Sharaxaada

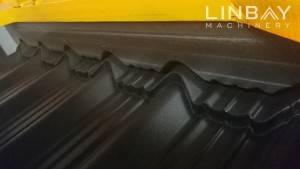

Mashiinka Samaynta Roll Layer Doublewaxay soo saari kartaa laba sawir oo kala duwan oo kala duwan oo hal mashiinka ah, waxay badbaadin kartaa qol badan iyo dabcan dhaqaale badan marka la barbar dhigo laba mashiin oo kala duwan.

Waxaad dooran kartaa laba nooc oo kala duwan oo sawirro muuqaal ah iyo sidoo kale sawir gacmeedyo jiingado ah, laakiin hal mar kaliya ayaa soo saari kara hal lakab oo muuqaal ah. Waxaa jira hal xajin oo ah hal dhinac oo mashiinka ah, waxaana kaliya oo aan u baahanahay si fudud in aan u dhaqaaqno hal taayir gacanta si aan u samayno astaanta lakabka kale.

Tilmaamaha Farsamada

| Mashiinka samaynta duubka xaashida lakabka leh | |||

| Maya | Shayga | Tilmaamid | Ikhtiyaar |

| 1 | Qalab ku habboon | Nooca: Gariiradda Galvanized, PPGI, Gariiradda Birta Kaarboon |

|

| Dhumucda (mm): 0.3-0.8 | |||

| Awoodda wax-soosaarka: 250 - 550MPa | |||

| Cadaadiska Tensil( Mpa):G350Mpa-G550Mpa | |||

| 2 | Xawaaraha samaynta magaca ah (m/daqiiqo) | 10-25 | Ama sida laga rabo |

| 3 | Saldhig la sameeyo | 20-23 | Marka loo eego profile kaaga |

| 4 | Qalabka wax lagu nadiifiyo | Qalabka wax lagu nadiifiyo ee gacanta | Decoiler Haydarooliga ah ama decoiler madax double |

| 5 | Matoorka mashiinka ugu weyn | Summada Shiinaha-Jarmalka | Siemens |

| 6 | PLC sumadda | Panasonic | Siemens |

| 7 | Summada beddelka | Yaskawa |

|

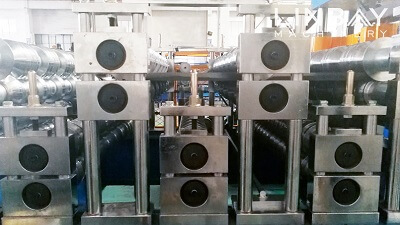

| 8 | Habka wadista | Silsilad wadista | Gearbox wadista |

| 9 | Qalabka Rollers-ka | Birta #45 | GCr15 |

| 10 | Dhismaha saldhiga | Saldhigga darbiga | Saldhig Bir la been abuurtay |

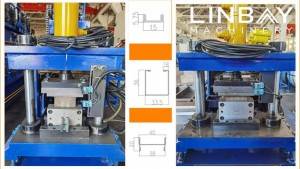

| 11 | Nidaamka feerka | No | Saldhigga feerka Haydarooliga ama riixista |

| 12 | Habka goynta | Goynta ka dib | Goynta ka hor |

| 13 | Shuruudda korontadu | 380V 60Hz | Ama sida laga rabo |

| 14 | Midabka mashiinka | Buluugga warshadaha | Ama sida laga rabo |

Shaxda socodka

Qalabka decoiler-ka--quudinta--duubka samaynta---maro-goynta--miis-baxa

1. Decoiler

2. Quudinta

3. Feer

4. Gawaarida samaynta duubka

5. Habka wadista baabuurta

6. Habka goynta

Kuwo kale

Miiska bannaanka