MBIRI

Dongosolo lachitsulo limagwira ntchito ngati ngalande yofunikira kwambiri yomwe imayikidwa m'mphepete mwa denga kuti madzi amvula achoke panyumba, zomwe zimathandiza kuti madzi asawonongeke. Gutters nthawi zambiri amapangidwa kuchokera ku zinthu monga aluminiyamu, malata, zitsulo zokhala ndi utoto, mkuwa, ndi galvalume, zokhala ndi makulidwe apakati pa 0.4 ndi 0.6 mm.

Mzerewu umakhala ndi mizere iwiri, yomwe imalola kupanga mizere iwiri yosiyana pa mzere womwewo, ngakhale osati nthawi imodzi. Kapangidwe kameneka kamathandizira kagwiritsidwe ntchito ka malo komanso kumachepetsa mtengo wamakina kwa kasitomala.

REAL CASE-MAIN TECHNICAL PARAMETERS

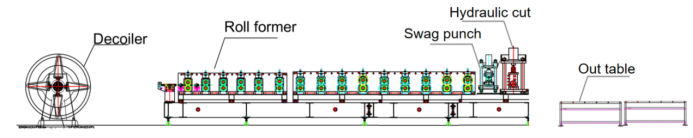

Tchati choyenda: Decoiler--Kutsogolera--Roll wakale--Swag punching--Hydraulic cutting--Out table

REAL CASE-MAIN TECHNICAL PARAMETERS

· Liwiro la Mzere: Zosinthika, kuyambira 0-12m/min.

· Zogwirizana: Aluminiyamu, kanasonkhezereka zitsulo, zitsulo TACHIMATA mtundu, galvalume, mkuwa.

· Makulidwe a Zinthu ZakuthupiKutalika: 0.4-0.6mm

· Makina Opangira Roll: Mapangidwe a mizere iwiri yokhala ndi khoma.

· Drive System: Dongosolo loyendetsedwa ndi unyolo.

· Kudula System: Njira yoyimitsa-ndi-kudula, pomwe mpukutu wakale umayima panthawi yodula.

· PLC Control: Siemens System.

ZINTHU ZONSE-MACHITA

1.Hydraulic decoiler*1

2.Makina opangira gudumu*1

3.Hydraulic swag punch machine*1

4.Makina odulira a Hydraulic*1

5.Kunja tebulo*2

6.PLC control cabinet*1

7.Hydraulic station*2

8.Bokosi lazigawo (Zaulere)*1

NDENDE CHENENE-KUTANTHAUZIRA

Hydraulic Decoiler

· Chimango: Chimango cholimbacho chimapangidwa kuti chithandizire zitsulo zachitsulo, chokhala ndi chowongolera chamagetsi cha hydraulic chomwe chimapangitsa kuti ntchito ziziyenda bwino komanso kuti zitetezeke pakupanga koyilo.

· Core Expansion Mechanism: Mandrel oyendetsedwa ndi ma hydraulic (kapena arbor) amasintha kuti agwirizane ndi zitsulo zachitsulo zokhala ndi mainchesi amkati a 490-510mm, kuteteza koyiloyo kuti ikhale yosalala komanso yokhazikika.

· Dinani Arm: Mkono wosindikizira wa hydraulic umatsimikizira kuti koyiloyo ikhalabe pamalo ake, kuchepetsa chiopsezo chobwerera mwadzidzidzi chifukwa cha kupsinjika kwamkati ndikuteteza chitetezo cha ogwira ntchito.

· Coil Retainer: Wotetezedwa ku ma mandrel blade okhala ndi zomangira ndi mtedza, chosungirako chimateteza koyilo yachitsulo kuti isagwe, ndipo ndiyosavuta kuyiyika kapena kuchotsa ngati pakufunika.

· Control System: Wokhala ndi PLC ndi gulu lowongolera lomwe limaphatikizapo batani loyimitsa mwadzidzidzi, kupititsa patsogolo chitetezo chantchito.

·Zosankha za Decoiler Pakupanga Mizere Yawiri-Row: Pamakina opangira mizere iwiri, chowongolera cha shaft imodzi chingagwiritsidwe ntchito ndikuyikanso kuti chisungire ndalama, ngakhale zimafunikira nthawi yochulukirapo. Kapenanso, ma decoiler awiri a shaft-shaft kapena chopopera cha shaft iwiri atha kugwiritsidwa ntchito popanga bwino.

Mabala Otsogolera

· Kuyanjanitsa: Imawonetsetsa kuti koyilo yachitsulo yakhazikika bwino ndi nsonga ya makina, kuletsa zovuta za chakudya zomwe zingayambitse kupindika, kupindika, ma burrs, kapena kusalongosoka kwa chinthu chomwe chamalizidwa.

· Kukhazikika: Kukhazikika kwazinthu ndikofunikira, ndi mipiringidzo yowongolera yomwe imatsimikizira chakudya chokhazikika, chomwe chili chofunikira kwambiri popanga zida zapamwamba zopanga mpukutu.

· Mayendedwe: Amawongolera bwino zinthuzo muzoyambira zopangira zodzigudubuza, zomwe ndi zofunika kwambiri pakukonza koyambirira.

· Kusamalira: Ndikofunikira kukonzanso zida zowongolera pafupipafupi, makamaka mukatha kuyenda kapena kugwiritsa ntchito nthawi yayitali. Asanatumize, Linbay amalemba m'lifupi mwake mu bukhu la ogwiritsa ntchito, kulola kuwongolera bwino kasitomala akalandira zida.

Makina Opanga Roll

· Zotsika mtengo Pakupanga Gutter: Zimaphatikizapo mapangidwe a khoma ndi makina oyendetsedwa ndi unyolo.

· Kusinthasintha Kwa Ma Size Angapo: Kukhazikitsa kwa mizere iwiri kumathandizira kupanga makulidwe awiri osiyana, kukhathamiritsa malo ndikuchepetsa mtengo wamakina.

· Chitetezo cha Chain: Unyolo umatsekeredwa mkati mwa chitsulo chachitsulo, kuonetsetsa chitetezo cha ogwira ntchito ndikutchinjiriza maunyolo kuti asawonongeke chifukwa cha zinyalala zoyendetsedwa ndi mpweya.

·Kuchita Bwino Bwino: Imachepetsa nthawi yokhazikitsa poyerekeza ndi machitidwe a mzere umodzi womwe umafuna kusintha kwamanja.

· Kupanga Roller: Zokhala ndi mipukutu 20 yopangira, kuphatikiza mipukutu iwiri yokhala ndi ma angled kuti mafunde ang'onoang'ono apangidwe monga momwe tawonera pachithunzipa.

·Ma Roller Okhazikika: Zodzigudubuza ndizokutidwa ndi chromium ndipo zimatenthedwa kuti zisamachite dzimbiri komanso dzimbiri, zomwe zimathandiza kuti moyo ukhale wautali.

· Main Motor: Standard specification ndi 380V, 50Hz, 3-phase, ndi zosankha makonda zilipo.

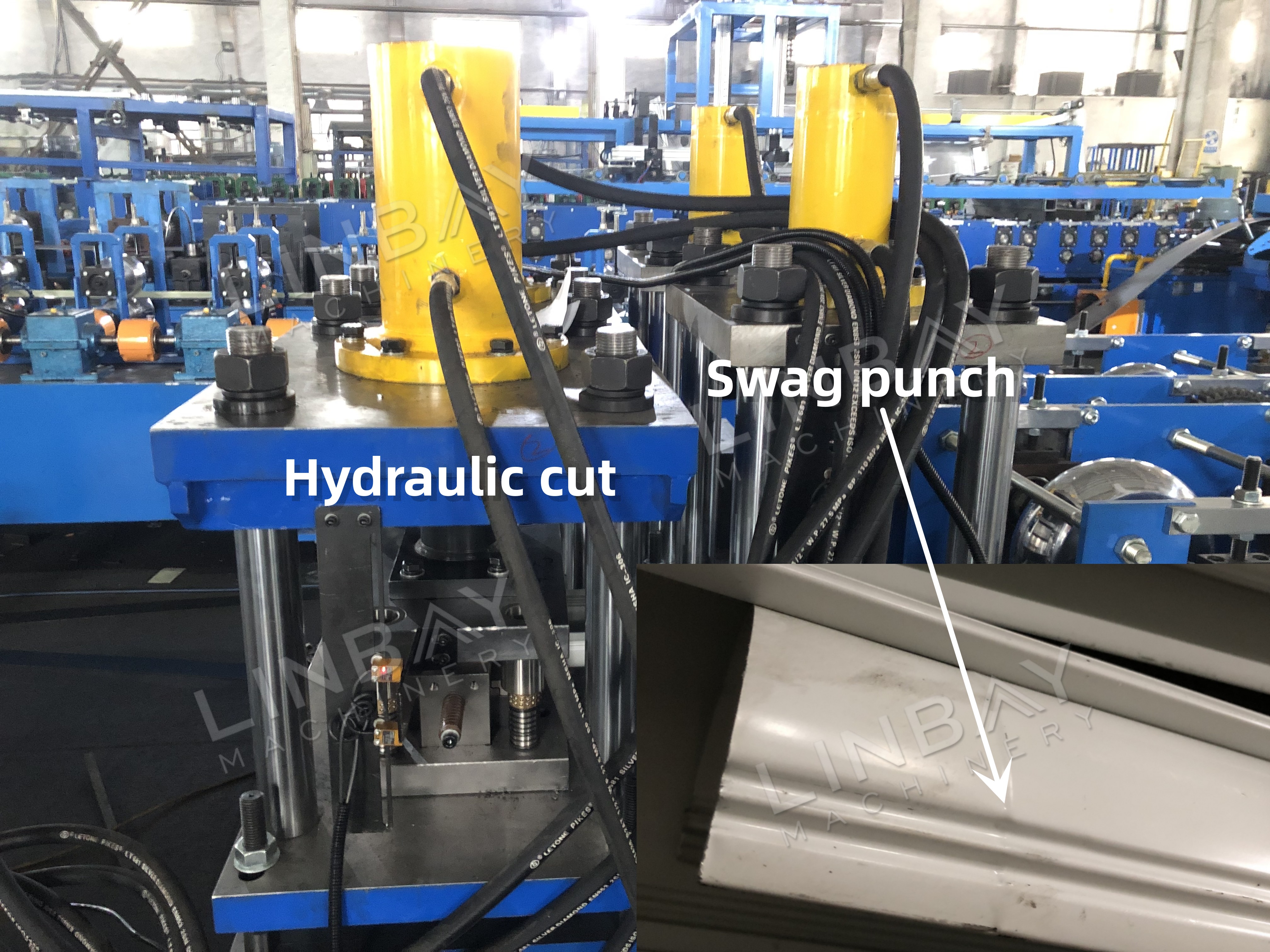

Swag Punching

· Kusintha kwa Gutter: Mapeto a ngalande yachitsulo amapindika kuti achepetse m'mimba mwake, kuti alowe mu gawo lina la ngalande kuti likhale lotetezeka.

· Kuthekera kwa Makina: Amagwiritsa ntchito nkhonya ya hydraulic punching kuti apange kulumikizana komaliza, kuwonetsetsa kuti pali kulumikizana kosalala komanso kotetezeka pakati pa magawo awiri a gutter.

Kudula kwa Hydraulic

· Custom Blades: Amapangidwa kuti agwirizane ndi mbiri ya ngalande, kuwonetsetsa kuti mabala oyera osapindika kapena ma burrs.

· Utali Wolondola Wodula: Amasunga kulolerana kwa ± 1mm. Kulondola uku kumatheka kudzera mu encoder yomwe imayesa kusuntha kwa koyilo yachitsulo, kutembenuza izi kukhala ma siginecha amagetsi otumizidwa ku nduna ya PLC. Othandizira amatha kusintha kutalika kwa kudula, kuchuluka kwa kupanga, ndi liwiro kudzera pa mawonekedwe a PLC.

1. Decoiler

2. Kudyetsa

3.Kukhomerera

4. Mipukutu yopangira zoyimira

5. Kuyendetsa galimoto

6. Kudula dongosolo

Ena

Kunja tebulo