kanema

Mbiri

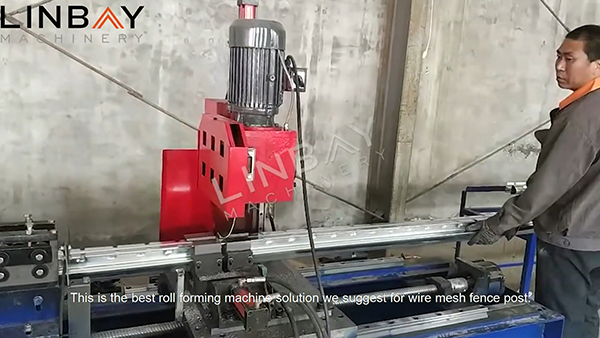

Mpanda wa mawaya, womwe nthawi zambiri umatchedwa kuti pichesi, umadziwika ndi mawonekedwe ake akunja ngati pichesi. Nthawi zambiri amapangidwa kuchokera ku zitsulo zokhala ndi mpweya wochepa kwambiri kapena zitsulo zotentha kwambiri, positi ya pichesi imagudubuzika mozizira kuti ikwaniritse mawonekedwe ake apadera.

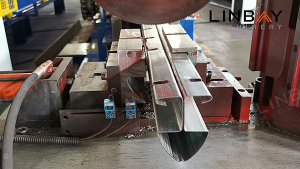

Mphepete mwa koyilo yachitsulo imapindika kunja kuti ipange mbedza yooneka ngati U, kumapangitsa kuti pakhale bata pomanga mawaya. Mipata ya Notch imayikidwa bwino mbali zonse ziwiri za positi ya pichesi kuti athandizire kuyika ma mesh achitsulo, ndi miyeso ya slot yosinthidwa kuti igwirizane ndi kukula kwa mauna.

Mzere wathunthu wopanga umapangidwa ndi notch punching ndi roll form form. Ma roller opangira ndi punch dies amapangidwa kuti awonetsetse kukhazikika kolondola komanso kuyika bwino kwa notch.

Mlandu weniweni-Main Techinical Parameters

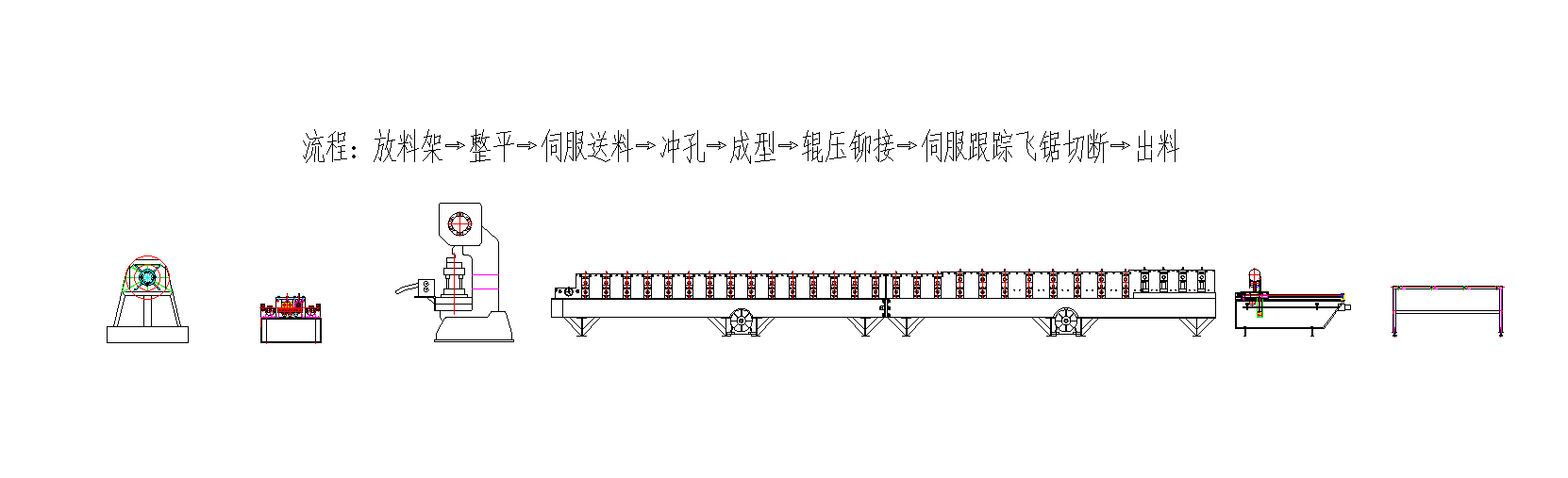

Tchati choyenda

Hydraulic decoiler-Leveler-Servo feeder-Punch press-Pit-Roll former-Flying saw cut-Out table

Main Technical Parameters:

1. Liwiro la mzere: Kusintha kuchokera ku 0 mpaka 6 m / min

2. Mbiri: Kukula kumodzi kwa mpanda wa mesh

3. Makulidwe a zinthu: 0.8-1.2mm (chifukwa ichi)

4. Zida zoyenera: Chitsulo chotentha chotentha, chitsulo chozizira chozizira

5. Makina opangira ma roll: Mapangidwe a khoma ndi makina oyendetsa unyolo

6. Chiwerengero cha malo opangira: 26

7. Dongosolo la Riveting: Mtundu wa roller; roll kale imakhalabe ikugwira ntchito panthawi ya riveting

8. Kudula dongosolo: Macheka kudula; mpukutu wakale umakhalabe ukugwira ntchito panthawi yodula

9. PLC cabinet: Okonzeka ndi Siemens system

Nkhani yeniyeni-Kufotokozera

Hydraulic decoiler

Decoiler imapereka kusinthasintha ndi zosankha zamanja, zamagetsi, ndi ma hydraulic. Kusankhidwa kwa mtundu kumadalira kulemera kwa koyilo ndi makulidwe kuti zitsimikizire kumasula kosalala komanso kopanda msoko.

Ma hydraulic decoiler awa ali ndi mphamvu yokweza matani 5 ndipo amakhala ndi zosungira zakunja kuti asagwere. Galimoto imayendetsa chipangizo chokulirapo, chomwe chimalola kukulitsa ndi kupindika kuti kukhale ndi ma diameter osiyanasiyana amkati a coil kuyambira 460mm mpaka 520mm.

Leveler

The leveler bwino flatten koyilo, kuthetsa kupsyinjika kwa mkati ndi kupsyinjika, potero kumawonjezera kukhomerera ndi kupanga njira.

Servo feeder & Punch Press

Ma servo feeder athu, omwe amadziwika ndi kuchedwa pang'ono kuyimitsidwa, amapereka chiwongolero cholondola pa chodyetsa. Izi zimatsimikizira kutalika kwa chakudya cha coil ndi malo okhomerera, kupititsa patsogolo kulondola kwa kupanga komanso kuchita bwino.

Mipanda yomalizidwa ya ma wire mesh imakhala ndi ma notche ambiri opangira kulumikizana ndi ma waya.

Makina opangira roll

Makina opangira mpukutuwa amapangidwa ndi khoma ndipo amagwira ntchito pogwiritsa ntchito makina oyendetsa. Panthawi yonse yopanga, koyiloyo imapunduka pang'onopang'ono mokakamiza, kumamatira ku "mawonekedwe a pichesi" omwe afotokozedwa muzojambula zomwe zaperekedwa.

Pofuna kupewa kupatukana kwa coil pamphambano ya positi panthawi yogwiritsira ntchito nthawi yayitali, njira zodzitetezera zimatsatiridwa. Kutsatira kupanga mipukutu, ma roller oyenda amakankhira kupindika, ndikupanga zowoneka bwino zomwe zimathandizira kukhazikika kwa positi ndikuwonjezera moyo.

Kuphatikiza apo, chifukwa cha mapangidwe ozungulira a zodzigudubuza zozungulira, mpukutu wakale ukhoza kupitiliza ntchito yake mosasunthika pomwe koyiloyo ikupita patsogolo panthawi ya riveting, ndikuchotsa kufunikira kokhazikitsa maziko ena osuntha a chipangizo chowombera.

Flying macheka kudula

Chifukwa cha mawonekedwe otsekedwa a mtengo wa pichesi, kudula kwa macheka kumatuluka ngati njira yoyenera kwambiri, kuteteza kupotoza kwa koyilo m'mphepete mwake. Komanso, kudula sikutulutsa zinyalala. Kukhathamiritsa kupanga mzere mphamvu, m'munsi makina odulira akhoza kusintha cham'mbuyo ndi patsogolo kulunzanitsa ndi mpukutu kupanga makina liwiro, kuonetsetsa ntchito mosadodometsedwa.

1. Decoiler

2. Kudyetsa

3.Kukhomerera

4. Mipukutu yopangira zoyimira

5. Kuyendetsa galimoto

6. Kudula dongosolo

Ena

Kunja tebulo