ividiyo

Iphrofayela

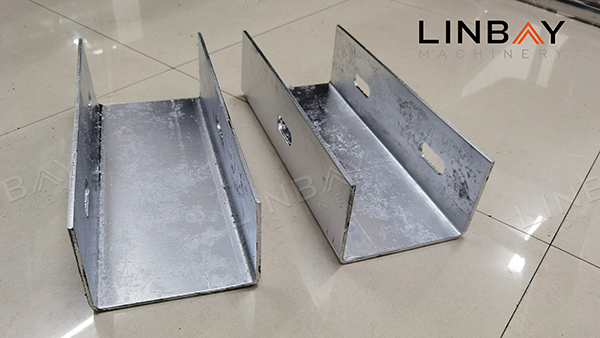

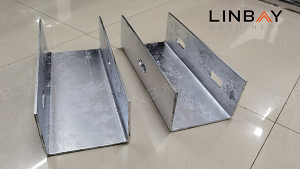

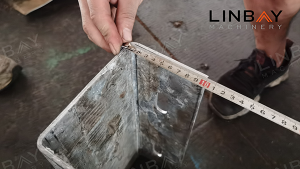

Amaphrofayili akhiqizwe kulo mugqa wokukhiqiza wonke akumafomu amise okwe-U, ikakhulukazi iposi le-U kanye nebhulokhi yesikhala ngaphakathi kwesistimu ye-Guardrail. I-spacer block isebenza njengebhulokhi yokumelana ebekwe phakathi kweposi ne- guardrail beam, enikeza ukugoba phezu komthelela.

Ngokuvamile, ama-U posts namabhulokhi e-spacer akhiwe ngensimbi engu-5mm egoqelwe ebandayo noma egoqelwe eshisayo, ngokubhobozwa kwembobo ngaphambi kwenqubo yokwenza. Lezi zimbobo zenzelwe izinjongo zokufaka isikulufu namantongomane.

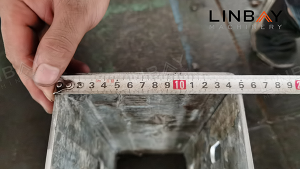

Ikesi langempela-Amapharamitha weTechinical Eyinhloko

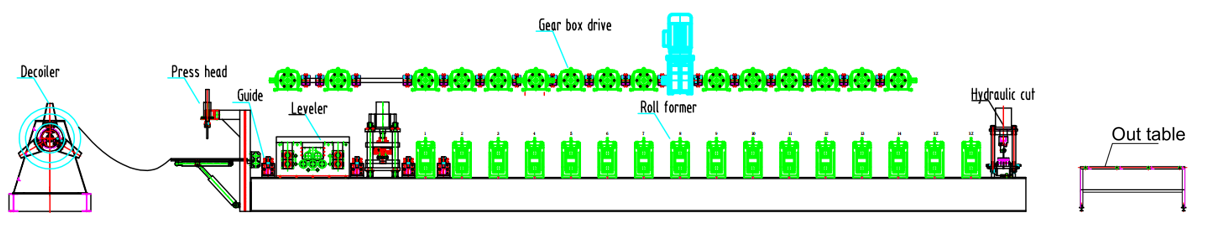

Ishadi eligelezayo

5I-T Hydraulic decoiler--Ukuqondisa--Ukulinganisa--Amanzipunch--Roll forming machine--Hydraulic cut--Out table

Amapharamitha Abalulekile Wezobuchwepheshe:

1. Isivinini somugqa: Ishintsheka kusuka ku-0 kuye ku-6m/min

2. Amaphrofayili: Isiteshi seposi kanye ne-Spacer

3. Ubukhulu bezinto: 5mm (yalolu hlelo lokusebenza)

4. Izinto ezifanele: Insimbi egoqwe eshisayo, insimbi egoqiwe ebandayo

5. Umshini wokwenza ama-roll: Isakhiwo se-cast-iron esinomshini wokushayela we-gearbox

6. Inani leziteshi ezakhayo: 16

7. Uhlelo lokubhoboza: I-Hydraulic; gingqa izitobhi zangaphambili ngesikhathi sokushaywa

8. Uhlelo lokusika: I-Hydraulic; Roll izitobhi zangaphambili ngesikhathi sokusika

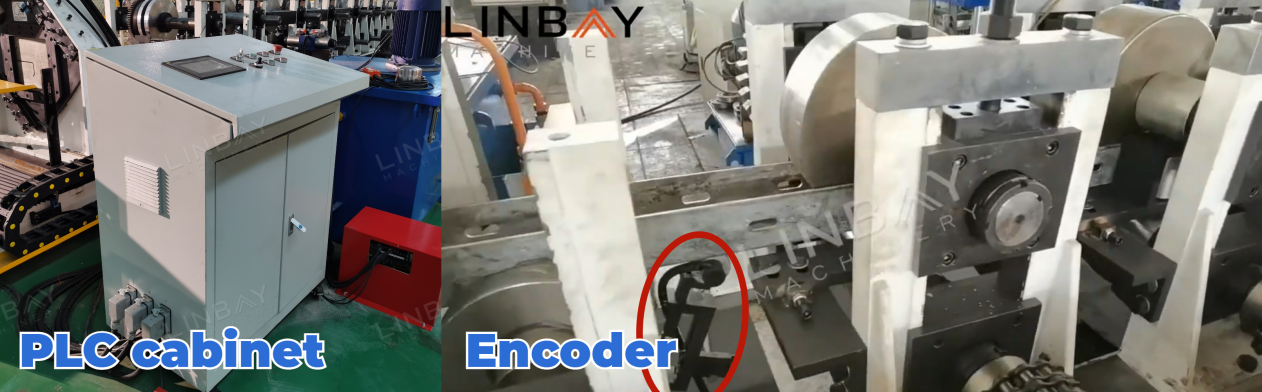

9. Ikhabhinethi ye-PLC: Ifakwe uhlelo lwe-Siemens

Ikesi langempela-Incazelo

I-Hydraulicdi-ecoiler

Iklanywe ngakho kokubili ukusebenza kahle nokuphepha engqondweni, i-hydraulic decoiler inikwa amandla yisiteshi esiqinile samanzi. Ifakwe i-coil retainer yangaphandle, ivimbela ngokuphumelelayo ikhoyili yensimbi ukuthi ingasheleli phakathi nokusebenza. Ukwengeza, ingalo yokucindezela ibamba ngokuvikelekile ikhoyili endaweni, ngaleyo ndlela iqinisekise ukuphepha kwezisebenzi ngokuvimbela noma yikuphi ukuqubuka okungalindelekile.

Ileveli

Ngokunciphisa ukucindezelwa kwangaphakathi kwamakhoyili, i-level iwalungisela ukubhoboza nokwenza izinqubo. Ihlanganiswe nesisekelo somshini wokwakha, isileveli asigcini nje ngokuthuthukisa ukusebenza kahle kodwa futhi silondoloza indawo ebalulekile yaphansi futhi sinciphisa izindleko zomhlaba ekusetheni umugqa wakho wokukhiqiza.

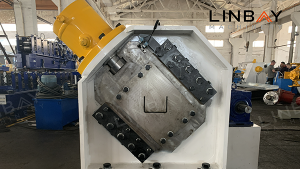

I-Hydraulicpunch

I-punch ye-hydraulic ingabhoboza kahle izimbobo kumakhoyili ensimbi afika ku-5mm ubukhulu, iwalungiselele ukufakwa kwezikulufu. Ixhunywe kusisekelo somshini wokwenza umqulu, iqinisekisa ukusebenza okunembayo, nakuba idinga ukumiswa kancane phakathi nokushaya.

Ngezivinini zokukhiqiza ezithuthukisiwe, isisombululo se-standalone hydraulic punch siyatholakala.

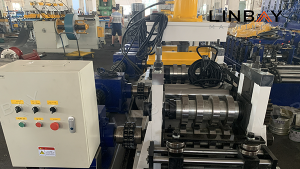

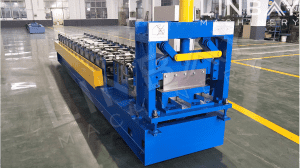

Rollformingmane

Emgogodleni womugqa wokukhiqiza kukhona umshini wokwenza umqulu, oziqhayisa ngesakhiwo esiqinile sensimbi esikwazi ukuphatha kalula ukwakheka kwekhoyili yensimbi engu-5mm. Wonke amarola akha amarola anikwa amandla uhlelo lwebhokisi likagiya futhi akhiwe kusukela ku-Gcr15, insimbi enekhabhoni ephezulu ye-chromium, enikeza ubulukhuni obukhethekile nokumelana nokugqokwa, okuthuthukiswa ngokufakwa kwe-chrome. Ukwengeza, ama-shafts angama-40Cr aphethwe ngokushisa aqinisekisa ukuqina nokuthembeka ngisho nangaphansi kwezimo ezidinga kakhulu.

Isifaki khodi ne-PLC

Ukunemba nokulawula kuhlanganiswe ngaphandle komthungo nesishumeki sekhodi kanye nesistimu ye-PLC. Iguqula ubude bekhoyili yensimbi ibe amasignali kagesi, isifaki khodi sinikeza impendulo enembile kukhabhinethi yokulawula ye-PLC. Amapharamitha afana nesivinini sokukhiqiza, ubuningi bomjikelezo ngamunye, nobude bokusika konke kungalungiswa kwikhabhinethi yokulawula ye-PLC, ukuqinisekisa ukuthi amaphutha okusika akhawulelwe ngaphakathi.±1mm. Amakhasimende angasetha ubude bokusika ngokuvumelana nezidingo zabo ngokusebenzisa iphaneli yokusebenza.

I-Hydrauliccut

Ukusikwa ngakunye kuveza imiphetho eshelelayo, engenazo i-burr, isusa imfucuza futhi iqinisekisa ukunemba okungenakuqhathaniswa, okugcina konga izindleko kumakhasimende. Kubalulekile ukuqaphela ukuthi umshini wokwenza umqulu uyama ngesikhathi sokusika ngakunye.

Siphinde sinikeze isisombululo esinesivinini esiphezulu lapho umshini wokwenza umqulu ungayeki ngesikhathi sokusika, uma uwudinga.

I-Hydraulicstation

Ukusebenza kahle kuhlangana nokuthembeka ngesiteshi sethu esisezingeni eliphezulu samanzi abandayo. Ifaka amafeni kagesi apholile, iqeda ukushisa ngempumelelo, igcina izinga lokushisa elilungile lokusebenza ukuze isebenze isikhathi eside. Ngamazinga amancane okuhluleka, iziteshi zethu zama-hydraulic ziqinisekisa ukuqina nokuphila isikhathi eside, ziqinisekisa ukugeleza kokusebenza kokukhiqiza okungaphazamiseki.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle