UMSHINI WE-SQUARE TUBE ROLL UKWAKHA

Lo mugqa wokukhiqiza wenzelwe ukudala amashubhu ayisikwele anogqinsi luka-2mm, nobukhulu obusuka ku-50-100mm ububanzi no-100-200mm ukuphakama.

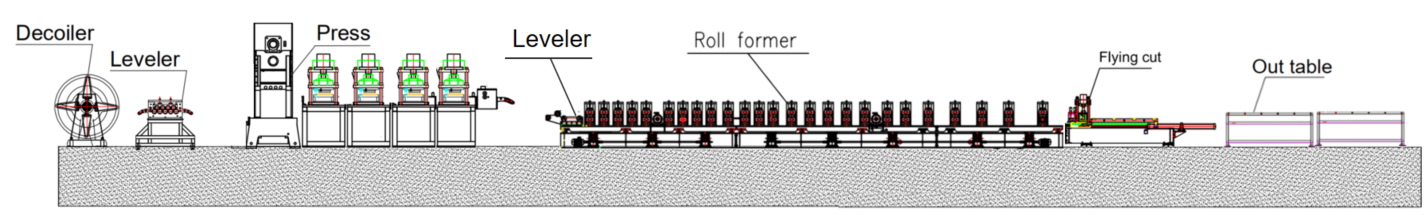

Ulayini wokukhiqiza uhlanganisa izinqubo ezimbalwa ezibalulekile: ukuqaqa, ukulinganisa kwangaphambi kokubhoboza, ukubhoboza, ukulinganisa kwangemuva kokubhoboza, ukwakheka kwama-roll, ukushisela nge-laser, ukukhipha intuthu, nokusika.

Ihambisana nokusetha okuphelele kanye ne-automation ethuthukisiwe, lo mugqa wokukhiqiza unikeza enye indlela ephakeme kunemishini evamile yokushisela, ikakhulukazi yamavolumu aphansi okukhiqiza.

I-REAL CASE-MAIN TECHNICAL PARAMETERS

Ishadi eligelezayo: I-Hydraulic decoiler enemoto elayishayo--Leveler--Servo feeder--Punch press--Hydraulic punch--Limiter--Guiding--Leveler--Roll former--Laser weld--Flying saw cut--Ithebula eliphumayo

I-REAL CASE-MAIN TECHNICAL PARAMETERS

· Isivinini somugqa esilungisekayo: 5-6m/min nge-laser welding

· Izinto ezihambisanayo: Insimbi egoqelwe ngokushisayo, insimbi egoqwe ngamakhaza, insimbi emnyama

· Ubukhulu bezinto: 2mm

· Umshini wokwenza ama-roll: Isakhiwo se-cast iron enejoyinti lendawo yonke

· Isistimu yokushayela: Isistimu eshayelwa yi-Gearbox ehlanganisa i-universal joint cardan shaft

· Isistimu yokusika: Isaha elindiza lisika, ngokuqhubeka nokusebenza komqulu ngesikhathi sokusika

· Ukulawulwa kwe-PLC: Uhlelo lwe-Siemens

I-REAL CASE-MACHINERY

1.I-Hydraulic decoiler*1

2.I-Standalone Leveler*1

3.Cindezela ngokucindezela*1

4.Umshini we-Hydraulic punch*1

5.Isiphakeli se-Servo*1

6.Izinga Elihlanganisiwe*1

7.Umshini wokwenza iroll*1

8.Laser welding machine*1

9.I-Welding Fume Purifier*1

10.Flying saw cutting machine*1

11.Ithebula elingaphandle*2

12.PLC control cabinet*2

13.Isiteshi samanzi*3

14.Ibhokisi lezingxenye eziyisipele(Mahhala)*1

INKCAZELO YANGEMPELA

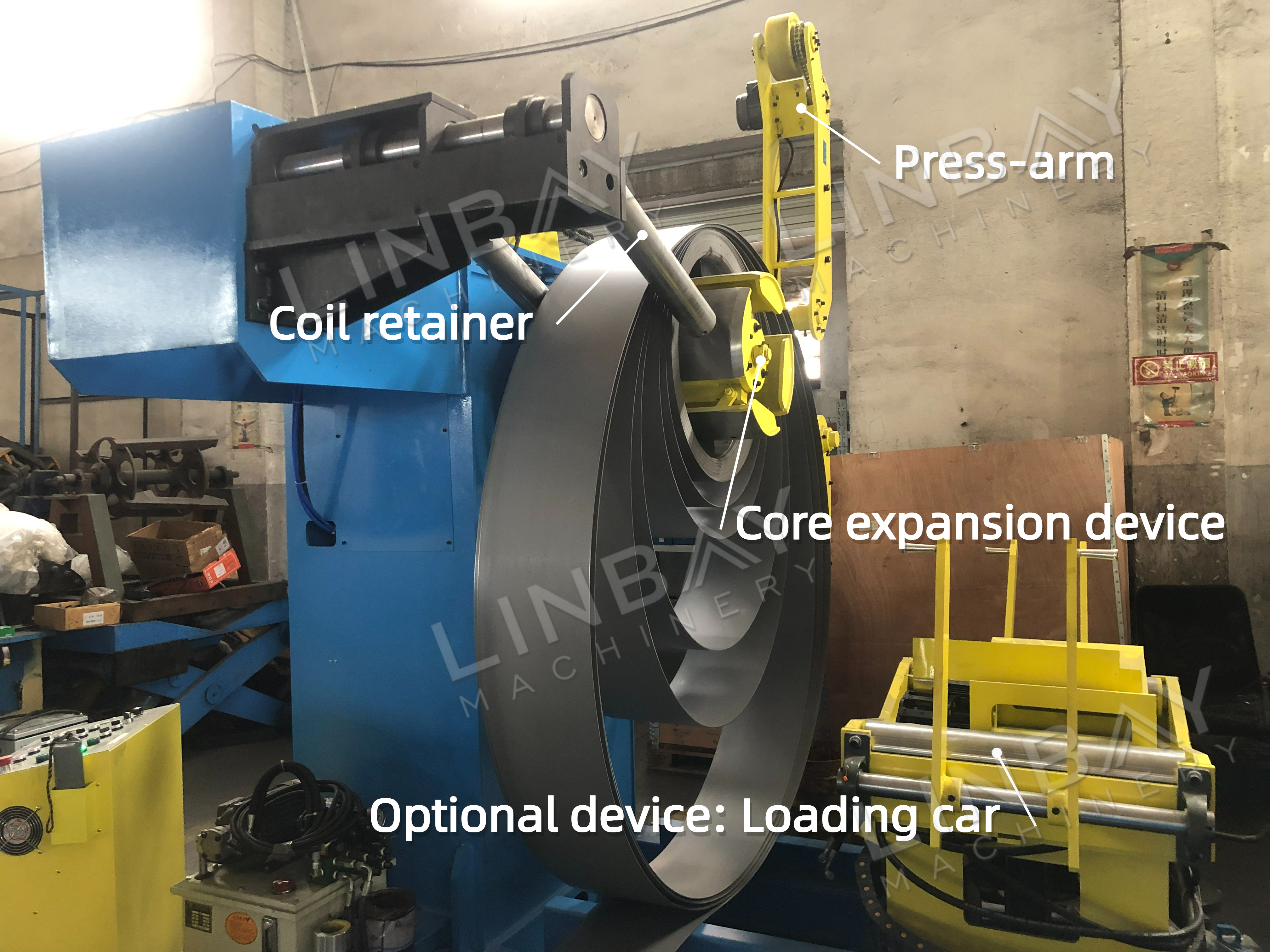

I-Hydraulic decoiler

•Umsebenzi: Uhlaka oluqinile lwakhiwe ukuze lusekele ukulayishwa kwekhoyili yensimbi. I-hydraulic decoiler ithuthukisa ukusebenza kahle nokuphepha ekuphakeleni amakhoyili ensimbi emgqeni wokukhiqiza.

•Idivayisi Yokunweba Okubalulekile: I-hydraulic mandrel noma i-arbor ilungisa ukuze ilingane amakhoyili ensimbi anobubanzi bangaphakathi obuyi-490-510mm, enwebekayo futhi ifinyela ukuze ibambe iqine ikhoyili futhi iqinisekise ukubola okushelelayo.

•Cindezela-ingalo: Ingalo yokucindezela ye-hydraulic ivikela ikhoyili yensimbi, ivimbele ukuhlehla kungazelelwe ngenxa yengcindezi yangaphakathi nokuvikela abasebenzi ekulimaleni okungenzeka.

•I-Coil Retainer: Idizayini iqinisekisa ukuthi ikhoyili ihlala isendaweni ngokuvikelekile kuyilapho ivumela ukuyifaka nokuyisusa kalula.

•Isistimu yokulawula: Uhlelo lufaka i-PLC kanye nephaneli yokulawula, ehlanganisa inkinobho yokumisa isimo esiphuthumayo ukuze uthole ukuphepha okwengeziwe.

Idivayisi Ongayikhetha: Ilayisha Imoto

•Ukushintshwa Kwekhoyili Okuphumelelayo: Isiza ekuguquleni amakhoyili ensimbi ngokuphepha nangempumelelo, ukunciphisa izindleko zabasebenzi.

•Ukuqondanisa kweHydraulic: Ipulatifomu ingalungiswa nge-hydraulically phezulu naphansi ukuze ihambisane ne-mandrel. Ukwengeza, imoto elayishayo, efakwe amasondo, ikwazi ukuhamba ngogesi emzileni.

•Umklamo Wokuphepha: Idizayini ye-concave ibamba ngokuqinile ikhoyili yensimbi, ivimbele noma yikuphi ukushelela.

Umshini ozikhethela wona: Shearer Butt Welder

· Ixhuma amakhoyili ensimbi wokugcina namasha, inciphise isikhathi sokudla kanye nezinyathelo zokulungisa amakhoyili amasha.

· Yehlisa izindleko zabasebenzi kanye nokumosha izinto ezibonakalayo.

· Iqinisekisa ukugunda okushelelayo, okungena-burr ukuze kulungiswe kahle futhi kushiselwe.

· Ifaka ukushisela kwe-TIG okuzenzakalelayo kokushisela okungaguquki futhi okuqinile.

· Kufaka izibuko zokuphepha etafuleni lokushisela ukuvikela amehlo abasebenzi.

· Izilawuli zokunyathela izinyawo zenza ukubamba ikhoyili kube lula.

· Yenzeka ngendlela oyifisayo kububanzi bekhoyili obuhlukene futhi ingahlanganiswa kalula emigqeni yokukhiqiza ehlukahlukene phakathi kobubanzi bayo.

I-Standalone Leveler

· Yehlisa ukucindezelwa kanye nokungapheleli kwendawo kumakhoyili ensimbi ngokuguqulwa kwepulasitiki, ukuvimbela amaphutha ejometri ngesikhathi sokwenza.

• Ukulinganisa kubalulekile kumakhoyili anogqinsi kuno-1.5mm adinga ukushaywa.

· Ngokungafani namaleveli ahlanganisiwe ahlanganiswe nama-decoiler noma imishini yokwenza ama-roll, amaleveli azimele asebenza ngesivinini esiphezulu.

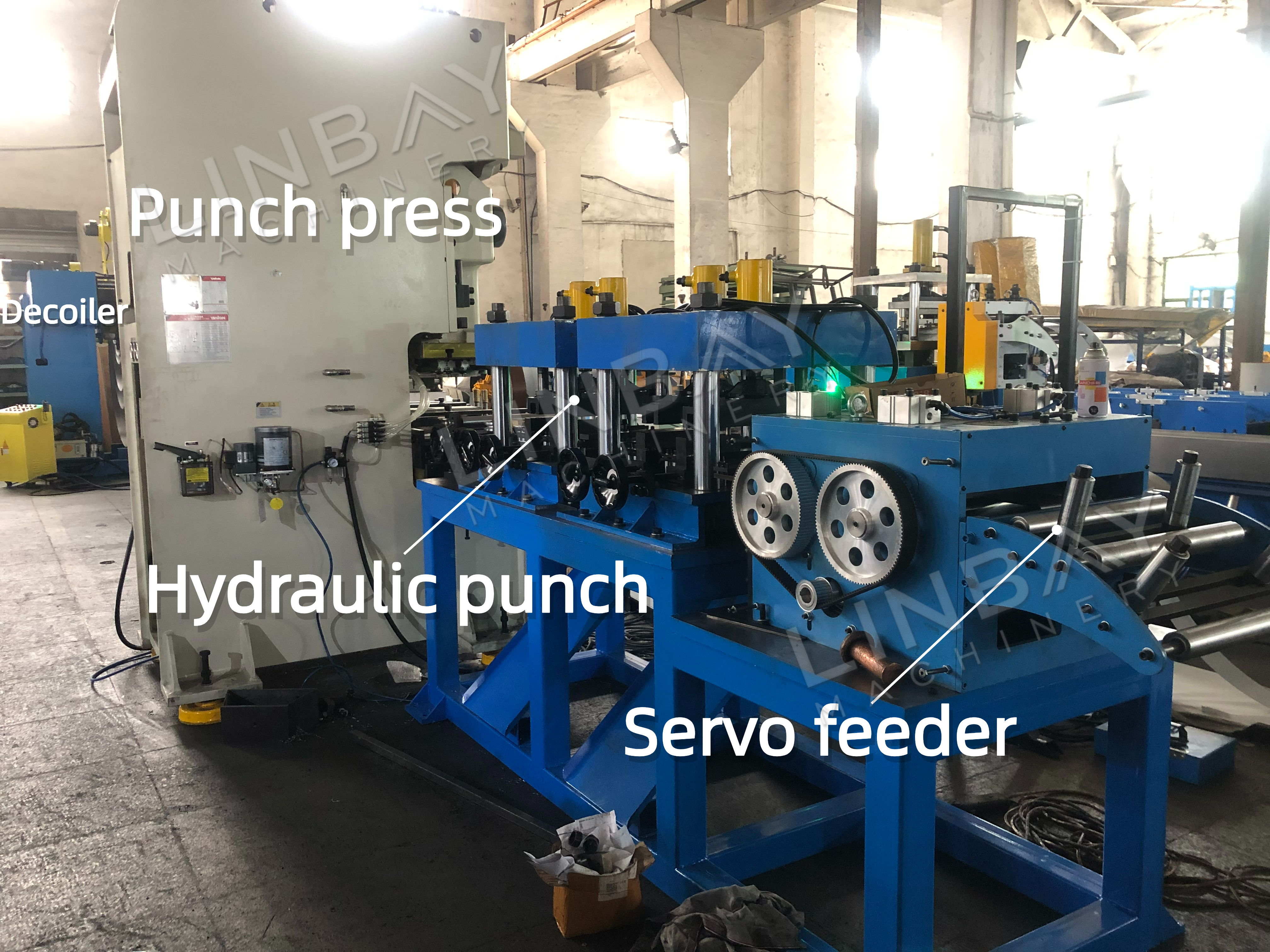

Ukubhoboza Ingxenye

• Kulo mugqa wokukhiqiza, sisebenzisa inhlanganisela ye-punch press kanye ne-hydraulic punch ukubhoboza imbobo. Ithimba lethu lonjiniyela lenze indlela elungile yokuphatha amaphethini emigodi eyinkimbinkimbi, ukulinganisa ukusebenza kahle kanye nezindleko ngokuhlanganisa izinzuzo zayo yomibili imishini yokubhoboza.

Punch Cindezela

· Ukusebenza okusheshayo.

· Ukunemba okuphezulu kwezikhala zembobo ngesikhathi sokubhoboza.

· Ilungele amaphethini emigodi engaguquki.

I-Hydraulic Punch

• Inikeza ukuguquguquka okukhulu kwamaphethini emigodi ahlukahlukene. I-punch ye-hydraulic ingakwazi ukuzivumelanisa nezimo zembobo ezihlukene, ilungise imvamisa yokubhoboza ngokufanele futhi ishaye ngokukhetha izimo ezihlukene nge-stroke ngayinye.

I-Servo Feeder

Isiphakeli, esishayelwa yi-servo motor, silawula ngokunembile ukuphakelwa kwamakhoyili ensimbi emshinini wokunyathelisa we-punch noma umshini ngamunye we-hydraulic punch. Ngezikhathi zokuphendula ezisheshayo kanye nokubambezeleka okuncane kokuqala kokumisa, ama-servo motors aqinisekisa ubude bokuphakelayo obunembile kanye nesikhala sembobo esingaguquki, kunciphisa kakhulu udoti ovela ekubhakeleni okungaqondile. Lolu hlelo futhi luwonga amandla, ludonsa amandla kuphela ngesikhathi sokusebenza, futhi lulondoloza amandla ngezikhathi zokungenzi lutho. Isiphakeli siyahleleka ngokugcwele, sivumela ukulungiswa okusheshayo ebangeni lesinyathelo kanye nesivinini sokushaya, ukwehlisa izikhathi zokusetha lapho ushintsha isikhunta se-punch. Ukwengeza, umshini wangaphakathi wokubamba umoya we-pneumatic uvikela ubuso bekhoyili yensimbi kunoma yimuphi umonakalo ongaba khona.

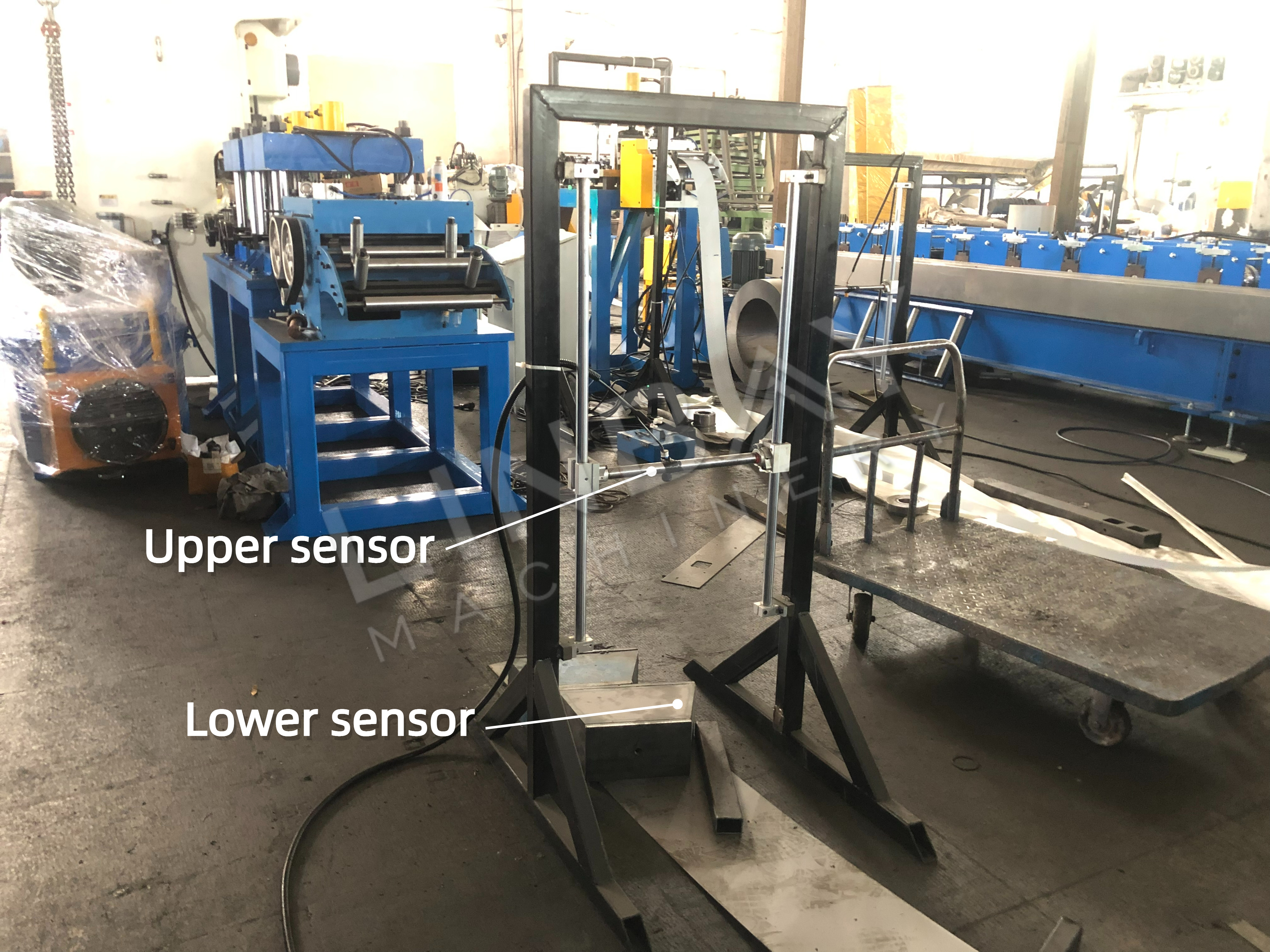

Umkhawulo

Ilawula ijubane lokukhiqiza ukuthuthukisa ukusebenza kahle kanye nokugcina ukusebenza okuphephile kwakho kokubili ikhoyili yensimbi nemishini. Uma ikhoyili ihlangana nenzwa engezansi, kusho ukuthi ukuqaqa, ukukala, nokubhoboza ngaphambi kwe-limiter kusebenza ngokushesha kunezigaba ezilandelayo zokubunjwa, ukushisela, nokusika. Lezi zinqubo zangaphambilini kufanele zime kancane ukuze kulinganiswe ukugeleza kokukhiqiza; ngaphandle kwalokho, ukunqwabelana kwekhoyili kungase kwenzeke, kuvimbele ukungena kwayo kahle emshinini wokwakha futhi kubangele ukuguquguquka. Ngokuphambene, uma ikhoyili ithinta inzwa engenhla, ikhombisa ukuthi izigaba zakamuva zihamba ngokushesha kunangaphambili, okudinga ukuthi kumiswe isikhashana ezinqubweni ngemva komkhawulo. Ukwehluleka ukwenza lokho kungaholela ekutheni ikhoyili idonswe emshinini wokwenza amasondo ngokushesha, kube sengozini yokulimala emshinini wokubhoboza nokwenza amarola. Noma yikuphi ukumiswa okwesikhashana kuzocupha isaziso kusibonisi sekhabhinethi ye-PLC ehambisanayo, okuvumela abasebenzi ukuthi baqalise kabusha ukusebenza ngokuvuma ukwaziswa.

Ukuqondisa

Injongo eyinhloko: Iqinisekisa ukuthi ikhoyili yensimbi ihambisana kahle nendawo emaphakathi yomshini, igwema izinkinga ezifana nokusonta, ukugoba, ama-burrs, nokungalungi kobukhulu emkhiqizweni oqediwe. Amarola aqondisayo abekwe ngendlela efanele endaweni yokungena nangaphakathi komshini wokwakha. Kubalulekile ukulinganisa lezi zisetshenziswa eziqondisayo njalo, ikakhulukazi ngemva kokuthutha noma ukusetshenziswa isikhathi eside komshini wokwenza umqulu. Ngaphambi kokuthunyelwa, ithimba le-Linbay likala ububanzi besiqondiso futhi lihlanganisa lolu lwazi kubhukwana lomsebenzisi, okuvumela amaklayenti ukuthi alinganise umshini lapho ulethwa.

Ileveli Yesibili (Setha kusisekelo esifanayo nomshini wokwenza ama-roll)

Ikhoyili ebushelelezi iqinisekisa ukuqondanisa okuphezulu kwe-seam post-forming, okusiza kakhulu ohlelweni lokushisela. Ileveli yesibili isebenzela ukuthuthukisa ikhwalithi yokulinganisa nokunciphisa ingcindezi ezindaweni ezishaywayo. Njengesinyathelo esengeziwe, ukubeka lesi silinganisi esisekelweni somshini owakhayo kunikeza indlela engabizi nefanelekile.

Umshini Wokwenza Roll

· Ukukhiqiza Okuhlukahlukene: Lo mugqa uyakwazi ukukhiqiza amashubhu ayisikwele anobukhulu obusuka ku-50-100mm ububanzi no-100-200mm ukuphakama. (I-Linbay ingaphinda inikeze ukwenza ngokwezifiso kwamanye amabanga osayizi.)

· Ukushintsha Usayizi Okuzenzakalelayo: Ngokusetha nokuqinisekisa usayizi ofunekayo esikrinini se-PLC, iziteshi ezakhayo zishintsha ngokuzenzakalelayo eceleni komzila wesiqondiso ziye ezindaweni ezinembile, zilungisa indawo yokuma ngokufanele. Lokhu okuzenzakalelayo kuthuthukisa ukunemba nokuba lula, kunciphisa isidingo sokulungisa mathupha kanye nezindleko ezihambisanayo.

· Ukutholwa kwe-Lateral Movement: Isifaki khodi silandelela ngokunembile ukunyakaza kwe-lateral kweziteshi ezakhayo futhi ngokushesha sidlulisela le datha ku-PLC, sigcina amaphutha okunyakaza ngaphakathi kokubekezelelana okungu-1mm.

· Izinzwa Zomkhawulo Wokuphepha: Izinzwa ezimbili zomkhawulo wokuphepha zibekwe ezinhlangothini zangaphandle zamareyili angumhlahlandlela. Inzwa yangaphakathi ivimba iziteshi ezakhayo ukuthi zisondele eduze kakhulu, zigweme ukungqubuzana, kuyilapho inzwa yangaphandle iqinisekisa ukuthi azisuki kude kakhulu.

· Uhlaka lwe-Cast-iron oluqinile: Kufakwe nozimele oqondile ozimele owenziwe ngensimbi ecijile, lesi sakhiwo esiqinile silungele izidingo zokukhiqiza eziphezulu.

· Isistimu YeDrayivu Enamandla: Ibhokisi lika-gearbox ne-universal joint kuletha amandla aqinile, okwenza ukuthi amakhoyili asebenze ngokushelelayo lapho ethuthukisa amakhoyili anogqinsi kuno-2mm noma uma akha isivinini esingaphezu kuka-20m/min.

· Ama-Roller Aqinile: Afakwe nge-Chrome-plated futhi aphethwe ukushisa, lawa ma-roller amelana nokugqwala nokugqwala, aqinisekisa ukuphila okude.

· I-Main Motor: Ukucushwa okujwayelekile kungu-380V, 50Hz, 3-isigaba, kunezinketho zokwenza ngokwezifiso ezitholakalayo.

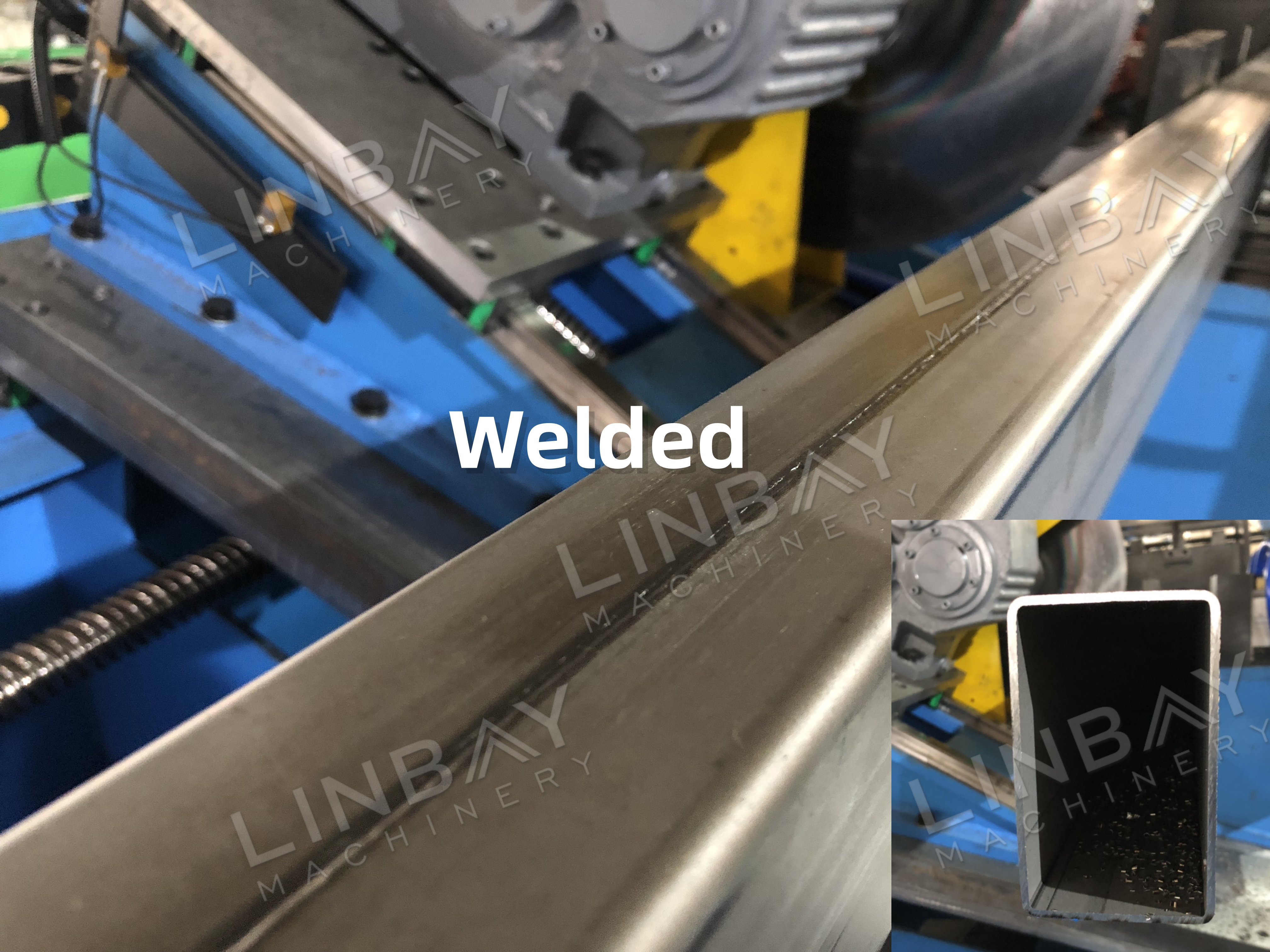

I-Laser Weld

· Ikhwalithi Ethuthukisiwe Nokunemba: Iletha ukunemba okuphezulu nokuxhumeka okuqinile.

· Ilunga Elihlanzekile Nelipholishiwe: Iqinisekisa isiphetho esihlanzekile, esibushelelezi endaweni ehlangene.

I-Welding Fume Purifier

• Ukulawula Iphunga Nokufutheka: Ibamba futhi isuse ngokuphumelelayo iphunga nentuthu ekhiqizwa ngesikhathi sokushisela, iqinisekisa indawo yefekthri ephephile futhi ivikela impilo yabasebenzi.

I-Flying Saw Cut

· I-Flying Cut: Iyunithi yokusika ivumelanisa nesivinini somshini wokwenza umqulu ngesikhathi sokusebenza, ikhulisa ukusebenza kahle kokukhiqiza kanye nokuphumayo.

· Ukusika Okuqondile: Nge-servo motor kanye nesilawuli sokunyakaza, iyunithi yokusika igcina ukunemba okungu-±1mm.

· Indlela yokusaha: Iletha ukusikeka okunembile ngaphandle kokuguqula imiphetho yamaphrofayela avaliwe.

· Ukusebenza Kwezinto Ezibalulekile: Ukusikwa ngakunye kukhiqiza imfucuza encane, kunciphisa izindleko zezinto ezibonakalayo.

·Ukusebenza Okuguquguqukayo: Ngokungafani nezinye izindlela zokusika ezidinga ama-blade athile osayizi abahlukahlukene, ukusika amasaha kuyavumelana nezimo, okunikeza ukonga kwezindleko kuma-blades.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle