IVIDIYO

I-Perfil

I-box beam ime njengenketho eqinile eyenzelwe yonaumsebenzi onzimaizicelo. Ngokuqondile, sethula aezimbili-piece uhlobo ibhokisi ugongoloukuze ucabangele. Ivamise ukwakhiwa ngensimbi egoqelwe ebandayo noma eshisiwe enogqinsi olusukela ku-1.5 kuya ku-2mm, idlula ngendlela eqondile.ukwakha umqulungaphambi kokumbozwa ukuze kuqinisekiswe ibhalansi yokukhanga okubonakalayo namandla ahlala njalo. Ukuhlanganiswa kubandakanya ukujoyina ngokuphephileizingcezu ezimbili zamaphrofayili ensimbi abunjwe yi-C, okuholela ekwakhekeni kweshubhu eliqinile. Ukuze kukhiqizwe imishayo yebhokisi, umshini wokwenza i-cold roll uvela njengokukhetha okuthandwayo, okunikeza ukusebenza kahle nokunemba.

Ikesi langempela-Amapharamitha weTechinical Eyinhloko

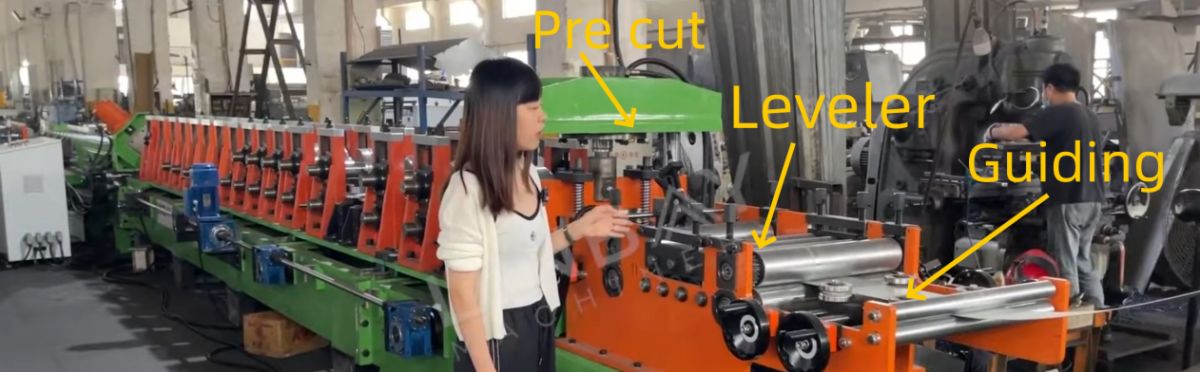

Amarola ayisiqondiso abalulekile ekusekeleni ukuqondanisa phakathi kwekhoyili yensimbi nemishini, ngempumeleloukugwema ukuhlanekezelayomugqa webhokisi. Ziphinde zidlale indima ebalulekile enqubweni yokubunjwa, ukuvimbela ukuwohloka kwekhoyili yensimbi.Ubuqothougongolo lwebhokisi lubambezela phezuluikhwalithi yomkhiqizo kanye nekhono lokuthwala umthwaloyeshalofu lonke. Abekwe ngendlela efanele eduze komugqa wokwakha, amarola ayisiqondiso aqinisekisa ukuqondanisa okucophelelayo.Izilinganisoebangeni ngalinye lerola eliqondisayo ukuya onqenqemeni libhalwe ngokucophelela kumanuwali, okuvumela ukulungisa okungenazihibe okusekelwe kule datha, ngisho nalapho kuba khona ukufuduka okuncane ngesikhathi sokuthutha noma sokukhiqiza.

Ileveli

Ukulandela isigaba esandulele, ikhoyili yensimbi iqhubekela enqubweni yokulinganisa. Lapha, umshini wokulinganisa ngenkuthaloiqeda noma yikuphi ukugoba okukhona kukhoyili yensimbi, ngaleyo ndlela ithuthukise ukuhleleka kwayo nokuhambisana kwayo, ngenxa yalokho ithuthukisa ikhwalithi yomkhiqizo wokugcina - ugongolo lwebhokisi. Ifakwe amaroli okuleveli amabili aphezulu na-3 aphansi, umshini wokulinganisa uqinisekisa ukunemba okucophelela ekulungiseleleni ikhoyili yensimbi yezinyathelo zokukhiqiza ezilandelayo.

I-Hydraulic Pre-Cut

Le incor yomugqa wokukhiqizaporatesi-hydraulic pre-cut device,ukwenza kube lula ukushintshwa kwamakhoyili ensimbi anobubanzi obuhlukahlukene nobukhulu, ngesikhathi esisodwaukunciphisa udoti wamakhoyili.

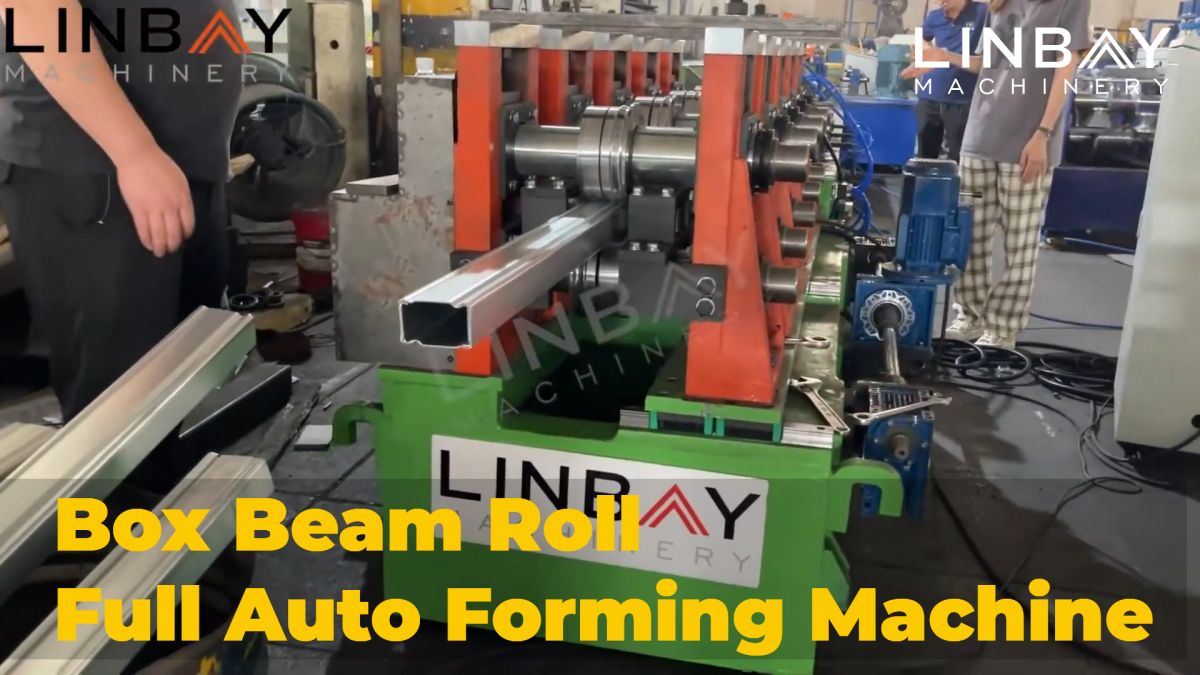

Umshini Wokwenza Roll

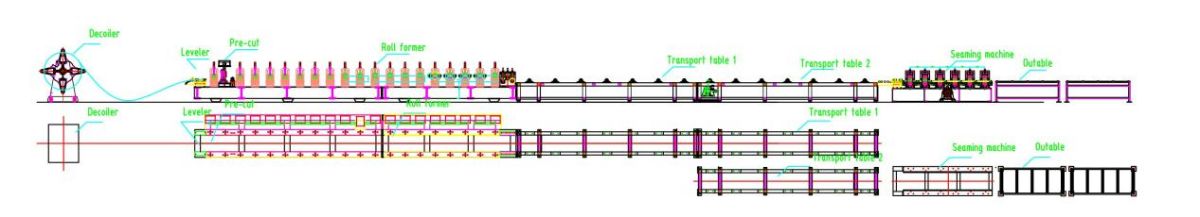

Ishadi eligelezayo

I-Decoiler Manuwali--Ukuqondisa--I-Leveler--Hydraulic pre cut--Umshini wokwenza i-Roll--I-hydraulic cut cut-Iplathifomu--Umshini wokuthunga--Ithebula elingaphandle

Main Techinical Amapharamitha

1.Isivinini somugqa: 0-4 m/min, siyalungiseka

2.Amaphrofayili: Osayizi abaningi-ubude obufanayo buka-50mm, nobubanzi obuhlukile buka-80, 100, 120mm

3.Material ukujiya:1.5-2mm

4.Impahla efanelekile:Insimbi egoqiwe eshisayo, insimbi egoqiwe ebandayo, insimbi

Umshini wokwenza i-5.Roll: I-Cast-iron stru

cture kanye chain ukushayela uhlelo.

6.Cha. Isiteshi esakhayo: 18

7.Isistimu yokusika: Ukusika kwe-hydraulic, roll yangaphambili ayimi lapho usika.

8.Ukushintsha usayizi: Ngokuzenzakalelayo.

Ikhabhinethi ye-9.PLC: Uhlelo lwe-Siemens.

Ikesi langempela-Incazelo

I-Decoiler Manual

I-decoiler yezandla ifakwe auhlelo lokubhulekaeklanywe ngobunono ukuze ilawule ukushuba komqulu oqedwayo futhi iqinisekise inqubo yokuqaqa ebushelelezi. Ukunciphisa ingozi yokuhlehla kungazelelwe, ikakhulukazi amakhoyili ensimbi angaphezu kuka-1.5mm ubukhulu,ingalo yokucindezelaisetshenziselwa ukubamba ngokuphephile ikhoyili yensimbi endaweni yayo. Ngaphezu kwalokho, amacembe okuvikela insimbi afakwa ngendlela efanele ukuze avimbele ukushelela kwekhoyili ngesikhathi sokuqaqa. Lo mklamo ocabangelayo awugcini nje ngokuthuthukisa ukuphepha kodwa futhi unikezaizindleko eziphezulu, ukuqinisekisa ukusebenza okuthembekile nokusebenza kahle.

Kulesi simo, i-decoiler yezandlangaphandle komthombo wawo wamandlauyasebenza. Ukuze uthole izidingo ezengeziwe zesivinini sokukhiqiza, sinikeza ongakukhethai-hydraulic decoilerinikwa amandla yisiteshi se-hydraulic.

Ukuqondisa

Enhliziyweni yawo wonke umugqa wokukhiqiza kukhona umshini wokwenza ama-roll, ingxenye ebalulekile. Yakhiwe ngocezu oluqinile lweInsimbi, lo mshini unesakhiwo esiqinile futhi uqhutshwa onokwethenjelwauhlelo lwe-chain. Ukuguquguquka kwayo kwenza ukukhiqizwa kosayizi abahlukahlukene ngokuphakama okungaguquki. Abasebenzisi bafaka kalula ubukhulu obuhleliwe esikrinini sokulawula se-PLC, okuvusayoukulungiswa okuzenzakalelayowokwakha iziteshi ezikhundleni eziqondile. Ngokuvamile, izisebenzi ezinolwazi zidinga cishe amaminithi angu-60 ukuze zenze inqubo ephelele yokushintsha ubukhulu, ehlanganisa kokubili ukunyakaza okuzenzakalelayo kweziteshi zokwakha kanye nokushintshwa ngesandla kwekhoyili yensimbi.

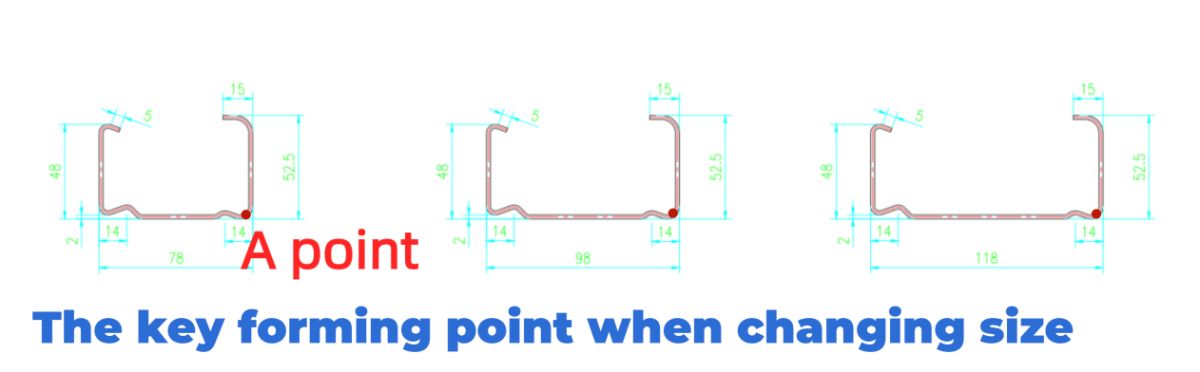

IIphuzuisebenza njengendawo ebalulekile yokwakha ukulungiswa kobubanzi. Njengoba iziteshi ezakha ama-roll zihamba eduze komzila, zishintsha ngokushintshashintsha indawo yaleli phuzu lokubumba elibalulekile, okwenza kube lula ukukhiqizwaibhokisi imishayo enobubanzi obuhlukahlukene.

Okwezinto zokwakha ama-roller, i-Gcr15 ikhethwa—insimbi enekhabhoni ephezulu ye-chromium edume ngobulukhuni bayo obukhethekile nokumelana nokugqokwa. Lawa ma-roller enziwa i-chrome-plating ukuze athuthukise ukuphila kwawo isikhathi eside, kuyilapho ama-shaft, enziwe ngempahla engu-40Cr, alashwa ngokushisa ukuze aqine.

I-Flying Hydraulic Cut

Ngemva kokwenza inqubo yokwenza umqulu, ikhoyili yensimbi kancane kancane ihambisana nephrofayili emise okwe-C. Ibe isisikwa ngokunembile ubude obudingekayo ngomshini wokusika osebenzisa amanzi amaningi, ugcina aiphutha lobude bokusika ngaphakathi kwe-1mm. Le nqubo yokusika inciphisa kahle ukumosheka kwekhoyili yensimbi futhi ivumelanise nesivinini sokukhiqiza somshini wokwenza umqulu, iqinisekisa ukusebenza okungenamthungo nokungaphazanyiswa.

Inkundla

I-C-profile yokuqala idluliselwa endaweni ephezulu bese iphushwa endaweni ephansi. Ngokulandelayo, iphrofayela yesibili ye-C iphushwa ngokucophelela emthambekeni ophakathi nendawo, lapho idivayisi ephetshwayo iyizungezisa khona. Lesi senzo siqondana futhi sinqwabelanisa kahle amaphrofayela we-C amabili aqondile.

Amarola aqondisayo aqinisekisa ukuqondana kwamaphrofayili amabili e-C, futhi ama-push rods aphusha umoya ewacindezela emshinini wokuthunga.

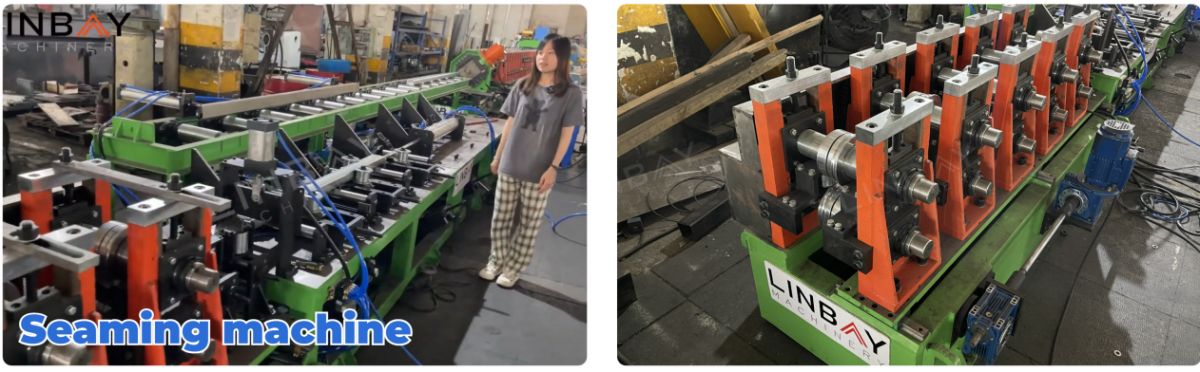

Umshini wokuthunga

Umshini wokuthunga ubonisa isakhiwo somshini wokwenza umqulu, uziqhayisa aIsakhiwo se-iron kanye nesistimu yokushayela iketango. Izilungisa ngokuzenzakalelayo izindawo zesiteshi sokuthunga ngokuvumelana nobubanzi bebhokisi. Lokhu emishaiqeda isidingo somshini wokushisela, njengokwejwayelekile, isisebenzi besidingeka ukuthi sishise amaphrofayili e-C amabili abe yibhokisi le-post-roll.

Isifaki khodi ne-PLC

Umshini wokwenza umqulu ufakwe aIsifaki khodi se-Japan Koyo, eguqula ngokunembile ubude bekhoyili ibe amasignali kagesi ekhabhinethi yokulawula ye-PLC. Lokhu kunemba kuqinisekisaamaphutha okusika akhawulelwe ku-1mm, ukuqinisekisa imishayo yebhokisi yekhwalithi ephezulu kanye nokunciphisa imfucuza. Ama-opharetha angakwazi ukulawula isivinini sokukhiqiza, ukusetha ubukhulu, ubude bokusika, nokuningi ngesikrini se-PLC. Ikhabhinethi iphinde igcine amapharamitha asetshenziswa kakhulu futhi ihlinzeka ngokuvikeleka ekulayisheni ngokweqile, isifunda esifushane, nokulahlekelwa kwesigaba. Izilungiselelo zolimi esikrinini se-PLC zingenziwa ngendlela oyifisayo ukuze zivumelane nezintandokazi zekhasimende.

Isiteshi seHydraulic

Isiteshi sethu se-hydraulic, esifakwe abalandeli bakagesi okupholisa, sihlakaza kahle ukushisa, siqinisekisa ukusebenza okunwetshiwe nokuthembekile ngezinga eliphansi lokuhluleka.

Iwaranti

Lapho kuthunyelwa, i-nameplate ikhombisa ngokusobala idethi yokulethwa, inikeza aisiqinisekiso seminyaka emibili yawo wonke ulayini wokukhiqiza kanye newaranti yeminyaka emihlanu emangalisayo yamarola namashafti.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle