IVIDIYO

I-Perfil

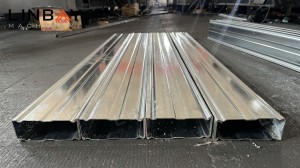

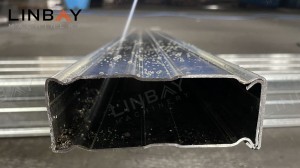

I-one-piece beam iyingxenye ebalulekilei-rack enzimaamasistimu, anesiqephu esiphambanayo esifana nebhokisi elingunxande. Ihlanganiswe kusetshenziswa amapuleti axhumayo nezikulufu, okwenza uhlaka oluqinile olunama-rack uprights. Lo mklamo uqinisekisa ukuzinza nokuqina kweshalofu, elikwazi ukusekela imithwalo emikhulu.

Ekukhiqizeni, kusetshenziswa ikhoyili yensimbi eyodwa ukuze kwakhiwe induku yebhokisi enocezu olulodwa.Insimbi egoqiwe ebandayo, insimbi egoqwe eshisayo, noma insimbi enothayela enogqinsi oluyi-1.5-2mmngokuvamile isetshenziselwa ukukhiqiza.

Ikesi langempela-Amapharamitha weTechinical Eyinhloko

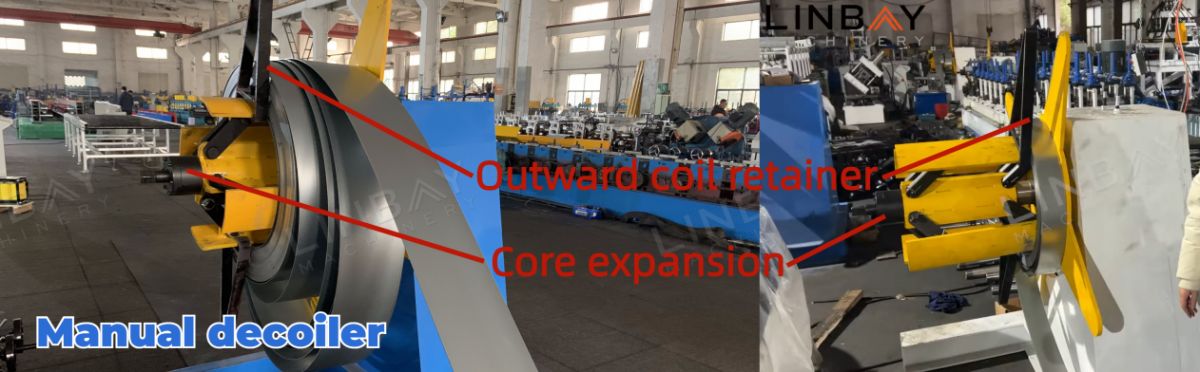

I-decoiler yezandla idizayinelwe ngedivayisi yebhuleki ukulungisa ukunwetshwa nokuqinisekisa ukuqaqa okubushelelezi phakathi kwebanga elingu-φ460-520 mm. Ingalo yokucindezela ifakiwe ukuvimbela inqwaba yekhoyili yensimbi, kuyilapho amaqabunga okuvikela insimbi avimbela ukushelela kwekhoyili, okuthuthukisa kokubili ukusebenza kahle kwezindleko nokuphepha.

Kulesi sibonelo, kusetshenziswa i-decoiler yezandla engenawo owawo umthombo wamandla. Ukwandisa umthamo wokukhiqiza, sinikeza i-hydraulic decoiler yokuzikhethela enikwa amandla yisiteshi samanzi.

Ukuqondisa

Ama-roller aqondisayo abalulekile ekugcineni ukuhambisana phakathi kwekhoyili yensimbi nomshini, ukuvimbela ukuhlanekezela kwe-tube beam. Zibuye zisize ekuvimbeleni ukubola kwekhoyili yensimbi ngesikhathi sokubunjwa. Ukuqonda kwenduku yebhokisi leshubhu kuba nomthelela omkhulu kwikhwalithi yomkhiqizo kanye namandla okuthwala umthwalo wesistimu yokubeka. Amarola aqondisayo abekwe ngendlela efanele kuwo wonke umugqa wokwakha ukuze kuqinisekiswe ukuqondana okunembayo. Izilinganiso zebanga lerola eliqondisayo ngalinye ukuya onqenqemeni zibhalwe ngokucophelela kumanuwali, okwenza kube lula ukulungisa ngokusekelwe kule datha, noma ngabe ukususwa okuncane kwenzeka ngesikhathi sokuthutha noma sokukhiqiza.

Ileveli

Ngemva kwalokho, ikhoyili yensimbi iqhubekela esilinganisweni, lapho ukugoba kwayo kususwa khona ngokuphumelelayo ukuze kuthuthukiswe ukucaba nokuhambisana, okuqinisekisa imikhiqizo yokugcina yekhwalithi ephezulu. Ileveli inamarola okulevelitha angu-3 aphezulu namane aphansi ukuze afeze lo msebenzi ngempumelelo.

Ishadi eligelezayo

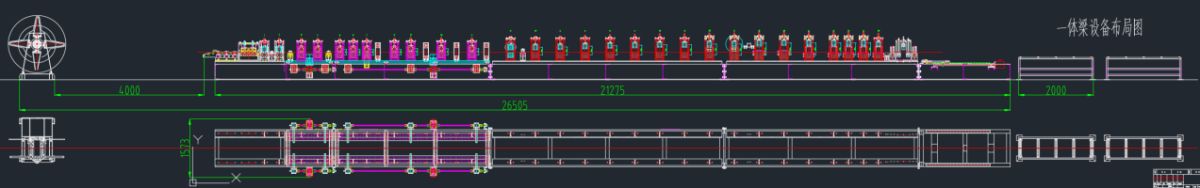

I-Manual decoiler--Ukuqondisa--I-Leveler--Umshini wokwenza i-Roll--Isaha elindiza elisikwayo--Ithebula

Main Techinical Amapharamitha

1.Isivinini somugqa: 5-6meters/min sincike ubude bokusika

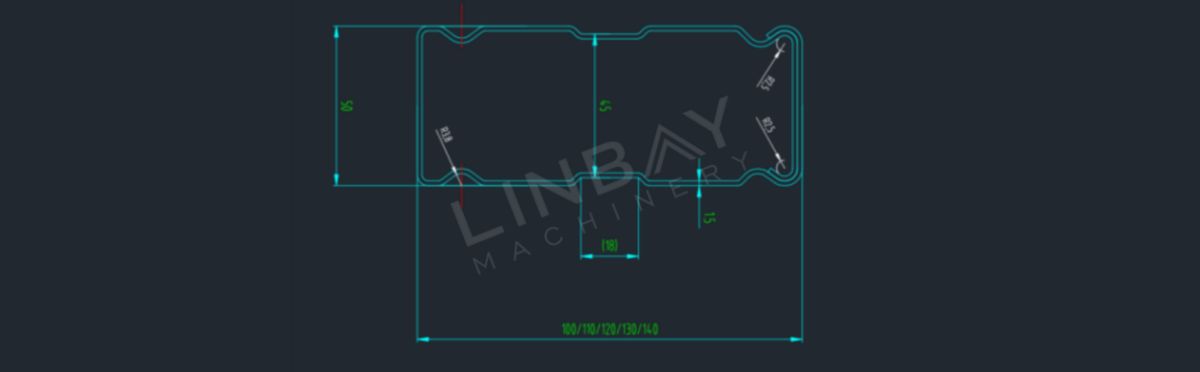

2.Amaphrofayili: Osayizi abaningi-ubude obufanayo buka-50mm, nobubanzi obuhlukile buka-100, 110, 120, 130, 140mm

3.Ukujiya kwempahla:1.9mm (kulokhu)

4.Impahla efanelekile:Insimbi egoqiwe eshisayo, insimbi egoqiwe ebandayo, insimbi

Umshini wokwenza i-5.Roll: Isakhiwo se-Cast-iron kanye nesistimu yokushayela iketango.

6.Cha. Isiteshi esakhayo: 28

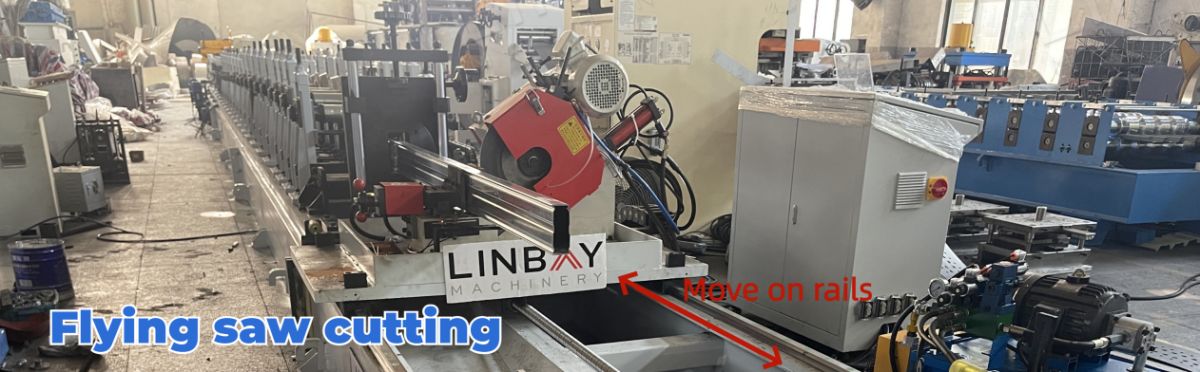

I-7.Isistimu yokusika: I-Saw cutting, i-roll yangaphambili ayimi lapho isika.

8.Ukushintsha usayizi: Ngokuzenzakalelayo.

Ikhabhinethi ye-9.PLC: Uhlelo lwe-Siemens.

Ikesi langempela-Incazelo

I-Decoiler Manual

Umshini Wokwenza Roll

Umshini wokwenza umqulu umi njengetshe legumbi lomugqa wokukhiqiza, uziqhayisa ngamasethi angu-28 eziteshi zokwakha kanye nesakhiwo esiqinile sensimbi. Iqhutshwa uhlelo lwamaketanga aqinile, ikhiqiza kahle imishayo yamabhokisi enosayizi abahlukahlukene enobude obufanayo nobubanzi obusukela phezulu.kusuka ku-100 kuye ku-140 mm. Ama-opharetha angakwazi ukufaka kalula osayizi abafiselekayo ngesikrini sokulawula se-PLC, okubangela ukulungiswa okuzenzakalelayo kokwakhiwa kweziteshi ukuze kumiswe kahle. Le nqubo ezenzakalelayo, okuhlanganisa nokushintsha kosayizi, ithatha cishe imizuzu eyi-10, iqhutshwa ukunyakaza kweziteshi ezakha ujantshi, ukulungisa amaphuzu angu-4 okhiye okwenza ububanzi obuhlukene.

Amarola akhiwe akhiwe kusukela ku-Gcr15, insimbi enekhabhoni ephezulu ye-chromium ebiza kakhulu ngobulukhuni bayo nokumelana nokugqokwa. Lawa ma-roller ane-chrome-plated ukuze aqine isikhathi eside, kuyilapho ama-shaft, enziwe ngezinto ezingu-40Cr, alashwa ngokucophelela ngokushisa ukuze athole amandla engeziwe.

I-Flying Saw Cut

Umumo ovaliwe wesigxobo sebhokisi sidinga ukusika okunembe kwesaha ukuze kugcinwe ubuqotho besakhiwo futhi kuvinjwe ukuwohloka konqenqema olusikiwe. Le ndlela inciphisa udoti wekhoyili yensimbi, iqinisekise izindawo zokusika ezibushelelezi ngaphandle kwama-burrs. Ama-saha ama-blade ekhwalithi ephezulu aqinisekisa ukunemba nobulukhuni, kuyilapho isistimu yokupholisa inweba ukuphila kwayo ukuze isebenze ngokuqhubekayo.

Nakuba isivinini sokusika isaha sihamba kancane kune-hydraulic shearing, umsebenzi wethu weselula uqinisekisa ukuvumelanisa nesivinini sokukhiqiza somshini wokwakha, okuvumela ukusebenza okungaphazamiseki kanye nokuhamba kahle komsebenzi.

Isifaki khodi ne-PLC

Umshini wokwenza umqulu uhlanganisa isifaki khodi saseJapane se-Koyo ukuze uhumushe ngokunembile ubude bekhoyili kuzimpawu zikagesi zekhabhinethi yokulawula ye-PLC. Isilawuli esinyakazayo ngaphakathi siqinisekisa ukunyakaza okungenamthungo komshini wokugunda, sigcina ubude obunembile bokusika ngaphandle kokusheshisa noma ukwehla. Lokhu kubangela amamaki okushisela ashelelayo futhi azinzile, avimbele ukuqhekeka kwephrofayili nokuqinisekisa ukukhiqizwa kwesitebhisi se-premium-grade.

Ama-operators anokulawula okugcwele phezu kwemingcele yokukhiqiza ngesikrini sekhabhinethi yokulawula ye-PLC, okuhlanganisa isivinini sokukhiqiza, ubukhulu bephrofayela, ubude bokusika, kanye nenani. Ngenkumbuloisitorejikumapharamitha asetshenziswa kakhulu, opharetha bangakwazi ukwenza lula ukukhiqizwa ngaphandle kokungena okuphindaphindiwe kwepharamitha. Ukwengeza, ulimi lwesikrini se-PLC lungenziwa ngendlela oyifisayo ukuze luvumelane nezintandokazi zomuntu ngamunye.

Isiteshi seHydraulic

Isiteshi sethu se-hydraulic, esifakwe abalandeli bakagesi okupholisa, sihlakaza kahle ukushisa, siqinisekisa ukusebenza isikhathi eside nokuthembekile ngezinga eliphansi lokuhluleka.

Iwaranti

Ngosuku lokuthunyelwa, idethi yamanje izoqoshwa ku-nameplate yensimbi, okuphawula ukuqala kwesiqinisekiso seminyaka emibili sawo wonke umugqa wokukhiqiza kanye newaranti yeminyaka emihlanu yamarola namashafti.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle