ukuphila isikhathi eside nokwethembeka.

Ikesi langempela-Amapharamitha Obuchwepheshe Abalulekile

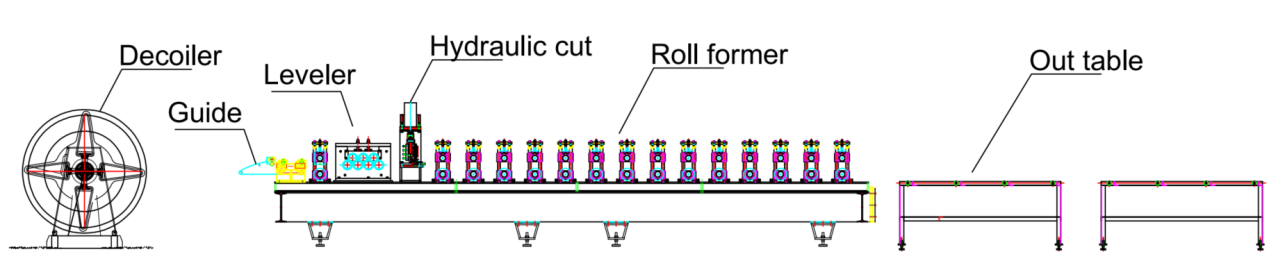

Ishadi eligelezayo: Di-ecoiler--Ukuqondisa--I-Leveler--Ukusika kwangaphambili--Roll ifomuumshini--Ithebula elingaphandle

- 1.Isivinini somugqa: 0-15m/min, siyalungiseka

- 2.Ubukhulu esimweni sangempela: Ububanzi obuningi 80-300mm, ubude obuhleliwe 50mm

- 3.Impahla efanelekile: Insimbi enama-galvanized

- 4.Material ukujiya: 1.5-2mm

- 5.I-Roll forming machine: Cast-iron isakhiwo kanye neketango lokushayela uhlelo

- I-6.Isistimu yokusika: Sika ngaphambi komshini wokwenza umqulu, onamandla we-hydraulic.

- Ikhabhinethi ye-7.PLC: Uhlelo lwe-Siemens.

Ikesi langempela-Imishini

1.I-Decoiler*1

2.Leveler(Ifakwe emshinini wokwenza umqulu)*1

3.Umshini we-Hydraulic pre-cut *1

4.Umshini wokwenza iroll*1

5.Ithebula elingaphandle*2

6.PLC control cabinet*1

7.Isiteshi samanzi*2

8.Ibhokisi lezingxenye eziyisipele(Mahhala)*1

Ikesi langempela-Incazelo

- I-Decoiler

Imvamisa, i-decoiler isebenza njengengxenye yokuqala yomugqa wokukhiqiza. Ingalo yayo yokucindezela iyakwazi ukuvikeleka ikhoyili yensimbi, ivimbele ukulimala ekuwohlokeni kwekhoyili ngesikhathi sokushintsha ikhoyili. Imishini yangaphandle yokugcina ikhoyili iphinde ivimbele amakhoyili ukuthi angasheleli asuke ku-mandrel.

Ukuqondisa

Amarola aqondisayo azoqondisa kahle ikhoyili yensimbi kumarola akhayo ukuze kugcinwe ukuqondanisa phakathi kwekhoyili yensimbi nomshini wokwenza umqulu, kuncishiswe noma yikuphi ukugoba okungenzeka noma ukuchezuka.

Ileveli

Ukuqina kwe-cross bracing kufinyelela ku-2.5mm, futhi kuphela uma iqonde ngokuphelele futhi ingasontekile inganikeza ukuzinza okungcono kakhulu kwefreyimu yokubeka. Umshini wokulinganisa unganciphisa ikhoyili yensimbi, ukhulule ingcindezi yangaphakathi, wenze kube lula ukubumba nokubumba ngokuqondile. Kulo mugqa wokukhiqiza, umshini wokulinganisa usethelwe kusisekelo somshini wokwenza umqulu, ongasindisa indawo yaphansi futhi unciphise izindleko zomhlaba.

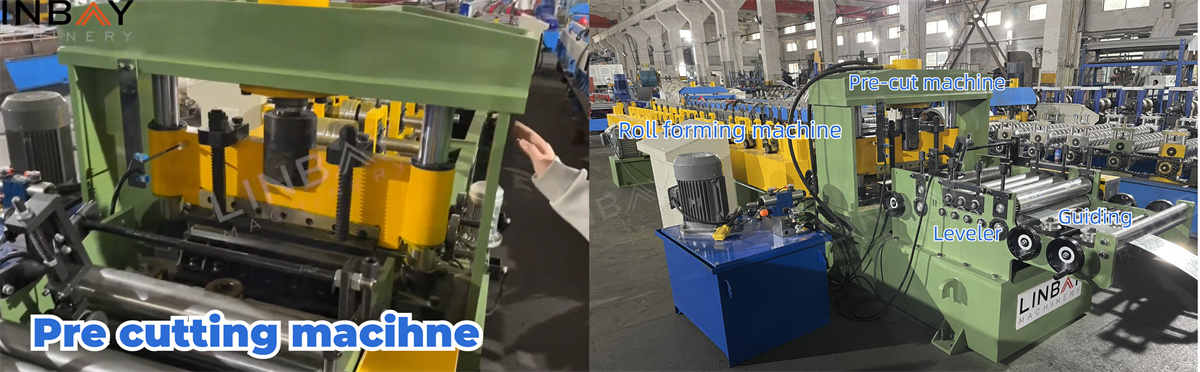

Umshini wokusika ngaphambili

Uma kuqhathaniswa nokusikwa kwangemva kokusika, ukusika ngaphambili ngaphambi kokwenza akuchithi. Lesi sixazululo senza kube lula ukushintshwa kwamakhoyili ensimbi anobubanzi obuhlukahlukene ukuze kukhiqizwe osayizi abaningi emugqeni ofanayo wokukhiqiza, ngaphandle kokudala noma iyiphi imfucuza.

Roll ifomuumshini

Umshini wokwenza umqulu uyingxenye ebaluleke kakhulu yawo wonke umugqa wokukhiqiza. Isebenzisa ukwakhiwa okuqinile kwe-iron esakhiweni sesiteshi, esakhiwe ngensimbi eqinile. Ukujikeleza kwama-roller akhayo kuqhutshwa uhlelo lwamaketanga.

Impahla yama-roller akha i-Gcr15, insimbi enekhabhoni ephezulu ye-chromium edume ngobulukhuni bayo obuhle kakhulu nokumelana nokugqokwa. Amarola afakwe nge-chrome ukuze andise impilo yawo yesevisi. Amashafu enziwe ngezinto ezingu-40Cr futhi aphathwa ngokushisa.

Ukuqiniswa kuhlanganiswa ngaphansi kwephrofayela ukuze kuthuthukiswe amandla ayo. Lo mshini wokwenza ama-roll ungakhiqiza i-cross bracing enobubanzi obungu-80-300mm nobude obungama-50mm. Ngokufaka ubukhulu obufunekayo kuphaneli yokulawula ye-PLC, isiteshi esakhayo sihamba ngojantshi siye endaweni efanele nenembayo. Iphuzu lokubumba liphinde lilungise njengoba isiteshi esakhayo sihamba.

Ukuphepha kokuhamba kweziteshi ezakha, 2 izinzwa zebanga asethwe esisekelweni somshini, ezihambisana nezikhundla ezingaphandle nezingaphakathi impela okuthiukwakhaesiteshinisingathuthelwa ku.Okwezinzwa, tiphuzu lakhe lokuzwa yilonalaphakweisisekelo seziteshi ezakhayo. Okungaphakathiinzwaukuvimbelaukwakhaesiteshiniskusukela ekusondeleni kakhulu nokudanga ukushayisana kwamarola.Okungaphezuluinzwaukuvimbelaukwakhaesiteshini ekuhlukaneni ne-ojantshinokuwa.

Isiteshi samanzi

Isiteshi se-hydraulic siza sifakwe izifanisi zokupholisa eziklanyelwe ukuqeda ukushisa okusebenzayo, okuqinisekisa ukusebenza okungaphazamiseki kanye nokukhulisa umkhiqizo. Lesi siteshi se-hydraulic sakhiwe ukuze sihlale, siqinisekisa ukuqina kwesikhathi eside.

Ikhabhinethi yokulawula ye-PLC ne-Encoder

Isifaki khodi siguqula ubude obuzwiwayo bekhoyili yensimbi bube amasignali kagesi adluliselwa kukhabhinethi yokulawula ye-PLC. Ngaphakathi kwekhabhinethi yokulawula, isivinini sokukhiqiza, umkhiqizo ngamunye wokukhiqiza, ubude bokusika, neminye imingcele ingaphathwa. Ngezilinganiso ezinembile kanye nempendulo evela kusifaki khodi, umshini wokusika ungalawula amaphutha okusika ngaphakathi kwe-±1mm.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle