Profile

Xadiidka DIN waa bir heersare ah oo bir ah oo caadi ahaan loo isticmaalo injineernimada korontada. Nashqaddeedu waxa ay sahlaysa in si fudud loo rakibo lagana saaro qaybaha, sida caadiga ah waxa ka muuqda dhawr godad ama godadka xidhitaanka iyada oo la isticmaalayo boolal ama habab la isku xidho. Cabirka caadiga ah ee biraha DIN waa 35mm x 7.5mm iyo 35mm x 15mm, oo dhumucdiisuna tahay 1mm.

Kiis-dhabeedka-Farsamada cabbirada ugu muhiimsan

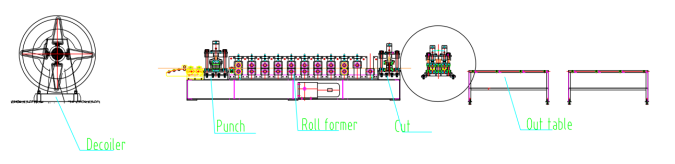

Jaantuska socodka: Decoiler--Hagaynta-- feerka Haydarooliga--Mashiinka samaynta duubka--Mashiinka goynta Haydarooliga

Xawaaraha 1.Line: 6-8m / min, la hagaajin karo

2.Waxyaabaha ku habboon: birta kulul ee kulul, birta duuban ee qabow

3.Material dhumucdiisuna: Dhumucda caadiga ah waa 1mm, iyo line-soo-saarka waxaa lagu habeyn karaa gudaha dhumucdiisuna waa 0.8-1.5mm.

Mashiinka samaynta 4.Roll: Qaab dhismeedka gidaarka

5.Nidaamka wadista: nidaamka wadista silsilada

6.Cutting system: Jooji in la gooyo, rogo joogsiyadii hore marka la jarayo.

7.PLC cabinet: Siemens system.

Mashiinada

1.Decoiler*1

2.Roll samaynta mashiinka * 1

3.Miiska bannaanka*2

4.PLC kantaroolka golaha*1

5.Hydraulic station*1

6.Spare parts box(Free)*1

Cabbirka weelka: 1x20GP

Sharaxaada kiis-dhabta ah

Qalabka wax lagu nadiifiyo

Decoiler waa qaybta bilawga ah ee khadka wax soo saarka. Marka la eego dhumucda yar iyo cabbirka xadiidka DIN, qalabka wax lagu nadiifiyo ayaa ku filan buuxinta shuruudaha wax soo saarka. Si kastaba ha noqotee, xawaaraha wax soo saarka sare, waxaan sidoo kale ku siinnaa xalalka decoilers koronto iyo haydarooliga.

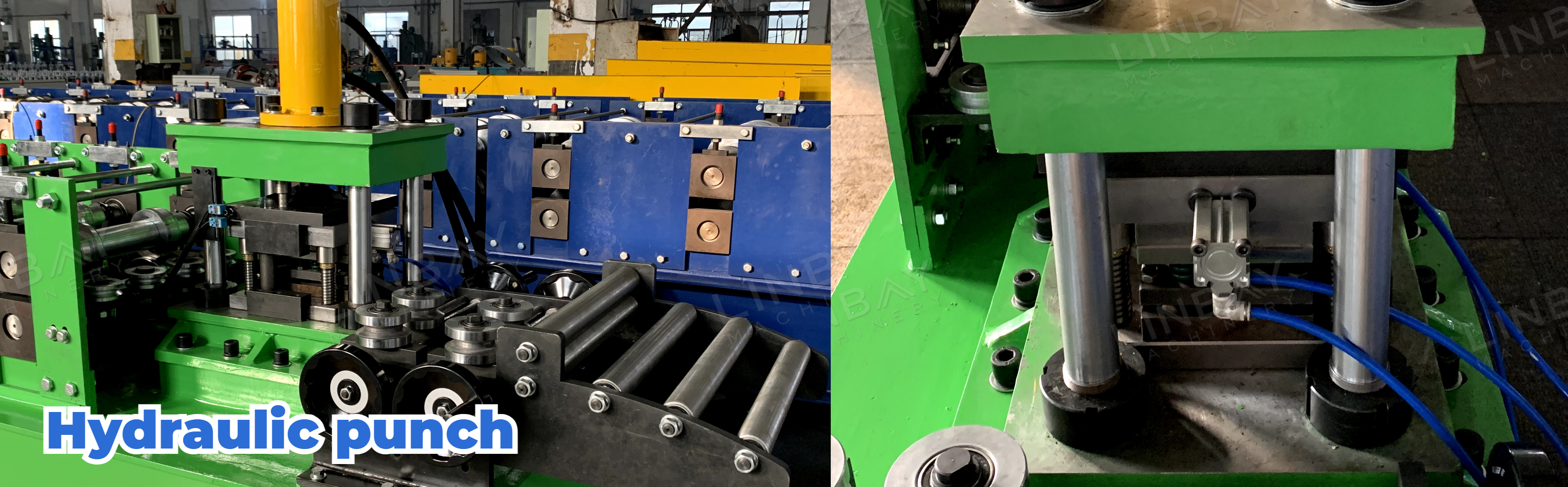

feerka Haydarooliga

Habayntan, feerka hawo-biyoodka ayaa lagu dhex daray mashiinka samaynta ugu weyn, wadaaga isla saldhigga. Inta lagu jiro feerka, gariiradda birta ah waxay si ku meel gaar ah u joojisaa gelitaanka mashiinka samaynta. Codsiyada u baahan xawaare sare oo wax soo saar ah, mashiinnada feerka haydarooliga ee taagan ayaa diyaar ah.

Hagaysa

Rollers-ka hagaya waxay xaqiijiyaan iswaafajinta u dhaxaysa gariiradda birta iyo mishiinka, iyagoo ka hortagaya qallooca inta lagu jiro habka samaynta.

Mashiinka samaynta duub

Mashiinka samaynta duuban ayaa ka shaqeeya qaab-dhismeedka gidaarka iyo nidaamka wadista silsiladda. Naqshaddeeda laba-saafka ah ayaa awood u siinaysa soo saarista laba cabbir oo xadiidka DIN ah. Si kastaba ha ahaatee, waa in la ogaadaa in labada saf aysan wada shaqeyn karin isku mar. Dalabka wax soo saarka sare, waxaan kugula talineynaa in la dejiyo khad wax soo saar gaar ah cabbir kasta.

Waa in la caddeeyo in saxnaanta dhererka goynta ee mashiinka samaynta duubka leh qaab-dhismeedka laba-geesoodka ah waa gudaha ± 0.5mm. Haddii shuruudaha saxda ah ee aad u baahan tahay ay ka yar tahay ± 0.5mm, laguma talinayo in la isticmaalo qaab-dhismeedka laba-saafka ah. Taa baddalkeeda, xalka helitaanka khad wax-soo-saarka madax-bannaan ee cabbir kasta ayaa ku habboon.

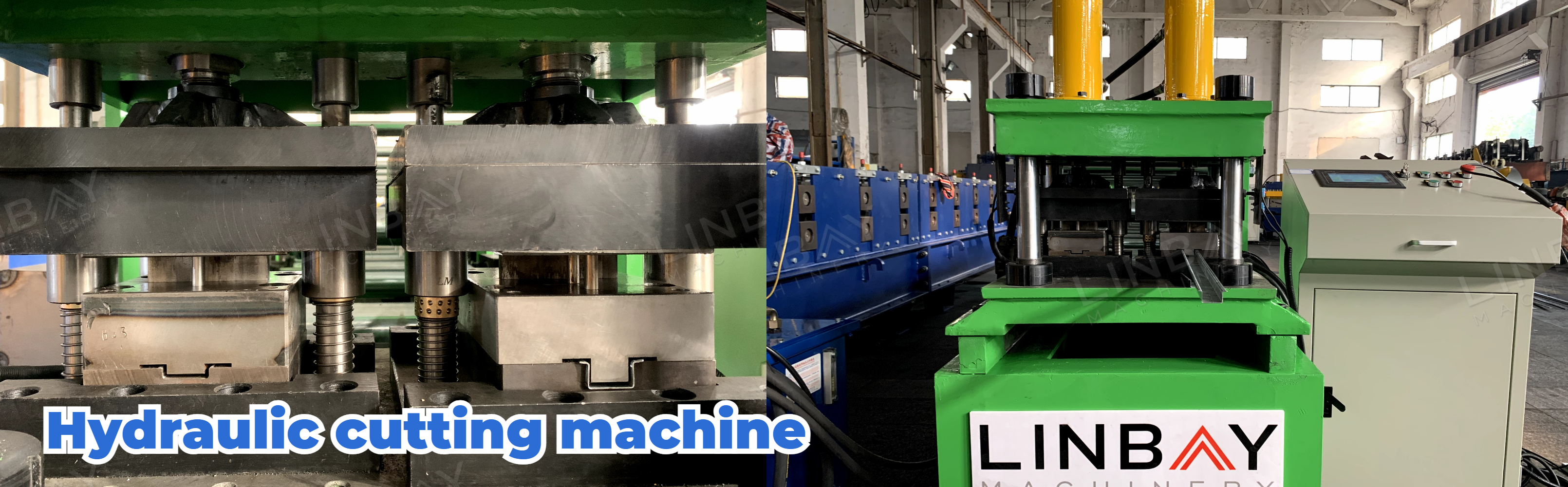

Mashiinka goynta Haydarooliga

Saldhigga mishiinka goynta ayaa ah mid taagan inta uu shaqaynayo, taas oo keenaysa in gariiradda birta ahi ay hakiso horumarkeeda inta ay goynayso.

Si loo gaaro xawaaraha wax soo saarka sare, waxaan ku siin mashiinka goynta duulaya. Erayga "duulida" waxa uu tilmaamayaa in saldhigga mishiinka wax goynta uu hore iyo gadaal u socon karo. Naqshadeyntani waxay awood u siinaysaa birta birta inay si joogto ah ugu gudubto mashiinka samaynta inta lagu jiro goynta, taas oo meesha ka saaraysa baahida loo qabo in la joojiyo mashiinka samaynta oo kor u qaadaya xawaaraha guud ee wax soo saarka.

Caaryada daabka goynta ee dhamaadka saf kasta waxa loo habeeyey si ay u dhigmaan qaabka cabbirka xadiidka DIN.

1. Decoiler

2. Quudinta

3. Feer

4. Gawaarida samaynta duubka

5. Habka wadista baabuurta

6. Habka goynta

Kuwo kale

Miiska bannaanka