Sharaxaada

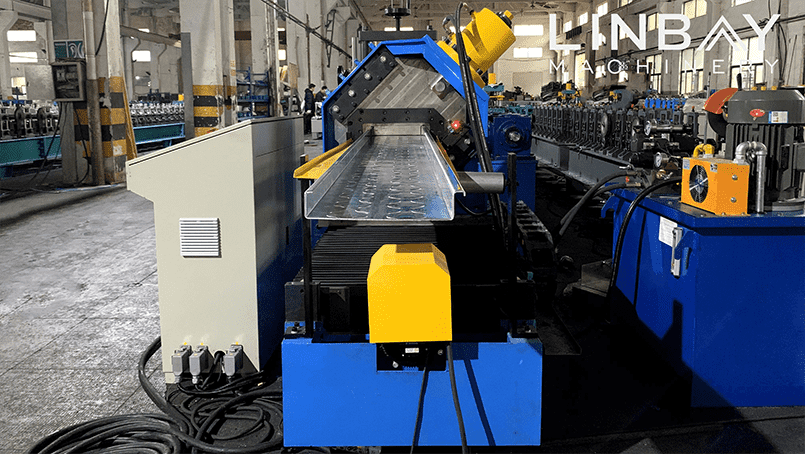

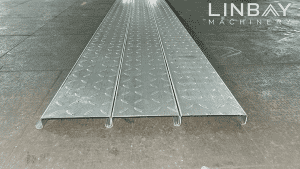

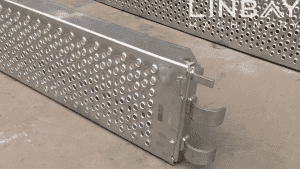

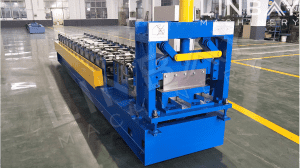

Mashiinka samaynta duubka looxa looxawaxay samayn kartaa loox qolof ah. Waxaan qaadanaa servo feeder si aan u hubinno in godadka ay sax yihiin. Waxaan isticmaalnaa garaacista garaacista si aan xawaaraha khadka uga dhigno mid dhakhso badan waxaanan isticmaalnaa goynta post-hydraulic si aan u hubinno in profile-ku qumman yahay.

Dhumucda alaabta ceeriin waxay ku dhowdahay 1-2mm.

Codsiga

Tilmaamaha Farsamada

| Mashiinka Samaynta Wareegga looxa looxa | |||

| Maya | Shayga | Tilmaamid | Ikhtiyaar |

| 1 | Qalab ku habboon | Nooca: Gariiradda Galvanized, PPGI, Gariiradda Birta Kaarboon |

|

|

|

| Dhumucda (mm): 1-2 |

|

|

|

| Awoodda wax-soosaarka: 250 - 550MPa |

|

|

|

| Cadaadiska Tensil( Mpa):G350Mpa-G550Mpa |

|

| 2 | Xawaaraha samaynta magaca ah (m/daqiiqo) | 10-25 | Ama sida laga rabo |

| 3 | Saldhig la sameeyo | 20 |

|

| 4 | Qalabka wax lagu nadiifiyo | Qalabka wax lagu nadiifiyo ee gacanta | Decoiler Haydarooliga ah ama decoiler madax double |

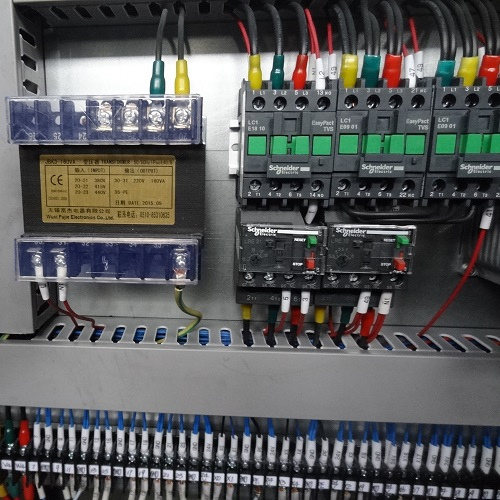

| 5 | Matoorka mashiinka ugu weyn | Summada Shiinaha-Jarmalka | Siemens |

| 6 | PLC sumadda | Panasonic | Siemens |

| 7 | Summada beddelka | Yaskawa |

|

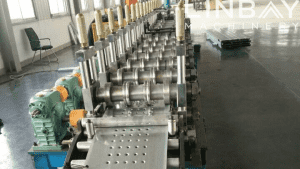

| 8 | Habka wadista | Silsilad wadista | Gearbox wadista |

| 9 | Qalabka Rollers-ka | Birta #45 | GCr15 |

| 10 | Dhismaha saldhiga | Torri qaab dhismeedka taagan | Saldhig Bir la been abuurtay Ama xarunta darbiga |

| 11 | Nidaamka feerka | No | Saldhigga feerka Haydarooliga ama riixista |

| 12 | Habka goynta | Goynta ka dib | Goynta ka hor |

| 13 | Shuruudda korontadu | 380V 60Hz | Ama sida laga rabo |

| 14 | Midabka mashiinka | Buluugga warshadaha | Ama sida laga rabo |

Shaxda cilladaysan

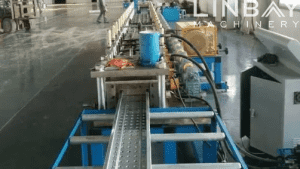

Qalab-gacmeedka--quudinta-- Saldhigga feerka-hydraulic--mashiinka samaynta---goynta biyaha--miis-baxa

1. Decoiler

2. Quudinta

3. Feer

4. Gawaarida samaynta duubka

5. Habka wadista baabuurta

6. Habka goynta

Kuwo kale

Miiska bannaanka