Iphrofayela

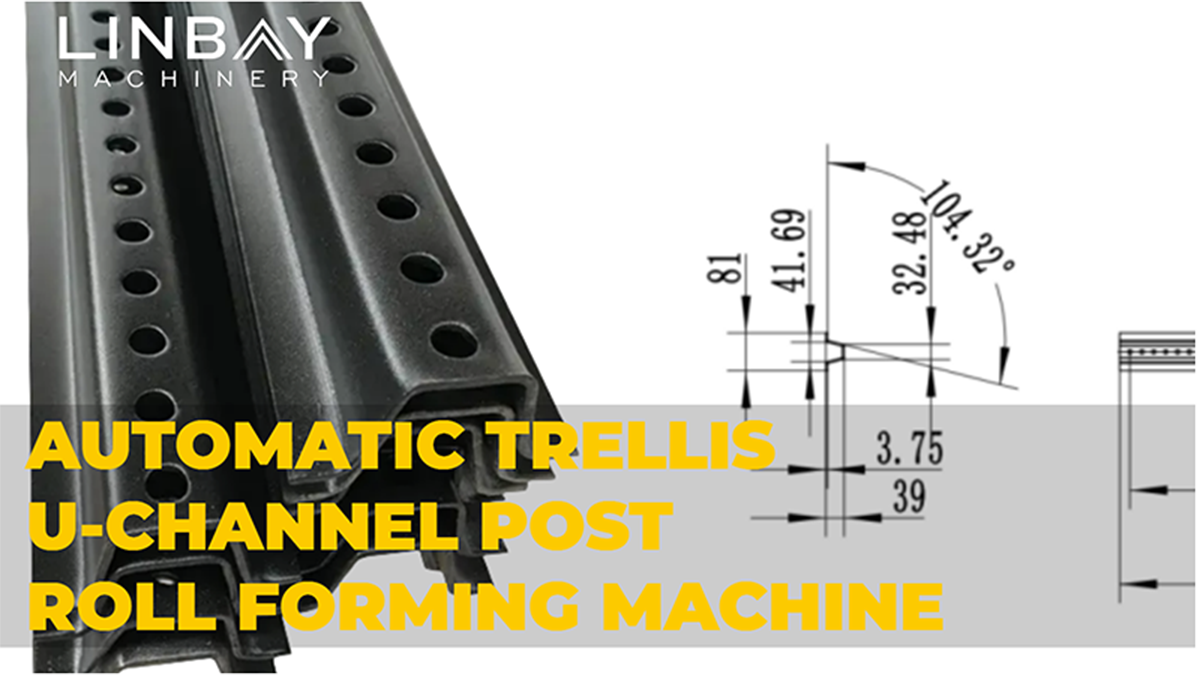

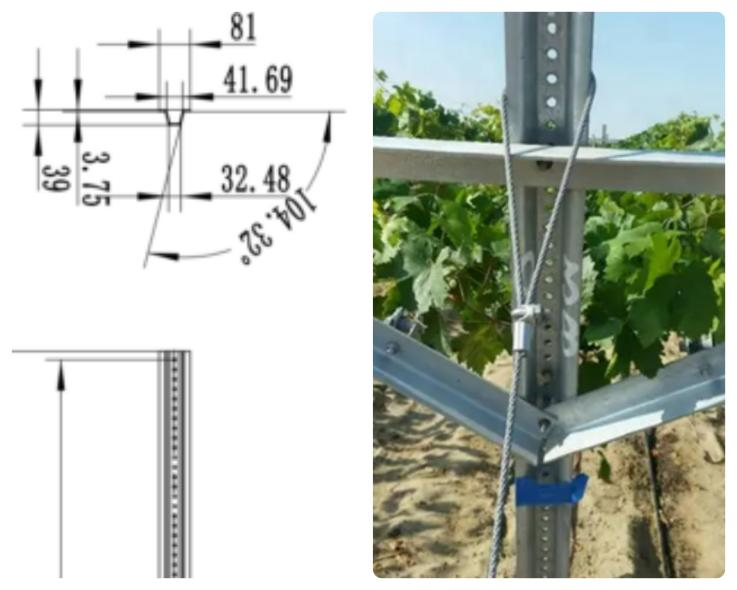

Ipali ye-Trellis U-channel iyipali yocingo emise okwesigqoko evame ukusetshenziswa emkhakheni wezolimo, ikakhulukazi kuma-grape trellises, ama-apula ozimele, nezinye izinto ezifanayo. Ihlanganisa ububanzi obuphezulu obungu-32.48mm, ububanzi obuphansi bungu-41.69mm, nobubanzi obuphelele bungu-81mm, nokuphakama okungu-39mm. Iposi ngalinye lilinganisa u-2473.2mm ubude futhi lifakwe izimbobo ezisondelene ezingu-107, eziqhubekayo zobubanzi obungu-9mm, okuvumela ukufakwa okuguquguqukayo kwabakaki ngosayizi abahlukahlukene.

Incazelo

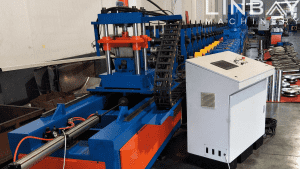

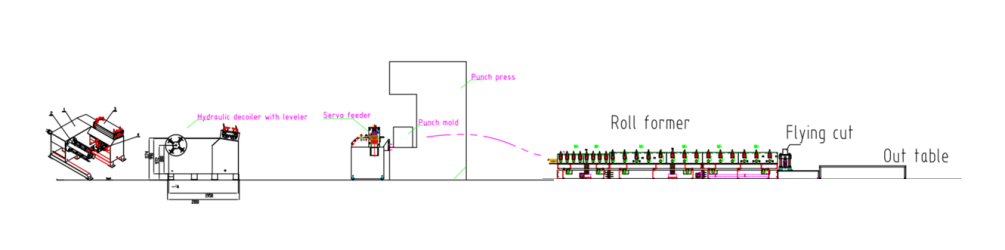

Ishadi eligelezayo

I-Decoiler ene-level--Servo feeder--Punch press--Roll former--Flying cut--out table

I-Decoiler ene-Level

Lo mshini uhlanganisa ukusebenza kokuhlehlisa nokubeka izinga. I-decoiler yayo ifaka i-brake device yokulungisa ukushuba kwe-decoiling roller, iqinisekise ukusebenza kahle. Amaqabunga okuvikela insimbi avimbela ukushelela kwekhoyili ngesikhathi sokuwohloka, athuthukisa ukuphepha kanye nokusebenza kahle kwezindleko kuyilapho wonga indawo yomugqa wokukhiqiza phansi.

Ngemva kokubola, ikhoyili yensimbi iqhubekela emshinini wokulinganisa. Uma kubhekwa ubukhulu bekhoyili (2.7-3.2mm) kanye nokushaya okuminyene, i-level ibalulekile ekususeni ukugoba ikhoyili, ithuthukise ukucaba nokuhambisana. Umshini wokulinganisa ufakwe amarola asezingeni eliphezulu angu-3 nangaphezulu angu-4 ukuze asebenze kahle.

I-Servo Feeder & Punch Cindezela

Ngale njongo, sisebenzisa umshini wokunyathelisa wamathani angu-110 okhiqizwe uhlobo lwe-Yangli, ohlanganiswe nesiphakeli se-servo. I-servo motor inika amandla ukuphendula okusheshayo ngokumosha isikhathi esincane sokuqala-stop, iqinisekisa ukulawulwa kwesikhundla okunembile. Ngobukhona bomhlaba be-Yangli nokuzibophezela kusevisi yekhwalithi ephezulu ngemuva kokuthengisa, amakhasimende angalindela ukwesekwa okuthembekile. Izibunjwa ezenziwe ngokwezifiso zenziwe ngendlela oyifisayo ngokusekelwe emidwebeni yokubhoboza ehlinzekwe ngamakhasimende, kwakheka kahle izimbobo ezinobubanzi obungu-9mm. Isibhakela siyafa, sakhiwe ngensimbi ye-SKD-11, sinikeza ukumelana nokugqokwa okukhethekile nobulukhuni.

Kuhlelo lokulawula lwe-PLC, senza lula okokufaka kwedatha ngokuphatha inani lezimbobo zokubhoboza. Ukwengeza, umsebenzi wememori yepharamitha uhlinzekwa ukugcina amasethi angu-10 wemingcele yokushaya, ehambisana nezidingo zokukhiqiza. Lesi sici sivumela ukubuyisa kalula nokusebenzisa amapharamitha agciniwe ngaphandle kwesidingo sokufaka kabusha.

Umkhawulo

Ukuze uvumelanise isivinini sokukhiqiza, isikhawuli sibekwe phakathi kwezigaba zokubhoboza nezokwakha umqulu. Lapho ikhoyili yensimbi ithinta umkhawulo ophansi, ikhombisa isivinini sokubhoboza esidlula isivinini sokwenza umqulu, umshini wokubhoboza uthola isignali yokuma. Ukwaziswa kuvela esikrinini se-PLC, okwenza opharetha aqale kabusha umsebenzi ngokuchofoza esibukweni.

Ngokuphambene nalokho, uma ikhoyili yensimbi ithinta umkhawulo ongaphezulu, iphakamisa isivinini sokwenza umqulu odlula isivinini sokubhoboza, umshini wokwenza umqulu uyamisa ukusebenza. Ngenkathi umshini wokwenza umqulu uqala kabusha umsebenzi, umshini wokubhoboza uyaqhubeka nokusebenza kwawo ngaphandle kokuphazamiseka.

Lokhu kusetha kuqinisekisa ukubambisana okuphelele nokufana kwesivinini sokukhiqiza emugqeni wokukhiqiza.

Ukuqondisa

Ngaphambi kokufaka isethi yokuqala yokwakha ama-roller, ikhoyili yensimbi iqondiswa ngesigaba somhlahlandlela usebenzisa ama-guiding rollers. Lawa ma-roller aqinisekisa ukuqondanisa phakathi kwekhoyili nendawo emaphakathi yomshini, avimbele ukuhlanekezelwa kwamaphrofayili akhiwe. Amarola aqondisayo abekwe ngendlela efanele kuwo wonke umugqa wokwakha. Izilinganiso ezisuka kurola oqondisayo ukuya onqenqemeni zilotshwe kubhukwana, okusiza ukumisa kabusha okungenamsebenzi uma ukususwa okuncane kwenzeka ngesikhathi sokuthutha noma ukulungiswa kokukhiqiza.

Umshini Wokwenza Roll

Enhliziyweni yomugqa wokukhiqiza kukhona umshini wokwenza ama-roll, ingxenye ebalulekile ehlanganisa iziteshi eziyi-10 zokwakha. Inesakhiwo esiqinile se-iron kanye nesistimu yokushayela i-gearbox, ekwazi ukwenza isivinini esifika ku-15m/min. Aklanywe ngensimbi ene-Cr12 ephezulu-carbon chromium, amarola akhayo ahamba phambili ngokuqina nokumelana nokuguga. Ukwelula ubude besikhathi sawo sokuphila, ama-roller afakwa nge-chrome plating, kuyilapho ama-shaft akhiwe ngezinto ezingu-40Cr.

Ikhodi ye-laser endizayo (Uma uthanda)

Ngaphambi kwenqubo yokusika, i-coder laser yokuzikhethela ingafakwa, ivumelaniswe nesivinini somshini wokusika ngaphandle kokuphazamisa ukusebenza okuqhubekayo komshini wokwenza umqulu. Le sistimu ethuthukisiwe ifakwe isixhumi esibonakalayo sesikrini esithintwayo, amehlo okungenisa, kanye nobakaki ophakamisayo. Isiza ukuphrinta nge-laser kwezakhi ezahlukahlukene njengombhalo, ihluzo, amakhodi e-QR, nokuningi. Lokhu okuzenzakalelayo kusiza ekulinganiseni imikhiqizo, ukulawula ukukhiqizwa, nokuthuthukisa umkhiqizo ngempumelelo.

I-Flying Hydraulic Cutting & Encoder

Ngaphakathi komshini wokwakha, isishumeki se-Koyo esivela e-Japan siguqula ubude obutholiwe bekhoyili yensimbi bube isignali kagesi, bese idluliselwa kukhabhinethi yokulawula ye-PLC. Lokhu kuvumela ukulawula okunembile kwamaphutha okusika, ukuqinisekisa ikhwalithi yomkhiqizo ngaphakathi kwe-margin engu-1mm kanye nokunciphisa imfucuza. Izibunjwa zokusika zenzelwe ngokuqondile ukufanisa iphrofayili, ziqinisekisa ukusikeka okubushelelezi, okungenayo i-burr ngaphandle kokuguqulwa. Igama elithi "flying" libonisa ukuthi umshini wokusika ungahamba ngesivinini esifanayo nesokwenza umqulu, uvumele ukusebenza okungenazihibe futhi kukhuphule ukusebenza kahle kokukhiqiza kukonke.

Isiteshi seHydraulic

Isiteshi se-hydraulic sifakwe abalandeli bokupholisa abahlanganisiwe ukuze baqede ukushisa ngokuphumelelayo, ukuqinisekisa ukusebenza okuqhubekayo nokuphila isikhathi eside. Eyaziwa ngezinga laso eliphansi lokuhluleka, isiteshi se-hydraulic sakhelwe ukuqina okunwetshiwe.

Ikhabhinethi yokulawula ye-PLC

Ngesikrini se-PLC, opharetha banamandla okuphatha isivinini sokukhiqiza, ukuchaza ubukhulu bokukhiqiza, ukusika ubude, nokuningi. Izici zokuphepha ezifakwe kukhabethe lokulawula le-PLC zifaka ukuvikela ekulayisheni ngokweqile, ukujikeleza okufushane, nokulahlekelwa kwesigaba. Ngaphezu kwalokho, ulimi oluboniswa esikrinini se-PLC lungalungiswa ukuze luhambisane nokuthandwa yikhasimende.

Iwaranti

Ulayini wokukhiqiza unikezwa iwaranti yeminyaka emibili kusukela ngosuku lokulethwa, olukhonjiswe ku-nameplate. Amarola namashaft athola iwaranti yeminyaka emihlanu.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle