ividiyo

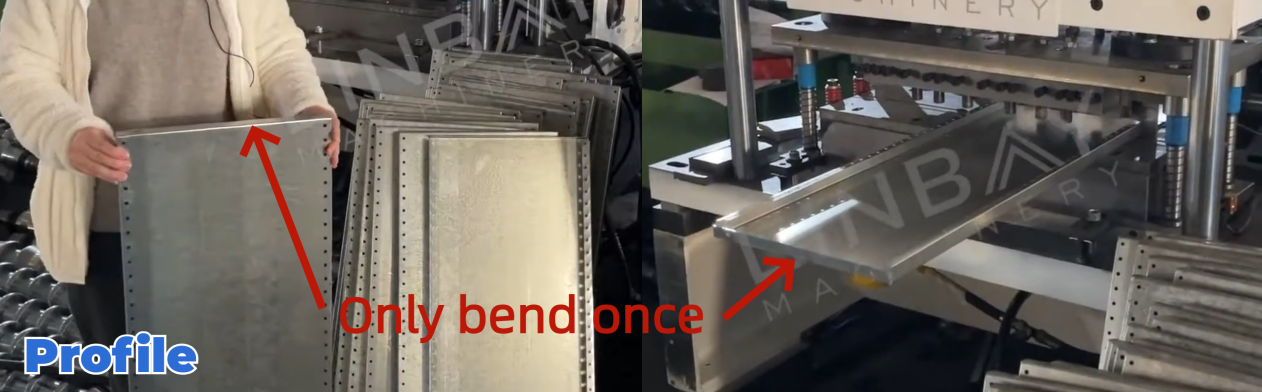

Iphrofayela

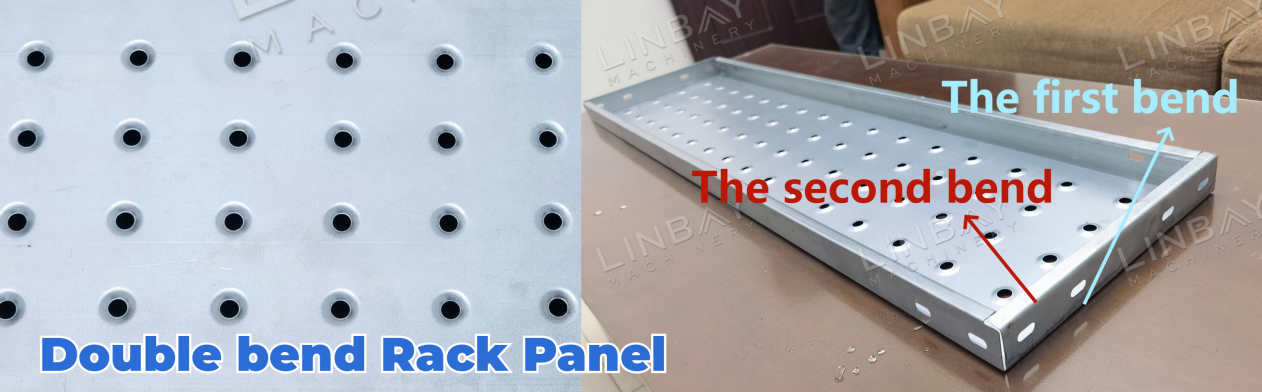

Iphaneli yeshalofu iyingxenye ebalulekile yesistimu yokuqopha, eklanyelwe ukubamba izimpahla. Ivamise ukwenziwa ngensimbi enothayela enogqinsi olusuka ku-1 kuya ku-2 wamamilimitha. Le phaneli itholakala ngobubanzi nobude obuhlukahlukene, kuyilapho ukuphakama kwayo kuhlala kungashintshi. Iphinde ibe nokugoba okukodwa ohlangothini olubanzi.

Ikesi langempela-Amapharamitha weTechinical Eyinhloko

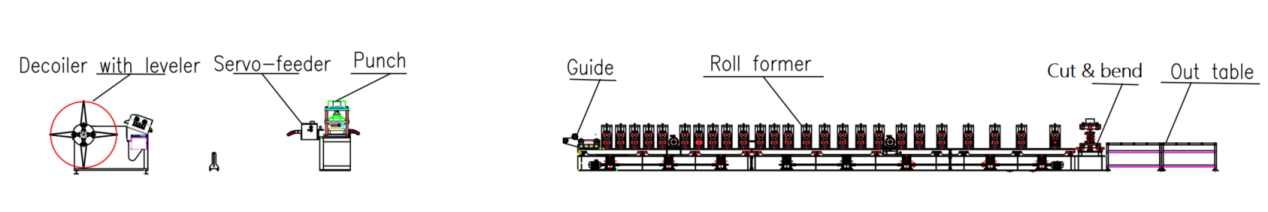

Ishadi eligelezayo

I-hydraulic decoiler ene-level--Servo feeder--Hydraulic punch--Ukuqondisa--Umshini wokwenza i-roll--Umshini wokusika nokugoba--Ithebula elingaphandle

Main Techinical Amapharamitha

1. Isivinini somugqa: Ishintsheka phakathi kuka-4-5 m/min

2. Amaphrofayili: Ububanzi nobude obuhlukahlukene, nobude obungaguquki

3. Ubukhulu bezinto: 0.6-1.2mm (yalolu hlelo lokusebenza)

4. Izinto ezifanele: Insimbi egoqwe eshisayo, insimbi egoqiwe ebandayo

5. Umshini wokwenza ama-roll:Cantilevered isakhiwo sephaneli ephindwe kabili ngesistimu yokushayela ngamaketanga

6. Isistimu yokusika nokugoba: Ukusika nokugoba kanyekanye, ngokumiswa kwe-roll ngesikhathi senqubo.

7. Ukulungiswa kosayizi: Okuzenzakalelayo

8. Ikhabhinethi ye-PLC: Uhlelo lwe-Siemens

Ikesi langempela-Incazelo

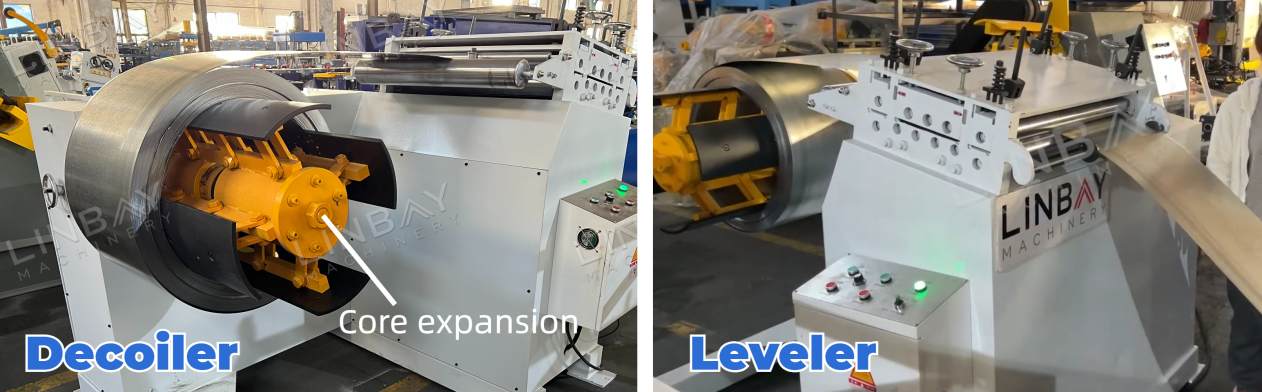

I-Hydraulic Decoiler ene-Level

Lo mshini uhlanganisa i-decoiler kanye neleveli, ukhulisa indawo yefekthri futhi wehlise izindleko zomhlaba. I-core expansion mechanism ingalungisa ukuze ilingane amakhoyili ensimbi anobubanzi bangaphakathi obuphakathi kuka-460mm no-520mm. Ngesikhathi sokuqaqa, izinto ezigcina ikhoyili zangaphandle ziqinisekisa ukuthi ikhoyili yensimbi ihlezi isendaweni evikelekile, okuthuthukisa ukuphepha kwezisebenzi.

Ileveli yenza kube lula ikhoyili yensimbi, ikhulule ingcindezi yangaphakathi futhi ivumele ukubhoboza okuphumelelayo kakhudlwana nokwenza ama-roll.

I-Servo Feeder & Hydraulic Punch

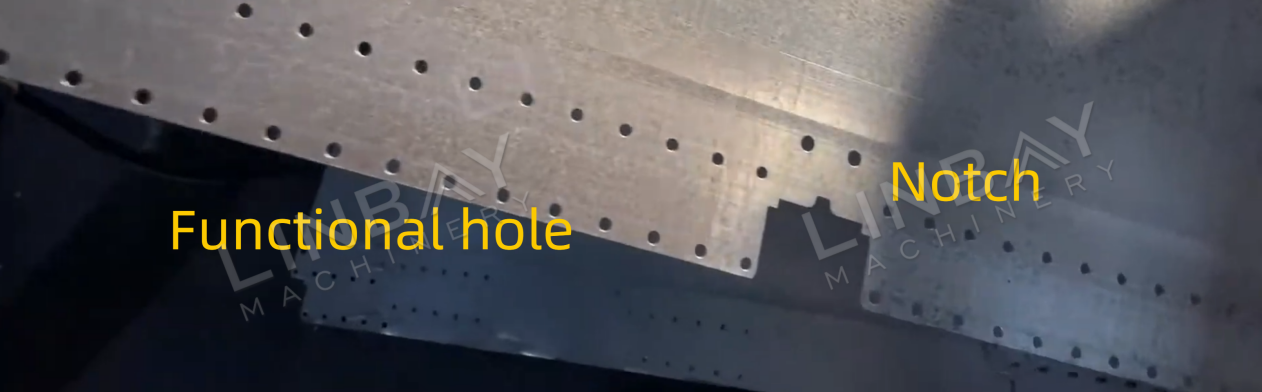

I-punch ye-hydraulic isebenza ngokuzimela, ihlukaniswe nesisekelo somshini wokwenza umqulu. Lo mklamo uvumela umshini wokwenza ama-roll ukuthi uqhubeke nokusebenza ngenkathi ukubhoboza kuqhubeka, okuthuthukisa ukusebenza kahle okuphelele komugqa wokukhiqiza. I-servo motor inciphisa ukubambezeleka kwesikhathi sokuqala, inikeze ukulawula okunembile phezu kobude bekhoyili yensimbi ukuze kushaye ngokunembile.

Phakathi nesiteji sokubhoboza, ama-notches adalwa ngaphezu kwezimbobo zokusebenza zokufakwa kwesikulufa. Njengoba ikhoyili yensimbi eyisicaba izokwakhiwa ibe yiphaneli enezinhlangothi ezintathu, lawa manotshi abalwa ngokunembile ukuze kuvinjelwe ukugqagqana noma izikhala ezinkulu emagumbini amane ephaneli yeshalofu.

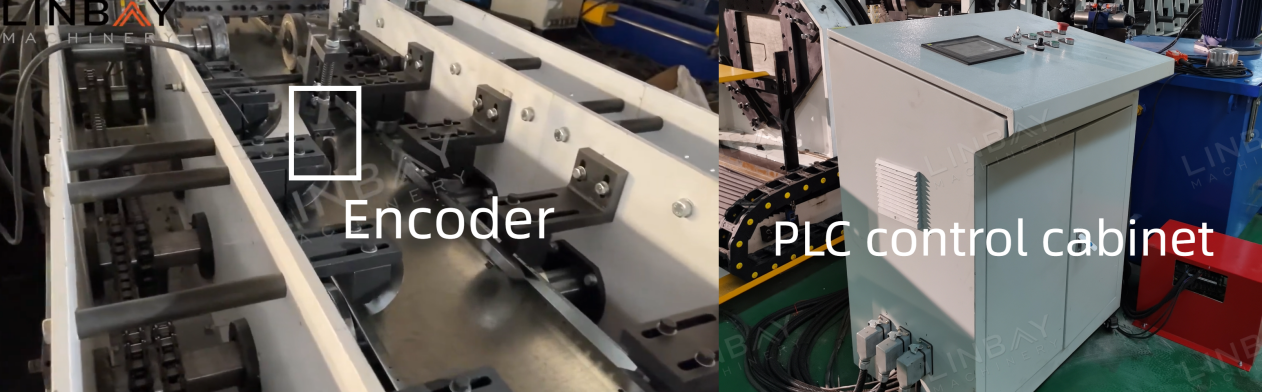

Isifaki khodi ne-PLC

Isifaki khodi siguqula ubude obutholiwe bekhoyili yensimbi bube isignali kagesi, bese idluliselwa kukhabhinethi yokulawula ye-PLC. Ngaphakathi kwekhabhinethi yokulawula, imingcele efana nesivinini sokukhiqiza, inani lokukhiqiza, ubude bokusika, njll., ingaphathwa ngokunembile. Ngenxa yokulinganisa okunembile kanye nempendulo enikezwe isishumeki, umsiki we-hydraulic angakwazi ukugcina ukunemba kokusika ngaphakathi±1mm, ukunciphisa amaphutha.

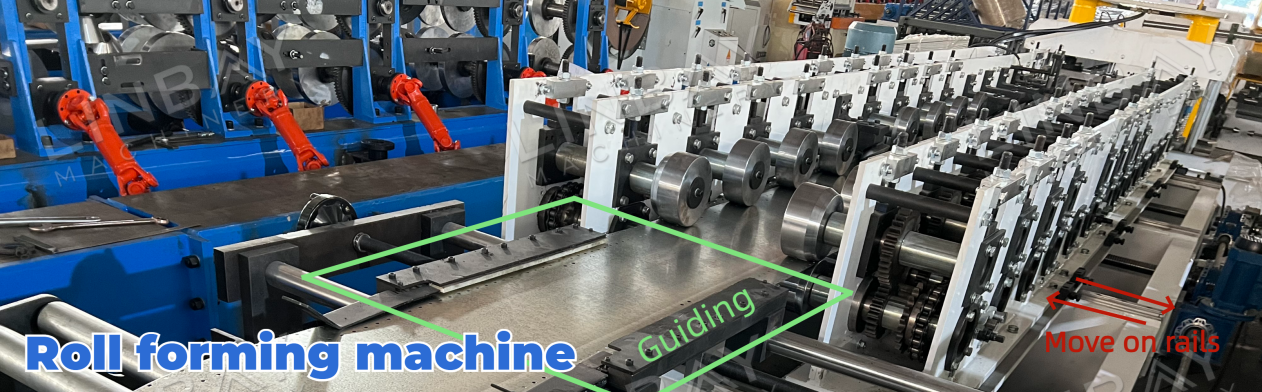

Umshini Wokwenza Roll

Ngaphambi kokungena emshinini wokwakha, ikhoyili yensimbi iqondiswa ngemigoqo ukuze igcine ukuhleleka komugqa ophakathi nendawo. Njengoba kunikezwe ukuma kwephaneli yeshalofu, izinhlangothi kuphela zekhoyili yensimbi zidinga ukwakhiwa. Ngakho-ke, sisebenzisa i-double wall panel cantilever isakhiwo ukuze sinciphise ukusetshenziswa kwezinto, ngaleyo ndlela silondoloze izindleko zempahla ye-roller. Amarola ama-chain-drive enza ingcindezi kukhoyili yensimbi ukuze iqhubekisele phambili nokubunjwa kwayo.

Umshini wokwakha uyakwazi ukukhiqiza amaphaneli eshalofu anobubanzi obuhlukene. Ngokufaka ubukhulu obufunekayo kuphaneli yokulawula ye-PLC, isiteshi esakhayo silungisa ngokuzenzakalelayo indawo yaso eduze kwamareyili lapho sithola amasiginali. Njengoba isiteshi esakhayo kanye nerola zihamba, amaphuzu akhayo kukhoyili yensimbi ashintsha ngokufanele. Le nqubo yenza umshini wokwenza umqulu ukwazi ukukhiqiza amaphaneli eshalofu anosayizi abahlukahlukene.

Isishumeki sifakiwe ukuze kutholwe ukunyakaza kwesiteshi esakhayo, kuqinisekiswe ukulungiswa kosayizi okunembile. Ngaphezu kwalokho, izinzwa ezimbili zokuma-izinzwa ezingaphandle nezingaphakathi impela-asetshenziswa ukuvimbela ukunyakaza okudlulele kumareyili, ngaleyo ndlela kugwenywe ukushelela noma ukungqubuzana phakathi kwamarola.

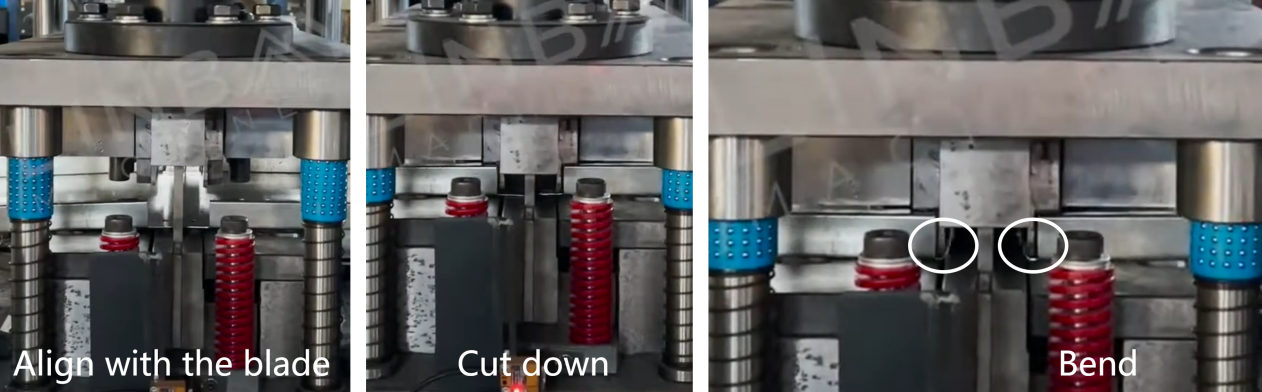

Umshini Wokusika Nokugoba

Kulesi simo, lapho iphaneli yeshalofu idinga ukugoba okukodwa ohlangothini olubanzi, senze isikhunta somshini wokusika ukuze senze ukusika nokugoba kanyekanye.

I-blade yehla ukuze yenze ukusika, emva kwalokho isikhunta sokugoba sikhuphukela phezulu, siqedele ngempumelelo ukugoba komsila wephaneli yokuqala kanye nekhanda lephaneli lesibili ngendlela ephumelelayo.

Olunye Uhlobo

Uma uthakaselwa ngamaphaneli eshalofu anamajika amabili ohlangothini olubanzi, mane uchofoze esithombeni ukuze ujule ngenqubo yokukhiqiza enemininingwane futhi ubukele ividiyo ehambisana nalokhu.

Umehluko obalulekile:

Uhlobo olugoba kabili lunikeza ukuqina okuthuthukisiwe uma kuqhathaniswa nohlobo lwe-single-bend, okuqinisekisa ukusetshenziswa isikhathi eside. Nokho, uhlobo lwe-single-bend luhlangabezana ngokwanele nezidingo zesitoreji. Ukwengeza, imiphetho yohlobo lokugoba kabili alubukhali, okuthuthukisa ukuphepha ngesikhathi sokusetshenziswa, kuyilapho uhlobo lwe-single-bend lungaba nemiphetho ebukhali.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle