ividiyo

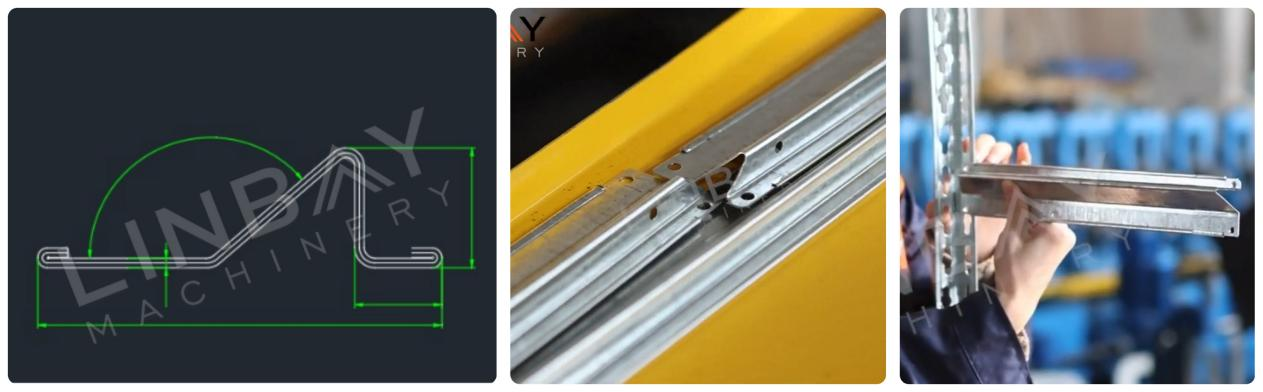

Iphrofayela

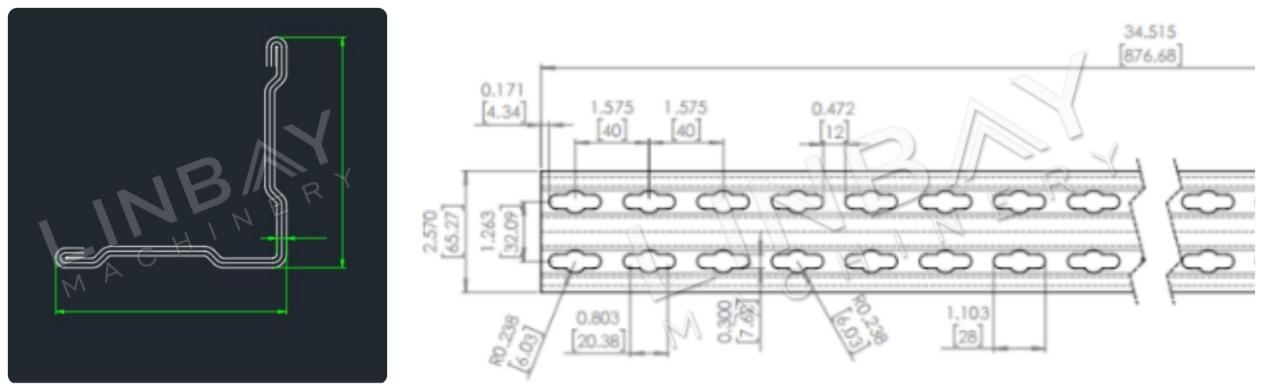

Leli ishalofu lomsebenzi wokukhanya liqondile, elifana nensimbi ye-engeli, enogqinsi luka-1.2mm. Iyingxenye eyinhloko yesakhiwo seshalofu, futhi ukuqondisa kwayo kuthinta ngokuqondile umthamo wokuthwala umthwalo weshalofu. Izimbobo zishaywa ezinhlangothini zombili ukuze kuxhunywe imishayo.

Leli ishalofu eliwumsebenzi olula, eliwugqinsi elingu-1.2mm, elihloselwe ukusekela amaphaneli eshalofu futhi lithuthukise umthamo wawo wonke wokuthwala umthwalo weshelufu lomsebenzi wokukhanya.

Incazelo

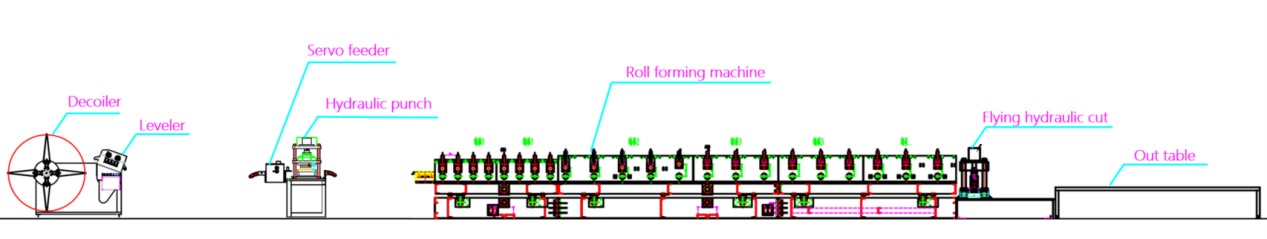

Ishadi eligelezayo

I-Decoiler ene-Level

Lo mshini uhlanganisa ukusebenza kokuhlehlisa nokubeka izinga.Ihlanganisa idivayisi yebhuleki ku-decoiler yokulungisa ukushuba kwe-roller e-decoiling, ukuqinisekisa isivinini esibushelelezi. Amaqabunga ensimbi avikelayo avimbela ukushelela kwekhoyili. Lo mklamo unikeza aengabizi, ukuphepha okuphezuluisixazululo se-decoiling.

Ngemva kwalokho, ikhoyili yensimbi ingena emshinini wokulinganisa. Ku-1.2mm ubukhulu, ukubhoboza okuminyene kudinga ukulinganisa ukuze kuqedwe ukugoba ikhoyili, kuthuthukisweflatness kanye parallelismngekhwalithi yomkhiqizo ethuthukisiwe. Ileveli inamarola angu-3 aphezulu na-4 aphansi.

I-Servo Feeder & Hydraulic Punch

Ikhoyili yensimbi iqhubekela emshinini ozimele we-hydraulic punch. Ukusebenzisa i-servo motor ye-feeder kunika amandla ukubhoboza okunembayo ngenxa yempendulo yayo esheshayo kanye nesikhathi esincane sokuqala sokuma, okuqinisekisa ukulawula okunembile kokushaya.

Umkhawulo

Ngesikhathi sezinqubo zokubhoboza kanye nokwakhiwa kwe-roll, kusetshenziswa isilinganiselivumelanisa isivinini sokukhiqiza. Lapho ikhoyili yensimbi ifinyelela kumkhawulo ophansi, okubonisa isivinini sokubhoboza esiphezulu kunesivinini sokwenza umqulu, i-punch ye-hydraulic ithola isignali yokuma kukhabhinethi yokulawula ye-PLC. I-alamu esheshayo ibonakala esikrinini se-PLC, okuvumela opharetha ukuthi aqalise kabusha umsebenzi ngokuchofoza isikrini. Ngaleso sikhathi, ngesikhathi sokumiswa, umshini wokwenza ama-roll uyaqhubeka nokusebenza.

Ngokuphambene, lapho ikhoyili yensimbi ishaya umkhawulo ongaphezulu, okubonisa isivinini sokwakheka esiphezulu kunesivinini sokubhoboza, umshini wokwenza umqulu uyama. Ngesikhathi sokuma kancane phakathi kokuma komshini wokwenza umqulu futhi uqala kabusha, i-punch ye-hydraulic ihlala isebenza.Ubude bomkhawulo ongaphezulu buyalungiseka ngokuya ngezidingo zekhasimende.

Lokhu kuqinisekisa ukuhlanganiswa okuphelele kanye nesivinini sokukhiqiza okufanayo komugqa wokukhiqiza.

Ukuqondisa

Ngaphambi kokuba ikhoyili yensimbi ingene ku-roller yokuqala yokwakha, inqamula ibha yokuqondisa ukuze igcine ukuqondana nomshini, ivimbele ukuhlanekezela kwephrofayela. Amarola aqondisayo abekwe ngendlela ehlelekile hhayi nje kuphela lapho kungenwa khona kodwa futhi nakuwo wonke umugqa wokwakha. Izilinganiso zebanga ngalinye lebha eqondisayo/irola ukuya onqenqemeni zilotshwe kumanuwali ukuze kulungiswe kahle uma kwenzeka ukuthutha ngesikhathi sokuthutha noma ukungaboni ngaso linye okubangelwa umsebenzi ngesikhathi sokukhiqiza.

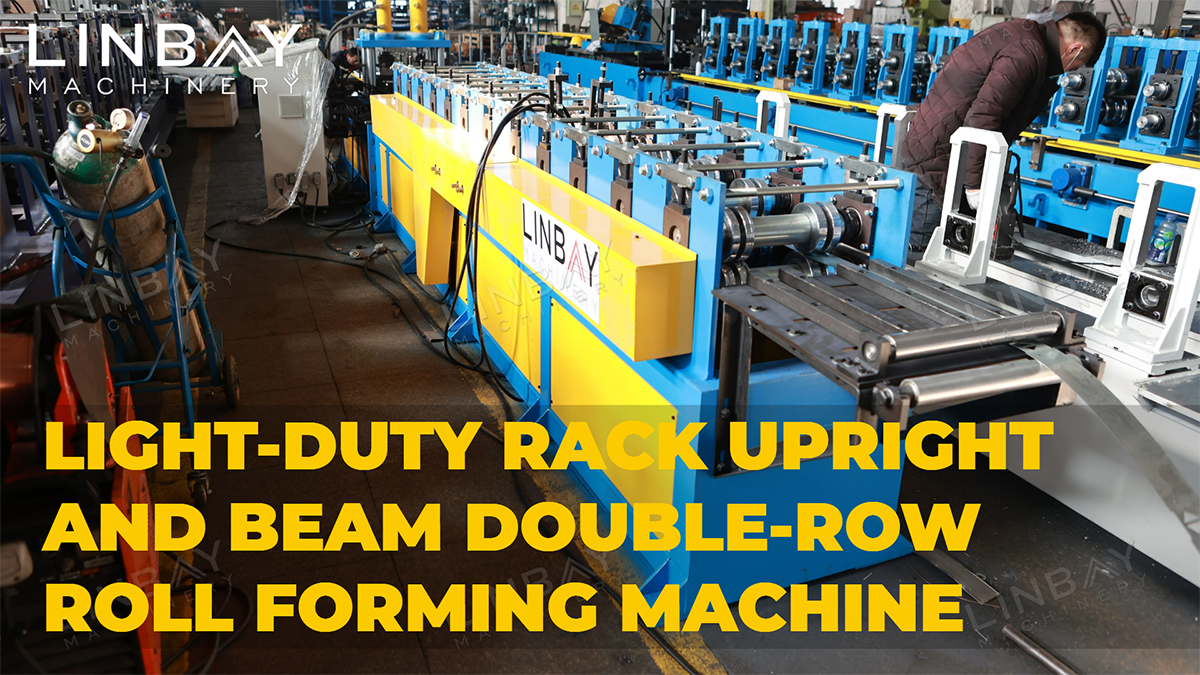

Umshini Wokwenza Roll

Umshini wokwenza ama-roll ume njengengxenye ebalulekile yawo wonke umugqa wokukhiqiza. Nge12 ukwakha iziteshi, iqhosha aisakhiwo panel panel kanye chain ukushayela uhlelo. Ngokuphawulekayo, i-aumugqa okabilidesign ekwazi ukwenza kokubiliamajamo aqondile kanye nama-beam amashelufu omsebenzi wokukhanya. Nakuba le migqa ingakwazi ukusebenza ngesikhathi esisodwa, iyahlinzekaukuguquguqukangezidingo ezahlukahlukene zokukhiqiza. Amakhava okuzivikela ochungechungeni abeka phambili ukuphepha kwabasebenzi. Ukwengeza, umshini uhlolwa ngamakhoyili ensimbi wamandla esivuno alinganayo kulawo asetshenziswa ekukhiqizeni amakhasimende, ukuqinisekisa ukuthi kube lula ngokushesha ekulethweni.

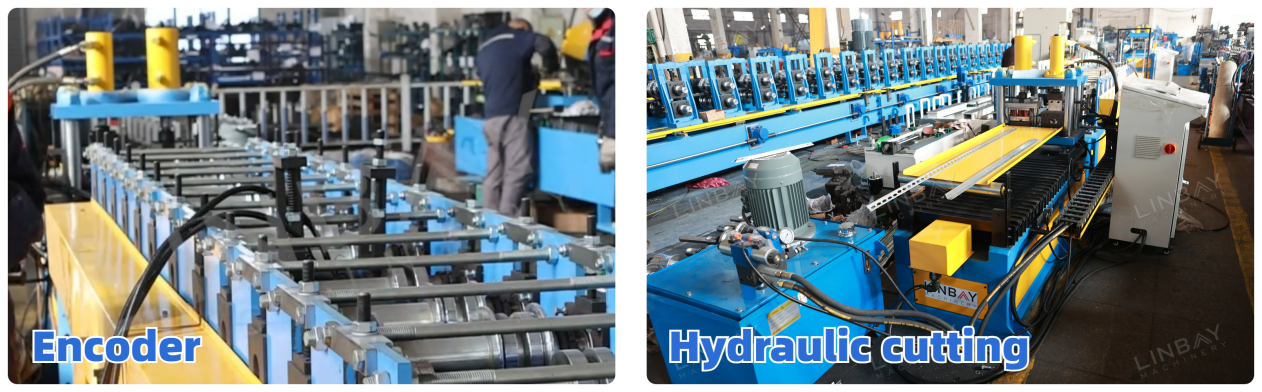

Ama-roller akhayo akhiwe kusukaGcr15, insimbi ene-carbon chromium ephezulu edume ngayoubulukhuni nokumelana nokugqoka. I-Chrome plating endaweni eyi-roller kwandisa isikhathi sayo sokuphila, kuyilapho ama-shaft akhiwa ngokuphathwa ukushisa.40Krimpahla.

I-Flying Hydraulic Cutting & Encoder

Umshini wokwenza umqulu uhlanganisa isishumeki se-Koyo saseJapane, siguqule ubude bekhoyili yensimbi ezwayo ibe amasiginali kagesi athunyelwe kukhabhinethi yokulawula ye-PLC. Lokhu kuvumela i-umshini wokusika ukulawula amaphutha okusika ngaphakathi kwe-1mm, ukuqinisekisa imikhiqizo yekhwalithi ephezulu kanye nokunciphisa imfucuza ekusikeni okungalungile. "Ukundiza" kusho amandla omshini wokusika wokuya emuva naphambili ngesivinini esifana nesomshini wokwenza umqulu ngesikhathi sokusika,ukunika amandla ukusebenza okuqhubekayo kanye nokuthuthukisa umthamo womugqa wokukhiqiza usuwonke.

Isiteshi seHydraulic

Isiteshi se-hydraulic sifakwe isiphephetha-moya esipholile sikagesiukuchithwa kokushisa okusebenzayo, ukuqinisekisa ukusebenza isikhathi eside, iphutha eliphansi, nokuqina.

I-PLC

Abasebenzi bangaphatha ukukhiqizaisivinini, setha ubukhulu bokukhiqiza, ubude bokusika, njll., ngesikrini se-PLC. Ikhabhinethi yokulawula ye-PLC ihlanganisa imisebenzi yokuvikela efana nokugcwala ngokweqile, isifunda esifushane, nokuvikela ukulahlekelwa kwesigaba. Ulimi oluboniswa esikrinini se-PLC lungabaeyenziwe ngokwezifiso olimini olulodwa noma izilimi eziningingokusekelwe ezidingweni zekhasimende.

Iwaranti

Ngaphambi kokulethwa, idethi yokulethwa iboniswa ku-nameplate, ukuqalaiwaranti yeminyaka emibili yawo wonke umugqa wokukhiqiza kanye newaranti yeminyaka emihlanu yamarola namashafti.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle