IVIDIYO

I-Perfil

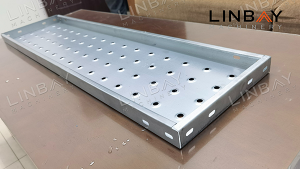

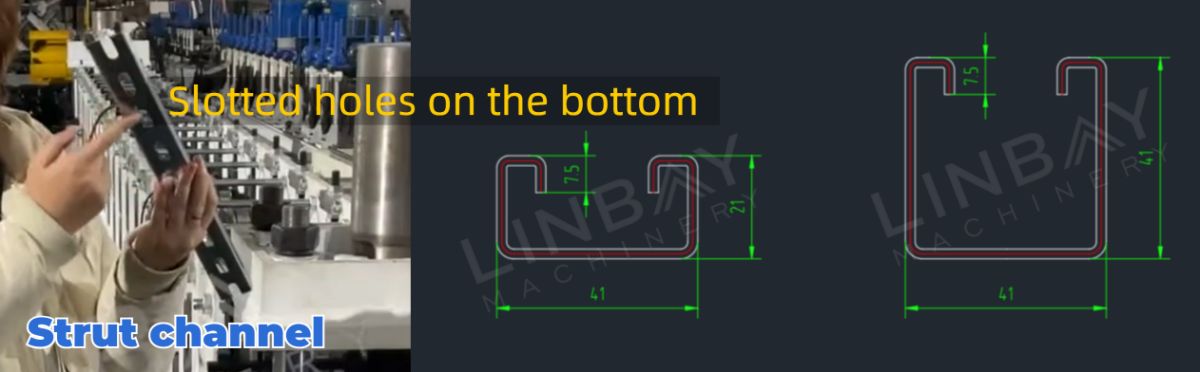

Isiteshi se-Strut sisebenza njengengxenye ebalulekile yokusekela nokuxhuma imithwalo yesakhiwo engasindi ekwakhiweni kwesakhiwo. Ubukhulu obujwayelekile beziteshi ze-strut ngokuvamile zifaka phakathi41*21mmfuthi41*41mm. Lezi ziteshi zivame ukwakhiwa ngezinto ezifanainsimbi egoqiwe eshisayo, insimbi egoqwe ngamakhaza, noma insimbi, efaka ukujiya okuvamise ukusukela1.5mm ukuze 2mm.

Ikesi langempela-Amapharamitha weTechinical Eyinhloko

Ishadi eligelezayo

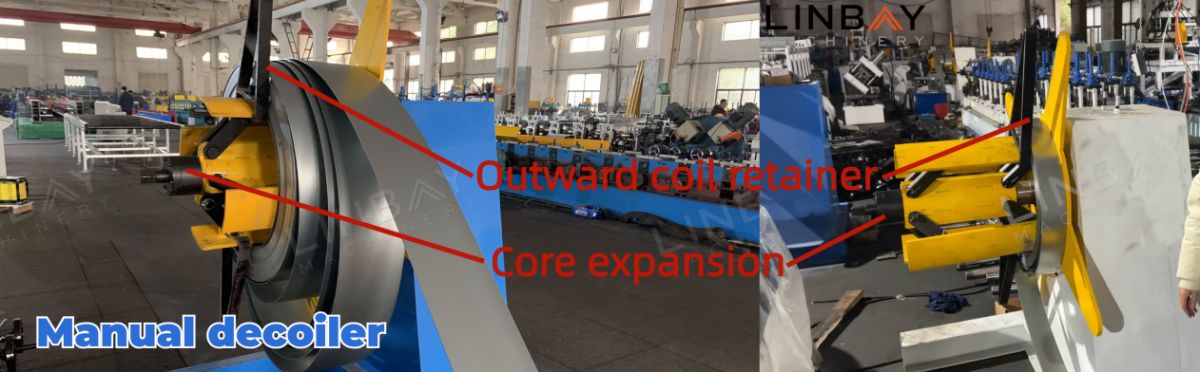

I-decoiler yezandla ifakwe idivayisi yebhuleki, evumela ukulungiswa kokunwetshwa okuyisisekelo phakathi kuka-φ490-510 mm,ukuqinisekisa ukuthululwa okushelelayo. Ngaphezu kwalokho, i-coil retainer yangaphandle ivimbela ukushelela kwekhoyili, ikhulise ukonga kwezindleko nokuphepha. Esimeni se-hydraulic decoiler, ingalo yokucindezela ivikela ikhoyili yensimbi, inciphise ubungozi bokuphuma kwamakhoyili kanye nokulimala okungenzeka kwesisebenzi. Ukuze kuhlangatshezwane nezidingo ezikhulayo zokukhiqiza, sihlinzeka nge-hydraulic decoiler enikelwe amandla yisiteshi samanzi.

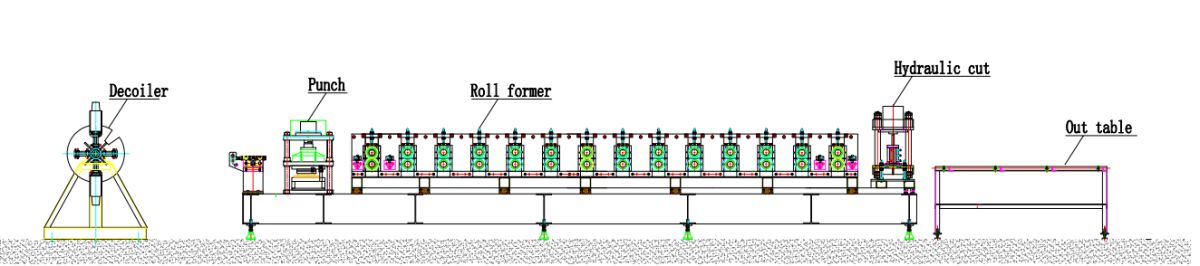

I-Manual decoiler--Ukuqondisa--I-punch ye-Hydraulic--Umshini wokwenza i-Roll--Hydraulic cut--Out table

Main Techinical Amapharamitha

1.Ijubane lomugqa: 0-12m/min ngaphandle kokushaya, 3m/min ngokushaya.

2.Ubukhulu bezinto ezibonakalayo: 2mm kulokhu.

3.Impahla efanelekile: Insimbi egoqiwe eshisayo, insimbi egoqiwe ebandayo, insimbi yamagalani.

I-4.Umshini wokwenza i-Roll: Isakhiwo sephaneli yodonga kanye nesistimu yokushayela iketango.

5.Cha. Isiteshi esakhayo: 20

I-6.Isistimu yokubhoboza: I-hydraulic, i-roll yangaphambili yokumisa lapho ushaya.

7.Isistimu yokusika:I-Hydraulic, i-roll yangaphambili yokumisa lapho usika.

8.Ukushintsha usayizi: amahora angu-2-3 ngesandla.

Ikhabhinethi ye-9.PLC: Uhlelo lwe-Siemens.

Ikesi langempela-Incazelo

I-Decoiler Manual

Ukuqondisa

Amarola aqondisayo adlala indima ebalulekile ekugcineni ukuhambisana phakathi kwekhoyili yensimbi nomshini, ukuvimbela ukuhlanekezelwa kwesiteshi se-strut.

Amarola aqondisayo adlala indima ebalulekile enqubweni yokubunjwa, avimbele ukuwohloka kwe-strip steel. Ukuqonda kweshubhu yeshubhu kubalulekile kwikhwalithi yomkhiqizo, okunomthelela ekusebenzeni okusekelayo kwalo lonke uhlaka lokufaka. Ama-guiding roller afakwe ngendlela ehlelekile kuwo wonke umshini wokwenza ama-roll, hhayi nje endaweni yokungena. Ngaphambi kokuthunyelwa, sikala ibanga ukusuka kurola ngayinye eqondisayo ukuya onqenqemeni lomshini bese sibhala lezi zilinganiso kumanuwali. Esimeni sokufuduka okuncane ngesikhathi sokuthutha noma inqubo yokukhiqiza, abasebenzi bangasebenzisa le datha erekhodiwe ukuze bamise kabusha amarola ngokunembile.

I-Hydraulic Punch

I-punch ye-hydraulic, enikwa amandla yisiteshi se-hydraulic, itholakala ngaphambi komshini wokwenza umqulu, okudinga ukuthi kumiswe isikhashana enqubweni yokwenza umqulu ngesikhathi sokubhoboza. Umshini we-hydraulic punch ulungiselelwe ngesinyathelo se-punch esingu-400 mm. Ukwandisa isivinini sokukhiqiza, siphakamisa isisombululo esizimele sokubhoboza nge-hydraulic esifanelana nemidwebo yokubhoboza enikeziwe.

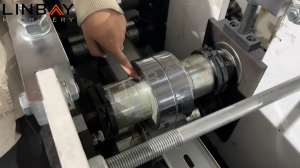

Umshini Wokwenza Roll

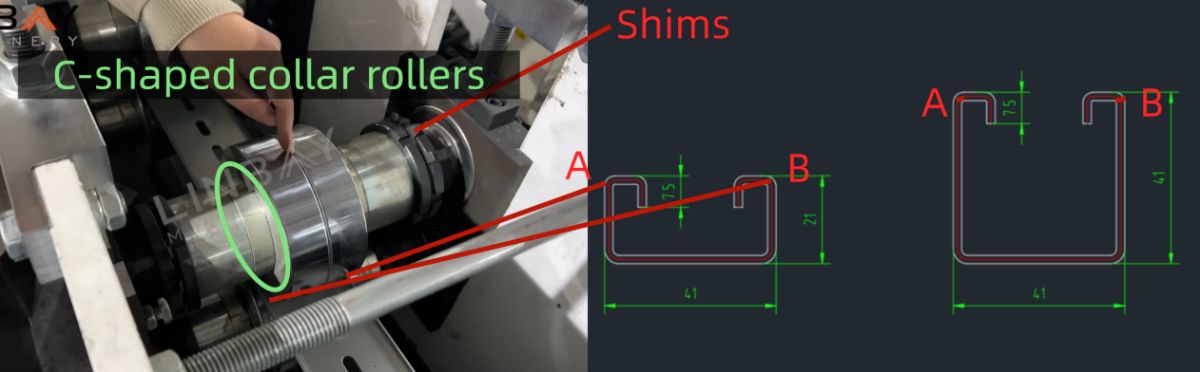

Umshini wokwenza ama-roll unesakhiwo sephaneli yodonga kanye nesistimu yokushayela ngamaketango, ehlinzeka ngesixazululo esingabizi kakhulu sokushintsha kosayizi okwenziwa ngesandla kanye nesikhathi sokushintsha cishe esingaba2-3 amahora.

Ukulungisa amaphoyinti okwakha kubalulekile ekushintsheni osayizi. Ukukhulula ama-shims ekugcineni kwama-roller bese ufaka esikhundleni noma ungezeAmarola wamakholomu amise okwe-C (imikhono)endaweni efanelekile kushintsha indawo yokwakheka kasayizi omusha wephrofayela. Ukwengeza, sinikeza iukushintsha usayizi okuzenzakalelayo isisombululongesikhathi sokushintshacishe imizuzu eyi-10.

Isixhumanisi sevidiyo esiya ku-【Ukufakwa】I-Linbay Shintsha imikhono yomshini wokwenza ama-roll

Ukusika kweHydraulic

Umshini wokusika ama-hydraulic, osetshenziswa yisiteshi se-hydraulic, unekhono lokusika amakhoyili ensimbi awugqinsi angu-2mm. Ama-blade ayo okusika afanelaniswe nesimo sephrofayela, akhiqiza cishe u-8mm wemfucuza ekusikeni ngakunye kuyilapho egcina indawo yokusika ecishe ingabi na-burr.

Isifaki khodi ne-PLC

Umshini wokwenza umqulu uhlanganisa isishumeki segama saseJapane i-Koyo, esihumusha ubude bekhoyili ezwayo ibe amasignali kagesi adluliselwa kukhabhinethi yokulawula ye-PLC. Lolu hlelo olunembayo luqinisekisa ukuthi amaphutha okusika ayagcinwangaphakathi kwebanga elingu ±1mm, ukuqinisekisa ukukhiqizwa kwemikhiqizo yekhwalithi ephezulu ngenkathi kunciphisa imfucuza ekusikeni okungalungile. Abasebenzisi bangalawula kalula isivinini sokukhiqiza, ubukhulu bokukhiqiza, ubude bokusika, nokuningi ngesikrini se-PLC. Ukwengeza, izici zekhabhinethi yokulawula ye-PLCinkumbulo yokugcinakumapharamitha asetshenziswa kakhulu futhi inikeza imisebenzi yokuvikela njengokulayisha ngokweqile, ukujikeleza okufushane, nokulahlekelwa kwesigaba.

Ulimi olukusikrini se-PLC lungenziwa ngendlela oyifisayo ngokusekelwe kokuthandwa yikhasimende.

Isiteshi seHydraulic

Isiteshi sethu se-hydraulic sifakwe abalandeli bakagesi okupholisa ukuze kukhishwe ukushisa ngokuphumelelayo, ukuqinisekisa ukusebenza isikhathi eside nokuthembekile ngezinga eliphansi lokuhluleka, ukujwayela indawo yokusebenza eshisayo.

Iwaranti

Ngosuku lokuthunyelwa, idethi yamanje izoqoshwa ku-nameplate yensimbi, okuphawula ukuqala kwesiqinisekiso seminyaka emibili sawo wonke umugqa wokukhiqiza kanye newaranti yeminyaka emihlanu yamarola namashafti.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle