I-Perfil

I-step beam idlala indima ebalulekileamasistimu wokuqopha we-pallet esindayo, ethonya ngokuqondile amandla namandla okuthwala umthwalo wesakhiwo sonke.

Abakhiqizi ngokuvamile basebenzisa imishini yokwenza ama-roll nge1.5-2mm insimbi eshisayo egoqwe noma ebandayoukukhiqiza imishayo yesinyathelo. Ukuze kuthuthukiswe ubude besikhathi sazo sokuphila nokuvimbela ukuwohloka okubangelwa ukungezwani kwekhoyili yensimbi, ukushisela kufakwa emajoyini ekhoyili yensimbi. Izinqubo ezimbili ezijwayelekile zokushisela ezisetshenziswa embonini ziyiI-MIG welder (njengalokhu) kanye ne-laser full welder.

Kokubili i-MIG welder kanye ne-laser full welder kunomthelela ekuqiniseni ubuqotho besakhiwo. Kodwa-ke, ngenxa yokumbozwa okuphelele kwamalunga ekushiseleni okugcwele, ukusebenza kwawo kudlula lokho kokushisela kwe-MIG. Amakhasimende angakhetha indlela yokushisela ngokusekelwe kubhajethi yawo kanye nezidingo zokulayisha ama-rack.

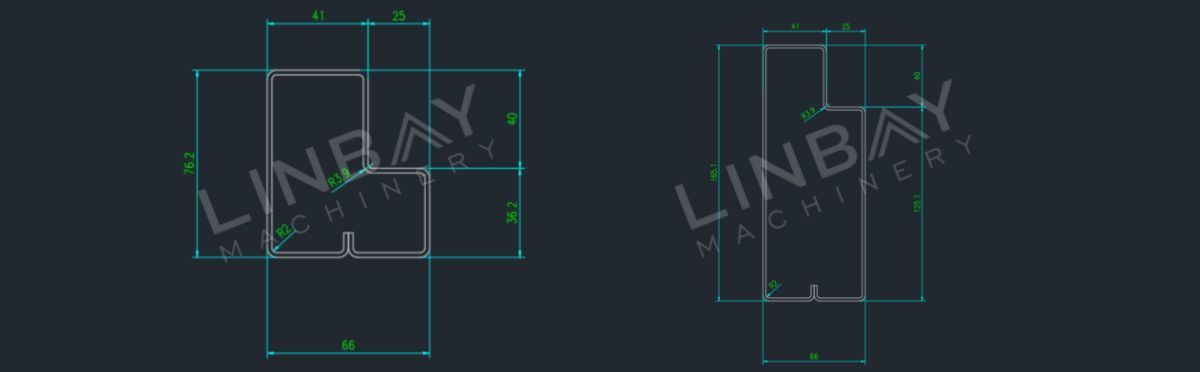

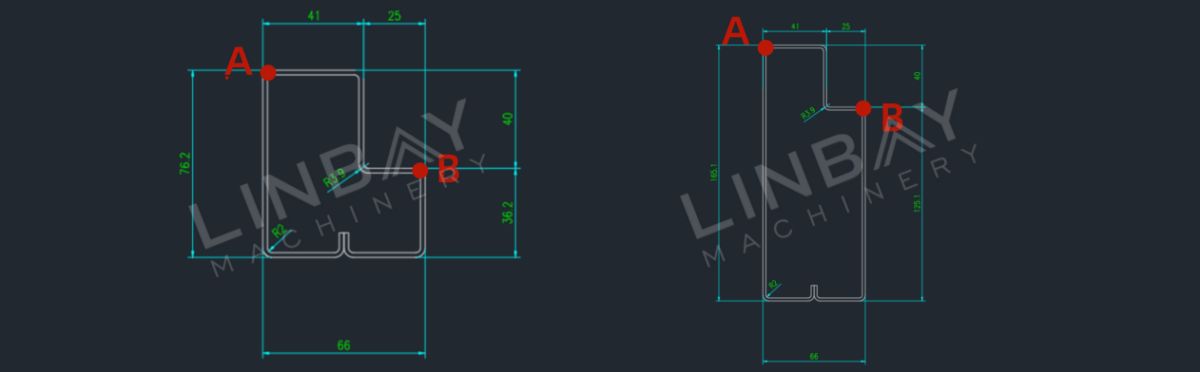

Ikesi langempela-Amapharamitha weTechinical Eyinhloko

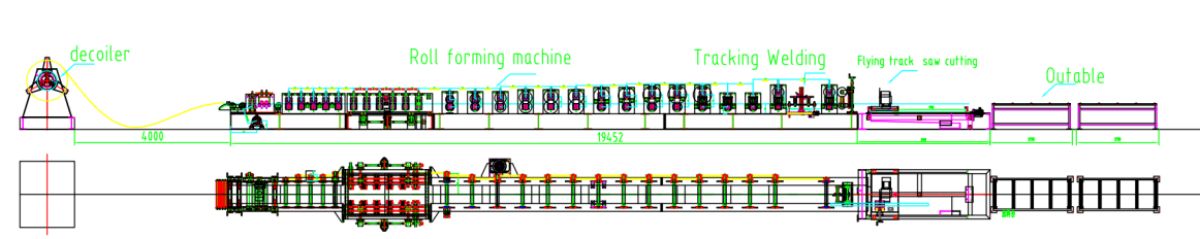

Ishadi eligelezayo

I-Manual decoiler--Ukuqondisa--I-Leveler--Umshini wokwenza i-Roll--Iwelder endizayo--Isaha elindizayo elisika--Ithebula

Main Techinical Amapharamitha

1.Isivinini somugqa: 4-5 m/min, iyalungiseka

2.Amaphrofayili: Osayizi abaningi-ububanzi obufanayo buka-66mm, nobude obuhlukile buka-76.2-165.1mm

3.Ubukhulu bezinto: 1.9mm (kulokhu)

4.Impahla efanelekile:Insimbi egoqiwe eshisayo, insimbi egoqiwe ebandayo, insimbi

I-5.Umshini wokwenza i-Roll: Isakhiwo se-cast-iron kanye nesistimu yokushayela iketango.

6.Cha. Isiteshi esakhayo: 26

I-7.Isistimu ye-Welding: 2 * amathoshi we-welding, i-roll yangaphambili ayimi lapho i-welding.

I-8.Isistimu yokusika: I-Saw cutting, i-rollerformer ayimi lapho isika.

9.Ukushintsha usayizi: Ngokuzenzakalelayo.

10.PLC iKhabhinethi: Siemens uhlelo.

Ikesi langempela-Incazelo

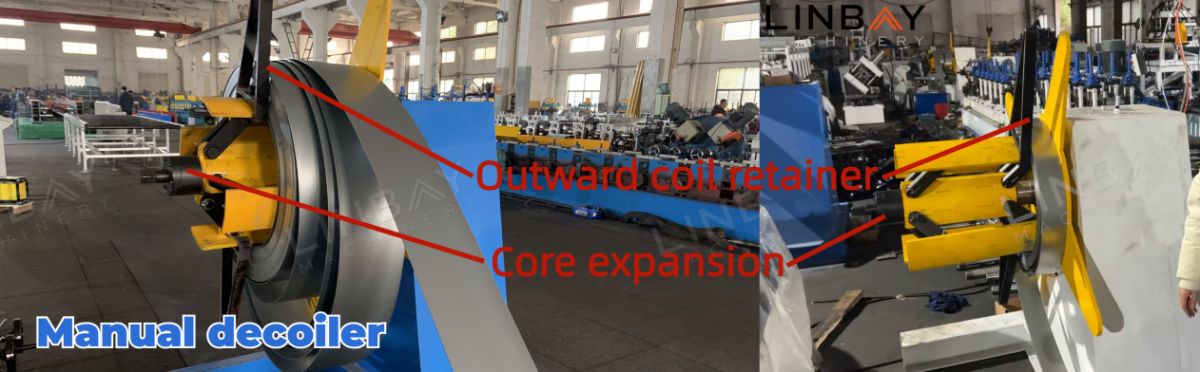

I-Decoiler Manual

I-decoiler yamanuwali ifaka aidivayisi yamabhulekiidizayinelwe ukulungisa ukungezwani kokunwetshwa okuyisisekelo phakathi kwebanga lika-φ490-510 mm, iqinisekisa ukusebenza kokuqaqa okubushelelezi. Uma kubhekwa ukusetshenziswa kwekhoyili yensimbi engu-1.9mm, kunengozi yokuvuleka kungazelelwe ngesikhathi sokuqaqa.Ukubhekana nalokhu kuphephaukukhathazeka, ingalo yokucindezela ifakwe ukuze ibambe ngokuphephile ikhoyili yensimbi endaweni, kuyilapho izindwani zensimbi ezivikelayo zengezwa ukuvimbela ukushelela kwekhoyili. Lo mklamo awunikezi kuphela isisombululo esingabizi kakhulu kodwa futhi ubeke phambili ukuphepha enqubweni yokuqaqa.

I-decoiler yezandla ineawekho amandla. Ngezidingo zomthamo wokukhiqiza ophezulu, sihlinzeka ngokuzikhethelai-hydraulic decoilerinikwa amandla yisiteshi se-hydraulic.

Isibonisi esiqondisayo nesidijithali

Amarola aqondisayo adlala indima ebalulekile ekugcineni ukuhambisana phakathi kwekhoyili yensimbi nemishini, ngaleyo ndlela avimbele ukuhlanekezelwa kwesitebhisi sesitebhisi nokubamba iqhaza enqubweni yokwenza umqulu ukuzevimbela ukuguqulwa kwe-rebound yensimbi. UbuqothoI-step beam ibalulekile kwikhwalithi yomkhiqizo futhi inomthelela ekusebenzeni komthwalo wayo yonke isistimu yokurakha. Ama-guiding rollers abekwe kahle hhayi nje ekuqaleni komshini wokwenza ama-roll kodwa futhiezindaweni ezihlukahlukene kuwo wonke umugqa wokwakha umqulu, ukuqinisekisa ukuqondanisa okunembayo kuyo yonke inqubo yokukhiqiza.

Amadivayisi wokubonisa idijithali ayasizaukurekhoda okululayesikhundla esifanele samarola aqondisayo. Futhiizilinganiso zebangakusukela ku-roller ngayinye eqondisayo ukuya emaphethelweni angakwesokunxele nangakwesokudla omshini wokwenza umqulu aqoshwa kumanuwali, okuvumela ukulungiswa okulula okusekelwe kule datha ngisho noma kwenzeka ukuthutha okuncane ngesikhathi sokuthutha noma sokukhiqiza.

Ileveli

Ngemva kwalokhu, ikhoyili yensimbi iqhubekela ku-level. Uma kubhekwa ukushuba kwayo okungu-1.9mm, kubalulekile ukuthisusa noma yikuphi ukugoba okukhona kukhoyili yensimbi, ngaleyo ndlela ithuthukisa ukucaba nokuhambisana kwayo kwekhwalithi yesitebhisi sesinyathelo. Ihlonyiswe ngamarola okulevelinga angu-3 aphezulu namane aphansi, isileveli sifinyelela le njongo ngempumelelo, siqinisekisa ukucaba okuseqophelweni eliphezulu kanye nokuhambisana kwenqubo elandelayo yokwakhiwa komqulu.

Umshini Wokwenza Roll

Enhliziyweni yawo wonke umugqa wokukhiqiza kukhona umshini wokwenza ama-roll. Ifakwe ukulawulwa kwesivinini esiguquguqukayo okugqugquzelwa i-inverter (yohlobo lwaseJapane) ye-Yaskawa, umshini unikeza ububanzi besivinini obuhlukahlukene ukusuka ku-0 ukuya ku-10m/min, okuqinisekisa ukuguquguquka kwezidingo ezihlukahlukene zokukhiqiza. Ihambisana neziteshi ezingama-26, iyasebenzaisakhiwo sephaneli yodonga kanye nesistimu yokushayela ngamaketanga, eklanywe ngobunono ukuze ilethe ukunemba nokusebenza kahle enqubweni yokwakha. Ngobuchwepheshe bawo bokusika kanye nomklamo oqinile, umshini wokwenza umqulu usebenza njengetshe legumbi lekhwalithi nokukhiqiza ngaphakathi komugqa wokukhiqiza.

Ikwazi ukukhiqizaosayizi abahlukahlukene, ububanzi obuyi-66mm nobude obusuka ku-76.2 kuye ku-165.1mm, lolu hlelo lunikeza ukuguquguquka kokukhiphayo. Ngemva kokufaka ububanzi obufunekayo obuphansi nobude ekhabetheni lokulawula le-PLC, iziteshi ezakhayo zilungisa ngokuzenzakalelayo ezindaweni eziqondile futhi ziguqule.amaphuzu okwakha abalulekile (amaphuzu A no-B), yenza kube lula ukushintsha kosayizi cishe emaminithini angu-10. Ukulungiswa kobude kuhambisana nokuhluka kwamaphoyinti okwakheka abalulekile (amaphoyinti A no-B), okuvumela ukukhiqizwa kwemishayo yesinyathelo enobude obuhlukile.

I-Gcr15, insimbi enekhabhoni ephezulu ye-chromium edume ngokuba lukhuni nokumelana nokuguga, isetshenziselwa izinto zokwakha amarola. Ukuze kunwetshwe ukuqina, amarola afakwa nge-chrome plating. Ukwengeza, ama-shafts enziwe ngezinto ezingu-40Cr aphathwa ukushisa, aqinise amandla futhi aqinisekise ukwakhiwa okuqinile.

Flying MIG Welder

Ukwelula ubude besikhathi sokuphila kwe-step beam nokuvimbela ukwehlukana emajoyini ekhoyili yensimbi, ukushisela kusetshenziswa emajoyini amakhoyili ensimbi ngephethini yechashazi. Isikhala phakathi kwechashazi ngalinye siyalungiseka ngokwezidingo zekhasimende. Ukwengeza, amathoshi amabili okushisela afakiwe ukwandisa isivinini somugqa. Lamathoshiinganyakaza kanyekanye nesivinini sokwenza umqulu, ukuqinisekisa ukusebenza okuqhubekayo komshini wokwenza umqulu.

I-Flying Saw Cutting

Ukulandela ukwakhiwa kwe-roll, ugongolo lwesinyathelo luqhubekela phambili emshinini wokusika, lisebenzisa umshini wokusika amasaha ngenxa yokuma okuvaliwe kwesigxobo sesinyathelo. Ama-saha blades akhethekile aqinisekisa ukunemba okuphezulu nobulukhuni, kuyilaphoisifutho sokupholisaivikela amasaha, andise isikhathi sokuphila kwawo. Nakuba ijubane lokusika isaha lihamba kancane kune-hydraulic shearing,umsebenzi weselula uhlanganiswe ukuze uvumelanise nesivinini sokukhiqiza somshini wokwenza umqulu, ukuqinisekisa ukusebenza okungaphazamiseki. Ngaphezu kwalokho, umshini wokusika amasaha uqinisekisa imfucuza encane ngesikhathi sokushintsha ikhoyili yensimbi nokusika iphrofayili.

Isifaki khodi ne-PLC

Ngaphakathi komshini wokwenza umqulu, isishumeki se-Koyo saseJapane siguqula ngokunembile ubude bekhoyili ezwiwayo ibe isignali kagesi, bese idluliselwa kukhabhinethi yokulawula ye-PLC. Isilawuli esinyakazayo, esigcinwe ngaphakathi kwekhabhinethi yokulawula kagesi, siqinisekisa ukusheshisa okungenamthungo kanye nokwehla ngesikhathi sokuhamba phambili nangemuva komshini wokusika, ngaleyo ndlela kuzuzwe ukunemba kobude bokusika okunembile. Le ndlela yokulawula ngokucophelela iqinisekisa amamaki okushisela azinzile futhi abushelelezi, avimbele imishayo yezinyathelo ukuthi ingaqhekeki futhi iqinisekise ukukhiqizwa okuzinzile, kwekhwalithi ephezulu. Abasebenzisi bangaphatha kalula isivinini sokukhiqiza, basethe ubukhulu bokukhiqiza, ukusika ubude, nokunye ngesikrini se-PLC. Ngaphezu kwalokho, ikhabhinethi yokulawula ye-PLC ifaka umsebenzi wokugcina inkumbulo wamapharamitha asetshenziswa kakhulu futhi inikeza isivikelo ekulayisheni ngokweqile, isekethe elifushane, nokulahlekelwa kwesigaba, iqinisekisa ukwethembeka nokusebenza nokuphepha.

Ulimi olukusikrini se-PLC lungenziwa ngendlela oyifisayo ngokwezidingo zamakhasimende.

Isiteshi seHydraulic

Isiteshi sethu se-hydraulic sine-fan kagesi epholile ukuze ikhiphe ukushisa kahle, iqinisekise ukusebenza isikhathi eside nokuthembekile ngezinga eliphansi lokuhluleka.

Iwaranti

Lapho kuthunyelwa, idethi yokulethwa iboniswa ku-nameplate yensimbi, ihlinzeka ngesiqinisekiso seminyaka emibili yawo wonke umugqa wokukhiqiza kanye newaranti yeminyaka emihlanu yama-roller nama-shafts.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle

1-300x168.jpg)