ividiyo

Iphrofayela

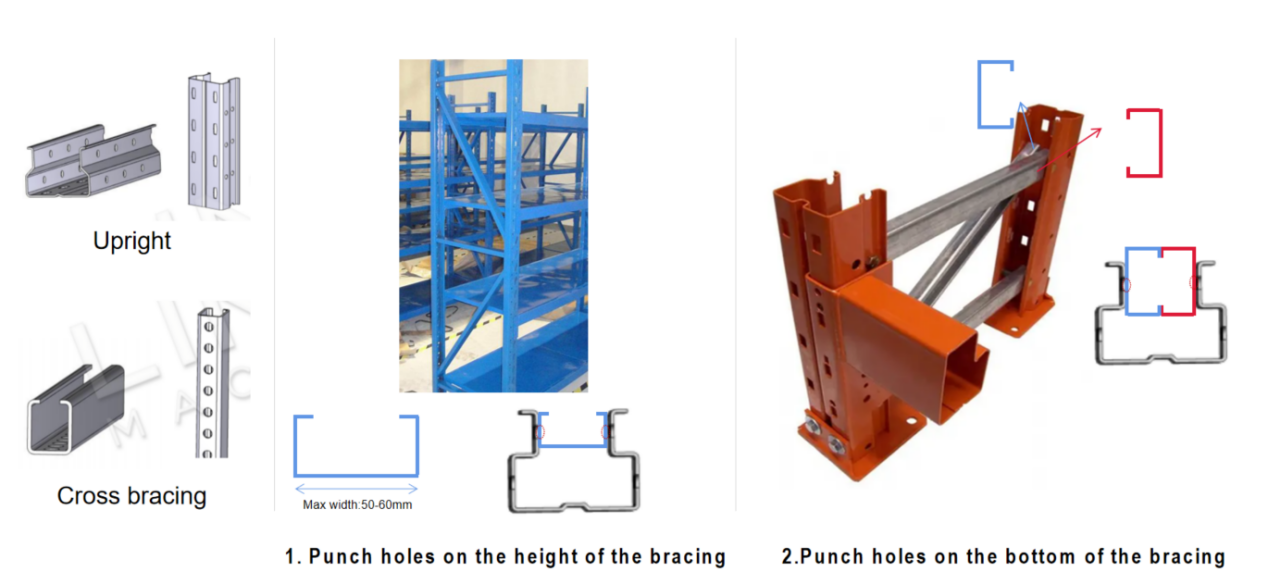

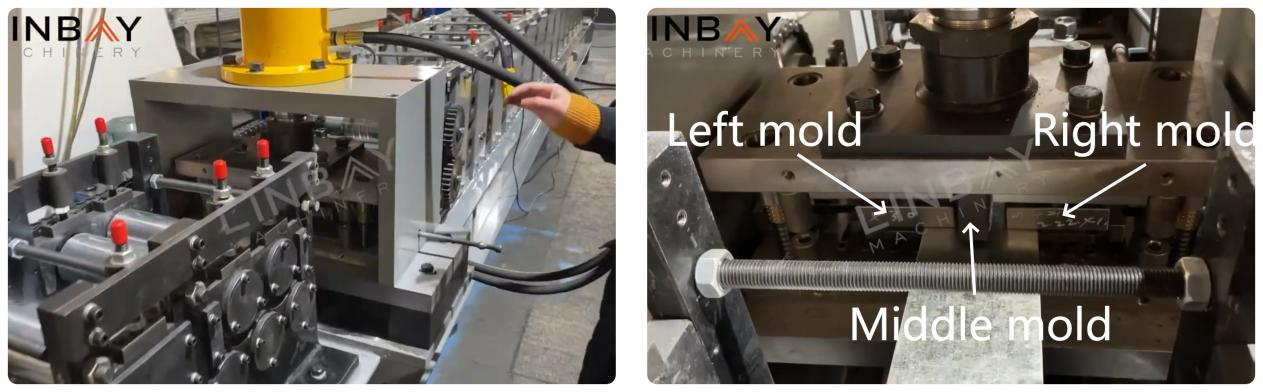

I-cross bracing idlala indima ebalulekile ezinhlelweni zokubeka amashelufu, iqinisa ukwakheka kweshalofu jikelele. Ibekwe ngaphakathi kwerack imile, inikeza ukwesekwa okungeziwe. Kuye ngendlela yokufaka ekhethiwe, izimbobo zokuxhuma zibekwe ngendlela ehlelekile ukuze kunamathiselwe okuphephile.

*Indlela Yokufaka Yoku-1: I-brace eyodwa ifakwa ngaphakathi kwerack imile, idinga izimbobo ezishaywe ngaphambili ekuphakameni kwe-bracing ukuze kufakwe isikulufu.

*Ukufaka Indlela yesi-2: Kufakwe ama-bracing amabili ngaphakathi kwerack eqondile, futhi edinga izimbobo ezishaywe ngaphambili ezansi kwe-bracing ukuze kufakwe isikulufu.

Kulesi simo, sisebenzise indlela yokufaka 1. Siphinde sinikeze isisombululo esivumelanayo esivumela ukubhoboza kanyekanye phansi kanye nezinhlangothi eziphakeme zokubopha ukuze kube nokuguquguquka okukhulu.

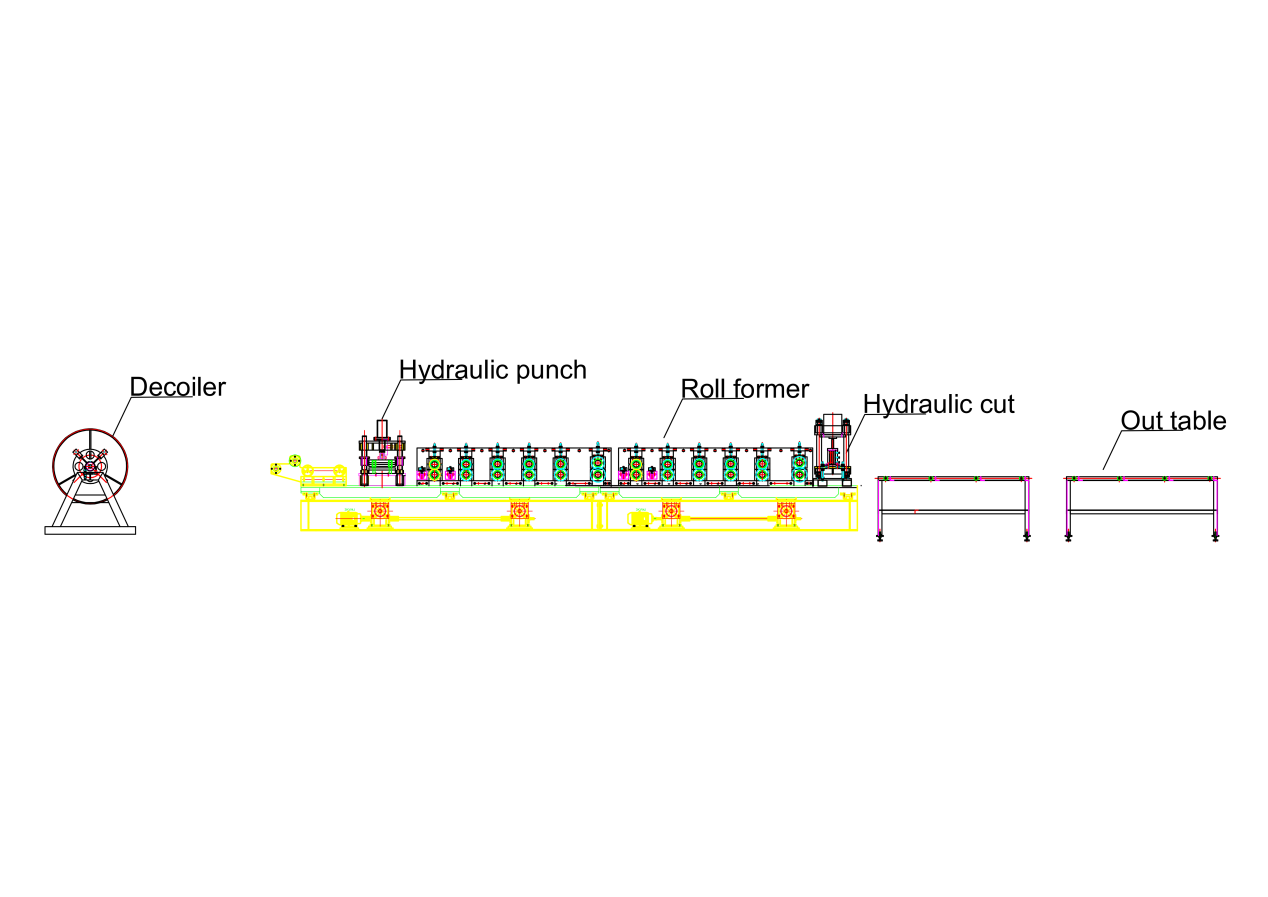

Incazelo

Ishadi eligelezayo

I-Decoiler--Guiding--Leveler--Hydraulic punch--Roll forming machine--Hydraulic cutting--Out table

I-Decoiler

I-decoiler ifakwe ingalo yokucindezela ukuze ivikele ngokuqinile ikhoyili yensimbi ngesikhathi ishintshwa, inciphise ubungozi bokukhululwa kungazelelwe kanye nokulimala okungenzeka kubasebenzi. Iphinde ibe nomshini wamabhuleki olawula ukushuba kwamarola, okuqinisekisa isivinini esingaguquki sokuqaqa. Ngaphezu kwalokho, izindwani zokuvikela insimbi zihlanganiswa ukuze kuvinjwe ikhoyili yensimbi ukuthi ingasheleli phakathi nenqubo yokuwohloka, okuthuthukisa ukuphepha nokusebenza kahle kwezindleko.

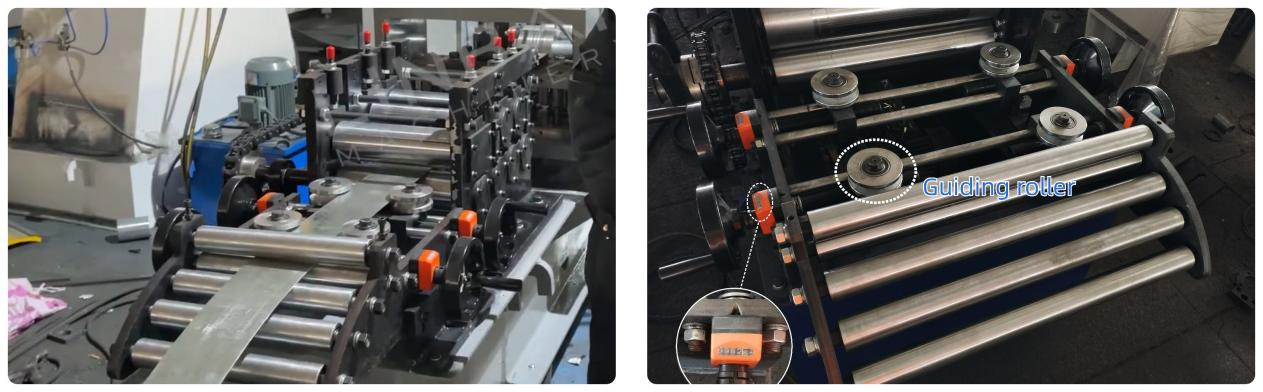

Ukuqondisa

Amarola aqondisayo adlala indima ebalulekile ekuqinisekiseni ukuhambisana phakathi kwekhoyili yensimbi nomshini, ukuwagcina ahambisana nomugqa ophakathi nendawo ukuze avimbele ukuhlanekezelwa kwamaphrofayili akhiwe. Lawa ma-roller abekwe ngendlela ehlelekile hhayi endaweni yokungena kuphela kodwa nakuwo wonke umugqa wokwakha. Amabanga ukusuka kurola ngayinye eqondisayo ukuya onqenqemeni aqoshwa ngokucophelela kumanuwali, okuvumela abasebenzi ukuthi benze izinguquko ezinembile ngokusekelwe kudatha enikeziwe. Lokhu kuqinisekisa ukuqondanisa okunembile, noma ngabe ukususwa kancane kwenzeka ngesikhathi sokuthutha noma ukulungiswa kokukhiqiza okwenziwe ngabasebenzi.

Ileveli

Umshini wokulinganisa udlala indima ebalulekile ekuthuthukiseni ukucaba nokuhambisana kwekhoyili yensimbi, uqinisekisa imiphumela yokukhiqiza yekhwalithi ephezulu. Ihlanganiswe emshinini wokwenza ama-roll, inama-roller asezingeni eliphezulu ama-2 nama-roller okulinganisa ama-3 aphansi. Kungenjalo, amakhasimende afuna amakhono esivinini esiphezulu angakhetha umshini wokulinganisa ozimele, nakuba unomugqa wokukhiqiza omkhudlwana.

I-Hydraulic Punch

Umshini we-hydraulic punch, onikwa amandla yisiteshi se-hydraulic, usebenzisa isikhunta kwesokunxele nakwesokudla ukuzebhoboza izimbobo ngokuqondile emgqeni omaphakathi wezinhlangothi zokuphakama ngemva kokwenza. Ukulandela ukusika, izimbobo ezimbili zikhona ekugcineni ngakunye kwe-cross bracing yokufaka isikulufu. Ukwengeza, isikhunta esiphakathi ku-punch ye-hydraulic canphrinta ilogo yekhasimendekukhoyili yensimbi ngaphandle kokungena, ukusiza ukukhushulwa komkhiqizo kanye nokwanda kwemakethe.

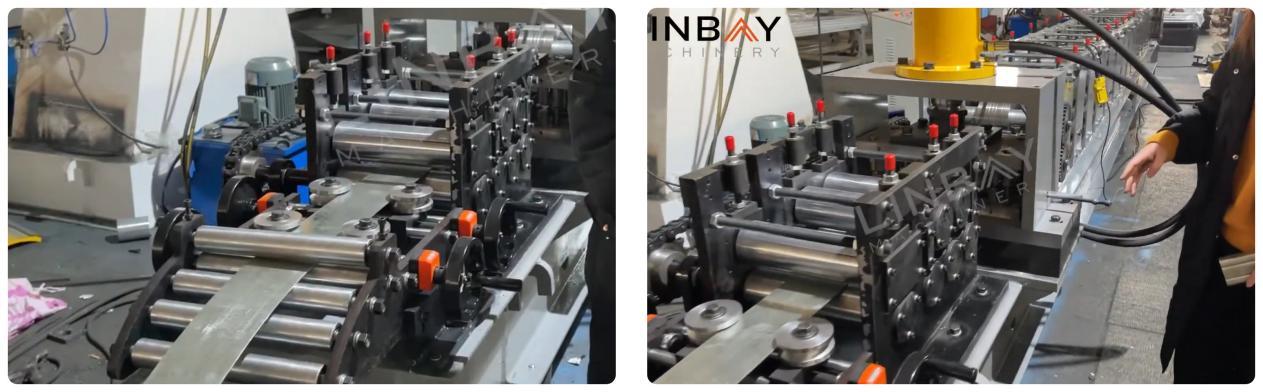

Umshini Wokwenza Roll

Umshini wokwenza umqulu, oqukethe u-aisakhiwo sephaneli yodonga kanye nesistimu yokushayela iketango, idlala indima ebalulekile emgqeni wokukhiqiza. Ilungiselelwe amakhasimende asebenzisayo450MPaisivuno amandla amakhoyili ensimbi, siqukethe22 ukwakha iziteshi. Ukuqinisekisa ukukhiqiza ngokushesha lapho ukulethwa, umshini wokwenza umqulu uhlolwa kusetshenziswa amakhoyili ensimbingamandla okukhiqiza afanayo (450MPa)njengalezo ezisetshenziswa ekukhiqizeni amakhasimende.

Ama-roller akhayo akhiwe kusukaGcr15, insimbi ene-carbon chromium ephethe i-chromium edume ngobulukhuni bayo obukhethekile nokumelana nokuguga. I-Chrome plating endaweni eyi-roller kwandisa isikhathi sayo sokuphila, okuhambisana namashafti enziwe nge-heat-treated40Krimpahla.

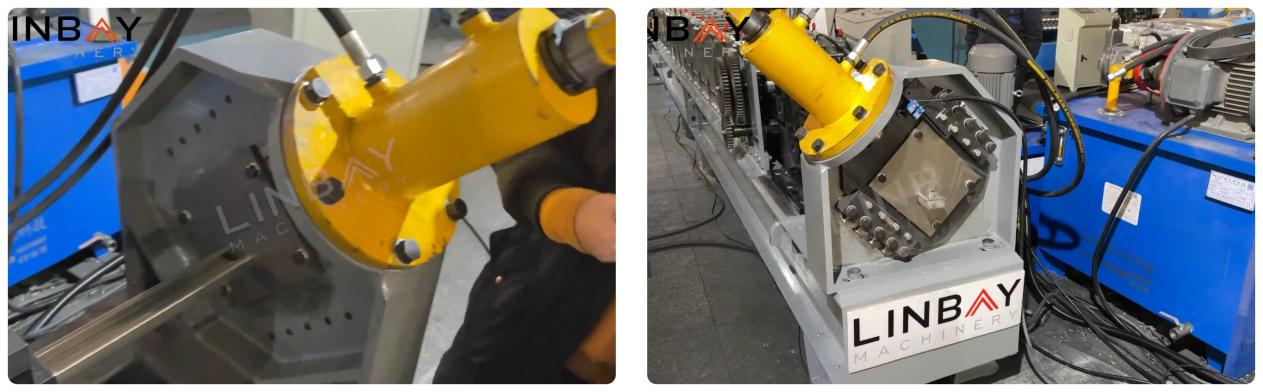

I-Hydraulic Cutting & Encoder

Ukuhlanganiswa kwesishumeki se-Koyo saseJapane kuvumela ukuguqulwa kobude bekhoyili yensimbi ezwayo ibe amasignali kagesi, adluliselwe kukhabhinethi yokulawula ye-PLC. Lolu hlelo olunembayo luyaqinisekisaukunemba kokusika ngaphakathi kwe-1mm,ngalokho kuqinisekisa imikhiqizo yekhwalithi ephezulu ngenkathi kunciphisa ukungcola okubangelwa ukusikeka okungalungile.

Isiteshi seHydraulic

Isiteshi se-hydraulic sifakwe isiphephetha-moya esipholile sokuqeda ukushisa okusebenzayo, siqinisekisa ukusebenza isikhathi eside, okunephutha eliphansi kanye nokuqina.

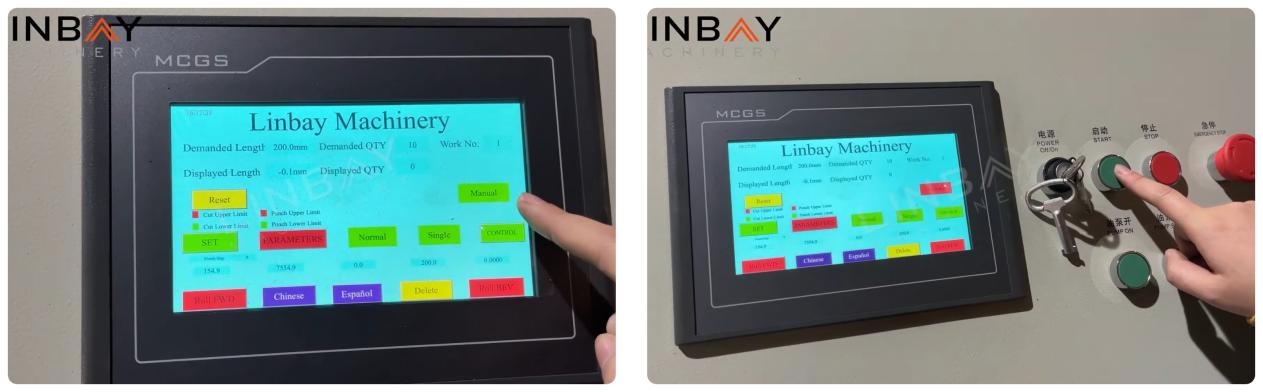

IKhabhinethi Yokulawula ye-PLC

Abasebenzisi banamandla okuphatha isivinini sokukhiqiza, ukusungula ubukhulu bokukhiqiza, nokunquma ubude bokusika ngesikrini se-PLC. Ikhabhinethi yokulawula ye-PLC ifakwe izici zokuzivikela ezifana nokugcwala ngokweqile, isifunda esifushane, nokuvikelwa kwesigaba sokulahlekelwa. Ukwengeza, ulimi oluboniswa esikrinini se-PLCingalungiselelwa izilimi ezithile noma izilimi eziningiukuhlangabezana nezintandokazi zekhasimende.

Iwaranti

Idethi yokulethwa ikhonjisiwe ku-nameplate, kuqalwa i-isiqinisekiso seminyaka emibili sawo wonke ulayini wokukhiqiza kanye newaranti yeminyaka emihlanu yamarola namashafti.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle