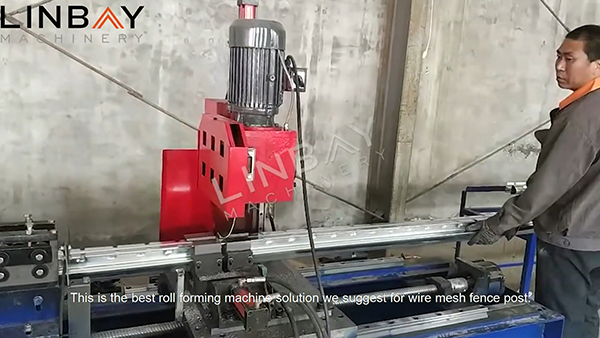

ividiyo

Iphrofayela

Ipali yocingo lwe-wire mesh, evame ukubizwa ngokuthi i-peach post, ithola igama layo kusukela ekubunjweni kwayo kwangaphandle okufana nepentshisi. Ivamise ukwakhiwa ngamakhoyili ensimbi anekhabhoni ephansi noma ashisayo, i-peach posting rolling ebandayo ukuze ifinyelele umumo wayo ohlukile.

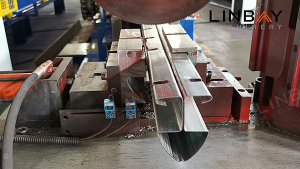

Imiphetho yekhoyili yensimbi igobeleka ngaphandle ukuze yenze ihhuku emise okwe-U, ithuthukisa ukuzinza lapho ivikela inetha locingo. Izikhala ze-notch zibekwe ngendlela efanelekile ezinhlangothini zombili zokuthunyelwe kwepentshisi ukuze kube lula ukufakwa kwe-mesh yocingo lwensimbi, nobukhulu bembobo benziwe ngendlela oyifisayo ukuze bulingane nosayizi wemeshi.

Ulayini wokukhiqiza ophelele uhlanganisa izinqubo zokubhoboza nokwakha ama-roll. Amarola akhayo kanye nama-punch dies enzelwe ukuqinisekisa ukubunjwa okunembile kanye nokubekwa kwenotshi okunembe.

Ikesi langempela-Amapharamitha weTechinical Eyinhloko

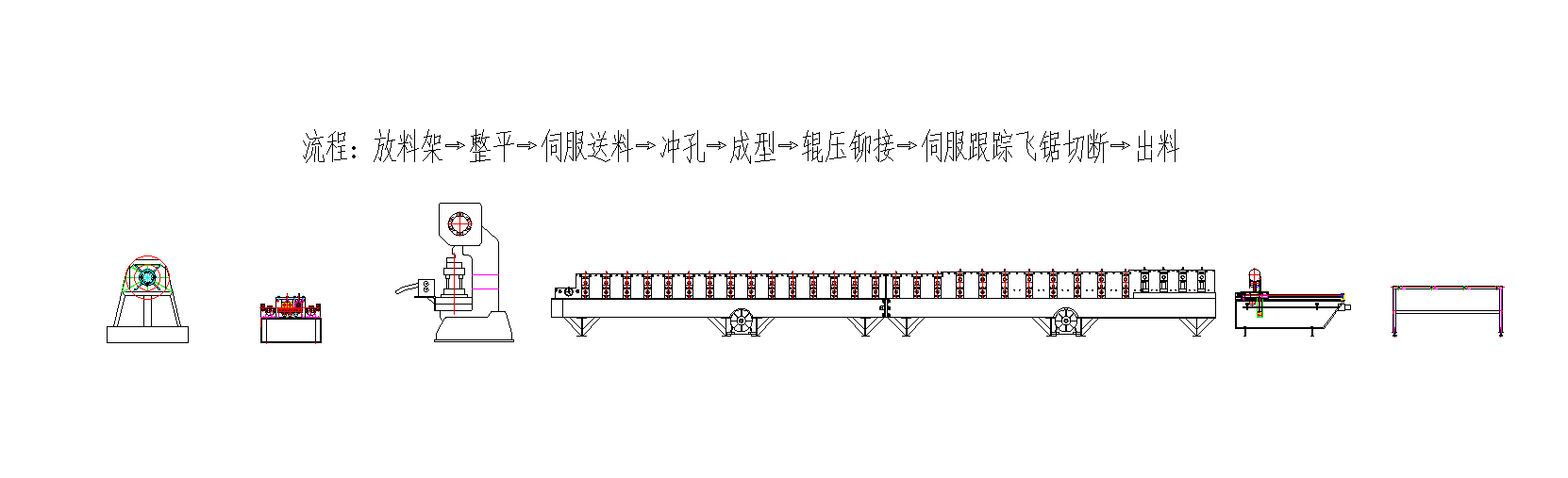

Ishadi eligelezayo

I-Hydraulic decoiler-Leveler-Servo feeder-Punch press-Pit-Roll former-Flying saw cut-Out table

Amapharamitha Abalulekile Wezobuchwepheshe:

1. Isivinini somugqa: Ishintsheka kusuka ku-0 kuye ku-6 m/min

2. Amaphrofayili: Usayizi owodwa wocingo olubiyelwe ngocingo

3. Ubukhulu bezinto: 0.8-1.2mm (yalolu hlelo lokusebenza)

4. Izinto ezifanele: Insimbi egoqwe eshisayo, insimbi egoqiwe ebandayo

5. Umshini wokwenza ama-roll: Isakhiwo sephaneli yodonga enohlelo lokushayela ngamaketango

6. Inani leziteshi ezakhayo: 26

7. Uhlelo lwe-Riveting: Uhlobo lwe-roller; I-roll yangaphambili ihlala isebenza ngesikhathi sokudubula

8. Uhlelo lokusika: Ukusika amasaha; I-roll yangaphambili ihlala isebenza ngesikhathi sokusika

9. Ikhabhinethi ye-PLC: Ifakwe uhlelo lwe-Siemens

Ikesi langempela-Incazelo

I-Hydraulic decoiler

I-decoiler ihlinzeka ngokuguquguquka ngezinketho zokusebenza ngesandla, zikagesi, kanye ne-hydraulic. Ukukhetha uhlobo kuncike esisindweni sekhoyili nokuqina ukuze kuqinisekiswe ukuqaqa okubushelelezi nokungenamthungo.

Le hydraulic decoiler inamandla okulayisha amathani angu-5 futhi ifakwe ngaphandle kwamakhoyili ukuvimbela ukushelela. Injini ishayela idivayisi yokunweba, okuvumela ukunwetshwa nokufinyela ukuze kuthwale amadayamitha angaphakathi ekhoyili ahlukahlukene asuka ku-460mm kuya ku-520mm.

Ileveli

I-level yenza isicaba ngokuphumelelayo, ikhulule ingcindezi yangaphakathi kanye nengcindezi, ngaleyo ndlela ithuthukise izinqubo zokubhoboza nokwenza.

I-Servo feeder & Punch cindezela

Isiphakeli sethu se-servo, esibonakala ngokubambezeleka okuncane kokuqala, sinikeza ukulawula okunembile phezu kwesiphakeli. Lokhu kuqinisekisa ubude besiphakeli sekhoyili obunembile kanye nokuma kwe-punch, kuthuthukisa ukunemba okuphelele kokukhiqiza nokusebenza kahle.

Izigxobo zothango eziqediwe zocingo zinezinotshi eziningi ezidizayinelwe ukuxhumana kwe-wire mesh.

Umshini wokwenza ama-roll

Lo mshini wokwenza umqulu wakhiwe ngesakhiwo sephaneli yodonga futhi usebenza kusetshenziswa isistimu yokushayela ngamaketango. Kuyo yonke inqubo yokwakha, ikhoyili ishintsha kancane kancane ngaphansi kokuphoqelelwa, ibambelela "ekumiseni kwepentshisi" okucacisiwe okuvezwe emidwebeni enikeziwe.

Ukuvimbela ukuhlukaniswa kwamakhoyili endaweni yokuhlangana ngesikhathi sokusetshenziswa isikhathi eside, izinyathelo zokuqapha ziyasetshenziswa. Ukulandela ukwakheka kwama-roll, ama-riveting roller acindezela ukugqagqana kwekhoyili, enze okuvelayo kwe-rivet okuqinisa ukusimama kokuthunyelwe futhi andise ubude bempilo.

Ngaphezu kwalokho, ngenxa yomklamo oyisiyingi wama-riveting rollers, i-roll yangaphambili ingakwazi ukuqhubeka nokusebenza kwayo ngaphandle komthungo njengoba ikhoyili iqhubekela phambili phakathi ne-riveting, isuse isidingo sokusetha esinye isisekelo esinyakazayo sedivayisi yokudonsa.

I-Flying saw cut

Ngenxa yokuma okuvalekile kwesigxobo sepentshisi, ukusika isaha kuvela njengendlela efanelekile, ukuvimbela noma yikuphi ukuwohloka kwekhoyili emaphethelweni asikiwe. Ngaphezu kwalokho, inqubo yokusika ayikhiqizi imfucuza. Ukwandisa umthamo womugqa wokukhiqiza, isisekelo somshini wokusika singalungiswa emuva naphambili ukuze sivumelanise nesivinini somshini wokwenza umqulu, kuqinisekiswe ukusebenza okungaphazamiseki.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle