kanema

Mbiri

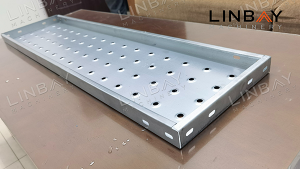

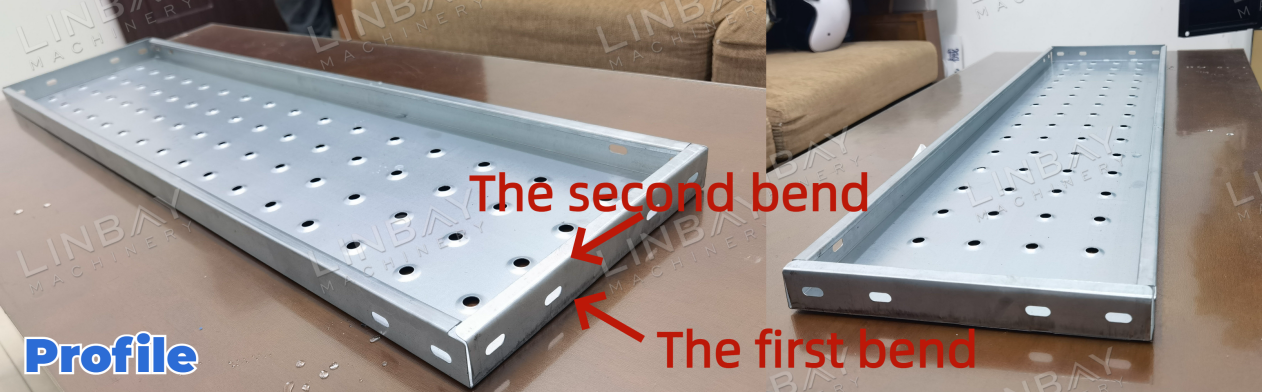

Mashelufu a alumali, omwe ali pamitengo ya racking system, amakhala ngati nsanja yolimba yosungiramo katundu motetezeka. Ukadaulo wathu wopanga umayang'ana kwambiri kupanga mashelufu opindika awiri, omwe amapereka kukhazikika kwapamwamba poyerekeza ndi mtundu wa bend imodzi. Kuphatikiza apo, kapangidwe kameneka kamachotsa mbali zowoneka bwino, ndikuyika patsogolo chitetezo cha ogwiritsa ntchito.

Mlandu weniweni-Main Techinical Parameters

Tchati choyenda

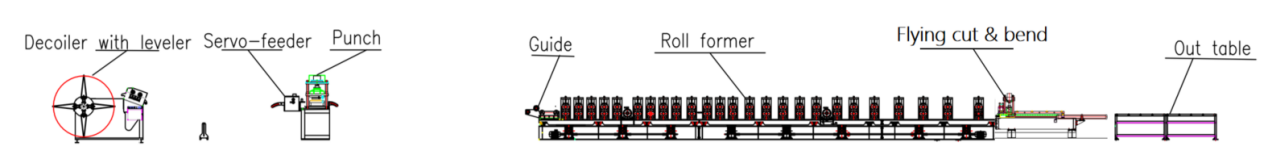

Hydraulic decoiler yokhala ndi leveler--Servo feeder-Hydraulic punch--Roll forming machine--Hydraulic cut and stamping--Table table

Main Technical Parameters:

1. Liwiro la mzere: Zosinthika kuchokera ku 0 mpaka 4 m / min

2. Mbiri: Makulidwe osiyanasiyana okhala ndi utali wofanana, wosiyana m'lifupi ndi kutalika

3. Makulidwe azinthu: 0.6-0.8mm (chifukwa ichi)

4. Zinthu zoyenera: Chitsulo chagalasi

5. Makina opangira mpukutu: Amagwiritsa ntchito mawonekedwe a cantilevered-wawiri-wall panel ndi makina oyendetsa unyolo

6. Chiwerengero cha masiteshoni: 13

7. Kudula dongosolo: Kudula ndi kupindika nthawi imodzi; roll kale ikugwirabe ntchito panthawiyi

8. Kusintha kwa kukula: Zodziwikiratu

9. PLC cabinet: Okonzeka ndi Siemens system

Nkhani yeniyeni-Kufotokozera

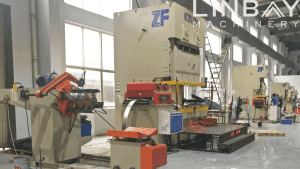

Hydraulic Decoiler yokhala ndi Leveler

Kukula kwapakati kumatha kusinthidwa kuti kugwirizane ndi ma diameter amkati achitsulo kuyambira 460mm mpaka 520mm. Pakumasula, zosungira zakunja za koyilo zimatsimikizira kuti koyilo yachitsulo imakhalabe bwino pa decoiler, kumalimbitsa chitetezo cha ogwira ntchito poletsa koyiloyo kuti isaduke.

Cholezerapo chimakhala ndi zodzigudubuza zomwe zimaphwanyitsa pang'onopang'ono koyilo yachitsulo, ndikuchotsa bwino kupsinjika kotsalira.

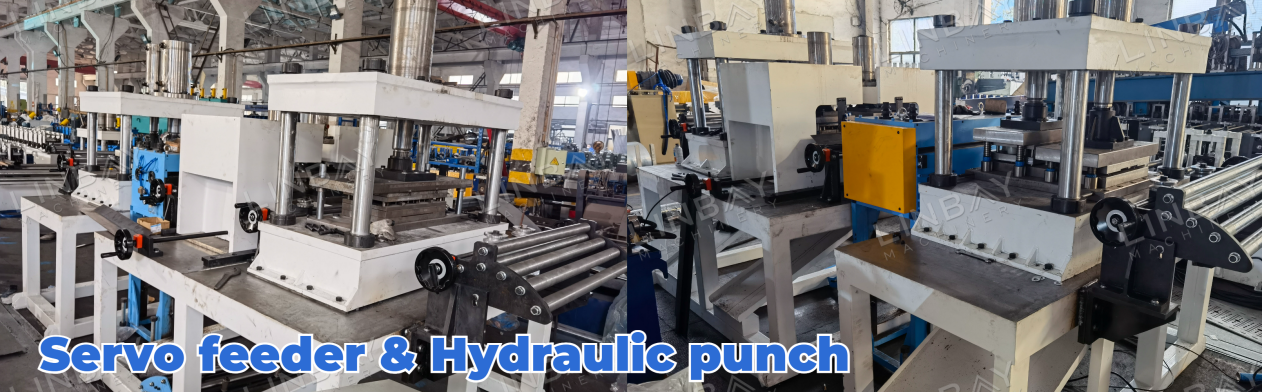

Servo Feeder & Hydraulic Punch

(1)Independent Hydraulic Punching

Dongosolo lokhomererali limagwira ntchito modziyimira pawokha, osagawana makina omwewo ndi makina opangira mpukutu, kuwonetsetsa kuti ntchito yopangira mpukutuyo imagwira ntchito mopanda msoko komanso mosasokoneza. Chodyetsa chimayendetsedwa ndi injini ya servo, yomwe imakhala ndi nthawi yochepa yoyambira kuyimitsa. Izi zimalola kuwongolera bwino kwa koyilo yachitsulo mu chodyetsa koyilo, kuonetsetsa kukhomerera kolondola komanso koyenera.

(2)Kukonzekera kwa nkhungu

Mabowo okhomeredwa pa alumali amagawidwa m'mabowo, mabowo ogwira ntchito, ndi mabowo opitilira pansi. Chifukwa cha kusiyanasiyana kwa mitundu ya mabowo pa shelufu imodzi, makina a hydraulic punch amakhala ndi nkhungu zinayi zodzipatulira, iliyonse yopangidwira mtundu umodzi wa dzenje. Kukonzekera uku kumakonzedwa kuti kumalize bwino mtundu uliwonse wa nkhonya, potero kumapangitsa kuti ntchito zonse ziziyenda bwino komanso zokolola.

Encoder & PLC

Encoder imamasulira kutalika kwa koyilo yachitsulo kukhala ma siginecha amagetsi, omwe kenako amatumizidwa ku kabati yowongolera ya PLC. Mkati mwa nduna zowongolera, ogwira ntchito amatha kuyendetsa liwiro lopanga, linanena bungwe limodzi lopanga, kudula kutalika, ndi zina. Ndi miyeso yolondola ndi mayankho kuchokera ku encoder, makina odulira amatha kukhalabe ndi zolakwika zodula mkati±1 mm.

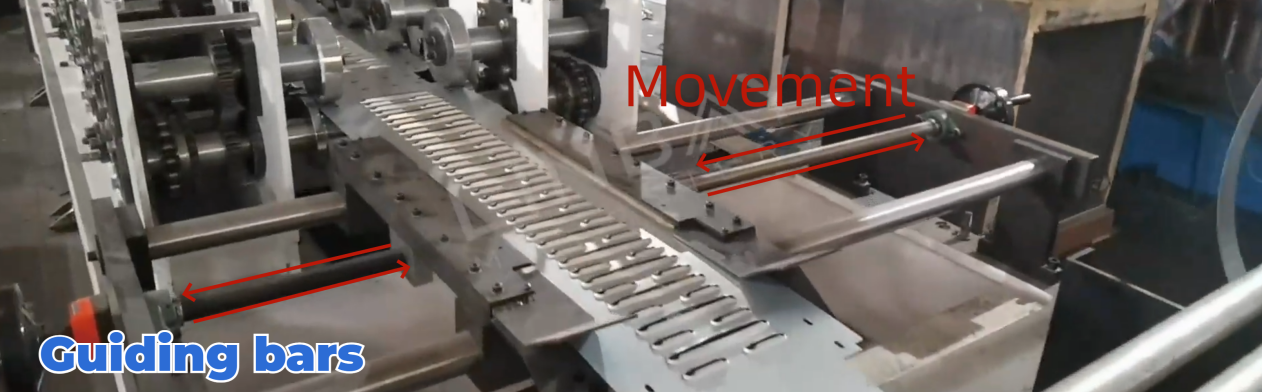

Makina opangira roll

Asanalowe mu makina opangira mpukutu, koyilo yachitsulo imadutsa mipiringidzo yowongolera. Mipiringidzo iyi imasinthidwa molingana ndi kukula kwa koyilo yachitsulo, kuonetsetsa kuti ikugwirizana ndendende ndi makina opanga mzere wapakati. Kuyanjanitsa uku ndikofunikira kuti mukhalebe owongoka ndi kunyamula katundu wa gulu la alumali.

Makina opangira awa amagwiritsa ntchito ma cantilever okhala ndi khoma lawiri. Popeza kuti kupanga kumafunikira mbali ziwiri zokha za gululo, chojambula cha cantilever chimagwiritsidwa ntchito kusunga zinthu zodzigudubuza. Dongosolo loyendetsa unyolo limayendetsa ma rollers ndikugwiritsa ntchito mphamvu ku koyilo yachitsulo, ndikupangitsa kupita patsogolo kwake ndi kupanga.

Makinawa amatha kupanga mashelufu amitundu yosiyanasiyana. Ogwira ntchito amalowetsa miyeso yomwe akufuna mu gulu la PLC control cabinet. Chizindikirocho chikalandiridwa, siteshoni yopangira kumanja imayenda motsatira njanji. Zomwe zimapangidwira pazitsulo zachitsulo zimasintha ndi kayendedwe ka siteshoni yopanga ndikupanga odzigudubuza.

Encoder imayikidwanso kuti izindikire mtunda wamayendedwe a siteshoni, kuwonetsetsa kulondola posintha makulidwe. Kuphatikiza apo, masensa awiri akuphatikizidwa: imodzi yowonera mtunda wakutali kwambiri ndipo ina ya mtunda wapafupi pomwe siteshoni yopangirayo imatha kuyenda panjanji. Sensa yakutali kwambiri imalepheretsa kusuntha kwakukulu kwa malo opangira, kupewa kutsetsereka, pomwe cholumikizira chapafupi chimalepheretsa malo opangirawo kuti asasunthike kwambiri mkati, motero amapewa kugunda.

Kudula kwa Hydraulic ndi kupindika

Mapanelo a alumali opangidwa pamzerewu amapindika pawiri mbali yayikulu. Tapanga chikombole chophatikizika chodulira ndi kupinda, chothandizira kudula ndi kupindika pawiri mkati mwa makina amodzi. Kapangidwe kameneka sikumangoteteza kutalika kwa mzere wopanga komanso malo apansi a fakitale komanso kumachepetsa nthawi yopanga.

Pa kudula ndi kupinda, makina odulira m'munsi amatha kuyenda m'mbuyo ndi kutsogolo mu kulunzanitsa ndi liwiro la makina opangira makina. Izi zimatsimikizira kupanga kosalekeza komanso kumawonjezera luso.

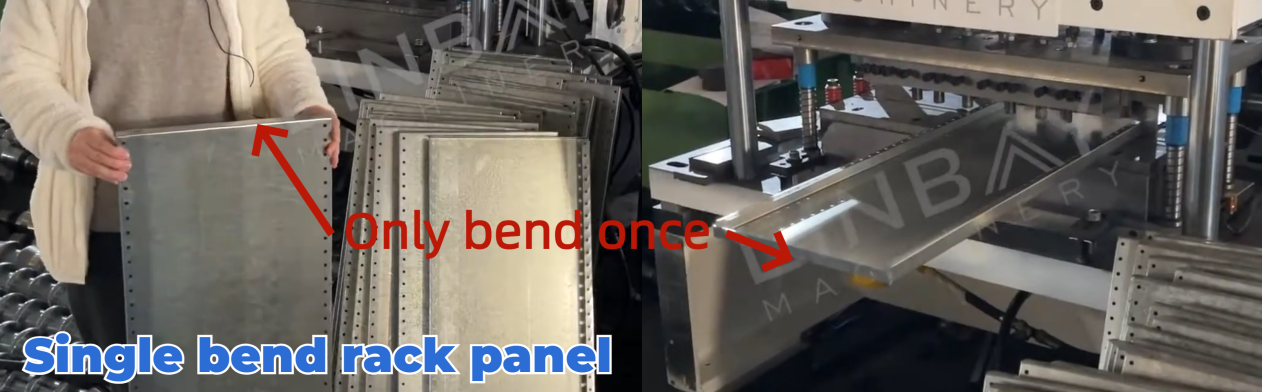

Njira ina

Ngati mukuchita chidwi ndi mashelufu a bend imodzi, ingodinani pachithunzichi kuti mufufuze mozama za kapangidwe kake ndikuwonera kanema.

Kusiyana kwakukulu:

Mtundu wopindika kawiri umapereka kukhazikika kwapamwamba, pomwe mtundu wa bend umodzi umakwaniritsanso mokwanira zosungirako.

Mphepete mwamtundu wa ma bend awiri sakhala akuthwa, kupititsa patsogolo chitetezo, pamene mtundu umodzi wokhotakhota ukhoza kukhala ndi m'mphepete mwake.

1. Decoiler

2. Kudyetsa

3.Kukhomerera

4. Mipukutu yopangira zoyimira

5. Kuyendetsa galimoto

6. Kudula dongosolo

Ena

Kunja tebulo