ividiyo

Iphrofayela

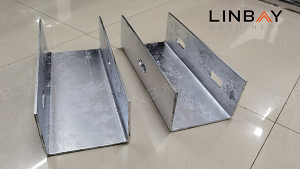

I-cross bracing ibalulekile kumasistimu ama-rack-duty-duty, ahlinzeka ngosekelo lwe-diagonal phakathi kwama-uprights amabili. Isiza ukuvimbela ukuntengantenga futhi igcine ukuqondanisa kwesakhiwo ngaphansi kwemithwalo esindayo. Imvamisa, i-cross bracing yenziwa ngensimbi egoqelwe eshisayo, egoqiwe ebandayo, noma enothayela enogqinsi luka-1.5 kuya ku-2 mm.

Ngokwesiko, i-cross bracing iye yakhiqizwa kusetshenziswa imishini yokugoba. Kodwa-ke, umugqa womshini wokwenza umqulu, ohlanganisa ukuqaqa, ukubeka izinga, ukwenza ama-roll, ukubhoboza, nokusika, uhlinzeka ngokuzenzakalelayo okuphezulu kanye nezindleko ezincishisiwe zomsebenzi wezandla. Lesi sixazululo sesiyisinqumo esikhethwa kakhulu kumakhasimende amaningi ngenxa yokusebenza kahle kwaso kanye nokusebenza kahle kwezindleko.

Izitayela zokubhoboza ziyahlukahluka kuye ngendlela yokufaka:

Indlela Yokufaka 1: I-brace eyodwa ifakwa ngaphakathi kwerack imile, idinga izimbobo ezishaywe ngaphambili ekuphakameni kokukaka ukuze kufakwe isikulufu.

Indlela Yokufaka 2: Izikaki ezimbili zifakwa ngaphakathi kwerack zimile, ezidinga izimbobo ezibhotshozwe ngaphambili ezansi kwebracing ukuze kufakwe isikulufu.

Ikesi langempela-Amapharamitha weTechinical Eyinhloko

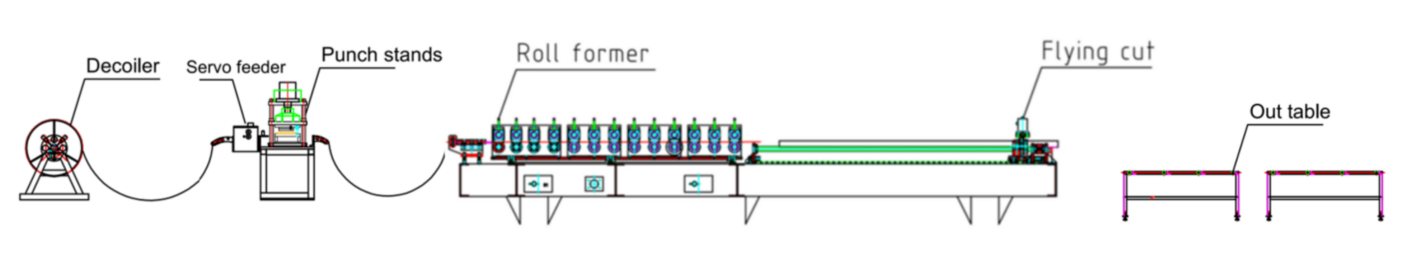

Ishadi eligelezayo: I-Decoiler--Servo feeder--Hydraulic punch--Guiding--Roll forming machine--Flying hydraulic cutting--Out table

Uma kuqhathaniswa nemigqa yokukhiqiza yomugqa owodwa emibili, ulayini wokukhiqiza wemigqa emibili ungakongela izindleko zomshini wokwenza owengeziwe, i-decoiler, nesiphakeli se-servo, kanye nesikhala esidingekayo komunye umugqa wokukhiqiza. Ukwengeza, ukwakheka kwemigqa emibili kunciphisa izindleko zesikhathi zokushintsha osayizi, ngokungafani nokushintsha kosayizi okwenziwa ngesandla emugqeni owodwa, ngaleyo ndlela kuthuthukise ukusebenza kahle.

Ikesi langempela-Amapharamitha Obuchwepheshe Abalulekile

1.Isivinini somugqa: 4-6m/min, iyalungiseka

2.Impahla efanelekile:Insimbi egoqiwe eshisayo, insimbi egoqiwe ebandayo, insimbi ewuthayela

3.Material ukujiya: 1.5-2mm.

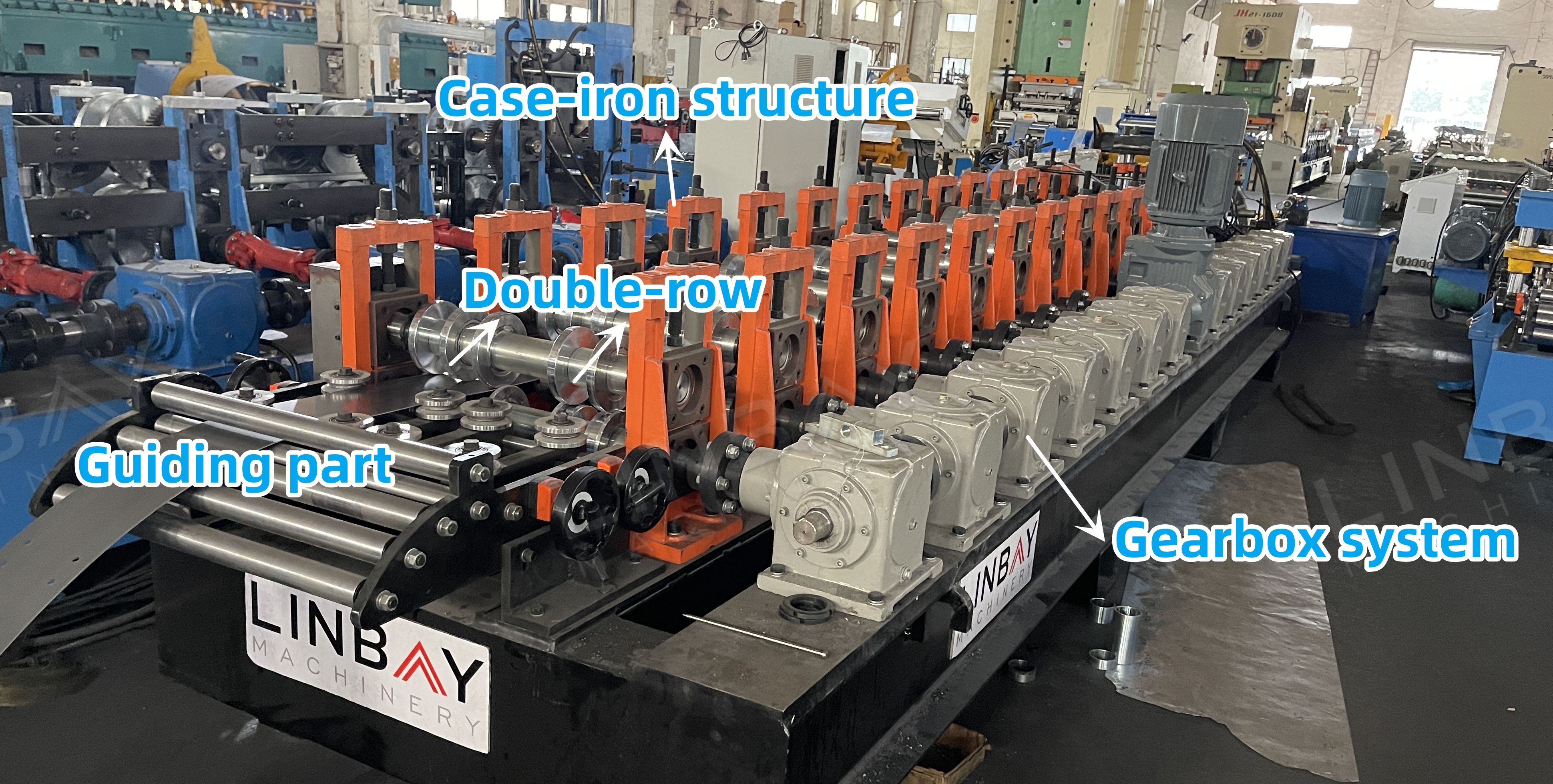

Umshini wokwenza i-4.Roll: Isakhiwo se-Cast-iron

5.Isistimu yokushayela: Isistimu yokushayela ye-Gearbox

I-6.Isistimu yokusika: Ukusikwa kwe-hydraulic endizayo, umqulu wangaphambili awumi lapho usika.

Ikhabhinethi ye-7.PLC: Uhlelo lwe-Siemens.

Ikesi langempela-Imishini

1.I-Hydraulic decoiler*1

2.Isiphakeli se-Servo*1

3.Umshini we-Hydraulic punch*1

4.Umshini wokwenza iroll*1

5.Umshini wokusika amanzi*1

6.Ithebula elingaphandle*2

7.PLC control cabinet*1

8.Isiteshi samanzi*2

9.Ibhokisi lezingxenye eziyisipele(Mahhala)*1

Ikesi langempela-Incazelo

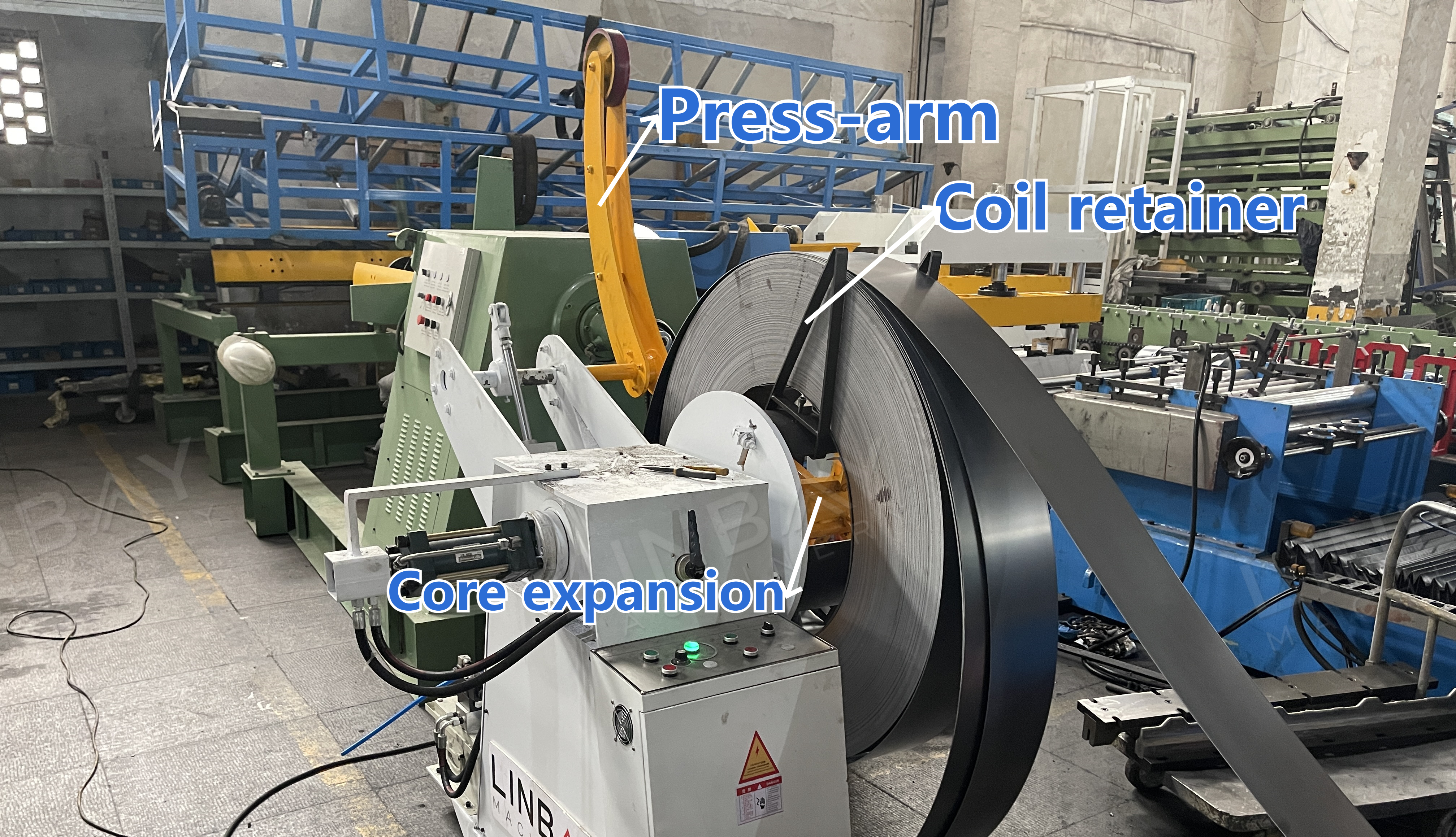

I-Decoiler

Ishafu emaphakathi ye-decoiler isekela ikhoyili yensimbi futhi isebenza njengedivayisi yokunweba, ifaka amakhoyili anobubanzi obungaphakathi obungu-490-510mm. I-press-arm device ekumshini wokukhipha ikhoyili ivikela ikhoyili ngesikhathi ilayishwa, ivimbele ukuthi ingaqhumeki ngenxa yokushuba kwangaphakathi nokuqinisekisa ukuphepha kwesisebenzi.

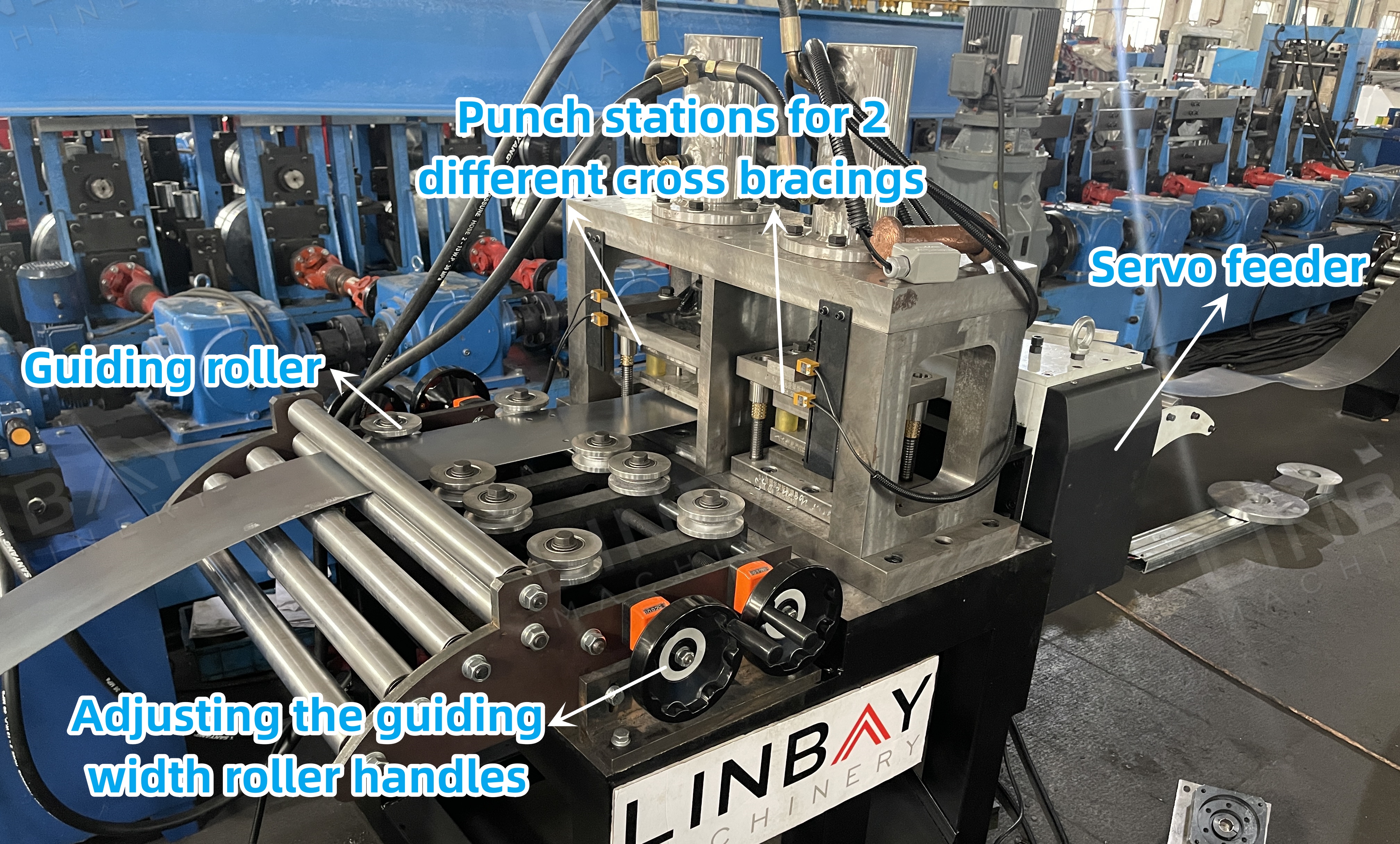

I-Hydraulic Punch & Servo Feeder

I-punch ye-hydraulic, enikwa amandla yisiteshi se-hydraulic, idala izimbobo kukhoyili yensimbi. I-cross bracing ishaywa kuzo zombili iziphetho, kungaba ku-flange noma phansi, ngokusekelwe ezidingweni zokufaka. Kunemishini ezimele futhi edidiyelwe ye-hydraulic punch. Uhlobo oluhlanganisiwe lwabelana ngesisekelo esifanayo nomshini wokwenza ama-roll futhi lumisa isikhashana eminye imishini ngesikhathi sokubhoboza.

Lo mugqa wokukhiqiza usebenzisa inguqulo ezimele, ovumela i-decoiler nomshini wokwakha ukuthi usebenze ngokuqhubekayo phakathi nokushaya, uqinisekisa ukukhiqizwa okungaphazamiseki. Inguqulo ezimele ihlanganisa i-servo feeder eshayelwa yi-servo motor, enciphisa ukubambezeleka kokuqala kokumisa futhi ilawule ngokunembile ubude bekhoyili bangaphambi kwesikhathi ukuze kubethelwe ngokunembile. I-pneumatic feed mechanism ngaphakathi kwe-feed ivikela ubuso bekhoyili ekuklwebheni.

Ukuqondisa

Ama-roller aqondisayo aqinisekisa ukuqondana okufanele kwekhoyili nomshini ukuze kuvinjelwe ukuhlanekezela ngesikhathi sokubunjwa, njengoba ukuqondisa kwe-cross bracing kuthinta ngokuqondile ukuzinza okuphelele kweshalofu.

Umshini Wokwenza Roll

Lo mshini wokubumba uziqhenya ngokwakhiwa kwe-iron kanye nesistimu yebhokisi lamagiya. Kubalulekile ukuqaphela ukuthi yomibili imigqa ayikwazi ukusebenza ngesikhathi esisodwa. Ngomthamo wokukhiqiza ophezulu, sincoma umugqa wokukhiqiza ohlukile wosayizi ngamunye.

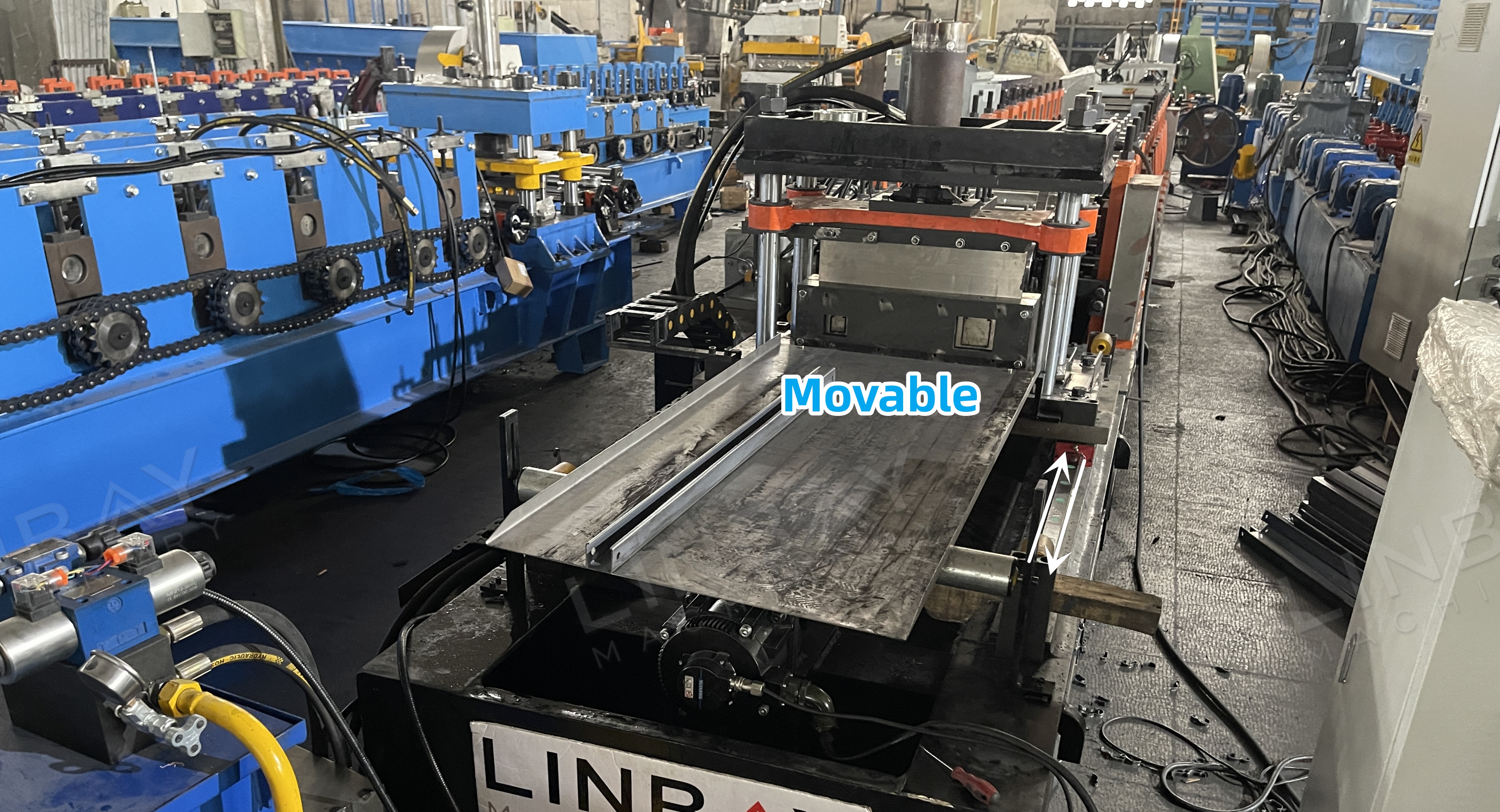

I-Flying Hydraulic Cutting

Idizayini "endizayo" yenza isisekelo somshini wokusika sihambe eduze kwethrekhi, sivumele ukuphakelwa okuqhubekayo kwamakhoyili ngomshini wokubumba ngaphandle kokuma ukuze asikwe, ngaleyo ndlela kuthuthukiswe isivinini somugqa.

I-blade yokusika kufanele ihambisane nokuma kwephrofayili, okudinga i-blade ehlukile yosayizi ngamunye.

Idivayisi Ongayikhetha: I-Shear Butt Welder

I-shear welder ihlanganisa kokubili ukugunda kanye nemisebenzi yokushisela, okuvumela ukuxhunywa kwamakhoyili ensimbi amasha namadala. Lokhu kunciphisa ukumosha izinto, kunciphisa isikhathi sokushintsha ikhoyili, futhi kwenze ukulungisa kube lula. Isebenzisa i-TIG welding ukuze kuqinisekiswe amalunga abushelelezi futhi ayisicaba.

Isiteshi seHydraulic

Isiteshi se-hydraulic sinezifeni ezipholile zokuqeda ukushisa okusebenzayo, ukuqinisekisa ukusebenza okuqhubekayo kanye nokukhiqiza okuthuthukisiwe. Kuqashelwa ukwethembeka nokusebenza okuhlala isikhathi eside.

Ikhabhinethi yokulawula ye-PLC kanye nesifaki khodi

Isifaki khodi siguqula ubude bekhoyili obulinganisiwe bube amasignali kagesi ekhabhinethi yokulawula ye-PLC. Le khabhinethi ilawula isivinini sokukhiqiza, okukhiphayo ngomjikelezo ngamunye, nobude bokusika. Ngenxa yempendulo enembile evela kusifaki khodi, umshini wokusika ufeza ukunemba kokusika ngaphakathi kuka-±1mm.

1. I-Decoiler

2. Ukondla

3.Ukubhoboza

4. Izitendi zokwakha amasondo

5. Uhlelo lokushayela

6. Uhlelo lokusika

Abanye

Ithebula elingaphandle