ividiyo

Iphrofayela

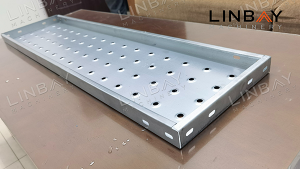

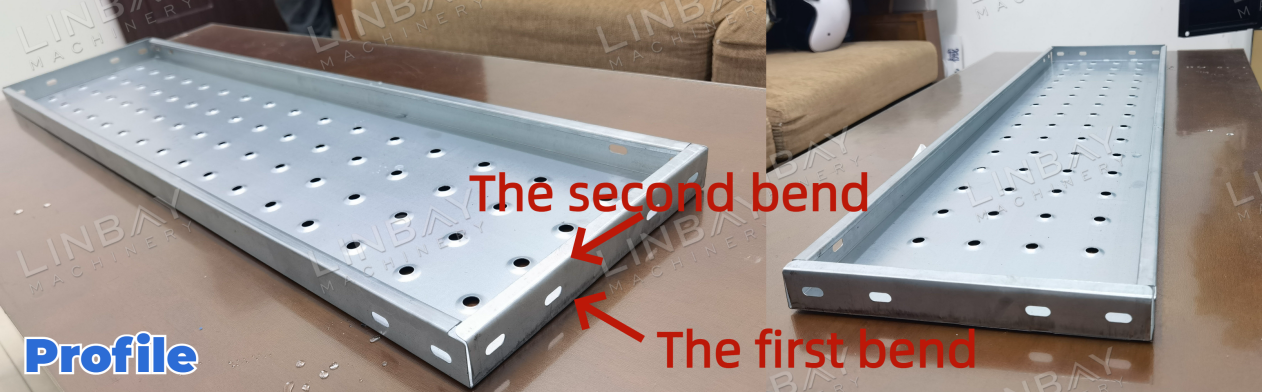

Iphaneli yeshalofu, ebekwe phezu kwemishayo yesistimu yokurakha, isebenza njengenkundla eqinile yokugcina impahla ngokuphephile. Ubuchwepheshe bethu bokukhiqiza bugxile ekukhiqizeni amaphaneli eshalofu agobile kabili, anikeza ukuqina okuphakeme uma kuqhathaniswa nohlobo lwe-single-bend. Ngaphezu kwalokho, lo mklamo ususa imiphetho ebukhali esobala, ubeke phambili ukuphepha komsebenzisi.

Ikesi langempela-Amapharamitha weTechinical Eyinhloko

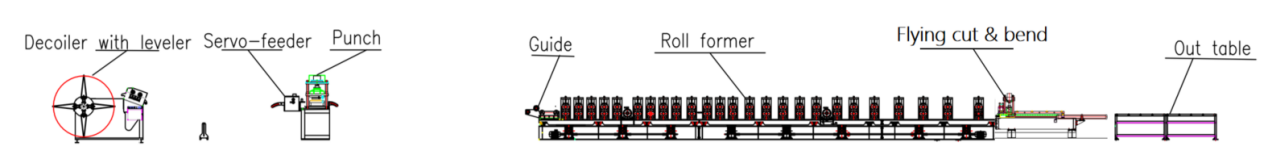

Ishadi eligelezayo

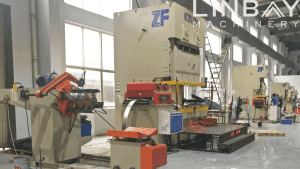

I-hydraulic decoiler ene-level--Servo feeder--Hydraulic punch--Roll forming machine--Hydraulic cut and stamping--Out table

Amapharamitha Abalulekile Wezobuchwepheshe:

1. Isivinini somugqa: Ishintsheka kusuka ku-0 kuye ku-4 m/min

2. Amaphrofayili: Osayizi abahlukahlukene abanobude obungaguquki, abahluka ngobubanzi nangobude

3. Ubukhulu bezinto: 0.6-0.8mm (yalolu hlelo lokusebenza)

4. Impahla efanelekile: Insimbi enama-galvanized

5. Umshini wokwenza ama-roll: Usebenzisa i-cantilevered double-wall structure kanye ne-chain drive system

6. Inani leziteshi ezakhayo: 13

7. Uhlelo lokusika: Ukusika kanye nokugoba ngesikhathi esisodwa; umqulu wangaphambili usasebenza ngesikhathi sohlelo

8. Ukulungiswa kosayizi: Okuzenzakalelayo

9. Ikhabhinethi ye-PLC: Ifakwe uhlelo lwe-Siemens

Ikesi langempela-Incazelo

I-Hydraulic Decoiler ene-Level

Ukunwetshwa okuyisisekelo kungalungiswa ukuze kulingane namadiamitha ekhoyili ensimbi asuka ku-460mm kuya ku-520mm. Ngesikhathi sokuqaqa, izibambi zekhoyili zangaphandle ziqinisekisa ukuthi ikhoyili yensimbi ihlala ivikelekile kumshini wokukhipha ikhoyili, ithuthukisa ukuphepha kwezisebenzi ngokuvikela ukuthi ikhoyili ingasheleli.

I-level ifakwe uchungechunge lwamarola athambisa kancane ikhoyili yensimbi, asuse ngempumelelo izingcindezi ezisalayo.

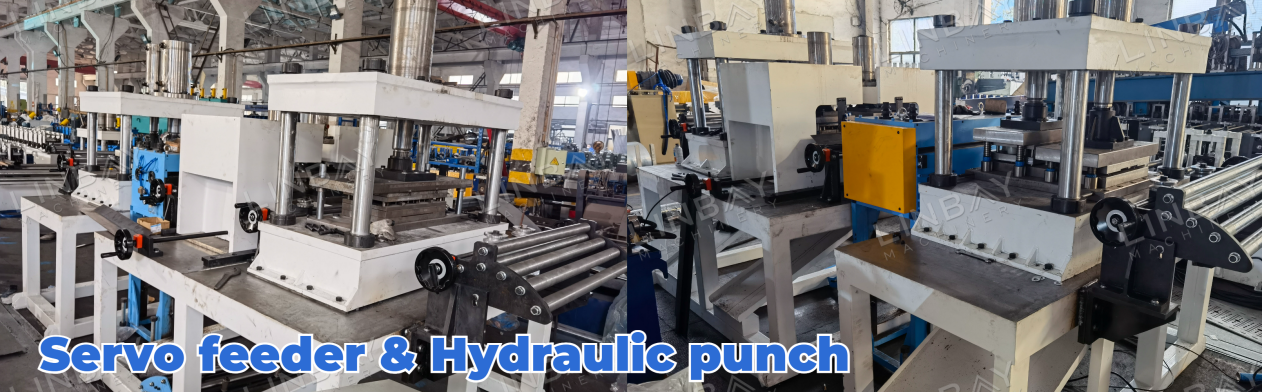

I-Servo Feeder & Hydraulic Punch

(1)I-Independent Hydraulic Punching

Le sistimu yokubhoboza isebenza ngokuzimela, ayihlanganyeli isisekelo somshini ofanayo nomshini wokwenza ama-roll, iqinisekisa ukusebenza okungenazihibe nokungaphazamiseki kwenqubo yokwenza umqulu. Isiphakeli sinikwa amandla yi-servo motor, enokulibaziseka okuncane kokuqala kokumisa. Lokhu kuvumela ukulawula okuqondileyo kokuqhubekela phambili kwekhoyili yensimbi kusiphakeli sekhoyili, ukuqinisekisa ukuthi ukubhoboza okunembile nokuphumelelayo.

(2)Isixazululo sesikhunta esilungiselelwe

Izimbobo ezibhontshiwe kuphaneli yeshalofu zihlukaniswa ngamanotshi, izimbobo ezisebenzayo, nezimbobo ezingezansi eziqhubekayo. Ngenxa yokuhlukahluka kwamafrikhwensi alezi zinhlobo zembobo kuphaneli yeshalofu elilodwa, umshini we-hydraulic punch ufakwe isikhunta esine esizinikezele, ngasinye senzelwe uhlobo oluthile lwembobo. Lokhu kusetha kwenzelwe ukuqedela ngempumelelo uhlobo ngalunye lokushaya, ngaleyo ndlela kuthuthukiswe ukusebenza kahle kanye nokukhiqiza okuphelele.

Isifaki khodi ne-PLC

Isifaki khodi sihumusha ubude bekhoyili yensimbi ezwayo ibe amasignali kagesi, abese ethunyelwa kukhabhinethi yokulawula ye-PLC. Ngaphakathi kwekhabhinethi yokulawula, opharetha bangakwazi ukuphatha isivinini sokukhiqiza, ukuphuma okukodwa kokukhiqiza, ubude bokusika, neminye imingcele. Ngezilinganiso ezinembile kanye nempendulo evela kusifaki khodi, umshini wokusika ungagcina amaphutha okusika ngaphakathi±1mm.

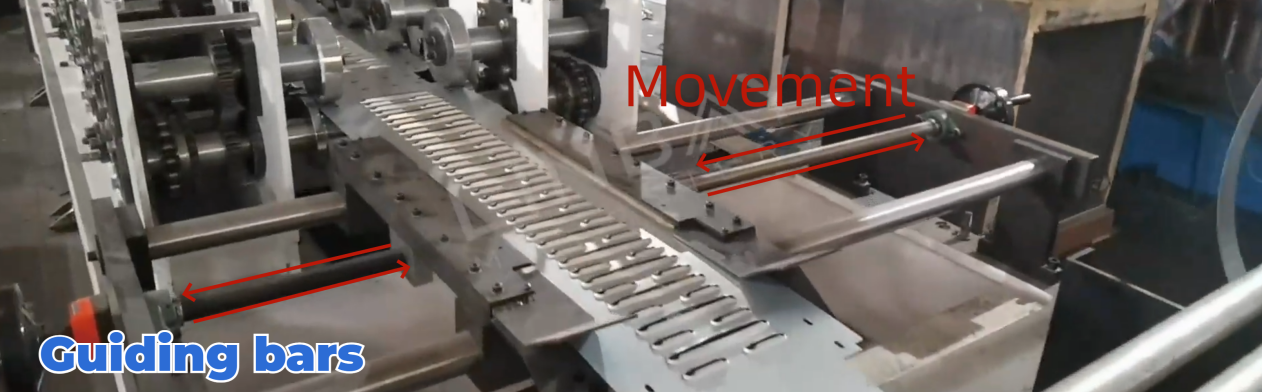

Umshini wokwenza ama-roll

Ngaphambi kokungena emshinini wokwenza umqulu, ikhoyili yensimbi idlula emigoqweni eqondisayo eguquguqukayo. Le migoqo ilungiswa ngokuya ngobubanzi bekhoyili yensimbi, iqinisekisa ukuthi ihambisana kahle nemishini yolayini wokukhiqiza eduze komugqa omaphakathi. Lokhu kuqondanisa kubalulekile ekugcineni ukuqondisa kanye namandla okuthwala umthwalo wephaneli yeshalofu.

Lo mshini wokwakha usebenzisa isakhiwo se-cantilever esinodonga oluphindwe kabili. Njengoba ukwakheka kudingekile kuphela ezinhlangothini ezimbili zephaneli, umklamo we-cantilever roller usetshenziselwa ukulondoloza impahla ye-roller. Isistimu yokushayela ngamaketango ihambisa ama-roller futhi isebenzise amandla kukhoyili yensimbi, ivumela ukuqhubekela phambili nokwakheka kwayo.

Umshini ungakhiqiza amaphaneli eshalofu anobubanzi obuhlukahlukene. Abasebenzi bafaka izilinganiso ezifiselekayo kuphaneli yekhabhinethi yokulawula ye-PLC. Uma isignali yamukelwe, isiteshi esakhayo esingakwesokudla sihamba ngokuzenzakalelayo kumareyili. Amaphuzu okwakha kukhoyili yensimbi alungisa ngokuhamba kwesiteshi esakhayo namarola okwakha.

Isifaki khodi siphinde sifakwe ukuze kutholwe ibanga lokunyakaza kwesiteshi esakhayo, kuqinisekiswe ukunemba lapho kushintsha osayizi. Ukwengeza, kufakwe izinzwa zokuma ezimbili: enye eyokubona ibanga elikude kanti enye eyebanga eliseduze isiteshi esakhayo esingahamba ngayo kumareyili. Inzwa yokuma ekude kakhulu ivimbela ukunyakaza okudlulele kwesiteshi esakhayo, igwema ukushelela, kuyilapho inzwa yendawo eseduze ivimbela isiteshi ukuthi sihambe siye kude kakhulu ngaphakathi, kanjalo sigwema ukungqubuzana.

Ukusika nokugoba kwe-hydraulic

Amaphaneli eshalofu akhiqizwa kulo mugqa wokukhiqiza afaka ukugoba kabili ohlangothini olubanzi. Sidizayine isikhunta esihlanganisiwe sokusika nokugoba, esivumela ukusika nokugoba kabili ngaphakathi komshini owodwa. Lo mklamo awugcini nje ngokugcina ubude bomugqa wokukhiqiza nendawo yaphansi yefekthri kodwa futhi unciphisa isikhathi sokukhiqiza.

Ngesikhathi sokusika nokugoba, isisekelo somshini wokusika singaya emuva futhi siye phambili ngokuvumelanisa nesivinini sokukhiqiza somshini wokwenza umqulu. Lokhu kuqinisekisa ukukhiqiza okungaphazamiseki futhi kuthuthukisa ukusebenza kahle.

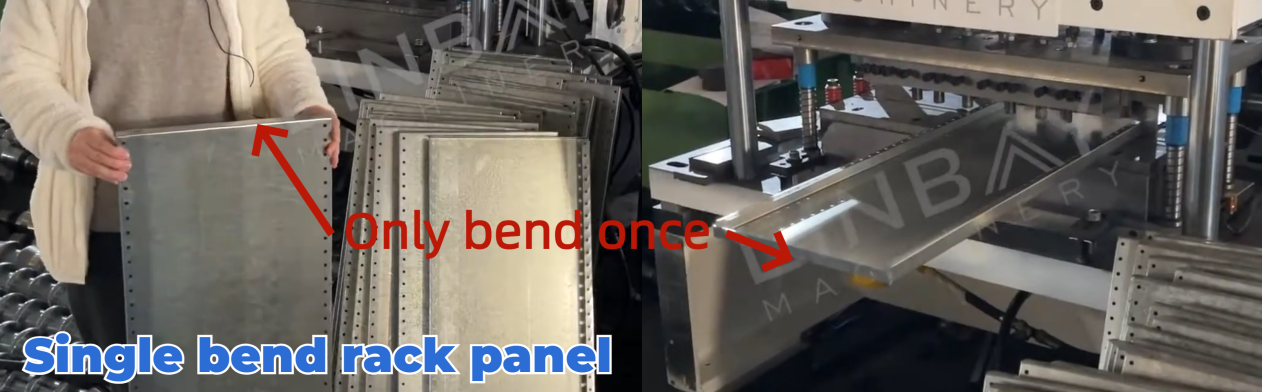

Esinye isisombululo

Uma uthakaselwa ngamaphaneli eshalofu eligobile elilodwa, mane uchofoze esithombeni ukuze ujule ngenqubo yokukhiqiza enemininingwane futhi ubukele ividiyo ehambisana naso.

Umehluko obalulekile:

Uhlobo olugobe kabili lunikeza ukuqina okuphakeme, kuyilapho uhlobo lwe-single-bend nalo luhlangabezana ngokwanele nezidingo zesitoreji.

Amaphethelo ohlobo lwe-double-bend awacijile, athuthukisa ukuphepha, kanti uhlobo lokugoba okukodwa lungaba nemiphetho ebukhali.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle