ividiyo

Inkangeleko yesimo

I-cross bracing ibalulekile kwiisistim zerack-duty-duty, ezibonelela ngenkxaso ye-diagonal phakathi kwee-uprights ezimbini. Inceda ukuthintela ukushukuma kwaye igcine ulungelelwaniso lwesakhiwo phantsi kwemithwalo enzima. Ngokuqhelekileyo, i-cross bracing yenziwe kwi-hot-rolled, i-cold-rolled, okanye i-galvanized steel kunye nobukhulu be-1.5 ukuya kwi-2 mm.

Ngokwemveli, ukudibanisa umnqamlezo kuye kwaveliswa kusetyenziswa oomatshini bokugoba. Nangona kunjalo, umgca womatshini wokwenza umqulu, obandakanya ukukhulula, ukulinganisa, ukuqulunqa umqulu, ukubetha, kunye nokusika, unikezela ngokuzenzekela okuphezulu kunye nokunciphisa iindleko zomsebenzi wezandla. Esi sisombululo sibe yinto ekhethwayo kubathengi abaninzi ngenxa yokusebenza kwayo kunye nokusebenza kakuhle kweendleko.

Izimbo zokungqimba ziyahluka ngokuxhomekeke kwindlela yokufakela:

Indlela yokuFakela i-1: I-brace enye ifakwe ngaphakathi kwi-rack ethe tye, ifuna imingxuma esele ifakwe ngaphambili kumphakamo we-bracing wofakelo lwe-screw.

Indlela yokuFakela i-2: I-braces ezimbini zifakwe ngaphakathi kwi-rack ethe tye, efuna imingxuma efakwe ngaphambili ezantsi kwe-bracing yokufakela isikrufu.

Ityala lokwenyani-Iiparamitha zoBuchule eziPhambili

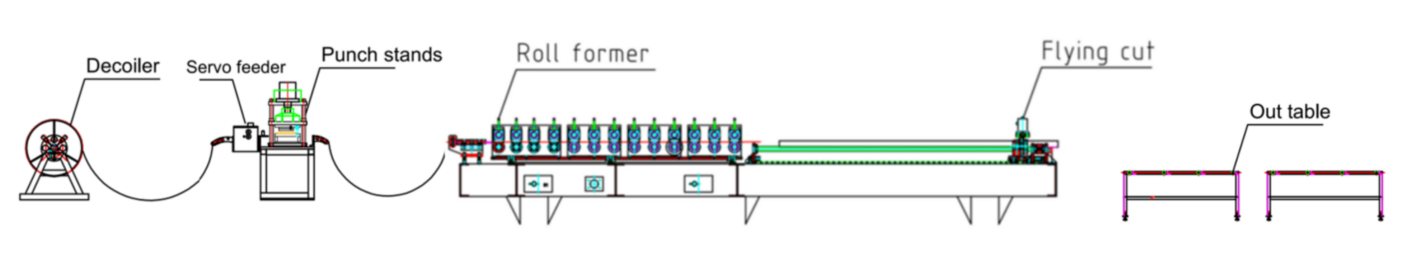

Itshathi equkuqelayo: I-Decoiler--Servo feeder--Hydraulic punch--Isikhokelo--Roll forming machine--Flying hydraulic cut--Out table

Xa kuthelekiswa nemigca emibini yemveliso yomqolo omnye, umgca wemveliso we-double-row ungagcina iindleko zomatshini owongezelelweyo wokwenza, i-decoiler, kunye ne-servo feeder, kunye nesithuba esifunekayo komnye umgca wemveliso. Ukongezelela, ubume bemiqolo emibini bunciphisa iindleko zexesha lokutshintsha ubungakanani, ngokungafaniyo nokuguqulwa kobungakanani bezandla kumgca omnye, ngaloo ndlela kuphucula ukusebenza kakuhle.

Imeko yokwenyani-Iiparamitha zobuGcisa eziPhambili

1.Isantya somgca: 4-6m / min, ukulungiswa

I-2.Izinto ezifanelekileyo: Intsimbi eshushu eqengqelekayo, intsimbi eqengqelekayo ebandayo, intsimbi efakwe igalvanized

3.Ubukhulu bezinto: 1.5-2mm.

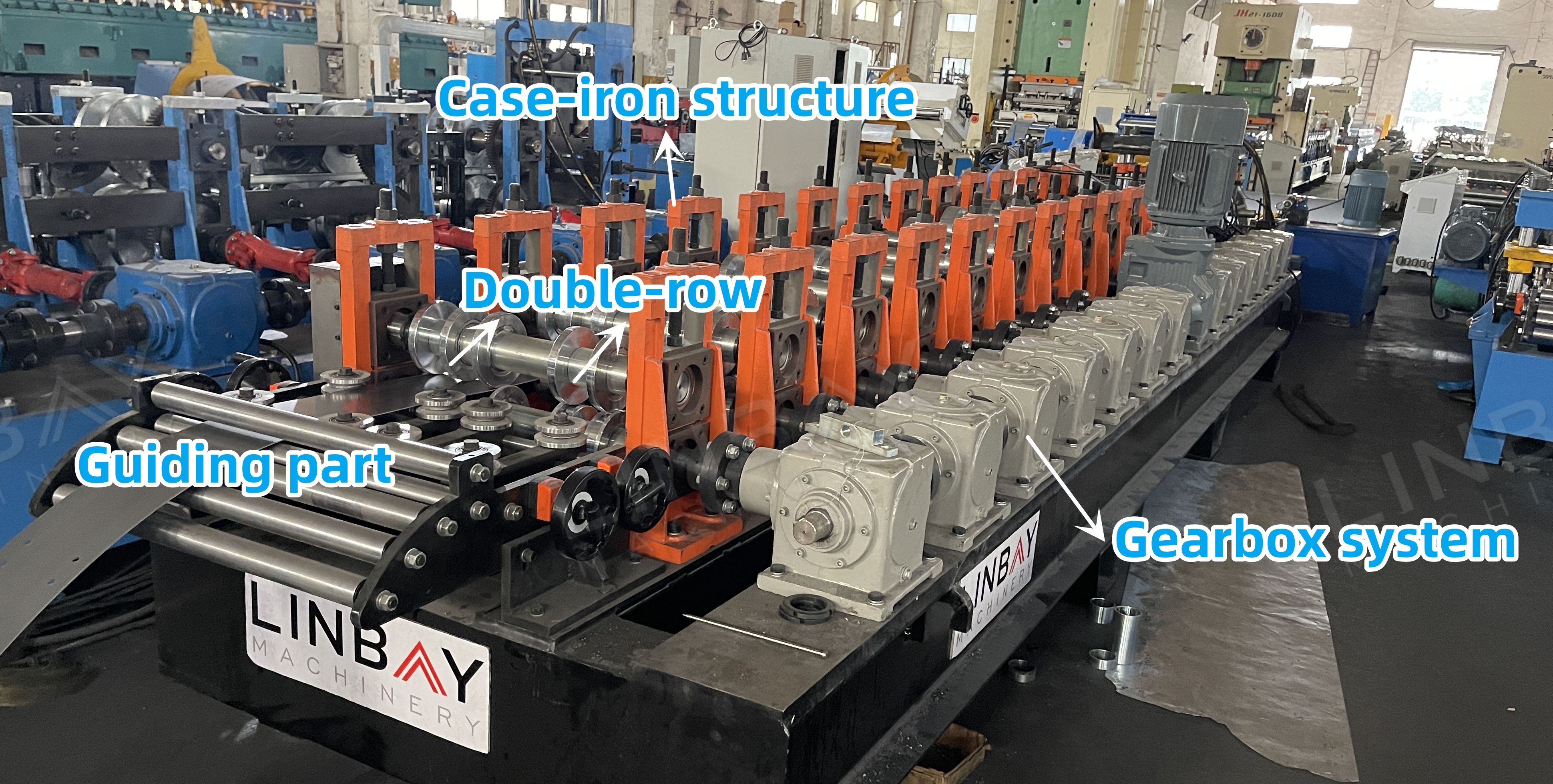

Umatshini wokwenza i-4.Roll: Isakhiwo se-Cast-iron

I-5.Inkqubo yokuqhuba: Inkqubo yokuqhuba i-Gearbox

I-6.Inkqubo yokusika: I-Flying hydraulic cutting, i-roll yangaphambili ayiyeki xa usika.

Ikhabhinethi ye-7.PLC: inkqubo ye-Siemens.

Ityala lokwenyani-oomatshini

1.I-Hydraulic decoiler*1

2.I-Servo feeder*1

3.Umatshini wepunch oHaydraulic*1

4.Umatshini wokwenza umqulu*1

5.Umatshini wokusika i-Hydraulic * 1

6.Ngaphandle kwetafile*2

7.PLC iKhabhinethi yolawulo*1

8.Isikhululo samanzi*2

9.Ibhokisi yezahlulo ezisecaleni(Mahala)*1

Imeko yokwenyani-Inkcazo

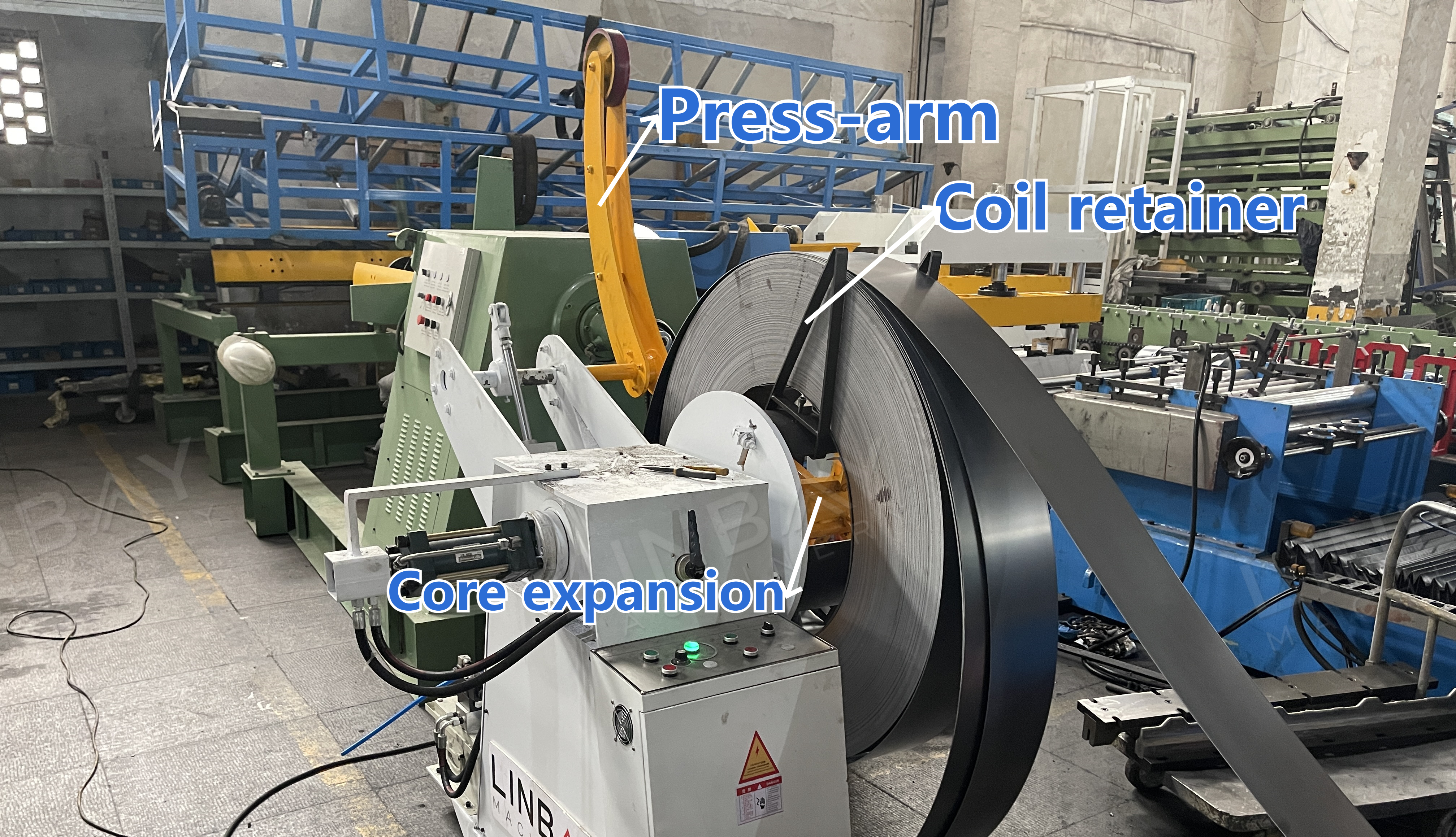

I-Decoiler

I-shaft ephakathi ye-decoiler isekela i-coil yensimbi kwaye isebenze njengesixhobo sokwandisa, i-coil ehlala kunye nobubanzi obungaphakathi be-490-510mm. Isixhobo sokucinezela-ingalo kwi-decoiler sikhusela ikhoyili ngexesha lokulayisha, ukukhusela ukuba ingavulwa ngenxa yoxinzelelo lwangaphakathi kunye nokuqinisekisa ukhuseleko lwabasebenzi.

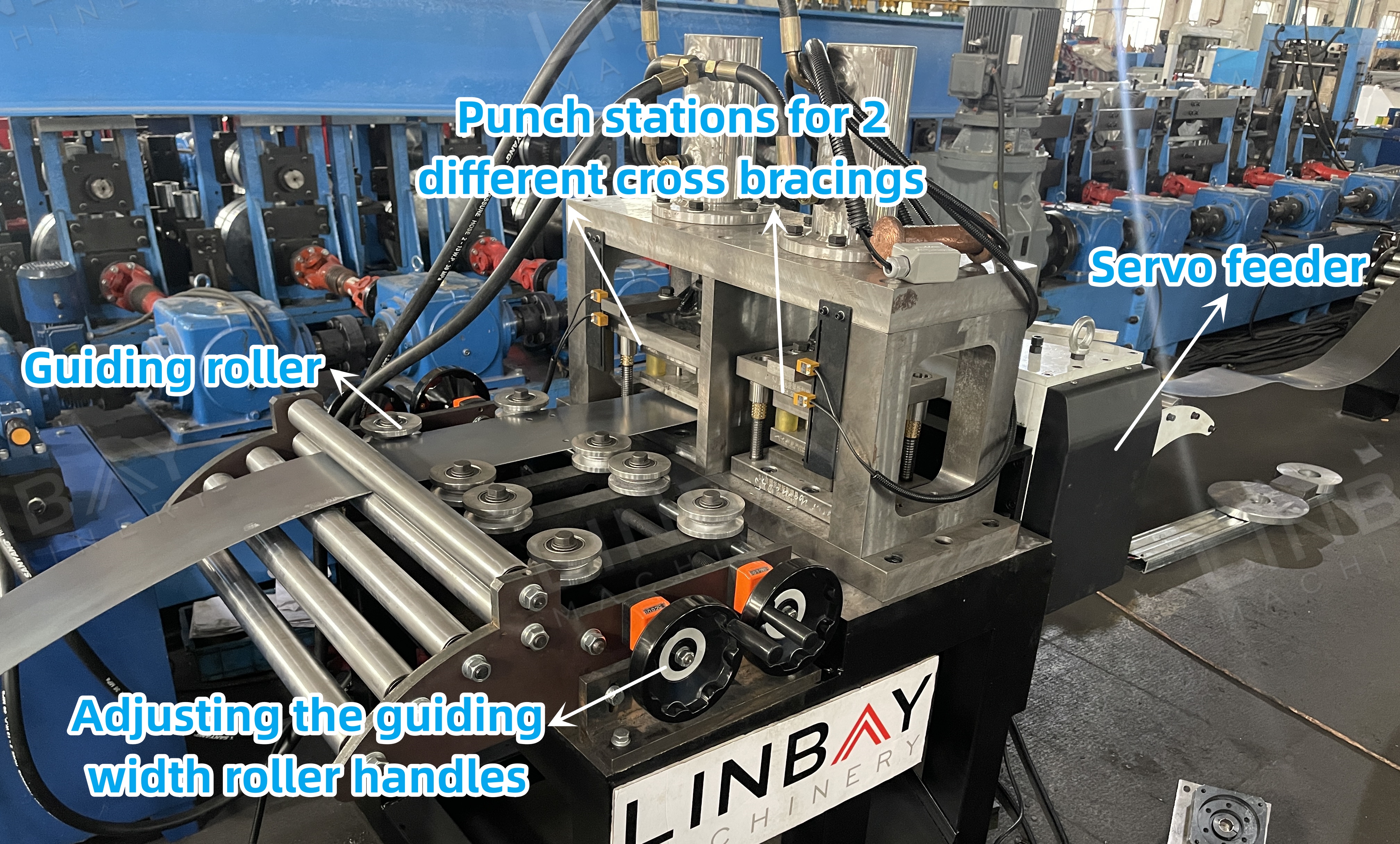

I-Hydraulic Punch kunye ne-Servo Feeder

I-punch ye-hydraulic, exhaswa yisikhululo se-hydraulic, idala imingxuma kwikhoyili yensimbi. I-cross bracing ibethelwa kwiiphelo zombini, mhlawumbi kwi-flange okanye ezantsi, ngokusekelwe kwiimfuno zofakelo. Kukho oomatshini abazimeleyo kunye nabahlanganisiweyo be-hydraulic punch. Uhlobo oludibeneyo lukwabelana ngesiseko esifanayo kunye nomatshini wokwenza umqulu kunye nokumisa abanye oomatshini ngexesha lokubetha.

Lo mgca wemveliso usebenzisa i-standalone version, eyenza ukuba i-decoiler kunye nomatshini wokwenza ukuba usebenze ngokuqhubekayo ngexesha lokubetha, ukuqinisekisa ukuveliswa okungaphazanyiswa. Uguqulelo oluzimeleyo lubandakanya i-servo feeder eqhutywa yi-servo motor, enciphisa ukulibaziseka kokuqalisa kwaye ilawula ngokuchanekileyo ubude be-coil kwangaphambili ukubethelwa ngokuchanekileyo. Indlela yokutya ye-pneumatic ngaphakathi kwe-feeder ikhusela umphezulu wekhoyili kwimikrwelo.

Ukukhokela

Ii-roller ezikhokelayo ziqinisekisa ukulungelelaniswa okufanelekileyo kwekhoyili kunye nomatshini wokuthintela ukuphazamiseka ngexesha lokuqulunqa, njengoko ukuchaneka kwe-cross bracing kuchaphazela ngokuthe ngqo ukuzinza okupheleleyo kweshelufu.

Umatshini wokwenza umqulu

Lo matshini wokwenza uqhayisa ngobume bentsimbi kunye nenkqubo yebhokisi yegiya. Kubalulekile ukuqaphela ukuba yomibini imiqolo ayikwazi ukusebenza ngaxeshanye. Ngomthamo ophezulu wemveliso, sincoma umgca wemveliso eyahlukileyo kwisayizi nganye.

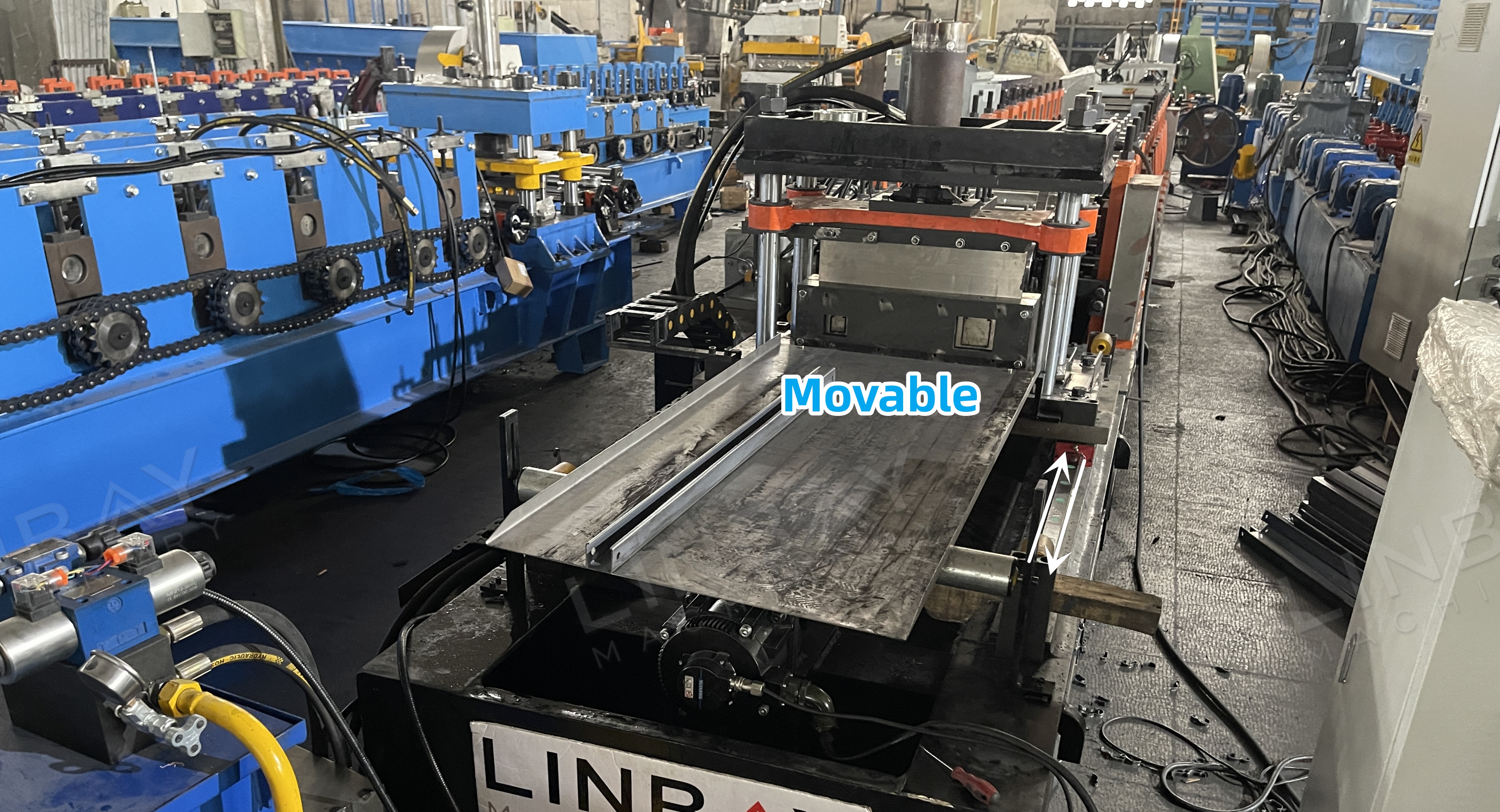

I-Flying Hydraulic Cutting

Uyilo "lokubhabha" luvumela isiseko somatshini wokusika ukuba sihambe ecaleni kwendlela, sivumela ukondla ngokuqhubekayo kwekhoyili ngomatshini wokubumba ngaphandle kokumisa ukusika, ngaloo ndlela kuphuculwe isantya somgca ngokubanzi.

I-blade yokusika kufuneka ihambelane nesimo seprofayili, idinga i-blade ehlukileyo kwisayizi nganye.

Isixhobo esinoKhenketho: Shear Butt Welder

I-welder ye-shear idibanisa imisebenzi yokucheba kunye ne-welding, ivumela ukudityaniswa kwee-coil zetsimbi ezintsha nezindala. Oku kunciphisa inkunkuma yezinto, kunciphisa ixesha lokutshintsha ikhoyili, kwaye lwenza lula uhlengahlengiso. Isebenzisa i-TIG welding ukuqinisekisa ukuba amalungu agudileyo kwaye acaba.

Isitishi seHydraulic

Isikhululo se-hydraulic sibonisa iifeni ezipholileyo zokuphelisa ubushushu obusebenzayo, ukuqinisekisa ukusebenza okuqhubekayo kunye nemveliso eyandisiweyo. Iyaziwa ngokuthembeka kwayo kunye nokusebenza okuhlala ixesha elide.

IKhabhinethi yoLawulo lwe-PLC kunye ne-Encoder

I-encoder iguqula ubude bekhoyili obulinganisiweyo kwimiqondiso yombane kwikhabhinethi yokulawula ye-PLC. Le khabhinethi ilawula isantya sokuvelisa, imveliso ngomjikelezo ngamnye, kunye nobude bokusika. Ngombulelo kwimpendulo echanekileyo evela kwi-encoder, umatshini wokusika ufezekisa ukuchaneka kokusika ngaphakathi kwe-± 1mm.

1. I-Decoiler

2. Ukutya

3.Ukubetha

4. Izitendi ezenza umqulu

5. Inkqubo yokuqhuba

6. Inkqubo yokusika

Abanye

Ngaphandle kwetafile